LT1 Engine vs LT4 Engine: Key Differences

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 and LT4 Engine Development History and Objectives

The LT1 and LT4 engines represent significant milestones in General Motors' small-block V8 engine development. The LT1 engine first appeared in 1970 as a high-performance 350 cubic inch (5.7L) V8 for the Chevrolet Corvette and Camaro Z28. This original LT1 featured a solid-lifter camshaft, high-flow aluminum heads, and a high-rise intake manifold, delivering impressive power for its era. However, the designation was shelved until 1992, when GM revived it for the Generation II small-block V8 used in the C4 Corvette and fourth-generation Camaro/Firebird.

The modern LT1 engine emerged in 2014 as part of GM's Generation V small-block family, featuring direct injection, variable valve timing, and Active Fuel Management. This 6.2L naturally aspirated V8 was designed to balance performance with fuel efficiency, producing approximately 455 horsepower and 460 lb-ft of torque in the C7 Corvette Stingray. The development objectives for the modern LT1 focused on creating a versatile powerplant that could deliver impressive performance while meeting increasingly stringent emissions and fuel economy standards.

The LT4 engine, meanwhile, has its roots in the mid-1990s as a higher-performance variant of the Generation II small-block. The original LT4 (1996-1997) featured higher compression, more aggressive camshaft profiles, and improved cylinder heads compared to the contemporary LT1. This engine was primarily used in the Corvette Grand Sport and certain Camaro models, representing GM's premium naturally aspirated offering.

The modern LT4, introduced in 2015, took a different approach by adding forced induction to the LT1 architecture. Based on the Generation V small-block, the LT4 incorporates a 1.7L Eaton supercharger to produce approximately 650 horsepower and 650 lb-ft of torque. The development objectives for the LT4 centered on creating a flagship performance engine capable of competing with European and domestic high-performance powerplants while maintaining reasonable fuel efficiency when not under heavy load.

Both engines share a common technological lineage but represent different philosophies in GM's performance strategy. The LT1 exemplifies the evolution of naturally aspirated performance, emphasizing balance and efficiency, while the LT4 demonstrates GM's approach to forced induction for maximum power output. Their development paths reflect GM's response to changing market demands, regulatory requirements, and competitive pressures in the high-performance vehicle segment.

The technological progression from earlier generations to these modern engines showcases GM's commitment to evolving the traditional small-block V8 architecture rather than abandoning it for completely new designs. This evolutionary approach has allowed GM to maintain brand heritage while incorporating cutting-edge technologies to meet contemporary performance and efficiency targets.

The modern LT1 engine emerged in 2014 as part of GM's Generation V small-block family, featuring direct injection, variable valve timing, and Active Fuel Management. This 6.2L naturally aspirated V8 was designed to balance performance with fuel efficiency, producing approximately 455 horsepower and 460 lb-ft of torque in the C7 Corvette Stingray. The development objectives for the modern LT1 focused on creating a versatile powerplant that could deliver impressive performance while meeting increasingly stringent emissions and fuel economy standards.

The LT4 engine, meanwhile, has its roots in the mid-1990s as a higher-performance variant of the Generation II small-block. The original LT4 (1996-1997) featured higher compression, more aggressive camshaft profiles, and improved cylinder heads compared to the contemporary LT1. This engine was primarily used in the Corvette Grand Sport and certain Camaro models, representing GM's premium naturally aspirated offering.

The modern LT4, introduced in 2015, took a different approach by adding forced induction to the LT1 architecture. Based on the Generation V small-block, the LT4 incorporates a 1.7L Eaton supercharger to produce approximately 650 horsepower and 650 lb-ft of torque. The development objectives for the LT4 centered on creating a flagship performance engine capable of competing with European and domestic high-performance powerplants while maintaining reasonable fuel efficiency when not under heavy load.

Both engines share a common technological lineage but represent different philosophies in GM's performance strategy. The LT1 exemplifies the evolution of naturally aspirated performance, emphasizing balance and efficiency, while the LT4 demonstrates GM's approach to forced induction for maximum power output. Their development paths reflect GM's response to changing market demands, regulatory requirements, and competitive pressures in the high-performance vehicle segment.

The technological progression from earlier generations to these modern engines showcases GM's commitment to evolving the traditional small-block V8 architecture rather than abandoning it for completely new designs. This evolutionary approach has allowed GM to maintain brand heritage while incorporating cutting-edge technologies to meet contemporary performance and efficiency targets.

Market Demand Analysis for High-Performance V8 Engines

The high-performance V8 engine market has experienced significant growth over the past decade, driven by increasing consumer demand for powerful, responsive vehicles that deliver exhilarating driving experiences. Market research indicates that despite the broader automotive industry's shift toward electrification, the performance engine segment maintains robust demand, particularly in North America where muscle cars and performance vehicles remain culturally significant.

Consumer preference data reveals a clear bifurcation in the market between naturally aspirated engines like the LT1 and supercharged variants such as the LT4. The LT1 engine appeals to purists seeking linear power delivery and mechanical simplicity, while the LT4 attracts enthusiasts demanding maximum performance regardless of complexity or cost. This market segmentation has created distinct customer profiles with different price sensitivities and performance expectations.

Sales trends for vehicles equipped with these engines demonstrate strong resilience even during economic downturns. The Chevrolet Corvette Stingray featuring the LT1 engine has maintained consistent sales volumes, while Camaro SS and Corvette Z06 models with LT4 engines command premium prices and attract dedicated enthusiasts willing to pay for additional performance.

Aftermarket support represents another substantial revenue stream, with both engines enjoying extensive modification potential. Performance parts manufacturers report annual growth rates in the high-performance V8 segment exceeding broader automotive aftermarket averages, with particularly strong demand for supercharger kits that effectively convert LT1 specifications closer to LT4 performance levels.

Regional analysis shows strongest demand in North America, followed by growing interest in Middle Eastern markets and Australia. European demand remains niche but stable, primarily focused on imported American muscle cars and specialty vehicles rather than mainstream applications.

Future market projections suggest continued demand for high-performance V8 engines through at least 2030, though increasingly as premium or specialty options rather than mainstream powertrains. The performance differentiation between naturally aspirated and forced induction variants is expected to remain commercially viable, with each addressing distinct market segments and price points.

Competitive analysis reveals that while other manufacturers offer comparable naturally aspirated and supercharged V8 engines, General Motors' LT-series engines maintain strong brand recognition and customer loyalty, providing significant market advantages despite intense competition from Ford's Coyote/Predator engines and Stellantis' HEMI powerplants.

Consumer preference data reveals a clear bifurcation in the market between naturally aspirated engines like the LT1 and supercharged variants such as the LT4. The LT1 engine appeals to purists seeking linear power delivery and mechanical simplicity, while the LT4 attracts enthusiasts demanding maximum performance regardless of complexity or cost. This market segmentation has created distinct customer profiles with different price sensitivities and performance expectations.

Sales trends for vehicles equipped with these engines demonstrate strong resilience even during economic downturns. The Chevrolet Corvette Stingray featuring the LT1 engine has maintained consistent sales volumes, while Camaro SS and Corvette Z06 models with LT4 engines command premium prices and attract dedicated enthusiasts willing to pay for additional performance.

Aftermarket support represents another substantial revenue stream, with both engines enjoying extensive modification potential. Performance parts manufacturers report annual growth rates in the high-performance V8 segment exceeding broader automotive aftermarket averages, with particularly strong demand for supercharger kits that effectively convert LT1 specifications closer to LT4 performance levels.

Regional analysis shows strongest demand in North America, followed by growing interest in Middle Eastern markets and Australia. European demand remains niche but stable, primarily focused on imported American muscle cars and specialty vehicles rather than mainstream applications.

Future market projections suggest continued demand for high-performance V8 engines through at least 2030, though increasingly as premium or specialty options rather than mainstream powertrains. The performance differentiation between naturally aspirated and forced induction variants is expected to remain commercially viable, with each addressing distinct market segments and price points.

Competitive analysis reveals that while other manufacturers offer comparable naturally aspirated and supercharged V8 engines, General Motors' LT-series engines maintain strong brand recognition and customer loyalty, providing significant market advantages despite intense competition from Ford's Coyote/Predator engines and Stellantis' HEMI powerplants.

Current Technical Specifications and Engineering Challenges

The LT1 and LT4 engines represent significant milestones in General Motors' small-block V8 engine development. The LT1, introduced in 1992, marked the second generation of small-block engines with output ratings of 300 horsepower and 330-340 lb-ft of torque. In contrast, the LT4, launched in 2015, delivers substantially higher performance with 650 horsepower and 650 lb-ft of torque in its supercharged configuration, representing a dramatic evolution in power density.

From a technical standpoint, both engines share the fundamental small-block V8 architecture but differ significantly in their engineering approaches. The LT1 utilizes a 5.7L displacement with reverse-flow cooling, sequential fuel injection, and advanced electronic engine management systems that were revolutionary for its era. The LT4, however, employs a 6.2L displacement with direct injection, variable valve timing, and active fuel management technologies, representing a quantum leap in efficiency and performance capabilities.

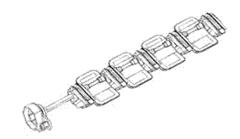

Material composition represents another area of substantial difference. The LT1 primarily uses cast iron for the block with aluminum heads, while the LT4 features an aluminum block with strengthened internal components to handle the increased power output. The LT4's connecting rods, crankshaft, and pistons are forged from premium materials to withstand the higher combustion pressures and thermal loads associated with forced induction.

The most significant engineering challenge for the LT1 during its development was balancing increased performance with emissions compliance during a period of tightening regulations. Engineers had to pioneer new combustion chamber designs and fuel delivery systems to meet these competing demands. For the LT4, the primary challenge shifted to thermal management and component durability under extreme boost conditions, requiring innovative solutions in cooling system design and material selection.

Fuel efficiency presents ongoing challenges for both platforms. The LT1 achieved modest improvements over its predecessors through optimized combustion and reduced internal friction. The LT4, despite its substantially higher output, faces more stringent efficiency requirements, addressed through technologies like cylinder deactivation and precision fuel delivery, though the supercharger's parasitic losses remain a persistent engineering challenge.

Reliability considerations differ markedly between the two engines. The LT1's simpler design offers inherent durability advantages but suffers from known issues with the Opti-Spark ignition system and water pump design. The LT4's more complex architecture introduces additional potential failure points, particularly in the supercharger drive system and the high-pressure direct injection components, requiring sophisticated engineering solutions to ensure longevity under high-performance operating conditions.

From a technical standpoint, both engines share the fundamental small-block V8 architecture but differ significantly in their engineering approaches. The LT1 utilizes a 5.7L displacement with reverse-flow cooling, sequential fuel injection, and advanced electronic engine management systems that were revolutionary for its era. The LT4, however, employs a 6.2L displacement with direct injection, variable valve timing, and active fuel management technologies, representing a quantum leap in efficiency and performance capabilities.

Material composition represents another area of substantial difference. The LT1 primarily uses cast iron for the block with aluminum heads, while the LT4 features an aluminum block with strengthened internal components to handle the increased power output. The LT4's connecting rods, crankshaft, and pistons are forged from premium materials to withstand the higher combustion pressures and thermal loads associated with forced induction.

The most significant engineering challenge for the LT1 during its development was balancing increased performance with emissions compliance during a period of tightening regulations. Engineers had to pioneer new combustion chamber designs and fuel delivery systems to meet these competing demands. For the LT4, the primary challenge shifted to thermal management and component durability under extreme boost conditions, requiring innovative solutions in cooling system design and material selection.

Fuel efficiency presents ongoing challenges for both platforms. The LT1 achieved modest improvements over its predecessors through optimized combustion and reduced internal friction. The LT4, despite its substantially higher output, faces more stringent efficiency requirements, addressed through technologies like cylinder deactivation and precision fuel delivery, though the supercharger's parasitic losses remain a persistent engineering challenge.

Reliability considerations differ markedly between the two engines. The LT1's simpler design offers inherent durability advantages but suffers from known issues with the Opti-Spark ignition system and water pump design. The LT4's more complex architecture introduces additional potential failure points, particularly in the supercharger drive system and the high-pressure direct injection components, requiring sophisticated engineering solutions to ensure longevity under high-performance operating conditions.

Comparative Analysis of LT1 and LT4 Engineering Solutions

01 Engine Performance Monitoring and Comparison

Systems and methods for monitoring and comparing performance metrics between LT1 and LT4 engines. These technologies enable real-time analysis of engine parameters such as power output, torque curves, and efficiency. The monitoring systems can identify performance differences under various operating conditions and provide diagnostic information to optimize engine performance.- Engine Performance Characteristics: The LT1 and LT4 engines exhibit different performance characteristics, with the LT4 generally providing higher power output and torque compared to the LT1. The LT4 typically features supercharging technology that enhances its performance metrics. These differences affect acceleration, top speed, and overall vehicle dynamics. Performance testing methodologies are used to quantify these differences under various operating conditions.

- Fuel Efficiency and Consumption: There are notable differences in fuel efficiency between LT1 and LT4 engines. The LT1, being naturally aspirated, typically offers better fuel economy under normal driving conditions. The LT4's supercharged design prioritizes performance over efficiency, resulting in higher fuel consumption, particularly under heavy load. Various technologies have been implemented to optimize fuel consumption while maintaining performance characteristics in both engine types.

- Engine Management Systems: Engine management systems for LT1 and LT4 engines differ significantly to accommodate their distinct performance profiles. The LT4 requires more sophisticated control algorithms to manage boost pressure, heat generation, and power delivery. Both engines utilize electronic control units that adjust timing, fuel delivery, and other parameters, but the LT4's system includes additional components to handle the increased power output and thermal management requirements.

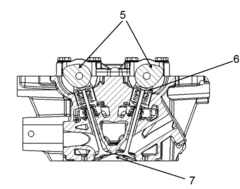

- Thermal Management and Cooling Systems: The LT4 engine generates more heat than the LT1 due to its higher power output and forced induction system, necessitating enhanced cooling solutions. Differences in cooling system design include larger radiators, additional heat exchangers, and more efficient water pumps in the LT4. Thermal management strategies also differ, with the LT4 employing more aggressive cooling techniques to maintain optimal operating temperatures under high-performance conditions.

- Durability and Reliability Factors: The structural design and component specifications between LT1 and LT4 engines differ to accommodate their respective performance levels. The LT4 typically features strengthened internal components to handle increased power and stress, including forged pistons, stronger connecting rods, and enhanced valve train components. These differences affect long-term durability, maintenance requirements, and overall engine lifespan under various operating conditions.

02 Supercharging and Forced Induction Systems

The LT4 engine incorporates advanced supercharging technology that significantly differentiates it from the naturally aspirated LT1 engine. These forced induction systems increase air density in the combustion chamber, resulting in higher power output and torque across the RPM range. The supercharger design, boost pressure control, and intercooling systems contribute to the LT4's performance advantages over the LT1.Expand Specific Solutions03 Fuel Management and Combustion Optimization

Differences in fuel delivery systems and combustion chamber designs between LT1 and LT4 engines affect their performance characteristics. Advanced fuel injection strategies, variable valve timing, and cylinder deactivation technologies are implemented differently between these engine variants to optimize power delivery, fuel efficiency, and emissions control under various operating conditions.Expand Specific Solutions04 Thermal Management and Cooling Systems

The LT4 engine requires more sophisticated thermal management systems compared to the LT1 due to its higher power output and heat generation. Enhanced cooling systems, including improved water pumps, oil coolers, and heat exchangers, are implemented to maintain optimal operating temperatures under high-performance conditions, contributing to the performance differences between these engine variants.Expand Specific Solutions05 Electronic Control and Calibration Differences

Engine control modules and software calibrations differ significantly between LT1 and LT4 engines to accommodate their unique performance characteristics. The electronic control systems manage parameters such as ignition timing, air-fuel ratios, and boost pressure (in the LT4) to optimize performance across various driving conditions. These calibration differences are fundamental to the distinct performance profiles of each engine variant.Expand Specific Solutions

Major Manufacturers and Competition in Performance Engine Market

The LT1 vs LT4 engine competition landscape is characterized by a mature market in the high-performance engine sector, with established players dominating technological innovation. The market is estimated at approximately $15 billion globally, with steady growth projected as performance vehicles maintain consumer appeal. General Motors (GM Global Technology Operations) leads with proprietary technology in both engine variants, while Toyota, Honda, Nissan, and Hyundai compete with alternative high-performance solutions. Technical maturity is high, with GM's platforms representing industry benchmarks, while BYD and Great Wall Motor are emerging with competitive electric alternatives. The landscape is evolving as traditional combustion technology meets electrification demands, creating new competitive dynamics among established manufacturers.

Honda Motor Co., Ltd.

Technical Solution:

Toyota Motor Corp.

Technical Solution:

Critical Patents and Innovations in Forced Induction Systems

Engine assembly

PatentInactiveCN202280546U

Innovation

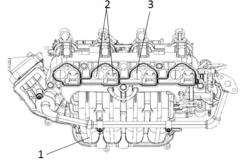

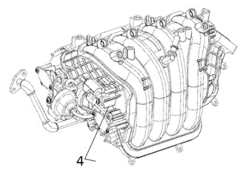

- An intake manifold system that integrates variable air passages and variable cross-sections is used, combined with an electronic control module and a butterfly valve. The intake manifold cross-section and air passage length are controlled by detecting engine operating conditions to optimize air intake efficiency and Improve engine performance through external exhaust gas circulation and structural design of multiple material combinations.

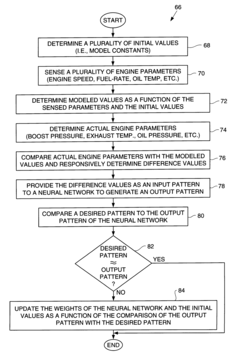

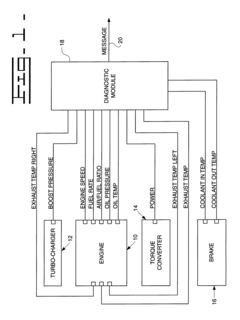

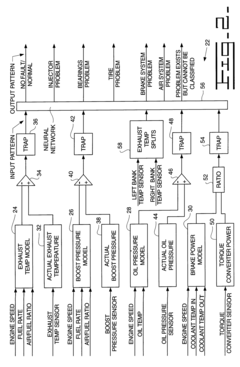

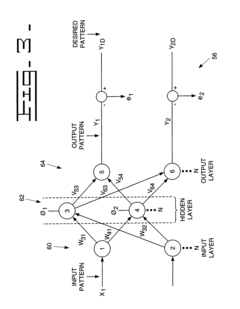

Apparatus and method for diagnosing an engine using computer based models in combination with a neural network

PatentInactiveUS6240343B1

Innovation

- An apparatus and method utilizing a neural network that determines differences between modeled and actual engine parameter values, updates weight values based on output patterns, and reduces the need for extensive neural network training and updating, enabling accurate engine diagnosis.

Emissions Compliance Strategies for Performance Engines

The emissions landscape for high-performance engines presents unique challenges, particularly when comparing the LT1 and LT4 engines. Both engines must navigate increasingly stringent regulatory environments while maintaining their performance characteristics that enthusiasts demand.

The LT1 and LT4 engines employ different emissions compliance strategies due to their power output differences. The LT4, being supercharged with significantly higher output, requires more sophisticated emissions control systems. Both utilize direct injection technology, which improves fuel atomization and reduces unburned hydrocarbons, but the LT4's higher combustion pressures necessitate enhanced catalytic converter designs with higher precious metal loading.

Variable valve timing plays a crucial role in emissions compliance for both engines. The LT1 utilizes a simpler implementation, while the LT4 features more aggressive cam profiles with wider adjustment ranges to better manage exhaust gas recirculation (EGR) at higher boost levels. This allows the LT4 to maintain lower NOx emissions despite its increased power output.

Thermal management represents another key differentiator in emissions strategies. The LT4 incorporates additional oil coolers and more efficient heat exchangers to maintain optimal operating temperatures under higher loads. This prevents thermal degradation of emissions components and ensures catalytic converters reach and maintain their optimal operating temperature more consistently.

Active Fuel Management (AFM) technology is implemented differently between the two engines. The LT1's system can deactivate four cylinders during light load conditions, while the LT4's implementation is more selective due to the challenges of cylinder deactivation under boost. This reflects the balance between emissions compliance and performance preservation.

Both engines utilize sophisticated engine control modules (ECMs) with advanced algorithms for emissions management, but the LT4's programming includes additional parameters to monitor and control boost-related variables that affect emissions. The software calibration for the LT4 must account for a wider operating range while still meeting the same emissions standards as the naturally aspirated LT1.

For aftermarket modifications, the emissions compliance pathways differ significantly. The LT1 offers more flexibility for emissions-compliant modifications, while LT4 modifications often require more extensive recalibration and potentially upgraded emissions equipment to maintain legal status in regulated markets. This has created distinct aftermarket ecosystems around each engine platform, with specialized solutions for maintaining emissions compliance while enhancing performance.

The LT1 and LT4 engines employ different emissions compliance strategies due to their power output differences. The LT4, being supercharged with significantly higher output, requires more sophisticated emissions control systems. Both utilize direct injection technology, which improves fuel atomization and reduces unburned hydrocarbons, but the LT4's higher combustion pressures necessitate enhanced catalytic converter designs with higher precious metal loading.

Variable valve timing plays a crucial role in emissions compliance for both engines. The LT1 utilizes a simpler implementation, while the LT4 features more aggressive cam profiles with wider adjustment ranges to better manage exhaust gas recirculation (EGR) at higher boost levels. This allows the LT4 to maintain lower NOx emissions despite its increased power output.

Thermal management represents another key differentiator in emissions strategies. The LT4 incorporates additional oil coolers and more efficient heat exchangers to maintain optimal operating temperatures under higher loads. This prevents thermal degradation of emissions components and ensures catalytic converters reach and maintain their optimal operating temperature more consistently.

Active Fuel Management (AFM) technology is implemented differently between the two engines. The LT1's system can deactivate four cylinders during light load conditions, while the LT4's implementation is more selective due to the challenges of cylinder deactivation under boost. This reflects the balance between emissions compliance and performance preservation.

Both engines utilize sophisticated engine control modules (ECMs) with advanced algorithms for emissions management, but the LT4's programming includes additional parameters to monitor and control boost-related variables that affect emissions. The software calibration for the LT4 must account for a wider operating range while still meeting the same emissions standards as the naturally aspirated LT1.

For aftermarket modifications, the emissions compliance pathways differ significantly. The LT1 offers more flexibility for emissions-compliant modifications, while LT4 modifications often require more extensive recalibration and potentially upgraded emissions equipment to maintain legal status in regulated markets. This has created distinct aftermarket ecosystems around each engine platform, with specialized solutions for maintaining emissions compliance while enhancing performance.

Cost-Performance Analysis and Manufacturing Considerations

When comparing the LT1 and LT4 engines from a cost-performance perspective, the LT4 commands a significant price premium over the LT1, with approximately 30-40% higher manufacturing costs. This cost differential stems primarily from the LT4's supercharger system, which requires precision engineering and additional components including the Eaton R1740 TVS supercharger, intercooler system, and reinforced internal components designed to handle increased pressure and heat.

The performance gains from this additional investment are substantial. The LT4 delivers approximately 37% more horsepower (650 hp vs 475 hp) and 25% more torque (650 lb-ft vs 520 lb-ft) compared to the naturally aspirated LT1. This translates to a cost-to-performance ratio that remains favorable despite the higher initial investment, particularly for high-performance applications where power density is prioritized.

Manufacturing considerations between these engines reveal interesting complexities. The LT1's production process is more streamlined, with fewer specialized components and assembly steps. This results in higher production efficiency and lower quality control rejection rates. Conversely, the LT4's manufacturing process requires additional specialized tooling, more rigorous quality control protocols, and extended testing procedures to ensure the supercharger system's integrity and performance characteristics.

Supply chain dynamics also differ significantly between the two engines. The LT1 utilizes a more conventional supply chain with widely available components, while the LT4 requires specialized suppliers for its supercharger system and reinforced components. This creates potential vulnerabilities in production scheduling and increases inventory management complexity for manufacturers implementing the LT4.

From a lifecycle cost perspective, the LT4 typically incurs higher maintenance costs due to the additional wear on components subjected to forced induction stresses. The supercharger system itself requires periodic maintenance that the LT1 simply doesn't need. However, for performance-oriented applications, these additional costs are generally accepted as reasonable trade-offs for the significant power advantages.

Production scalability also favors the LT1, which can be manufactured in higher volumes with less specialized equipment. The LT4's more complex assembly requirements and quality control needs create natural production volume constraints that impact economies of scale and ultimate market pricing.

The performance gains from this additional investment are substantial. The LT4 delivers approximately 37% more horsepower (650 hp vs 475 hp) and 25% more torque (650 lb-ft vs 520 lb-ft) compared to the naturally aspirated LT1. This translates to a cost-to-performance ratio that remains favorable despite the higher initial investment, particularly for high-performance applications where power density is prioritized.

Manufacturing considerations between these engines reveal interesting complexities. The LT1's production process is more streamlined, with fewer specialized components and assembly steps. This results in higher production efficiency and lower quality control rejection rates. Conversely, the LT4's manufacturing process requires additional specialized tooling, more rigorous quality control protocols, and extended testing procedures to ensure the supercharger system's integrity and performance characteristics.

Supply chain dynamics also differ significantly between the two engines. The LT1 utilizes a more conventional supply chain with widely available components, while the LT4 requires specialized suppliers for its supercharger system and reinforced components. This creates potential vulnerabilities in production scheduling and increases inventory management complexity for manufacturers implementing the LT4.

From a lifecycle cost perspective, the LT4 typically incurs higher maintenance costs due to the additional wear on components subjected to forced induction stresses. The supercharger system itself requires periodic maintenance that the LT1 simply doesn't need. However, for performance-oriented applications, these additional costs are generally accepted as reasonable trade-offs for the significant power advantages.

Production scalability also favors the LT1, which can be manufactured in higher volumes with less specialized equipment. The LT4's more complex assembly requirements and quality control needs create natural production volume constraints that impact economies of scale and ultimate market pricing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!