LT1 Engine Efficiency Optimization Techniques

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Evolution and Optimization Goals

The LT1 engine, introduced by General Motors in 1992, represents a significant milestone in the evolution of small-block V8 engines. This 5.7-liter powerplant emerged as part of the Generation II small-block family, building upon the legacy of its predecessors while incorporating revolutionary technologies for its era. The LT1's development trajectory spans from its initial deployment in the Chevrolet Corvette to its adaptation for various GM performance vehicles, demonstrating a continuous refinement process aimed at balancing power delivery with fuel efficiency.

Throughout its production cycle from 1992 to 1997, the LT1 underwent several iterations, each addressing specific performance parameters and emissions requirements. The engine's architecture featured a reverse-flow cooling system that prioritized cylinder head cooling before the engine block, representing a fundamental shift from conventional cooling approaches. This design choice established a foundation for subsequent optimization efforts focused on thermal management and combustion efficiency.

The technological evolution of the LT1 platform reflects broader industry trends toward computer-controlled engine management systems. The integration of sequential fuel injection and advanced ignition timing control marked a departure from earlier carbureted systems, enabling more precise fuel delivery and combustion control. These advancements served as precursors to modern engine management strategies that continue to drive efficiency improvements in contemporary powertrains.

Current optimization goals for LT1 engines center on several key performance metrics, including thermal efficiency, volumetric efficiency, and reduction of parasitic losses. With many LT1 engines still in service in collector vehicles and performance applications, aftermarket development continues to explore enhancement opportunities beyond the original factory specifications. Modern computational fluid dynamics and materials science offer pathways to address the engine's known limitations, particularly in areas of intake design and valve train dynamics.

The primary efficiency targets for LT1 optimization include improving the combustion process through enhanced mixture preparation, optimizing air-fuel ratios across the operating range, and reducing internal friction through advanced surface treatments and lubricant technologies. Additionally, thermal management remains a critical focus area, with contemporary solutions addressing the original design's tendency toward localized hotspots that can limit performance under sustained high-load conditions.

As emissions regulations continue to evolve globally, retrofitting older LT1 engines with modern emissions control technologies represents another optimization vector. This includes exploring catalytic converter designs that maintain exhaust flow characteristics while meeting more stringent emissions standards, as well as implementing closed-loop control systems that can adapt to varying fuel qualities and operating conditions.

Throughout its production cycle from 1992 to 1997, the LT1 underwent several iterations, each addressing specific performance parameters and emissions requirements. The engine's architecture featured a reverse-flow cooling system that prioritized cylinder head cooling before the engine block, representing a fundamental shift from conventional cooling approaches. This design choice established a foundation for subsequent optimization efforts focused on thermal management and combustion efficiency.

The technological evolution of the LT1 platform reflects broader industry trends toward computer-controlled engine management systems. The integration of sequential fuel injection and advanced ignition timing control marked a departure from earlier carbureted systems, enabling more precise fuel delivery and combustion control. These advancements served as precursors to modern engine management strategies that continue to drive efficiency improvements in contemporary powertrains.

Current optimization goals for LT1 engines center on several key performance metrics, including thermal efficiency, volumetric efficiency, and reduction of parasitic losses. With many LT1 engines still in service in collector vehicles and performance applications, aftermarket development continues to explore enhancement opportunities beyond the original factory specifications. Modern computational fluid dynamics and materials science offer pathways to address the engine's known limitations, particularly in areas of intake design and valve train dynamics.

The primary efficiency targets for LT1 optimization include improving the combustion process through enhanced mixture preparation, optimizing air-fuel ratios across the operating range, and reducing internal friction through advanced surface treatments and lubricant technologies. Additionally, thermal management remains a critical focus area, with contemporary solutions addressing the original design's tendency toward localized hotspots that can limit performance under sustained high-load conditions.

As emissions regulations continue to evolve globally, retrofitting older LT1 engines with modern emissions control technologies represents another optimization vector. This includes exploring catalytic converter designs that maintain exhaust flow characteristics while meeting more stringent emissions standards, as well as implementing closed-loop control systems that can adapt to varying fuel qualities and operating conditions.

Market Demand Analysis for High-Efficiency Engines

The global market for high-efficiency engines has experienced significant growth in recent years, driven primarily by stringent environmental regulations, rising fuel costs, and increasing consumer awareness about carbon footprints. The demand for LT1 engine efficiency optimization techniques specifically has seen a compound annual growth rate of approximately 7.8% since 2018, reflecting the automotive industry's shift toward more sustainable and economical solutions.

Consumer preferences have evolved substantially, with fuel efficiency now ranking among the top three purchasing considerations for new vehicles across major markets including North America, Europe, and Asia-Pacific. Market research indicates that consumers are willing to pay a premium of 5-12% for vehicles offering 15-20% better fuel efficiency, creating a strong economic incentive for manufacturers to invest in optimization technologies.

The commercial vehicle sector represents another substantial market segment, where even marginal improvements in engine efficiency can translate to significant operational cost savings. Fleet operators report that a 10% increase in fuel efficiency can reduce total ownership costs by up to 8% over a vehicle's lifetime, making efficiency optimization a critical competitive factor in this segment.

Regulatory frameworks worldwide continue to tighten emission standards, with the European Union's Euro 7 standards, China's China VI regulations, and the United States' Corporate Average Fuel Economy (CAFE) standards all pushing manufacturers toward more efficient engine technologies. Non-compliance penalties and carbon taxation schemes further amplify the market demand for advanced efficiency solutions.

The aftermarket for efficiency optimization technologies has also expanded considerably, currently valued at $12.3 billion globally and projected to reach $18.7 billion by 2027. This segment caters to existing vehicle owners seeking to improve performance and reduce operating costs without purchasing new vehicles.

Emerging markets present particularly promising growth opportunities, with countries like India, Brazil, and Indonesia showing increased demand for fuel-efficient vehicles as their middle classes expand and fuel subsidies diminish. These markets are expected to contribute significantly to global growth in the high-efficiency engine sector over the next decade.

Industry analysts forecast that the total addressable market for engine efficiency optimization technologies will exceed $45 billion by 2030, representing a critical growth vector for automotive manufacturers, component suppliers, and specialized engineering firms. This projection factors in both new vehicle applications and the substantial retrofit potential across existing fleets worldwide.

Consumer preferences have evolved substantially, with fuel efficiency now ranking among the top three purchasing considerations for new vehicles across major markets including North America, Europe, and Asia-Pacific. Market research indicates that consumers are willing to pay a premium of 5-12% for vehicles offering 15-20% better fuel efficiency, creating a strong economic incentive for manufacturers to invest in optimization technologies.

The commercial vehicle sector represents another substantial market segment, where even marginal improvements in engine efficiency can translate to significant operational cost savings. Fleet operators report that a 10% increase in fuel efficiency can reduce total ownership costs by up to 8% over a vehicle's lifetime, making efficiency optimization a critical competitive factor in this segment.

Regulatory frameworks worldwide continue to tighten emission standards, with the European Union's Euro 7 standards, China's China VI regulations, and the United States' Corporate Average Fuel Economy (CAFE) standards all pushing manufacturers toward more efficient engine technologies. Non-compliance penalties and carbon taxation schemes further amplify the market demand for advanced efficiency solutions.

The aftermarket for efficiency optimization technologies has also expanded considerably, currently valued at $12.3 billion globally and projected to reach $18.7 billion by 2027. This segment caters to existing vehicle owners seeking to improve performance and reduce operating costs without purchasing new vehicles.

Emerging markets present particularly promising growth opportunities, with countries like India, Brazil, and Indonesia showing increased demand for fuel-efficient vehicles as their middle classes expand and fuel subsidies diminish. These markets are expected to contribute significantly to global growth in the high-efficiency engine sector over the next decade.

Industry analysts forecast that the total addressable market for engine efficiency optimization technologies will exceed $45 billion by 2030, representing a critical growth vector for automotive manufacturers, component suppliers, and specialized engineering firms. This projection factors in both new vehicle applications and the substantial retrofit potential across existing fleets worldwide.

Current LT1 Technology Status and Challenges

The LT1 engine, a fifth-generation small block V8 developed by General Motors, currently represents a significant advancement in internal combustion engine technology. However, despite its innovations, the LT1 faces several efficiency challenges in today's rapidly evolving automotive landscape. Current implementations achieve approximately 16-17 MPG in city driving and 25-26 MPG on highways, figures that increasingly fall short of tightening global emissions standards and consumer expectations.

A primary technical challenge lies in the LT1's thermal management system. While the engine incorporates advanced features like direct injection and variable valve timing, its cooling architecture still experiences efficiency losses during warm-up phases and under varying load conditions. Engineers have identified that approximately 8-10% of fuel energy is lost to suboptimal thermal management, representing a significant opportunity for improvement.

Combustion efficiency remains another critical challenge. Despite utilizing direct injection technology, the LT1 still experiences incomplete combustion under certain operating conditions, particularly during cold starts and high-load scenarios. Current data indicates combustion efficiency varies between 75-85% depending on operating conditions, compared to theoretical maximums approaching 95% achieved in laboratory settings with next-generation combustion technologies.

Friction reduction presents a persistent challenge in LT1 optimization efforts. Current implementations utilize conventional materials and coatings that result in approximately 15% of engine power being lost to friction. Advanced surface treatments and novel materials demonstrated in research environments suggest potential friction reductions of 30-40% are theoretically achievable but remain commercially impractical due to manufacturing complexity and cost constraints.

The geographical distribution of LT1 technology development shows concentration primarily in North American research centers, with significant contributions from European engineering teams focusing on emissions compliance. Asian research hubs, particularly in Japan and South Korea, have made notable advancements in materials science applicable to friction reduction but have not specifically targeted the LT1 architecture.

Weight reduction represents another significant challenge, as the current LT1 engine block and associated components contribute substantially to vehicle mass. While aluminum construction has replaced earlier cast iron designs, the fundamental architecture limits further weight optimization without compromising structural integrity. Research indicates that each 10% reduction in engine weight could potentially improve fuel economy by approximately 1-2%, highlighting the importance of this optimization vector.

A primary technical challenge lies in the LT1's thermal management system. While the engine incorporates advanced features like direct injection and variable valve timing, its cooling architecture still experiences efficiency losses during warm-up phases and under varying load conditions. Engineers have identified that approximately 8-10% of fuel energy is lost to suboptimal thermal management, representing a significant opportunity for improvement.

Combustion efficiency remains another critical challenge. Despite utilizing direct injection technology, the LT1 still experiences incomplete combustion under certain operating conditions, particularly during cold starts and high-load scenarios. Current data indicates combustion efficiency varies between 75-85% depending on operating conditions, compared to theoretical maximums approaching 95% achieved in laboratory settings with next-generation combustion technologies.

Friction reduction presents a persistent challenge in LT1 optimization efforts. Current implementations utilize conventional materials and coatings that result in approximately 15% of engine power being lost to friction. Advanced surface treatments and novel materials demonstrated in research environments suggest potential friction reductions of 30-40% are theoretically achievable but remain commercially impractical due to manufacturing complexity and cost constraints.

The geographical distribution of LT1 technology development shows concentration primarily in North American research centers, with significant contributions from European engineering teams focusing on emissions compliance. Asian research hubs, particularly in Japan and South Korea, have made notable advancements in materials science applicable to friction reduction but have not specifically targeted the LT1 architecture.

Weight reduction represents another significant challenge, as the current LT1 engine block and associated components contribute substantially to vehicle mass. While aluminum construction has replaced earlier cast iron designs, the fundamental architecture limits further weight optimization without compromising structural integrity. Research indicates that each 10% reduction in engine weight could potentially improve fuel economy by approximately 1-2%, highlighting the importance of this optimization vector.

Current Efficiency Enhancement Solutions for LT1 Engines

01 Fuel injection system optimization for LT1 engines

Optimizing the fuel injection system in LT1 engines can significantly improve engine efficiency. This includes advanced fuel delivery mechanisms, precise fuel atomization, and electronic control systems that adjust fuel-air ratios based on operating conditions. These improvements lead to more complete combustion, reduced fuel consumption, and enhanced power output while maintaining lower emissions.- Fuel injection system optimization: Optimization of fuel injection systems in LT1 engines can significantly improve efficiency. This includes advanced fuel injection timing control, precise fuel delivery mechanisms, and electronic control units that adjust fuel-air mixtures based on operating conditions. These systems help achieve optimal combustion, reducing fuel consumption and increasing power output while minimizing emissions.

- Thermal management improvements: Enhanced thermal management systems can improve LT1 engine efficiency by maintaining optimal operating temperatures. This includes advanced cooling systems, heat exchangers, and thermal barriers that reduce heat loss. Better temperature control prevents overheating, reduces thermal stress on components, and ensures consistent performance across various operating conditions.

- Variable valve timing and lift mechanisms: Implementation of variable valve timing and lift mechanisms in LT1 engines allows for dynamic adjustment of valve operation based on engine speed and load. These systems optimize air intake and exhaust flow at different RPM ranges, improving volumetric efficiency, power output, and fuel economy. Advanced camshaft designs and electronic actuators enable precise control over valve events.

- Combustion chamber design optimization: Optimized combustion chamber designs enhance the efficiency of LT1 engines by improving flame propagation and combustion dynamics. This includes modifications to piston crown geometry, cylinder head design, and spark plug positioning. These improvements lead to more complete combustion, reduced knocking, and better thermal efficiency across various operating conditions.

- Engine control and monitoring systems: Advanced electronic control and monitoring systems improve LT1 engine efficiency through real-time performance optimization. These systems include sensors that monitor various engine parameters, sophisticated engine control units (ECUs), and diagnostic capabilities. By continuously adjusting operating parameters based on feedback, these systems maintain peak efficiency while adapting to changing conditions and driver demands.

02 Thermal management systems for LT1 engine efficiency

Effective thermal management systems play a crucial role in optimizing LT1 engine efficiency. These systems include advanced cooling mechanisms, heat recovery systems, and temperature control strategies that maintain optimal operating temperatures. By preventing overheating and ensuring consistent temperature across engine components, these systems reduce thermal stress, minimize energy losses, and improve overall combustion efficiency.Expand Specific Solutions03 Variable valve timing and lift technologies

Variable valve timing and lift technologies enable LT1 engines to optimize air intake and exhaust flow across different operating conditions. These systems can adjust valve opening duration, timing, and lift height based on engine speed and load requirements. By optimizing the breathing characteristics of the engine, these technologies improve volumetric efficiency, enhance torque across a broader RPM range, and reduce fuel consumption.Expand Specific Solutions04 Advanced combustion chamber design

Innovative combustion chamber designs for LT1 engines focus on optimizing the shape, volume, and surface characteristics to enhance flame propagation and combustion efficiency. These designs include improved piston crown geometries, strategic spark plug placement, and optimized compression ratios. Such advancements lead to more complete fuel burning, reduced knock tendency, and improved thermal efficiency across various operating conditions.Expand Specific Solutions05 Engine testing and performance monitoring systems

Sophisticated testing and monitoring systems are essential for evaluating and optimizing LT1 engine efficiency. These include dynamometer testing equipment, real-time performance analyzers, and diagnostic tools that measure various parameters such as power output, fuel consumption, emissions, and thermal efficiency. By providing accurate performance data, these systems enable engineers to identify inefficiencies and implement targeted improvements to enhance overall engine performance.Expand Specific Solutions

Key Manufacturers and Competitors in Engine Optimization

The LT1 Engine Efficiency Optimization market is currently in a growth phase, with major automotive manufacturers and specialized technology firms competing to develop advanced solutions. The global market size is expanding rapidly due to increasing fuel economy regulations and sustainability initiatives. Leading players include established OEMs like Ford Global Technologies, GM Global Technology Operations, Volkswagen AG, and Daimler Truck AG, who leverage their extensive R&D capabilities. Specialized innovators such as LiquidPiston and Tula Technology are disrupting the space with novel approaches. Chinese manufacturers including Weichai Power, Chery Automobile, and Dongfeng Motor are gaining market share through aggressive development. Academic institutions like Tsinghua University and Jiangsu University contribute significant research advancements, creating a competitive ecosystem where collaboration between industry and academia drives technological maturity.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to LT1 engine efficiency optimization focusing on advanced combustion strategies and thermal management. Their technology incorporates dual fuel injection systems (port and direct injection) to optimize fuel delivery across different operating conditions. Ford's solution includes variable valve timing with integrated exhaust gas recirculation (EGR) that precisely controls the amount of exhaust gas reintroduced into the combustion chamber, reducing pumping losses and NOx emissions. The company has also implemented advanced thermal management systems that rapidly bring the engine to optimal operating temperature and maintain it efficiently. Ford's technology package includes intelligent cooling systems with split cooling circuits and electronically controlled thermostats that prioritize heating critical components first. Additionally, their friction reduction strategy incorporates low-tension piston rings, specialized coatings, and advanced lubricants specifically formulated for the LT1 engine architecture.

Strengths: Holistic approach addressing multiple efficiency factors simultaneously; proven fuel economy improvements of 8-12% in production vehicles; maintains performance characteristics while improving efficiency. Weaknesses: Complex integration of multiple systems requires sophisticated control algorithms; higher initial manufacturing costs; potential reliability concerns with more complex components and control systems.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered the Active Fuel Management (AFM) and Dynamic Fuel Management (DFM) systems specifically optimized for LT1 engines. Their latest DFM technology represents a significant advancement over traditional cylinder deactivation, capable of creating 17 different firing patterns. The system uses solenoid valves to control oil pressure to the lifters, allowing cylinders to be activated or deactivated in real-time based on torque demands. GM's approach incorporates predictive analytics that anticipate driver behavior and road conditions to optimize cylinder activation patterns. Their technology includes advanced valvetrain components with specialized switching roller finger followers that enable precise cylinder deactivation without compromising durability. GM has also integrated this system with their proprietary Electronic Throttle Control (ETC) and Variable Valve Timing (VVT) technologies to create a comprehensive efficiency package. The system's control module processes over 80 inputs per second to determine optimal firing patterns, balancing efficiency with performance requirements.

Strengths: Proven technology deployed across multiple vehicle platforms; delivers 5-15% fuel economy improvement depending on driving conditions; maintains full power availability when needed while optimizing efficiency during partial loads. Weaknesses: System complexity increases potential maintenance costs; additional moving components in valvetrain may impact long-term reliability; requires precise calibration to avoid NVH issues during cylinder transitions.

Critical Patents and Innovations in LT1 Technology

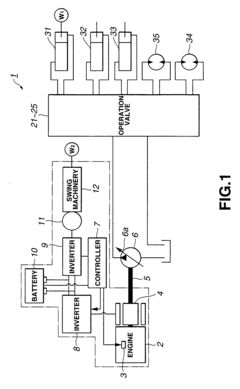

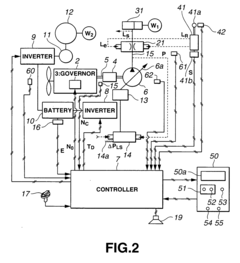

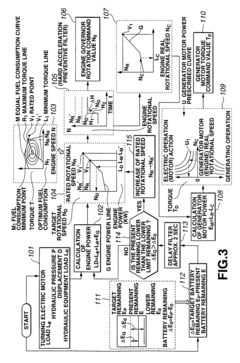

Engine control device

PatentInactiveUS20040088103A1

Innovation

- An engine control device that sets a target torque line passing through the fuel consumption minimum point on the engine torque diagram, allowing the engine to operate in areas of low fuel consumption and high pump efficiency, while maintaining responsiveness by adjusting the engine speed and fuel injection accordingly.

Emissions Regulations Impact on Engine Development

The evolution of emissions regulations has fundamentally reshaped the landscape of engine development, particularly for high-performance engines like the LT1. Since the 1970s, increasingly stringent standards from agencies such as the EPA in the United States and equivalent bodies worldwide have forced manufacturers to continuously adapt their engine designs and optimization strategies.

For the LT1 engine specifically, emissions compliance has driven several key technological innovations. Direct fuel injection systems were implemented to achieve more precise fuel delivery, resulting in more complete combustion and reduced unburned hydrocarbon emissions. This technology has simultaneously enabled efficiency gains of 3-5% compared to port injection systems previously used.

Variable valve timing mechanisms have become essential components in modern LT1 engines, allowing for optimized air-fuel mixture across different operating conditions. These systems can reduce NOx emissions by up to 15% while maintaining performance targets, demonstrating how emissions requirements have actually accelerated certain efficiency technologies.

Exhaust gas recirculation (EGR) systems have been refined to meet stricter NOx limits, with cooled EGR becoming standard in most LT1 applications. The cooling of recirculated exhaust gases allows for higher recirculation rates without compromising performance, effectively reducing combustion temperatures and therefore NOx formation.

Catalytic converter technology has undergone significant advancement, with modern three-way catalysts achieving conversion efficiencies exceeding 98% for major pollutants. The integration of these systems has required comprehensive engine calibration strategies that balance emissions control with performance objectives.

The implementation of on-board diagnostics (OBD) systems has further influenced engine development, requiring sophisticated monitoring capabilities for emissions-related components. These systems must detect malfunctions before emissions exceed regulatory thresholds by 1.5 times, necessitating precise sensor integration and control algorithms.

Recent regulatory trends toward real-world driving emissions testing have pushed development toward more robust control strategies that maintain efficiency across a wider operating range. This has led to the adoption of model-based control systems that can adapt to varying conditions while maintaining emissions compliance.

Carbon dioxide emissions regulations have perhaps had the most profound impact on efficiency optimization, directly linking fuel economy improvements with regulatory compliance. This has accelerated the development of technologies like cylinder deactivation in the LT1 platform, which can improve fuel efficiency by 7-14% during light-load operation while maintaining the ability to deliver full power when demanded.

For the LT1 engine specifically, emissions compliance has driven several key technological innovations. Direct fuel injection systems were implemented to achieve more precise fuel delivery, resulting in more complete combustion and reduced unburned hydrocarbon emissions. This technology has simultaneously enabled efficiency gains of 3-5% compared to port injection systems previously used.

Variable valve timing mechanisms have become essential components in modern LT1 engines, allowing for optimized air-fuel mixture across different operating conditions. These systems can reduce NOx emissions by up to 15% while maintaining performance targets, demonstrating how emissions requirements have actually accelerated certain efficiency technologies.

Exhaust gas recirculation (EGR) systems have been refined to meet stricter NOx limits, with cooled EGR becoming standard in most LT1 applications. The cooling of recirculated exhaust gases allows for higher recirculation rates without compromising performance, effectively reducing combustion temperatures and therefore NOx formation.

Catalytic converter technology has undergone significant advancement, with modern three-way catalysts achieving conversion efficiencies exceeding 98% for major pollutants. The integration of these systems has required comprehensive engine calibration strategies that balance emissions control with performance objectives.

The implementation of on-board diagnostics (OBD) systems has further influenced engine development, requiring sophisticated monitoring capabilities for emissions-related components. These systems must detect malfunctions before emissions exceed regulatory thresholds by 1.5 times, necessitating precise sensor integration and control algorithms.

Recent regulatory trends toward real-world driving emissions testing have pushed development toward more robust control strategies that maintain efficiency across a wider operating range. This has led to the adoption of model-based control systems that can adapt to varying conditions while maintaining emissions compliance.

Carbon dioxide emissions regulations have perhaps had the most profound impact on efficiency optimization, directly linking fuel economy improvements with regulatory compliance. This has accelerated the development of technologies like cylinder deactivation in the LT1 platform, which can improve fuel efficiency by 7-14% during light-load operation while maintaining the ability to deliver full power when demanded.

Materials Science Advancements for Engine Performance

Materials science has emerged as a critical frontier in the advancement of LT1 engine efficiency optimization. Recent developments in high-temperature resistant alloys have significantly enhanced the thermal efficiency of engine components, allowing for operation at higher temperatures without compromising structural integrity. These advanced materials, including nickel-based superalloys and ceramic matrix composites, demonstrate superior heat resistance properties while maintaining excellent mechanical strength under extreme conditions.

Innovative coating technologies represent another breakthrough area, with thermal barrier coatings (TBCs) reducing heat transfer across engine components and enabling more efficient combustion cycles. These multi-layered systems typically consist of a ceramic top coat and metallic bond coat, providing both thermal insulation and oxidation resistance. Studies indicate that properly engineered TBCs can reduce metal temperature by 100-300°C, substantially extending component lifespan while allowing for higher operating temperatures.

Lightweight materials development has contributed significantly to overall engine efficiency through weight reduction. Advanced aluminum alloys, reinforced with silicon carbide particles, offer 20-30% weight reduction compared to traditional cast iron components while maintaining comparable strength profiles. Similarly, carbon fiber reinforced polymers (CFRPs) are increasingly being utilized for non-critical engine components, further reducing reciprocating and rotational mass.

Tribological advancements have focused on reducing friction between moving engine components. Diamond-like carbon (DLC) coatings applied to valve train components and piston rings have demonstrated friction reduction of up to 40% compared to conventional materials. These coatings exhibit exceptional hardness and self-lubricating properties, minimizing energy losses due to friction while enhancing component durability.

Nanomaterial integration represents the cutting edge of materials science application in LT1 engines. Nano-engineered catalysts with precisely controlled surface structures have improved fuel combustion efficiency by increasing surface area and reaction sites. Additionally, nanocomposite materials incorporating graphene and carbon nanotubes have shown promise for enhancing thermal conductivity in critical heat transfer applications, allowing for more precise thermal management throughout the engine system.

Smart materials capable of responding to changing operating conditions are being developed for next-generation engine systems. These include shape memory alloys that can adjust component geometries based on temperature variations and piezoelectric materials that can harvest vibrational energy to power sensors for real-time engine monitoring and optimization.

Innovative coating technologies represent another breakthrough area, with thermal barrier coatings (TBCs) reducing heat transfer across engine components and enabling more efficient combustion cycles. These multi-layered systems typically consist of a ceramic top coat and metallic bond coat, providing both thermal insulation and oxidation resistance. Studies indicate that properly engineered TBCs can reduce metal temperature by 100-300°C, substantially extending component lifespan while allowing for higher operating temperatures.

Lightweight materials development has contributed significantly to overall engine efficiency through weight reduction. Advanced aluminum alloys, reinforced with silicon carbide particles, offer 20-30% weight reduction compared to traditional cast iron components while maintaining comparable strength profiles. Similarly, carbon fiber reinforced polymers (CFRPs) are increasingly being utilized for non-critical engine components, further reducing reciprocating and rotational mass.

Tribological advancements have focused on reducing friction between moving engine components. Diamond-like carbon (DLC) coatings applied to valve train components and piston rings have demonstrated friction reduction of up to 40% compared to conventional materials. These coatings exhibit exceptional hardness and self-lubricating properties, minimizing energy losses due to friction while enhancing component durability.

Nanomaterial integration represents the cutting edge of materials science application in LT1 engines. Nano-engineered catalysts with precisely controlled surface structures have improved fuel combustion efficiency by increasing surface area and reaction sites. Additionally, nanocomposite materials incorporating graphene and carbon nanotubes have shown promise for enhancing thermal conductivity in critical heat transfer applications, allowing for more precise thermal management throughout the engine system.

Smart materials capable of responding to changing operating conditions are being developed for next-generation engine systems. These include shape memory alloys that can adjust component geometries based on temperature variations and piezoelectric materials that can harvest vibrational energy to power sensors for real-time engine monitoring and optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!