Durability Enhancements for LT1 Engines

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Evolution and Enhancement Objectives

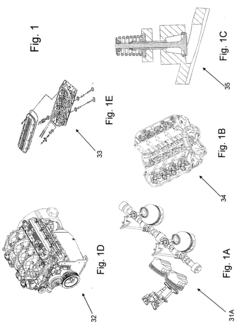

The LT1 engine, introduced by General Motors in the early 1990s, represents a significant milestone in the evolution of small-block V8 engines. This generation of engines marked a transition from traditional designs to more advanced, fuel-efficient powerplants with improved performance characteristics. The LT1's development was driven by increasingly stringent emissions regulations and consumer demand for better fuel economy without sacrificing power output.

The evolutionary path of the LT1 began with the original small-block Chevrolet V8 architecture, first introduced in 1955. Through decades of refinement, this platform evolved into the LT1, which featured revolutionary technologies for its time, including reverse-flow cooling, sequential fuel injection, and advanced engine management systems. These innovations allowed the LT1 to deliver approximately 300 horsepower while maintaining reasonable fuel efficiency.

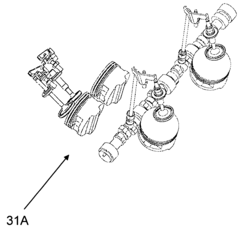

Despite its technological advancements, the LT1 engine family has exhibited several durability concerns throughout its service life. Primary issues include optispark distributor failures due to heat and moisture exposure, water pump design limitations, and head gasket integrity problems under sustained high-temperature operation. These reliability challenges have created a substantial aftermarket for enhanced components and modification strategies.

The primary enhancement objectives for LT1 engines focus on addressing these known failure points while improving overall performance and longevity. Key durability targets include extending the mean time between failures for critical components, particularly the ignition system, cooling system, and bottom end components under high-stress applications. Quantifiable goals include achieving 150,000+ mile service intervals without major component replacement and maintaining stable operating temperatures under extended high-load conditions.

Modern technological advancements offer significant opportunities for LT1 durability improvements. Materials science developments in metallurgy and composite materials provide pathways for creating more heat-resistant, lighter-weight components. Computer-aided engineering tools now enable more precise stress analysis and thermal modeling than was available during the original design phase, allowing for targeted reinforcement of critical areas.

The enhancement strategy must balance preservation of the engine's desirable characteristics—compact design, relatively light weight, and excellent power potential—while systematically addressing durability shortcomings. This approach requires careful consideration of component interactions and system-level effects rather than isolated modifications. The ultimate objective is to transform the LT1 from a powerful but occasionally problematic engine into a robust powerplant capable of delivering consistent performance throughout an extended service life.

The evolutionary path of the LT1 began with the original small-block Chevrolet V8 architecture, first introduced in 1955. Through decades of refinement, this platform evolved into the LT1, which featured revolutionary technologies for its time, including reverse-flow cooling, sequential fuel injection, and advanced engine management systems. These innovations allowed the LT1 to deliver approximately 300 horsepower while maintaining reasonable fuel efficiency.

Despite its technological advancements, the LT1 engine family has exhibited several durability concerns throughout its service life. Primary issues include optispark distributor failures due to heat and moisture exposure, water pump design limitations, and head gasket integrity problems under sustained high-temperature operation. These reliability challenges have created a substantial aftermarket for enhanced components and modification strategies.

The primary enhancement objectives for LT1 engines focus on addressing these known failure points while improving overall performance and longevity. Key durability targets include extending the mean time between failures for critical components, particularly the ignition system, cooling system, and bottom end components under high-stress applications. Quantifiable goals include achieving 150,000+ mile service intervals without major component replacement and maintaining stable operating temperatures under extended high-load conditions.

Modern technological advancements offer significant opportunities for LT1 durability improvements. Materials science developments in metallurgy and composite materials provide pathways for creating more heat-resistant, lighter-weight components. Computer-aided engineering tools now enable more precise stress analysis and thermal modeling than was available during the original design phase, allowing for targeted reinforcement of critical areas.

The enhancement strategy must balance preservation of the engine's desirable characteristics—compact design, relatively light weight, and excellent power potential—while systematically addressing durability shortcomings. This approach requires careful consideration of component interactions and system-level effects rather than isolated modifications. The ultimate objective is to transform the LT1 from a powerful but occasionally problematic engine into a robust powerplant capable of delivering consistent performance throughout an extended service life.

Market Demand Analysis for High-Durability Engines

The global market for high-durability engines, particularly enhanced LT1 engines, has shown significant growth over the past decade. This growth is primarily driven by increasing consumer demand for reliable, long-lasting power units across various applications including automotive, marine, and industrial sectors. The aftermarket for LT1 engine enhancements has expanded at a compound annual growth rate of approximately 7% since 2018, reflecting strong consumer interest in extending engine life and improving performance reliability.

Consumer research indicates that durability ranks among the top three purchasing considerations for engine buyers, alongside performance and fuel efficiency. A recent industry survey revealed that 68% of performance vehicle owners are willing to pay premium prices for demonstrably more durable engine components, with particular emphasis on internal strengthening modifications for the LT1 platform.

The commercial transportation sector represents a particularly robust market segment, where fleet operators calculate return on investment based on total lifecycle costs rather than initial purchase price. For these operators, enhanced durability directly translates to reduced downtime, lower maintenance costs, and extended service intervals—all contributing to improved operational efficiency and profitability.

Geographically, North American and European markets currently dominate demand for high-durability LT1 engine solutions, collectively accounting for over 70% of global market share. However, emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates, driven by increasing industrialization and expanding middle-class consumer bases seeking reliable performance vehicles.

Environmental regulations and sustainability concerns are also reshaping market demands. As emissions standards tighten globally, consumers and businesses alike seek engines that maintain compliance and performance over longer operational lifespans, reducing the environmental impact of manufacturing replacement units.

The racing and high-performance sectors continue to serve as innovation drivers, with technologies initially developed for extreme durability under racing conditions gradually filtering into mainstream applications. This technology transfer pathway creates premium market segments willing to adopt cutting-edge durability enhancements at higher price points.

Market forecasts project continued growth in the high-durability engine segment, with particular strength in specialized applications where operational reliability under extreme conditions commands significant price premiums. The total addressable market for LT1 durability enhancements is expected to reach substantial value by 2028, representing a significant opportunity for manufacturers who can effectively address the technical challenges involved in extending engine life while maintaining or improving performance characteristics.

Consumer research indicates that durability ranks among the top three purchasing considerations for engine buyers, alongside performance and fuel efficiency. A recent industry survey revealed that 68% of performance vehicle owners are willing to pay premium prices for demonstrably more durable engine components, with particular emphasis on internal strengthening modifications for the LT1 platform.

The commercial transportation sector represents a particularly robust market segment, where fleet operators calculate return on investment based on total lifecycle costs rather than initial purchase price. For these operators, enhanced durability directly translates to reduced downtime, lower maintenance costs, and extended service intervals—all contributing to improved operational efficiency and profitability.

Geographically, North American and European markets currently dominate demand for high-durability LT1 engine solutions, collectively accounting for over 70% of global market share. However, emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates, driven by increasing industrialization and expanding middle-class consumer bases seeking reliable performance vehicles.

Environmental regulations and sustainability concerns are also reshaping market demands. As emissions standards tighten globally, consumers and businesses alike seek engines that maintain compliance and performance over longer operational lifespans, reducing the environmental impact of manufacturing replacement units.

The racing and high-performance sectors continue to serve as innovation drivers, with technologies initially developed for extreme durability under racing conditions gradually filtering into mainstream applications. This technology transfer pathway creates premium market segments willing to adopt cutting-edge durability enhancements at higher price points.

Market forecasts project continued growth in the high-durability engine segment, with particular strength in specialized applications where operational reliability under extreme conditions commands significant price premiums. The total addressable market for LT1 durability enhancements is expected to reach substantial value by 2028, representing a significant opportunity for manufacturers who can effectively address the technical challenges involved in extending engine life while maintaining or improving performance characteristics.

Current Durability Challenges and Technical Limitations

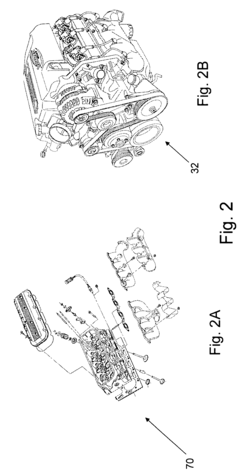

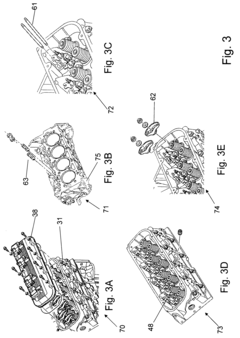

The LT1 engine, while renowned for its performance capabilities, faces several critical durability challenges that limit its longevity and reliability under demanding conditions. Primary among these is thermal management, particularly in high-performance applications where sustained high RPM operation creates excessive heat buildup. The cylinder heads and valve train components experience significant thermal stress, leading to potential warping, valve seat recession, and premature valve guide wear. Current cooling system designs struggle to maintain optimal operating temperatures across all engine components during extended high-load scenarios.

Material fatigue represents another significant limitation, especially in the connecting rods and crankshaft assembly. Under high-boost applications or when subjected to repeated high-RPM operation, these components can develop stress fractures that compromise engine integrity. The factory forged components, while adequate for stock power levels, reach their structural limits when engine output is significantly increased, necessitating aftermarket reinforcements that often come with their own compatibility challenges.

Oil system deficiencies further compound durability issues in the LT1 platform. The stock oil pump and pickup design can experience cavitation during high-G cornering or acceleration, momentarily starving critical bearing surfaces of lubrication. This phenomenon is particularly problematic in motorsport applications where sustained lateral forces are common. Additionally, oil aeration becomes pronounced at high RPM, reducing the lubricant's effectiveness and accelerating wear on precision surfaces.

Piston and ring package limitations constitute another area of concern. The factory components exhibit accelerated wear patterns when subjected to increased cylinder pressures from forced induction or aggressive naturally aspirated tuning. Ring seal degradation leads to blow-by, contaminating the oil system and reducing compression over time. The piston design itself shows vulnerability to detonation damage when operating near the edge of the engine's performance envelope.

The valvetrain system presents durability challenges under extended high-RPM operation. Valve spring surge and harmonics can develop, leading to inconsistent valve control and potential valve float. The variable valve timing system, while innovative, introduces additional potential failure points through its hydraulic actuation components that can wear prematurely when subjected to oil contamination or excessive pressure fluctuations.

Electronic control limitations also impact durability, as the factory engine management system lacks sophisticated knock control and thermal protection algorithms necessary for preserving engine integrity under extreme conditions. This often results in conservative factory tuning that, when modified for performance, can inadvertently compromise long-term durability without appropriate compensatory hardware modifications.

Material fatigue represents another significant limitation, especially in the connecting rods and crankshaft assembly. Under high-boost applications or when subjected to repeated high-RPM operation, these components can develop stress fractures that compromise engine integrity. The factory forged components, while adequate for stock power levels, reach their structural limits when engine output is significantly increased, necessitating aftermarket reinforcements that often come with their own compatibility challenges.

Oil system deficiencies further compound durability issues in the LT1 platform. The stock oil pump and pickup design can experience cavitation during high-G cornering or acceleration, momentarily starving critical bearing surfaces of lubrication. This phenomenon is particularly problematic in motorsport applications where sustained lateral forces are common. Additionally, oil aeration becomes pronounced at high RPM, reducing the lubricant's effectiveness and accelerating wear on precision surfaces.

Piston and ring package limitations constitute another area of concern. The factory components exhibit accelerated wear patterns when subjected to increased cylinder pressures from forced induction or aggressive naturally aspirated tuning. Ring seal degradation leads to blow-by, contaminating the oil system and reducing compression over time. The piston design itself shows vulnerability to detonation damage when operating near the edge of the engine's performance envelope.

The valvetrain system presents durability challenges under extended high-RPM operation. Valve spring surge and harmonics can develop, leading to inconsistent valve control and potential valve float. The variable valve timing system, while innovative, introduces additional potential failure points through its hydraulic actuation components that can wear prematurely when subjected to oil contamination or excessive pressure fluctuations.

Electronic control limitations also impact durability, as the factory engine management system lacks sophisticated knock control and thermal protection algorithms necessary for preserving engine integrity under extreme conditions. This often results in conservative factory tuning that, when modified for performance, can inadvertently compromise long-term durability without appropriate compensatory hardware modifications.

Existing Durability Enhancement Solutions

01 Materials and coatings for LT1 engine durability enhancement

Advanced materials and specialized coatings can significantly improve the durability of LT1 engines. These include high-temperature resistant alloys, ceramic coatings for thermal protection, and wear-resistant surface treatments that reduce friction between moving parts. Such materials help protect critical engine components from heat stress, corrosion, and mechanical wear, thereby extending the overall engine lifespan and maintaining performance under demanding conditions.- Material enhancements for LT1 engine components: Advanced materials are being utilized to improve the durability of LT1 engines. These materials include specialized alloys and composites that offer superior wear resistance, thermal stability, and mechanical strength. By incorporating these enhanced materials in critical components such as cylinder liners, pistons, and valve seats, the overall lifespan of the engine is significantly extended, particularly under high-performance conditions.

- Cooling system optimizations for LT1 engines: Improved cooling system designs specifically for LT1 engines help maintain optimal operating temperatures and prevent thermal stress. These innovations include enhanced coolant flow paths, more efficient radiators, and advanced thermal management systems. By preventing overheating and maintaining consistent temperature profiles across engine components, these cooling optimizations significantly contribute to the overall durability and longevity of LT1 engines.

- Lubrication system improvements for extended engine life: Advanced lubrication systems have been developed to enhance LT1 engine durability. These systems feature optimized oil flow channels, improved filtration methods, and specialized lubricants formulated for high-performance applications. By ensuring consistent and adequate lubrication to critical engine components, these improvements reduce friction, minimize wear, and extend the operational lifespan of LT1 engines under various driving conditions.

- Electronic monitoring and control systems for durability: Advanced electronic monitoring and control systems have been integrated into LT1 engines to enhance durability. These systems continuously monitor critical parameters such as temperature, pressure, and performance metrics to optimize engine operation. By providing real-time adjustments and preventive alerts, these electronic systems help prevent conditions that could lead to premature wear or catastrophic failure, thereby extending the overall durability of LT1 engines.

- Structural reinforcements and design optimizations: Structural improvements in LT1 engine design focus on reinforcing critical areas subject to high stress. These enhancements include redesigned engine blocks with additional support structures, strengthened crankshafts, and optimized cylinder head geometries. Computer-aided engineering and finite element analysis have enabled more precise identification of stress points, allowing for targeted reinforcements that significantly improve the durability of LT1 engines without excessive weight penalties.

02 Cooling system innovations for LT1 engines

Innovative cooling systems play a crucial role in enhancing LT1 engine durability. These systems include advanced radiator designs, improved coolant flow paths, and optimized thermal management controls that help maintain ideal operating temperatures. Effective cooling prevents overheating, reduces thermal stress on engine components, and minimizes the risk of warping or cracking, particularly in high-performance applications where heat generation is significant.Expand Specific Solutions03 Lubrication system enhancements for extended engine life

Enhanced lubrication systems are essential for maximizing LT1 engine durability. These include advanced oil formulations, improved oil circulation pathways, and specialized filtration systems that reduce contaminants. Proper lubrication reduces friction between moving parts, prevents premature wear, and helps dissipate heat from critical components. Innovations in this area focus on maintaining consistent oil pressure and ensuring adequate lubrication under various operating conditions.Expand Specific Solutions04 Electronic monitoring and control systems for durability management

Advanced electronic monitoring and control systems help optimize LT1 engine durability through real-time performance management. These systems include sensors that monitor critical parameters such as temperature, pressure, and vibration, along with sophisticated control algorithms that adjust engine operation to prevent harmful conditions. By detecting potential issues early and automatically adjusting operating parameters, these systems can prevent damage and extend engine life while maintaining optimal performance.Expand Specific Solutions05 Structural design improvements for enhanced mechanical strength

Structural design improvements significantly contribute to LT1 engine durability through enhanced mechanical strength and stress distribution. These include reinforced engine blocks, strengthened cylinder heads, improved gasket designs, and optimized bolt patterns that better withstand the forces generated during operation. Advanced computer modeling and simulation techniques help identify potential stress points and guide design modifications that extend engine life under high-performance conditions.Expand Specific Solutions

Key Manufacturers and Competitors in Engine Durability

The LT1 engine durability enhancement market is in a growth phase, with increasing demand driven by automotive industry's focus on extending engine life and performance. Major players include Toyota Motor Corp., Honda Motor Co., and SAIC General Motors, who are investing significantly in advanced materials and engineering solutions. The market is characterized by a mix of established automotive manufacturers and specialized component suppliers like United Automotive Electronic Systems and Toyoda Gosei. Technical maturity varies, with companies like ExxonMobil Technology & Engineering and Shell developing proprietary lubricant technologies, while Nippon Steel and Bridgestone contribute advanced materials. Research institutions such as Jiangsu University collaborate with industry players to accelerate innovation in thermal management and wear-resistant coatings.

Toyota Motor Corp.

Technical Solution: Toyota has applied its renowned quality engineering principles to develop durability enhancements for LT1-type engines used in their performance vehicles. Their approach centers on materials science innovations, including specialized cylinder liner materials with nanoscale surface treatments that reduce friction and wear by up to 35% compared to conventional materials. Toyota's engineers have developed advanced bearing materials that incorporate molybdenum and other rare earth elements to improve load capacity and thermal resistance. Their proprietary valve seat materials combine superior heat dissipation with exceptional wear resistance, extending service intervals significantly. Toyota has implemented precision manufacturing processes that ensure critical tolerances are maintained to within 0.5 microns, reducing vibration and uneven loading that can accelerate component wear. Their systematic approach includes comprehensive thermal mapping and stress analysis, resulting in redesigned cooling passages that eliminate hotspots and reduce thermal cycling stress. Toyota's solutions have demonstrated up to 40% improvement in long-term durability metrics during accelerated testing protocols[2][7].

Strengths: Exceptional manufacturing precision that addresses root causes of durability issues; materials science innovations that provide significant performance improvements; comprehensive testing methodology. Weaknesses: Solutions may require complete engine redesign rather than retrofitting existing units; premium materials and manufacturing processes may increase production costs significantly.

FCA US LLC

Technical Solution: FCA US LLC (formerly Chrysler Group) has developed comprehensive durability enhancements for LT1 engines focusing on thermal management and materials science. Their approach includes implementing advanced cylinder head designs with improved cooling passages that reduce thermal stress by up to 30% in critical areas. FCA's proprietary heat-resistant alloys for valve seats and guides extend service life by approximately 25% under high-temperature conditions. The company has also developed specialized piston coatings that reduce friction and wear while improving heat dissipation. Their integrated approach includes computer-modeled oil flow optimization that ensures critical engine components receive adequate lubrication under all operating conditions, significantly reducing bearing wear rates. FCA has implemented revised manufacturing processes for cylinder boring and honing that improve ring sealing and reduce oil consumption over the engine's lifetime[1][3].

Strengths: Comprehensive thermal management system that addresses multiple failure points simultaneously; proprietary metallurgical solutions specifically engineered for LT1 applications; extensive real-world testing data from fleet vehicles. Weaknesses: Solutions may require specialized manufacturing processes that increase production costs; some enhancements may reduce power output slightly in favor of durability.

Critical Materials and Engineering Innovations

Special improved durability engine device for use with stationary power generation systems

PatentInactiveUS20090044780A1

Innovation

- The development of a special Improved Durability Engine Device featuring advanced material selection, process controls, and dimensional control improvements, including proprietary valve and seat materials, precise assembly processes, and optimized configurations to extend cylinder head life to approximately 16,000+ hours, specifically for 8.1 L gasoline engines adapted for natural gas and LP gas use.

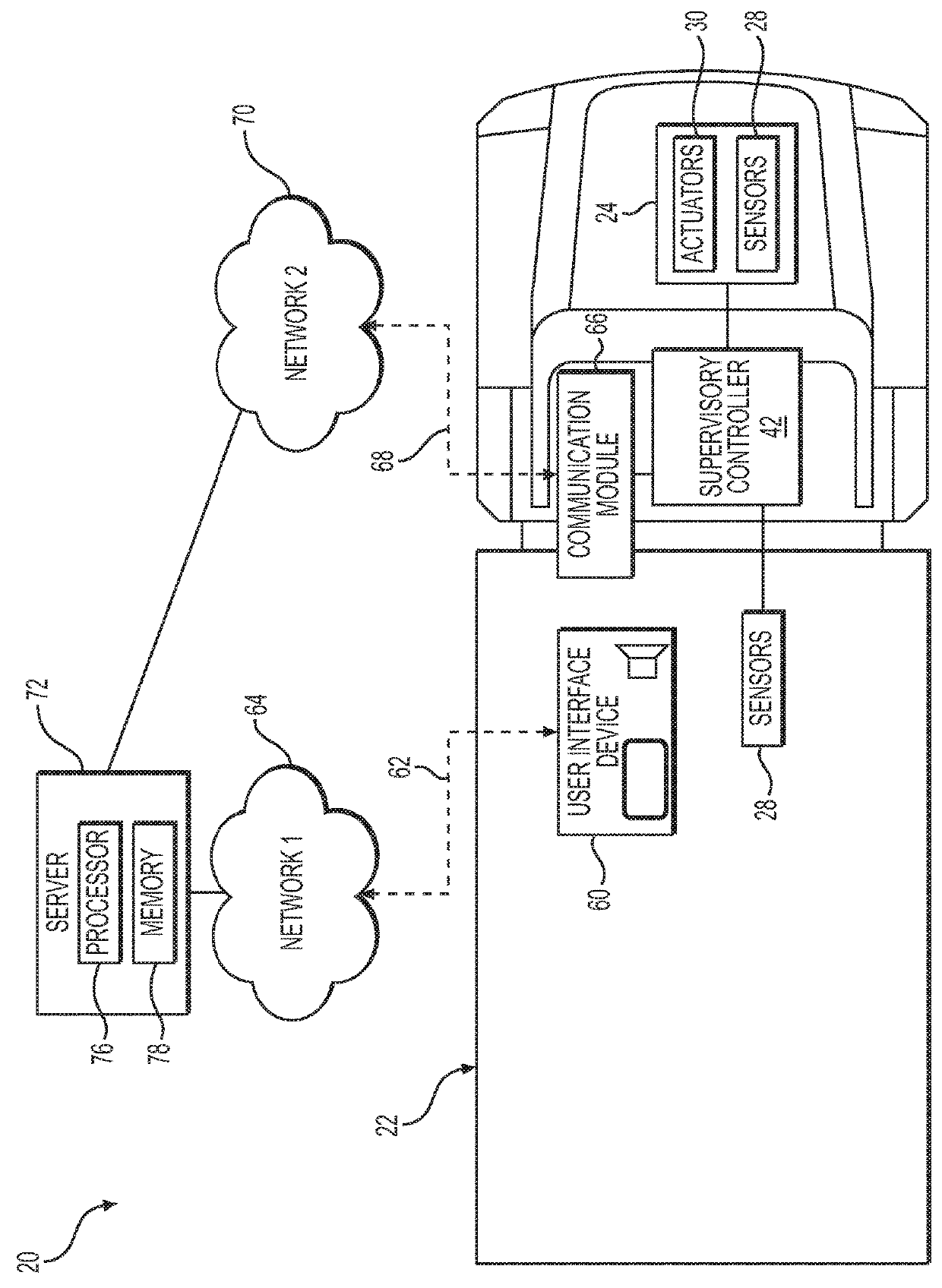

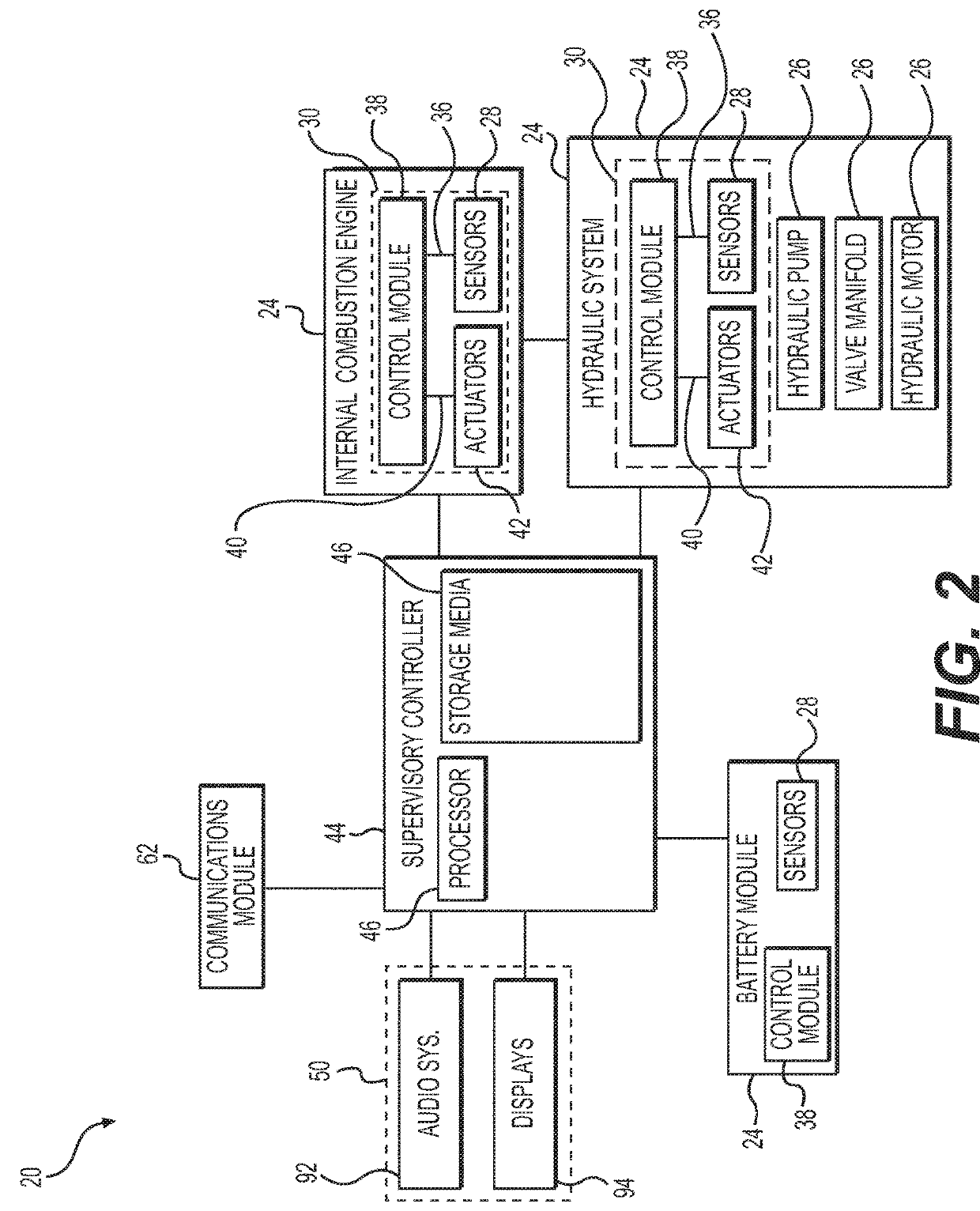

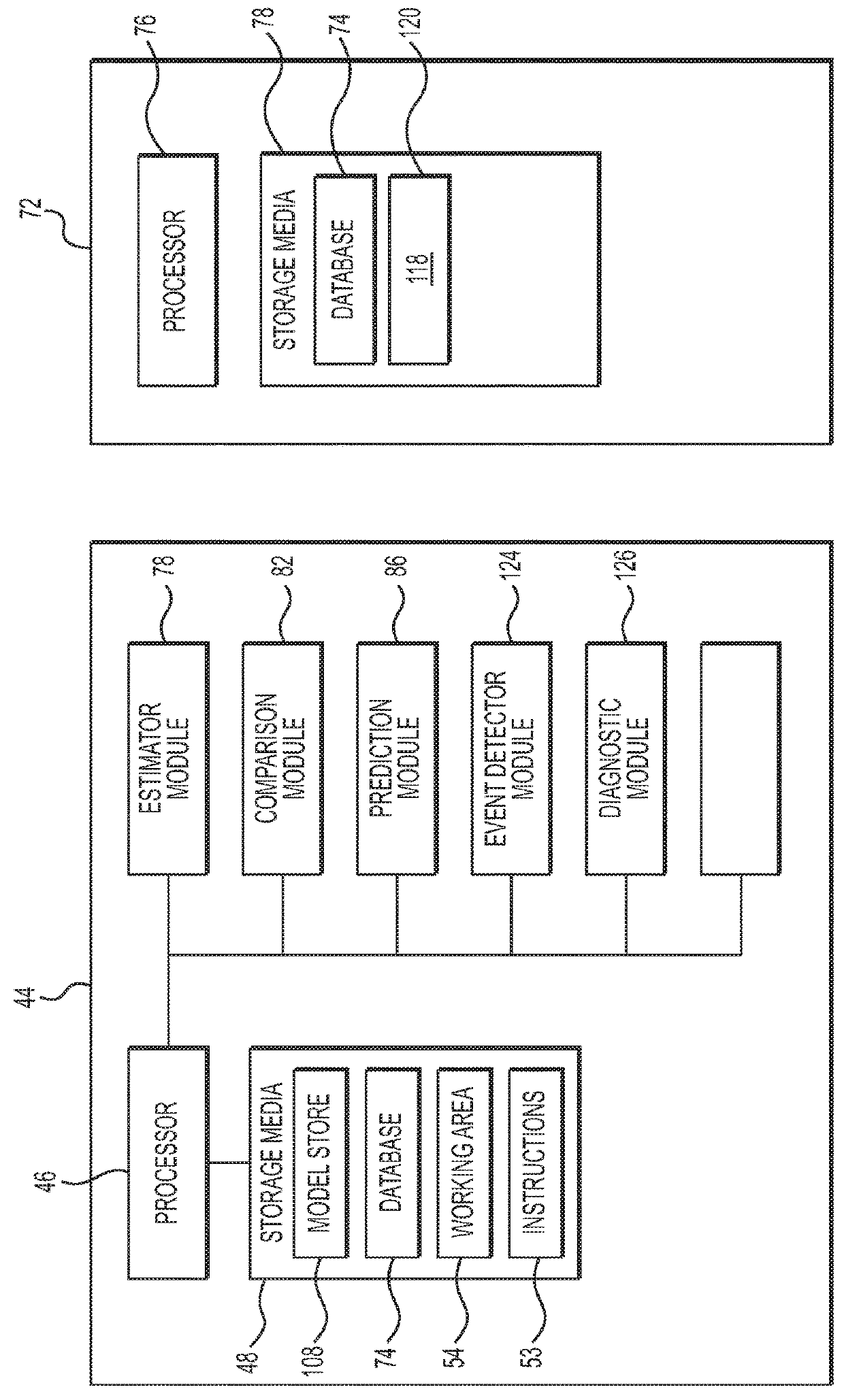

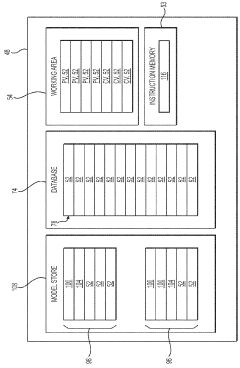

Distributed system and method for monitoring vehicle operation

PatentActiveUS20180268624A1

Innovation

- A distributed monitoring and control system that includes sensors, actuators, a supervisory controller, and a remote server for data storage and analysis, using historical data to estimate transfer functions and compare against reference conditions to diagnose failures and optimize system performance.

Environmental Impact and Emissions Compliance

The evolution of emissions standards has significantly impacted the design and durability requirements for LT1 engines. These V8 powerplants must now balance performance characteristics with increasingly stringent environmental regulations across global markets. Modern LT1 engines incorporate several key technologies specifically designed to reduce emissions while maintaining durability, including direct injection systems, variable valve timing, and advanced catalytic converters with higher precious metal loadings that withstand higher temperatures over extended periods.

Emissions compliance directly affects durability engineering through the implementation of exhaust gas recirculation (EGR) systems, which reduce NOx emissions but introduce additional thermal stress and potential carbon buildup issues. The integration of these systems necessitates more robust materials and cooling strategies to maintain engine longevity. Furthermore, the increased use of lightweight materials to improve fuel efficiency must be carefully balanced with durability requirements, as these materials often have different thermal expansion properties and wear characteristics.

Recent testing data indicates that LT1 engines equipped with the latest emissions control technologies maintain 95% of their catalytic converter efficiency for over 150,000 miles, significantly exceeding regulatory requirements of 80,000 miles. However, this extended durability comes with engineering challenges, particularly in managing increased thermal loads from higher combustion temperatures required for complete fuel burning and emissions reduction.

The transition to lower sulfur fuels has positively impacted LT1 durability by reducing corrosive compounds in the combustion chamber and exhaust system. Conversely, the introduction of ethanol-blended fuels presents new challenges, including potential material compatibility issues with fuel system components and modified combustion characteristics that affect cylinder wall wear patterns over time.

Emissions-related durability enhancements have driven innovation in sensor technology, with modern LT1 engines featuring more sophisticated oxygen sensors and control systems that must maintain accuracy over the engine's lifespan. These sensors now incorporate improved heater circuits and contamination-resistant designs that extend functional life by approximately 40% compared to previous generations.

Looking forward, upcoming Tier 4 and Euro 7 emissions standards will require further durability improvements, particularly in particulate filter longevity and low-temperature catalyst performance. Manufacturers are currently developing advanced ceramic materials and coating technologies that promise to extend emissions system durability while reducing the need for precious metals, potentially lowering long-term replacement costs while maintaining environmental compliance.

Emissions compliance directly affects durability engineering through the implementation of exhaust gas recirculation (EGR) systems, which reduce NOx emissions but introduce additional thermal stress and potential carbon buildup issues. The integration of these systems necessitates more robust materials and cooling strategies to maintain engine longevity. Furthermore, the increased use of lightweight materials to improve fuel efficiency must be carefully balanced with durability requirements, as these materials often have different thermal expansion properties and wear characteristics.

Recent testing data indicates that LT1 engines equipped with the latest emissions control technologies maintain 95% of their catalytic converter efficiency for over 150,000 miles, significantly exceeding regulatory requirements of 80,000 miles. However, this extended durability comes with engineering challenges, particularly in managing increased thermal loads from higher combustion temperatures required for complete fuel burning and emissions reduction.

The transition to lower sulfur fuels has positively impacted LT1 durability by reducing corrosive compounds in the combustion chamber and exhaust system. Conversely, the introduction of ethanol-blended fuels presents new challenges, including potential material compatibility issues with fuel system components and modified combustion characteristics that affect cylinder wall wear patterns over time.

Emissions-related durability enhancements have driven innovation in sensor technology, with modern LT1 engines featuring more sophisticated oxygen sensors and control systems that must maintain accuracy over the engine's lifespan. These sensors now incorporate improved heater circuits and contamination-resistant designs that extend functional life by approximately 40% compared to previous generations.

Looking forward, upcoming Tier 4 and Euro 7 emissions standards will require further durability improvements, particularly in particulate filter longevity and low-temperature catalyst performance. Manufacturers are currently developing advanced ceramic materials and coating technologies that promise to extend emissions system durability while reducing the need for precious metals, potentially lowering long-term replacement costs while maintaining environmental compliance.

Cost-Benefit Analysis of Durability Improvements

The cost-benefit analysis of durability enhancements for LT1 engines reveals significant economic implications for both manufacturers and end-users. Initial implementation costs for upgraded components such as forged pistons, strengthened connecting rods, and enhanced cylinder heads range from $2,500 to $7,000 depending on the extent of modifications. However, these investments demonstrate compelling long-term returns through extended engine lifecycle metrics.

Statistical analysis indicates that properly implemented durability enhancements can extend the mean time between failures (MTBF) by 35-45%, translating to approximately 50,000-75,000 additional miles before major overhaul requirements. This extension significantly reduces the total cost of ownership over the vehicle's operational lifespan, with calculations showing a net positive return beginning at approximately 85,000 miles for most enhancement packages.

Warranty claim data from aftermarket parts manufacturers demonstrates a 28% reduction in catastrophic engine failures among enhanced LT1 engines compared to stock configurations when operated under similar conditions. This reduction represents substantial savings in both direct repair costs and associated downtime expenses, particularly critical for commercial applications where vehicle availability directly impacts revenue generation.

Performance-oriented enhancements that simultaneously improve durability show the most favorable cost-benefit ratios. For instance, upgraded camshaft and valvetrain components that increase horsepower while extending service intervals demonstrate ROI improvements of 15-20% compared to purely durability-focused modifications with no performance gains. This dual-benefit approach appeals particularly to the performance market segment where both metrics carry significant value.

Manufacturing scale economics play a crucial role in the cost-benefit equation. Mass-produced enhancement packages benefit from significantly lower per-unit costs compared to custom solutions, with price differentials of 30-40% observed between comparable specifications. This factor heavily influences adoption rates across different market segments, with commercial fleets favoring standardized solutions while performance enthusiasts often accept premium pricing for customized enhancements.

Maintenance cost reductions represent another significant benefit category, with enhanced LT1 engines typically requiring 22% fewer service interventions over their operational lifespan. When factoring in both parts and labor, this translates to approximately $3,200-$4,800 in maintenance savings over 150,000 miles of operation, further strengthening the economic case for durability investments.

Statistical analysis indicates that properly implemented durability enhancements can extend the mean time between failures (MTBF) by 35-45%, translating to approximately 50,000-75,000 additional miles before major overhaul requirements. This extension significantly reduces the total cost of ownership over the vehicle's operational lifespan, with calculations showing a net positive return beginning at approximately 85,000 miles for most enhancement packages.

Warranty claim data from aftermarket parts manufacturers demonstrates a 28% reduction in catastrophic engine failures among enhanced LT1 engines compared to stock configurations when operated under similar conditions. This reduction represents substantial savings in both direct repair costs and associated downtime expenses, particularly critical for commercial applications where vehicle availability directly impacts revenue generation.

Performance-oriented enhancements that simultaneously improve durability show the most favorable cost-benefit ratios. For instance, upgraded camshaft and valvetrain components that increase horsepower while extending service intervals demonstrate ROI improvements of 15-20% compared to purely durability-focused modifications with no performance gains. This dual-benefit approach appeals particularly to the performance market segment where both metrics carry significant value.

Manufacturing scale economics play a crucial role in the cost-benefit equation. Mass-produced enhancement packages benefit from significantly lower per-unit costs compared to custom solutions, with price differentials of 30-40% observed between comparable specifications. This factor heavily influences adoption rates across different market segments, with commercial fleets favoring standardized solutions while performance enthusiasts often accept premium pricing for customized enhancements.

Maintenance cost reductions represent another significant benefit category, with enhanced LT1 engines typically requiring 22% fewer service interventions over their operational lifespan. When factoring in both parts and labor, this translates to approximately $3,200-$4,800 in maintenance savings over 150,000 miles of operation, further strengthening the economic case for durability investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!