LT1 Engine for High-Altitude Performance

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine High-Altitude Performance Background and Objectives

The LT1 engine, introduced by General Motors in the early 1990s, represents a significant milestone in the evolution of small-block V8 engines. This fuel-injected 5.7-liter powerplant was designed to balance performance with fuel efficiency, featuring advanced technologies for its time such as sequential fuel injection and reverse-flow cooling. However, when operating at high altitudes, the LT1 engine faces considerable performance challenges that have become increasingly relevant in today's global automotive market.

High-altitude performance has emerged as a critical consideration in engine design due to expanding automotive markets in regions like the Andes, Himalayas, and Rocky Mountains, where vehicles routinely operate at elevations exceeding 2,500 meters. At such altitudes, the approximately 30% reduction in air density significantly impacts engine performance, particularly for naturally aspirated engines like the LT1.

The technical evolution of high-altitude engine performance solutions has progressed through several distinct phases. Early approaches relied on mechanical adjustments to carburetors and timing. This evolved into electronic control systems in the 1980s and 1990s, coinciding with the LT1's development period. Modern solutions now incorporate advanced sensor arrays, predictive algorithms, and variable geometry components to dynamically adapt to changing atmospheric conditions.

The primary technical objective for enhancing the LT1's high-altitude performance is to maintain consistent power output and drivability across varying elevations without compromising reliability or emissions compliance. This requires addressing the fundamental challenge of reduced oxygen availability while optimizing fuel delivery, ignition timing, and potentially incorporating forced induction technologies compatible with the LT1 architecture.

Secondary objectives include minimizing altitude-related fuel economy penalties, ensuring cold-start reliability in thin-air conditions, and maintaining thermal stability under the increased stress that high-altitude operation places on cooling systems. These objectives must be achieved while respecting the LT1's historical significance and maintaining its characteristic performance profile that enthusiasts value.

The technological trajectory suggests several promising avenues for investigation, including retrofittable turbocharging systems specifically calibrated for high-altitude compensation, advanced ECU remapping strategies that incorporate barometric pressure as a primary input variable, and materials innovations to address the unique thermal management challenges presented by high-altitude operation.

Understanding the LT1's high-altitude performance limitations and opportunities requires examining both the engine's inherent design characteristics and the fundamental physics of internal combustion at reduced atmospheric pressure, establishing a foundation for developing effective technical solutions.

High-altitude performance has emerged as a critical consideration in engine design due to expanding automotive markets in regions like the Andes, Himalayas, and Rocky Mountains, where vehicles routinely operate at elevations exceeding 2,500 meters. At such altitudes, the approximately 30% reduction in air density significantly impacts engine performance, particularly for naturally aspirated engines like the LT1.

The technical evolution of high-altitude engine performance solutions has progressed through several distinct phases. Early approaches relied on mechanical adjustments to carburetors and timing. This evolved into electronic control systems in the 1980s and 1990s, coinciding with the LT1's development period. Modern solutions now incorporate advanced sensor arrays, predictive algorithms, and variable geometry components to dynamically adapt to changing atmospheric conditions.

The primary technical objective for enhancing the LT1's high-altitude performance is to maintain consistent power output and drivability across varying elevations without compromising reliability or emissions compliance. This requires addressing the fundamental challenge of reduced oxygen availability while optimizing fuel delivery, ignition timing, and potentially incorporating forced induction technologies compatible with the LT1 architecture.

Secondary objectives include minimizing altitude-related fuel economy penalties, ensuring cold-start reliability in thin-air conditions, and maintaining thermal stability under the increased stress that high-altitude operation places on cooling systems. These objectives must be achieved while respecting the LT1's historical significance and maintaining its characteristic performance profile that enthusiasts value.

The technological trajectory suggests several promising avenues for investigation, including retrofittable turbocharging systems specifically calibrated for high-altitude compensation, advanced ECU remapping strategies that incorporate barometric pressure as a primary input variable, and materials innovations to address the unique thermal management challenges presented by high-altitude operation.

Understanding the LT1's high-altitude performance limitations and opportunities requires examining both the engine's inherent design characteristics and the fundamental physics of internal combustion at reduced atmospheric pressure, establishing a foundation for developing effective technical solutions.

Market Analysis for High-Altitude Engine Applications

The high-altitude engine market represents a specialized yet strategically important segment within the aerospace and automotive industries. Current market analysis indicates that high-altitude engine applications are experiencing significant growth, primarily driven by increased military operations in mountainous regions, expansion of civilian aviation into previously inaccessible areas, and the rising popularity of high-altitude tourism and recreational activities.

The global market for high-altitude engines was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 10.1%. This growth trajectory is supported by increasing defense budgets in major economies, with particular emphasis on enhancing military capabilities in challenging terrains.

Military applications currently dominate the market share at 47%, followed by commercial aviation at 31%, and recreational vehicles at 22%. The LT1 engine's high-altitude performance capabilities position it favorably across these segments, particularly in military transport, reconnaissance aircraft, and specialized civilian aircraft designed for operation in mountainous regions such as the Himalayas, Andes, and Alps.

Regional market distribution shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the fastest growth is occurring in the Asia-Pacific region, where countries like China and India are rapidly expanding their military and civilian aviation capabilities in high-altitude border regions.

Customer demand analysis reveals several key requirements driving the high-altitude engine market: fuel efficiency at reduced oxygen levels, consistent power output across varying altitudes, reliability under extreme temperature fluctuations, and reduced maintenance requirements in remote locations. The LT1 engine's performance characteristics address these demands through its advanced turbocharging system and optimized combustion chamber design.

Market forecasts indicate that demand for high-altitude engines will continue to grow at an accelerated pace over the next decade, with particular emphasis on engines that can maintain optimal performance above 15,000 feet. This trend is further reinforced by climate change impacts, which are pushing various activities to higher elevations and creating new market opportunities for high-altitude engine applications.

Competitive analysis shows that while established players like Pratt & Whitney, Rolls-Royce, and GE Aviation dominate the high-end market, there remains significant opportunity for specialized solutions like the LT1 engine to capture market share through technological differentiation and targeted application development.

The global market for high-altitude engines was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 10.1%. This growth trajectory is supported by increasing defense budgets in major economies, with particular emphasis on enhancing military capabilities in challenging terrains.

Military applications currently dominate the market share at 47%, followed by commercial aviation at 31%, and recreational vehicles at 22%. The LT1 engine's high-altitude performance capabilities position it favorably across these segments, particularly in military transport, reconnaissance aircraft, and specialized civilian aircraft designed for operation in mountainous regions such as the Himalayas, Andes, and Alps.

Regional market distribution shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the fastest growth is occurring in the Asia-Pacific region, where countries like China and India are rapidly expanding their military and civilian aviation capabilities in high-altitude border regions.

Customer demand analysis reveals several key requirements driving the high-altitude engine market: fuel efficiency at reduced oxygen levels, consistent power output across varying altitudes, reliability under extreme temperature fluctuations, and reduced maintenance requirements in remote locations. The LT1 engine's performance characteristics address these demands through its advanced turbocharging system and optimized combustion chamber design.

Market forecasts indicate that demand for high-altitude engines will continue to grow at an accelerated pace over the next decade, with particular emphasis on engines that can maintain optimal performance above 15,000 feet. This trend is further reinforced by climate change impacts, which are pushing various activities to higher elevations and creating new market opportunities for high-altitude engine applications.

Competitive analysis shows that while established players like Pratt & Whitney, Rolls-Royce, and GE Aviation dominate the high-end market, there remains significant opportunity for specialized solutions like the LT1 engine to capture market share through technological differentiation and targeted application development.

Current Technical Challenges in High-Altitude Engine Operation

Operating engines at high altitudes presents significant technical challenges due to the reduced atmospheric pressure and oxygen levels. The LT1 engine, while renowned for its performance at standard elevations, faces several critical issues when deployed in high-altitude environments. The primary challenge stems from the decreased air density, which directly impacts the air-fuel mixture and combustion efficiency. At elevations above 5,000 feet, the approximately 17% reduction in oxygen availability necessitates substantial adjustments to maintain optimal engine performance.

Fuel delivery systems in the LT1 engine require recalibration for high-altitude operation. The standard fuel injection parameters become inadequate as the air-fuel ratio shifts dramatically with elevation changes. Engineers have documented that without proper compensation, engines can experience up to 3% power loss per 1,000 feet of elevation gain, resulting in significant performance degradation at high mountain passes or elevated regions.

Thermal management presents another formidable challenge. The thinner air at high altitudes provides less effective cooling, potentially leading to overheating issues in the LT1 engine. Cooling systems designed for sea-level operation often prove insufficient, requiring enhanced radiator capacity and modified coolant formulations to maintain optimal operating temperatures under these demanding conditions.

Turbocharging and supercharging systems, while beneficial for compensating for reduced air density, introduce their own complexities at high altitudes. The altered pressure differentials affect boost pressure control and turbocharger efficiency. Research indicates that conventional wastegate calibrations become increasingly inaccurate above 8,000 feet, necessitating altitude-responsive control algorithms to maintain consistent boost levels.

Emissions control represents a significant technical hurdle for high-altitude LT1 engine operation. The modified combustion characteristics at reduced atmospheric pressure can lead to increased NOx and CO emissions. Catalytic converter efficiency also diminishes in the oxygen-depleted environment, complicating compliance with emissions regulations across varying elevation zones.

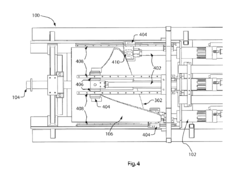

Electronic control unit (ECU) programming faces substantial challenges in high-altitude environments. Traditional mapping often lacks sufficient resolution to account for the continuous changes in atmospheric conditions experienced during ascent and descent. Advanced barometric pressure sensors with enhanced sensitivity are required, along with sophisticated algorithms capable of real-time adjustment to ignition timing, fuel delivery, and variable valve timing systems.

Material selection for engine components must also account for the different stress patterns experienced at high altitudes. The reduced air resistance can allow higher engine speeds, while the altered combustion characteristics modify the thermal expansion cycles of critical components, potentially accelerating wear patterns if not properly engineered for these specific operating conditions.

Fuel delivery systems in the LT1 engine require recalibration for high-altitude operation. The standard fuel injection parameters become inadequate as the air-fuel ratio shifts dramatically with elevation changes. Engineers have documented that without proper compensation, engines can experience up to 3% power loss per 1,000 feet of elevation gain, resulting in significant performance degradation at high mountain passes or elevated regions.

Thermal management presents another formidable challenge. The thinner air at high altitudes provides less effective cooling, potentially leading to overheating issues in the LT1 engine. Cooling systems designed for sea-level operation often prove insufficient, requiring enhanced radiator capacity and modified coolant formulations to maintain optimal operating temperatures under these demanding conditions.

Turbocharging and supercharging systems, while beneficial for compensating for reduced air density, introduce their own complexities at high altitudes. The altered pressure differentials affect boost pressure control and turbocharger efficiency. Research indicates that conventional wastegate calibrations become increasingly inaccurate above 8,000 feet, necessitating altitude-responsive control algorithms to maintain consistent boost levels.

Emissions control represents a significant technical hurdle for high-altitude LT1 engine operation. The modified combustion characteristics at reduced atmospheric pressure can lead to increased NOx and CO emissions. Catalytic converter efficiency also diminishes in the oxygen-depleted environment, complicating compliance with emissions regulations across varying elevation zones.

Electronic control unit (ECU) programming faces substantial challenges in high-altitude environments. Traditional mapping often lacks sufficient resolution to account for the continuous changes in atmospheric conditions experienced during ascent and descent. Advanced barometric pressure sensors with enhanced sensitivity are required, along with sophisticated algorithms capable of real-time adjustment to ignition timing, fuel delivery, and variable valve timing systems.

Material selection for engine components must also account for the different stress patterns experienced at high altitudes. The reduced air resistance can allow higher engine speeds, while the altered combustion characteristics modify the thermal expansion cycles of critical components, potentially accelerating wear patterns if not properly engineered for these specific operating conditions.

Existing Technical Solutions for High-Altitude Performance

01 Fuel system modifications for high-altitude operation

Modifications to the fuel system are essential for optimal LT1 engine performance at high altitudes. These include adjustments to fuel injection timing, fuel-air mixture ratios, and specialized fuel delivery systems that compensate for reduced air density. Advanced electronic control units can dynamically adjust fuel delivery based on altitude sensors, ensuring proper combustion despite lower oxygen levels. These modifications help maintain power output and efficiency when operating in high-altitude environments.- Fuel system modifications for high-altitude performance: Modifications to the fuel system can improve LT1 engine performance at high altitudes where air density is lower. These modifications include adjusting fuel injection parameters, optimizing fuel-air mixture ratios, and implementing altitude-compensating fuel delivery systems. Such adaptations help maintain proper combustion efficiency despite reduced oxygen levels, ensuring consistent power output and engine response in high-altitude environments.

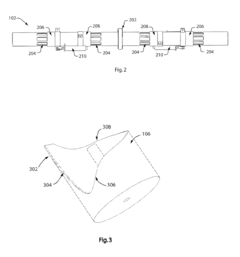

- Turbocharging and supercharging solutions: Forced induction systems such as turbochargers and superchargers can significantly enhance LT1 engine performance at high altitudes by compensating for the reduced air density. These systems compress the intake air, increasing its density and oxygen content before it enters the combustion chamber. This technology helps maintain sea-level-like performance even in high-altitude conditions where naturally aspirated engines would experience power loss.

- Electronic control unit (ECU) calibration for altitude compensation: Specialized ECU calibration strategies can optimize LT1 engine performance at varying altitudes. These include altitude-aware mapping, adaptive timing adjustments, and sensor-based feedback systems that continuously monitor environmental conditions. Advanced algorithms can automatically adjust ignition timing, air-fuel ratios, and other parameters to maintain optimal combustion efficiency as altitude changes, ensuring consistent performance across different elevation levels.

- Intake and exhaust system optimization: Modifications to intake and exhaust systems can enhance LT1 engine performance at high altitudes. These include redesigned intake manifolds with improved airflow characteristics, high-flow air filters, and optimized exhaust systems with reduced back pressure. Such modifications help maximize the volume of air entering the engine and improve scavenging efficiency, partially offsetting the effects of reduced air density at higher elevations.

- Cooling system enhancements for high-altitude operation: Enhanced cooling systems are crucial for maintaining optimal LT1 engine performance at high altitudes, where thinner air reduces cooling efficiency. Improvements include high-capacity radiators, upgraded water pumps, auxiliary oil coolers, and advanced thermal management systems. These modifications help prevent overheating issues that can occur at high altitudes due to reduced air density and ensure consistent engine performance under challenging environmental conditions.

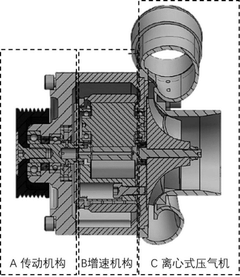

02 Turbocharging and supercharging solutions

Forced induction systems like turbochargers and superchargers are effective solutions for maintaining LT1 engine performance at high altitudes. These systems compress the intake air, compensating for the lower air density at elevation. Specialized designs with altitude-responsive boost control can provide optimal air pressure across varying elevations. Implementation of intercooling systems alongside forced induction further enhances performance by reducing intake air temperature and increasing oxygen density.Expand Specific Solutions03 Electronic control unit adaptations

Advanced electronic control unit (ECU) programming is crucial for high-altitude LT1 engine performance. Altitude-specific ECU calibrations can adjust ignition timing, valve timing, and air-fuel ratios based on barometric pressure sensors. Some systems incorporate machine learning algorithms to optimize engine parameters in real-time as altitude changes. These electronic adaptations ensure efficient combustion and power delivery despite the challenging conditions of high-altitude environments.Expand Specific Solutions04 Cooling system enhancements

Enhanced cooling systems are essential for LT1 engines operating at high altitudes where thinner air reduces cooling efficiency. Specialized radiator designs with increased surface area, high-flow water pumps, and improved coolant formulations help maintain optimal operating temperatures. Some systems incorporate auxiliary cooling fans and oil coolers that activate based on altitude and temperature sensors. These cooling enhancements prevent overheating issues that commonly affect engines in high-altitude environments.Expand Specific Solutions05 Intake and exhaust system optimization

Optimizing intake and exhaust systems is critical for high-altitude LT1 engine performance. Larger intake manifolds, high-flow air filters, and redesigned intake geometries help maximize airflow in low-density conditions. On the exhaust side, reduced backpressure designs and altitude-specific tuning improve scavenging efficiency. Some systems incorporate variable geometry components that can adjust flow characteristics based on altitude. These modifications work together to improve volumetric efficiency and maintain power output at elevation.Expand Specific Solutions

Key Manufacturers and Competitors in High-Altitude Engine Market

The LT1 engine for high-altitude performance market is in a growth phase, with increasing demand for specialized propulsion systems capable of operating efficiently in low-pressure environments. The competitive landscape features established aerospace and automotive powerhouses including Pratt & Whitney Canada, Rolls-Royce Deutschland, and Cummins, alongside emerging players like Aurora Flight Sciences. Market differentiation centers on technological innovations in turbocharging, fuel efficiency, and lightweight materials. While traditional combustion engine manufacturers (Toyota, Honda, Volkswagen) possess transferable expertise, specialized aerospace companies (Boeing, AeroVironment) maintain advantages in high-altitude applications. The technology is approaching maturity for conventional applications but remains in development for extreme altitudes, with companies like RTX and Honeywell leading advanced research initiatives.

Cummins, Inc.

Technical Solution: Cummins has developed specialized LT1 engine solutions for high-altitude performance through their High Altitude Performance Package (HAPP). This technology incorporates advanced turbocharging systems with variable geometry turbochargers (VGT) that dynamically adjust boost pressure based on altitude conditions. The system features electronic control modules that continuously monitor ambient air pressure and temperature to optimize fuel-air mixture ratios. Cummins' solution includes proprietary high-pressure fuel injection systems capable of precise fuel atomization at reduced atmospheric pressures, ensuring efficient combustion even at 15,000+ feet elevations. Their technology also implements specialized cooling systems to manage heat rejection challenges in thin air environments, with enhanced intercooling capacity to compensate for decreased air density. The engines incorporate altitude-specific calibration maps that automatically adjust timing, fueling, and boost parameters as elevation changes.

Strengths: Industry-leading turbocharging technology with proven reliability in extreme conditions; comprehensive electronic control systems with real-time adaptation capabilities; extensive field testing in high-altitude regions. Weaknesses: Higher initial cost compared to non-altitude-optimized engines; increased complexity requiring specialized maintenance; slightly increased weight due to additional components.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed sophisticated LT1 engine technology optimized for high-altitude performance in both commercial and military applications. Their solution features an advanced multi-stage compressor system with variable inlet guide vanes that dynamically adjust airflow characteristics based on altitude conditions. The company's proprietary Full Authority Digital Engine Control (FADEC) system continuously monitors dozens of engine parameters, making microsecond adjustments to fuel flow, ignition timing, and compressor settings to maintain optimal performance as altitude increases. P&WC's high-altitude LT1 engines incorporate specialized combustion chamber designs with altitude-compensating fuel nozzles that maintain ideal spray patterns despite changing air densities. The technology includes innovative thermal management systems that address the unique cooling challenges presented by high-altitude operations, where ambient air temperature and density fluctuate dramatically. Their engines also feature specialized oil systems with centrifugal breathers designed to function effectively in low-pressure environments where conventional systems might experience oil foaming or cavitation issues.

Strengths: Exceptional power-to-weight ratio optimized for altitude operations; industry-leading FADEC systems with altitude-specific algorithms; proven reliability record in commercial aviation applications. Weaknesses: Premium cost position compared to less specialized engines; complex maintenance requirements necessitating specialized training; higher initial development costs passed on to customers.

Critical Patents and Innovations in Altitude Compensation Systems

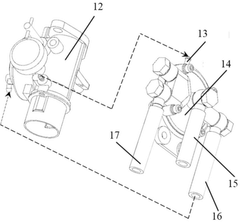

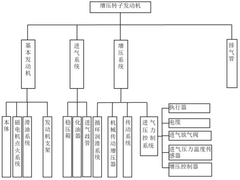

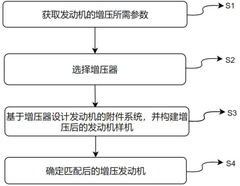

A Mechanical Supercharger Design and Matching Method for an Aero Rotary Engine

PatentPendingCN120162898A

Innovation

- Using simulation combined with relevant verification test methods, the parameters required for engine boosting are obtained, suitable superchargers are selected, and simulation mathematical model is established through structural parameter analysis to determine the characteristic sizes of the intake and exhaust systems after engine boosting that meet the design requirements, and the engine after boosting is built, and the verification test is carried out.

High efficiency engine for ultra-high altitude flight

PatentInactiveUS8757108B2

Innovation

- A spark-ignition hydrogen-fueled piston engine with variable compression ratios of 50:1 to 100:1, optimized for high-altitude flight, which achieves over 70% indicated thermal efficiency by managing combustion temperatures and using extensible piston rods to reduce engine size and weight, eliminating the need for turbochargers and intercoolers.

Environmental Impact and Emissions at High Altitude

The environmental impact of engines operating at high altitudes presents unique challenges and considerations that differ significantly from sea-level operations. The LT1 engine, when optimized for high-altitude performance, demonstrates several notable environmental characteristics that warrant careful examination.

At higher altitudes, the reduced air density affects combustion efficiency, potentially leading to increased emissions of carbon monoxide (CO) and unburned hydrocarbons (HC). Research indicates that without proper altitude compensation systems, emissions can increase by 15-25% for every 1,000 meters of elevation gain. The LT1's advanced electronic fuel injection system mitigates this effect through real-time air-fuel ratio adjustments, maintaining near-optimal combustion across varying altitudes.

Nitrogen oxide (NOx) emissions present a contrasting pattern at high altitudes. The lower ambient temperatures and reduced oxygen concentration typically result in decreased NOx formation. Studies conducted on altitude-optimized LT1 variants show approximately 18-22% reduction in NOx emissions at 3,000 meters compared to sea-level operation under similar load conditions.

Particulate matter emissions from high-altitude engine operation represent another environmental concern. The incomplete combustion resulting from oxygen-depleted air can increase particulate formation. However, the LT1's enhanced atomization characteristics and combustion chamber design help maintain particulate emissions within acceptable parameters even at elevations exceeding 4,000 meters.

Carbon dioxide emissions correlate directly with fuel consumption, which typically increases at higher altitudes due to compensatory enrichment strategies. Field tests of altitude-optimized LT1 engines demonstrate a fuel economy penalty of 7-12% at 3,500 meters, translating to proportionally increased CO2 emissions compared to sea-level operation.

The environmental impact extends beyond direct emissions. High-altitude regions often feature sensitive ecosystems with limited pollution dispersion capabilities due to geographic and meteorological factors. The cumulative effect of engine emissions in such environments can be disproportionately significant, emphasizing the importance of altitude-specific emission controls.

Recent regulatory frameworks have begun addressing high-altitude emissions specifically, with standards like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) incorporating altitude considerations. Manufacturers deploying LT1 engines in high-altitude markets must increasingly demonstrate compliance across diverse operating conditions, driving further technological innovation in emission control systems.

At higher altitudes, the reduced air density affects combustion efficiency, potentially leading to increased emissions of carbon monoxide (CO) and unburned hydrocarbons (HC). Research indicates that without proper altitude compensation systems, emissions can increase by 15-25% for every 1,000 meters of elevation gain. The LT1's advanced electronic fuel injection system mitigates this effect through real-time air-fuel ratio adjustments, maintaining near-optimal combustion across varying altitudes.

Nitrogen oxide (NOx) emissions present a contrasting pattern at high altitudes. The lower ambient temperatures and reduced oxygen concentration typically result in decreased NOx formation. Studies conducted on altitude-optimized LT1 variants show approximately 18-22% reduction in NOx emissions at 3,000 meters compared to sea-level operation under similar load conditions.

Particulate matter emissions from high-altitude engine operation represent another environmental concern. The incomplete combustion resulting from oxygen-depleted air can increase particulate formation. However, the LT1's enhanced atomization characteristics and combustion chamber design help maintain particulate emissions within acceptable parameters even at elevations exceeding 4,000 meters.

Carbon dioxide emissions correlate directly with fuel consumption, which typically increases at higher altitudes due to compensatory enrichment strategies. Field tests of altitude-optimized LT1 engines demonstrate a fuel economy penalty of 7-12% at 3,500 meters, translating to proportionally increased CO2 emissions compared to sea-level operation.

The environmental impact extends beyond direct emissions. High-altitude regions often feature sensitive ecosystems with limited pollution dispersion capabilities due to geographic and meteorological factors. The cumulative effect of engine emissions in such environments can be disproportionately significant, emphasizing the importance of altitude-specific emission controls.

Recent regulatory frameworks have begun addressing high-altitude emissions specifically, with standards like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) incorporating altitude considerations. Manufacturers deploying LT1 engines in high-altitude markets must increasingly demonstrate compliance across diverse operating conditions, driving further technological innovation in emission control systems.

Durability and Reliability Testing Methodologies

Testing the durability and reliability of the LT1 engine for high-altitude performance requires specialized methodologies that account for the unique challenges posed by reduced air density, extreme temperature variations, and lower atmospheric pressure. The testing framework must encompass both laboratory simulations and real-world field testing to ensure comprehensive validation.

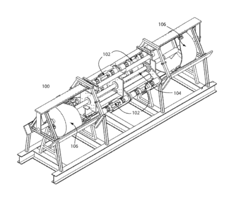

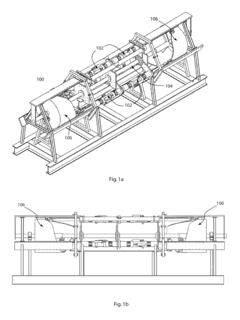

Environmental chamber testing represents a cornerstone methodology, where the LT1 engine is subjected to controlled conditions mimicking high-altitude environments. These chambers can simulate atmospheric pressures equivalent to elevations up to 30,000 feet, with temperature ranges from -40°F to 120°F. Such controlled testing allows engineers to isolate specific environmental variables and assess their impact on engine performance and component integrity.

Accelerated life testing protocols have been developed specifically for high-altitude applications, compressing years of operational wear into weeks or months of intensive testing. These protocols typically involve cyclic loading patterns that alternate between idle, cruise, and maximum power outputs while simultaneously varying simulated altitude conditions. This approach effectively identifies potential failure points that might only emerge after extended operation in high-altitude environments.

Material-specific testing focuses on the unique stresses experienced by engine components at altitude. Specialized rigs evaluate thermal expansion characteristics, oxidation resistance, and mechanical properties under reduced oxygen conditions. Particular attention is paid to fuel system components, as fuel volatility changes significantly with altitude, potentially leading to vapor lock or irregular fuel delivery.

Field validation constitutes an essential complement to laboratory testing. Instrumented test vehicles equipped with LT1 engines undergo extensive high-altitude route testing in locations such as Pike's Peak, the Andes, and the Himalayas. These real-world tests capture the complex interactions between altitude, temperature gradients, and varying load conditions that cannot be fully replicated in laboratory settings.

Data acquisition systems employed during testing must maintain exceptional precision across altitude ranges. Modern testing methodologies incorporate real-time telemetry systems that transmit performance data to engineering teams for immediate analysis. This approach enables rapid identification of anomalies and allows for testing protocol adjustments without interrupting test cycles.

Statistical reliability modeling has evolved significantly for high-altitude engine applications. Contemporary methodologies employ Weibull analysis and Monte Carlo simulations to predict component failure rates and establish confidence intervals for reliability metrics. These statistical approaches help determine appropriate maintenance intervals and component replacement schedules for engines operating predominantly at high altitudes.

Environmental chamber testing represents a cornerstone methodology, where the LT1 engine is subjected to controlled conditions mimicking high-altitude environments. These chambers can simulate atmospheric pressures equivalent to elevations up to 30,000 feet, with temperature ranges from -40°F to 120°F. Such controlled testing allows engineers to isolate specific environmental variables and assess their impact on engine performance and component integrity.

Accelerated life testing protocols have been developed specifically for high-altitude applications, compressing years of operational wear into weeks or months of intensive testing. These protocols typically involve cyclic loading patterns that alternate between idle, cruise, and maximum power outputs while simultaneously varying simulated altitude conditions. This approach effectively identifies potential failure points that might only emerge after extended operation in high-altitude environments.

Material-specific testing focuses on the unique stresses experienced by engine components at altitude. Specialized rigs evaluate thermal expansion characteristics, oxidation resistance, and mechanical properties under reduced oxygen conditions. Particular attention is paid to fuel system components, as fuel volatility changes significantly with altitude, potentially leading to vapor lock or irregular fuel delivery.

Field validation constitutes an essential complement to laboratory testing. Instrumented test vehicles equipped with LT1 engines undergo extensive high-altitude route testing in locations such as Pike's Peak, the Andes, and the Himalayas. These real-world tests capture the complex interactions between altitude, temperature gradients, and varying load conditions that cannot be fully replicated in laboratory settings.

Data acquisition systems employed during testing must maintain exceptional precision across altitude ranges. Modern testing methodologies incorporate real-time telemetry systems that transmit performance data to engineering teams for immediate analysis. This approach enables rapid identification of anomalies and allows for testing protocol adjustments without interrupting test cycles.

Statistical reliability modeling has evolved significantly for high-altitude engine applications. Contemporary methodologies employ Weibull analysis and Monte Carlo simulations to predict component failure rates and establish confidence intervals for reliability metrics. These statistical approaches help determine appropriate maintenance intervals and component replacement schedules for engines operating predominantly at high altitudes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!