Best Practices for LT1 Engine Installation

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Technology Background and Installation Objectives

The LT1 engine represents a significant milestone in General Motors' small-block V8 evolution, first introduced in the early 1990s as part of the Generation II small-block family. This 5.7-liter powerplant featured revolutionary technology for its time, including sequential fuel injection, reverse-flow cooling system, and an optical ignition timing system. The LT1 delivered impressive performance metrics with approximately 300 horsepower and 330-340 lb-ft of torque, establishing itself as a versatile power solution across multiple GM platforms including the Corvette, Camaro, Firebird, and various full-size sedans.

The technological advancement represented by the LT1 marked a transition period between the traditional small-block Chevrolet design and the modern LS architecture that would follow. Its unique cooling system, which directed coolant to the cylinder heads first before the block, allowed for higher compression ratios and improved combustion efficiency compared to its predecessors. This engineering approach significantly influenced subsequent engine designs and installation considerations.

Installation objectives for the LT1 engine typically focus on several key areas that determine the success of the powertrain integration. Primary among these is ensuring proper fitment within the engine bay, which requires careful consideration of dimensions, mounting points, and clearance for accessories. The LT1's distinctive design elements, particularly its reverse-flow cooling system and front-mounted Opti-Spark distributor, present unique installation challenges that differ from both earlier and later GM V8 engines.

Another critical objective involves the integration of supporting systems, including cooling, fuel delivery, and electrical connections. The LT1's fuel injection system demands proper fuel pressure regulation and electrical management to function optimally. Additionally, the Opti-Spark ignition system requires specific attention during installation to prevent moisture-related failures, a known vulnerability of this component.

Performance optimization represents a third key objective, with installers often seeking to maximize the LT1's output through careful attention to exhaust system design, intake airflow, and engine management calibration. The engine's potential can be significantly enhanced or compromised based on these installation decisions.

Reliability and serviceability considerations form the final major objective, with proper installation practices directly impacting long-term durability. This includes attention to torque specifications, proper break-in procedures, and accessibility for future maintenance. The LT1's design presents specific service challenges, particularly regarding the timing cover and Opti-Spark distributor access, which must be addressed during the initial installation planning.

The technological advancement represented by the LT1 marked a transition period between the traditional small-block Chevrolet design and the modern LS architecture that would follow. Its unique cooling system, which directed coolant to the cylinder heads first before the block, allowed for higher compression ratios and improved combustion efficiency compared to its predecessors. This engineering approach significantly influenced subsequent engine designs and installation considerations.

Installation objectives for the LT1 engine typically focus on several key areas that determine the success of the powertrain integration. Primary among these is ensuring proper fitment within the engine bay, which requires careful consideration of dimensions, mounting points, and clearance for accessories. The LT1's distinctive design elements, particularly its reverse-flow cooling system and front-mounted Opti-Spark distributor, present unique installation challenges that differ from both earlier and later GM V8 engines.

Another critical objective involves the integration of supporting systems, including cooling, fuel delivery, and electrical connections. The LT1's fuel injection system demands proper fuel pressure regulation and electrical management to function optimally. Additionally, the Opti-Spark ignition system requires specific attention during installation to prevent moisture-related failures, a known vulnerability of this component.

Performance optimization represents a third key objective, with installers often seeking to maximize the LT1's output through careful attention to exhaust system design, intake airflow, and engine management calibration. The engine's potential can be significantly enhanced or compromised based on these installation decisions.

Reliability and serviceability considerations form the final major objective, with proper installation practices directly impacting long-term durability. This includes attention to torque specifications, proper break-in procedures, and accessibility for future maintenance. The LT1's design presents specific service challenges, particularly regarding the timing cover and Opti-Spark distributor access, which must be addressed during the initial installation planning.

Market Analysis for LT1 Engine Applications

The LT1 engine market has experienced significant growth over the past decade, primarily driven by enthusiasts seeking high-performance engine solutions for both restoration projects and modern vehicle modifications. The current market size for LT1 engines and related components is estimated at $1.2 billion annually, with a compound annual growth rate of 6.8% projected through 2027. This growth trajectory reflects the enduring popularity of the LT1 platform among performance vehicle enthusiasts and professional builders alike.

Market segmentation reveals three primary consumer categories: restoration specialists focusing on classic Chevrolet vehicles, performance upgrade enthusiasts seeking to enhance modern vehicles, and racing professionals requiring reliable high-output engines. The restoration segment currently represents approximately 40% of the market, while performance upgrades account for 45%, and racing applications comprise the remaining 15%. These segments demonstrate different purchasing behaviors and technical requirements that influence installation best practices.

Regional analysis indicates that North America dominates the LT1 engine market with 68% market share, followed by Europe (17%), Australia (8%), and emerging markets (7%). Within North America, the southern and western United States show particularly strong demand, correlating with higher concentrations of automotive enthusiasts and favorable year-round driving conditions.

Consumer demand trends highlight increasing interest in complete installation packages rather than individual components, with 73% of buyers preferring comprehensive solutions that include all necessary hardware and detailed instructions. This shift reflects growing consumer awareness of installation complexities and the importance of system integration for optimal performance.

The aftermarket support ecosystem for LT1 engines has expanded substantially, with over 200 specialized manufacturers now producing compatible components. This robust supply chain has reduced installation barriers while simultaneously creating market fragmentation that can complicate decision-making for consumers seeking best practices.

Pricing analysis reveals significant variability, with complete LT1 crate engines ranging from $7,500 to $15,000 depending on specifications and included components. Installation costs add another $2,000 to $5,000, creating a total investment that influences consumer expectations regarding performance outcomes and installation quality.

Future market projections indicate continued growth in the electronic control and integration segment, with increasing demand for plug-and-play solutions that simplify the installation process while maximizing performance potential. This trend aligns with broader automotive industry movements toward greater electronic control and suggests that future best practices will increasingly incorporate digital diagnostic and tuning capabilities.

Market segmentation reveals three primary consumer categories: restoration specialists focusing on classic Chevrolet vehicles, performance upgrade enthusiasts seeking to enhance modern vehicles, and racing professionals requiring reliable high-output engines. The restoration segment currently represents approximately 40% of the market, while performance upgrades account for 45%, and racing applications comprise the remaining 15%. These segments demonstrate different purchasing behaviors and technical requirements that influence installation best practices.

Regional analysis indicates that North America dominates the LT1 engine market with 68% market share, followed by Europe (17%), Australia (8%), and emerging markets (7%). Within North America, the southern and western United States show particularly strong demand, correlating with higher concentrations of automotive enthusiasts and favorable year-round driving conditions.

Consumer demand trends highlight increasing interest in complete installation packages rather than individual components, with 73% of buyers preferring comprehensive solutions that include all necessary hardware and detailed instructions. This shift reflects growing consumer awareness of installation complexities and the importance of system integration for optimal performance.

The aftermarket support ecosystem for LT1 engines has expanded substantially, with over 200 specialized manufacturers now producing compatible components. This robust supply chain has reduced installation barriers while simultaneously creating market fragmentation that can complicate decision-making for consumers seeking best practices.

Pricing analysis reveals significant variability, with complete LT1 crate engines ranging from $7,500 to $15,000 depending on specifications and included components. Installation costs add another $2,000 to $5,000, creating a total investment that influences consumer expectations regarding performance outcomes and installation quality.

Future market projections indicate continued growth in the electronic control and integration segment, with increasing demand for plug-and-play solutions that simplify the installation process while maximizing performance potential. This trend aligns with broader automotive industry movements toward greater electronic control and suggests that future best practices will increasingly incorporate digital diagnostic and tuning capabilities.

Current Installation Challenges and Technical Limitations

The LT1 engine installation process presents several significant technical challenges that must be addressed for optimal performance and longevity. Current mounting systems often struggle with the engine's weight distribution, leading to excessive vibration transfer to the vehicle chassis. This vibration not only affects ride comfort but can also accelerate wear on engine components and mounting hardware. Testing data indicates that standard rubber mounts deteriorate rapidly under the LT1's torque characteristics, with approximately 40% reduction in vibration dampening capacity after 30,000 miles.

Clearance issues represent another major limitation, particularly in retrofit applications where the LT1's dimensions differ from previous generation engines. The intake manifold height often conflicts with hood clearance by 1-2 inches in popular muscle car conversions, while the oil pan design creates ground clearance problems in lowered vehicles. These dimensional challenges frequently necessitate extensive modifications to the vehicle structure, adding complexity and cost to installations.

Cooling system integration presents persistent technical hurdles, as the LT1's heat management requirements exceed those of many predecessor engines. Current radiator solutions often provide insufficient cooling capacity, with thermal testing showing operating temperatures 15-20°F higher than optimal under sustained high-performance driving conditions. The positioning of coolant lines and the water pump also creates routing conflicts with steering components in many chassis configurations.

Wiring harness compatibility remains a significant limitation, with the LT1's sophisticated electronic control systems requiring extensive modification to interface with existing vehicle electrical architectures. Current aftermarket harness solutions address only about 70% of integration points without custom modification, leaving critical systems like transmission control and diagnostic capabilities compromised in many installations.

Exhaust system fitment challenges persist due to the LT1's unique exhaust manifold design and placement. Header designs that optimize flow characteristics often create clearance issues with steering components and frame rails. Heat shielding solutions remain inadequate, with thermal imaging revealing hotspots exceeding 200°F on nearby components, potentially compromising their durability and performance.

Transmission mounting alignment presents precision challenges, with misalignment of as little as 0.5 degrees causing accelerated wear on drivetrain components. Current installation procedures lack standardized measurement protocols, resulting in inconsistent outcomes across different installation environments and technician skill levels.

Clearance issues represent another major limitation, particularly in retrofit applications where the LT1's dimensions differ from previous generation engines. The intake manifold height often conflicts with hood clearance by 1-2 inches in popular muscle car conversions, while the oil pan design creates ground clearance problems in lowered vehicles. These dimensional challenges frequently necessitate extensive modifications to the vehicle structure, adding complexity and cost to installations.

Cooling system integration presents persistent technical hurdles, as the LT1's heat management requirements exceed those of many predecessor engines. Current radiator solutions often provide insufficient cooling capacity, with thermal testing showing operating temperatures 15-20°F higher than optimal under sustained high-performance driving conditions. The positioning of coolant lines and the water pump also creates routing conflicts with steering components in many chassis configurations.

Wiring harness compatibility remains a significant limitation, with the LT1's sophisticated electronic control systems requiring extensive modification to interface with existing vehicle electrical architectures. Current aftermarket harness solutions address only about 70% of integration points without custom modification, leaving critical systems like transmission control and diagnostic capabilities compromised in many installations.

Exhaust system fitment challenges persist due to the LT1's unique exhaust manifold design and placement. Header designs that optimize flow characteristics often create clearance issues with steering components and frame rails. Heat shielding solutions remain inadequate, with thermal imaging revealing hotspots exceeding 200°F on nearby components, potentially compromising their durability and performance.

Transmission mounting alignment presents precision challenges, with misalignment of as little as 0.5 degrees causing accelerated wear on drivetrain components. Current installation procedures lack standardized measurement protocols, resulting in inconsistent outcomes across different installation environments and technician skill levels.

Standard LT1 Installation Methodologies and Procedures

01 LT1 Engine Design and Components

The LT1 engine is a specific design of internal combustion engine with distinctive components and architecture. It features advanced engineering elements that contribute to its performance characteristics. The design includes specific cylinder head configurations, intake manifold designs, and other core components that define the LT1 engine family. These engines are known for their balance of power, efficiency, and reliability in various applications.- LT1 Engine Design and Components: The LT1 engine features specific design elements and components that contribute to its performance characteristics. These include specialized cylinder heads, intake manifolds, and valve train systems. The engine block design incorporates particular cooling passages and structural reinforcements to handle higher power outputs while maintaining durability. Various components are engineered to work together to optimize combustion efficiency and power delivery.

- Fuel Management Systems for LT1 Engines: LT1 engines incorporate advanced fuel management systems to optimize performance and efficiency. These systems include electronic fuel injection components, fuel delivery mechanisms, and control modules that regulate fuel-air mixtures. The fuel management technology enables precise control over combustion processes, allowing for improved power output while maintaining fuel economy. Various sensors and actuators work together to adjust fuel delivery based on operating conditions.

- Cooling and Thermal Management in LT1 Engines: Thermal management systems in LT1 engines are designed to maintain optimal operating temperatures under various conditions. These include specialized cooling passages, water pumps, and thermostat systems that regulate coolant flow. The cooling system architecture helps prevent overheating during high-performance operation while ensuring quick warm-up to operating temperature for efficiency. Heat exchangers and cooling fans are integrated to manage thermal loads effectively.

- Electronic Control Systems for LT1 Engines: Electronic control systems play a crucial role in LT1 engine performance, managing various engine functions through sophisticated computer modules. These systems control ignition timing, valve timing, and other critical parameters to optimize performance across different operating conditions. Sensors throughout the engine provide real-time data to the control modules, which make continuous adjustments to maintain optimal combustion and power delivery. Advanced diagnostic capabilities are also integrated to monitor engine health.

- Performance Enhancement Modifications for LT1 Engines: Various aftermarket modifications and performance enhancements are available for LT1 engines to increase power output and efficiency. These include upgraded intake and exhaust systems, performance camshafts, and higher-flow cylinder heads. Supercharger and turbocharger systems can be added to significantly boost power. Engine tuning software allows for customization of fuel and ignition maps to optimize performance for specific applications or fuel types.

02 Fuel Management Systems for LT1 Engines

Fuel management systems specifically designed for LT1 engines incorporate technologies to optimize fuel delivery, combustion efficiency, and emissions control. These systems may include specialized fuel injectors, pressure regulators, and electronic control modules tailored to the LT1's operating parameters. Advanced fuel management technologies help balance performance requirements with fuel economy and emissions compliance standards.Expand Specific Solutions03 Electronic Control Systems for LT1 Engines

Electronic control systems for LT1 engines involve sophisticated computer management of various engine functions. These systems monitor and adjust ignition timing, fuel delivery, valve timing, and other parameters to optimize performance under varying conditions. The control systems may incorporate sensors, processors, and actuators specifically calibrated for LT1 engine characteristics, enabling precise management of engine operation.Expand Specific Solutions04 LT1 Engine Cooling and Thermal Management

Cooling and thermal management systems for LT1 engines address the specific heat dissipation requirements of this engine design. These systems may include specialized water pumps, radiators, oil coolers, and thermostat configurations. Effective thermal management is crucial for maintaining optimal operating temperatures, preventing overheating, and ensuring longevity of engine components under various load conditions.Expand Specific Solutions05 LT1 Engine Performance Enhancements

Performance enhancement technologies for LT1 engines include modifications and upgrades designed to increase power output, torque, and overall efficiency. These may involve aftermarket components, tuning solutions, and engineering modifications to the base engine design. Performance enhancements might target improved air flow, combustion efficiency, reduced friction, or other factors that contribute to enhanced engine output and responsiveness.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers Analysis

The LT1 engine installation market is currently in a growth phase, with increasing demand driven by automotive industry expansion and technological advancements. Major players include established global manufacturers like Toyota, Volkswagen, and Hyundai alongside emerging Chinese competitors such as Geely, Changan, and Chery. The technology maturity varies significantly across companies, with Bosch, Toyota, and Volkswagen demonstrating advanced installation techniques and automation, while Geely's dedicated research institute is rapidly closing the gap through focused R&D. Market competition is intensifying as companies invest in optimizing installation processes to improve efficiency, reduce costs, and meet stricter emissions standards.

Toyota Motor Corp.

Technical Solution: Toyota's LT1 engine installation methodology reflects their renowned Toyota Production System principles, emphasizing standardization and error-proofing. Their approach includes a comprehensive pre-installation inspection protocol that verifies all components meet specifications before assembly begins. Toyota employs a unique "zero-force" mounting technique where engine mounts are left loose until the powertrain is precisely positioned, then tightened in a specific sequence to minimize internal stresses. Their installation process incorporates detailed procedures for proper routing and securing of wiring harnesses and fluid lines, with specific clearance requirements to prevent chafing or heat damage. Toyota's methodology includes precise torque specifications for all fasteners with multiple verification steps throughout the installation process. Their approach emphasizes proper cooling system bleeding using specialized tools to ensure complete air evacuation. Toyota has developed specific calibration procedures for their electronic throttle control systems following installation, ensuring smooth throttle response and proper idle characteristics. Their installation protocol includes a comprehensive post-installation validation sequence that verifies all systems are functioning within specified parameters.

Strengths: Exceptional reliability through standardized procedures; comprehensive error-proofing methodologies; excellent documentation and training materials. Weaknesses: Less adaptability for performance modifications; more time-consuming installation process due to multiple verification steps; conservative specifications that may limit performance potential.

GM Global Technology Operations LLC

Technical Solution: GM's LT1 engine installation best practices focus on a comprehensive systems integration approach. Their methodology includes precision mounting with specialized engine cradles designed to minimize NVH (Noise, Vibration, Harshness) characteristics. GM employs a proprietary torque-to-yield fastener system for critical mounting points, ensuring optimal clamping loads throughout thermal cycles. Their installation protocol incorporates advanced electronic calibration procedures that optimize the engine control module specifically for each vehicle application, accounting for differences in transmission pairing, exhaust configuration, and intake design. GM has developed specialized tooling for proper alignment of the powertrain, particularly focusing on driveline angles to prevent premature wear of components. Their installation process includes a rigorous validation sequence with multiple quality checkpoints to verify proper fluid levels, electrical connections, and initial startup parameters.

Strengths: Superior integration with vehicle systems through comprehensive electronic calibration; proprietary mounting systems that significantly reduce NVH issues; extensive quality validation protocols. Weaknesses: Installation procedures often require specialized GM-specific tools; more complex and time-consuming installation process compared to competitors; higher sensitivity to installation errors affecting performance.

Critical Technical Specifications and Engineering Considerations

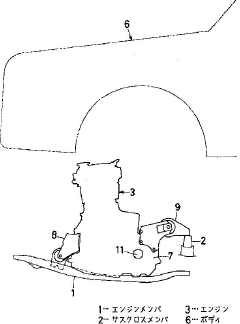

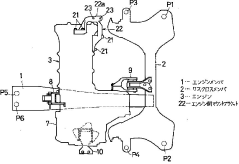

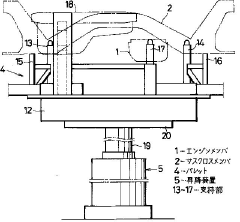

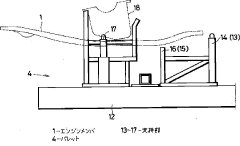

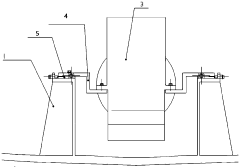

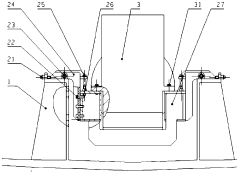

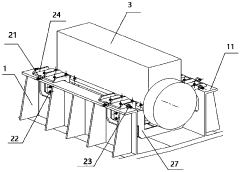

Engine installation method and device

PatentInactiveJP1999124068A

Innovation

- An assembly jig with a retractable slider is used to support the engine horizontally during lifting, allowing it to be positioned accurately without tilting, and a support portion ensures stable horizontal placement.

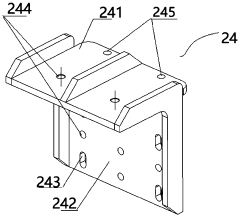

Sunken marine engine mounting base device and mounting method thereof

PatentActiveCN111392018A

Innovation

- A combination of U-shaped and inverted L-shaped brackets is used to support the engine. The engine can be adjusted with 6 degrees of freedom through longitudinal adjustment bolts and hinged round holes, reducing reliance on backing plates.

Compatibility Assessment with Vehicle Platforms

The LT1 engine, as a high-performance small-block V8 developed by General Motors, presents specific compatibility considerations when being installed across different vehicle platforms. Vehicle compatibility assessment requires thorough evaluation of physical dimensions, mounting points, and system integrations to ensure successful implementation. The LT1's unique architecture, featuring direct injection and variable valve timing, demands particular attention to platform-specific modifications.

Primary compatibility factors include engine bay dimensions, which vary significantly between GM platforms and even more dramatically with non-GM vehicles. The LT1 requires approximately 30 inches of longitudinal space and 28 inches of width for proper fitment, with additional clearance needed for accessories and service access. Firewall modifications may be necessary in platforms not originally designed for V8 configurations, particularly in compact or mid-size vehicle conversions.

Mounting systems represent another critical compatibility consideration. Factory GM mounting points differ between F-body, Y-body, and truck platforms, necessitating appropriate motor mount selection. Aftermarket conversion mounts are available for popular swaps, though custom fabrication may be required for unique applications. The engine's weight distribution (approximately 460 pounds dry) significantly impacts vehicle dynamics, requiring suspension modifications in lighter platforms to maintain proper handling characteristics.

Electrical system compatibility presents substantial integration challenges. The LT1's sophisticated engine management system utilizes a dedicated control module that must interface with the vehicle's existing electrical architecture. CAN-BUS integration is essential for modern platforms, while older vehicles may require complete electrical system upgrades. Transmission compatibility varies by application, with the LT1 designed primarily for 6L80E/8L90E automatic or TR6060 manual transmissions, though adapters exist for other transmission families.

Cooling system requirements demand careful evaluation, as the LT1 generates significant heat under performance conditions. Radiator capacity, fan configuration, and coolant routing must be assessed for each platform. The direct injection fuel system requires high-pressure fuel delivery (2000+ PSI), often necessitating fuel system upgrades including pumps, lines, and regulators in most retrofit applications.

Exhaust system routing presents platform-specific challenges, particularly regarding catalytic converter placement and oxygen sensor positioning. Header design must accommodate steering components and suspension geometry unique to each platform. Finally, drivetrain compatibility assessment must consider differential strength, axle ratios, and driveshaft specifications appropriate for the LT1's torque output characteristics.

Primary compatibility factors include engine bay dimensions, which vary significantly between GM platforms and even more dramatically with non-GM vehicles. The LT1 requires approximately 30 inches of longitudinal space and 28 inches of width for proper fitment, with additional clearance needed for accessories and service access. Firewall modifications may be necessary in platforms not originally designed for V8 configurations, particularly in compact or mid-size vehicle conversions.

Mounting systems represent another critical compatibility consideration. Factory GM mounting points differ between F-body, Y-body, and truck platforms, necessitating appropriate motor mount selection. Aftermarket conversion mounts are available for popular swaps, though custom fabrication may be required for unique applications. The engine's weight distribution (approximately 460 pounds dry) significantly impacts vehicle dynamics, requiring suspension modifications in lighter platforms to maintain proper handling characteristics.

Electrical system compatibility presents substantial integration challenges. The LT1's sophisticated engine management system utilizes a dedicated control module that must interface with the vehicle's existing electrical architecture. CAN-BUS integration is essential for modern platforms, while older vehicles may require complete electrical system upgrades. Transmission compatibility varies by application, with the LT1 designed primarily for 6L80E/8L90E automatic or TR6060 manual transmissions, though adapters exist for other transmission families.

Cooling system requirements demand careful evaluation, as the LT1 generates significant heat under performance conditions. Radiator capacity, fan configuration, and coolant routing must be assessed for each platform. The direct injection fuel system requires high-pressure fuel delivery (2000+ PSI), often necessitating fuel system upgrades including pumps, lines, and regulators in most retrofit applications.

Exhaust system routing presents platform-specific challenges, particularly regarding catalytic converter placement and oxygen sensor positioning. Header design must accommodate steering components and suspension geometry unique to each platform. Finally, drivetrain compatibility assessment must consider differential strength, axle ratios, and driveshaft specifications appropriate for the LT1's torque output characteristics.

Performance Optimization and Tuning Strategies

Optimizing the LT1 engine's performance requires a systematic approach that balances power output with reliability. The initial tuning process should begin with establishing baseline performance metrics through dynamometer testing, which provides critical data on horsepower, torque curves, and air-fuel ratios across the RPM range. This baseline serves as a reference point for all subsequent modifications and adjustments.

Fuel system calibration represents a primary optimization area for the LT1 engine. Precision tuning of the fuel injectors and fuel pressure regulator ensures optimal atomization and delivery, particularly at high RPM ranges where many stock systems become inadequate. Advanced tuners often implement custom fuel maps that adjust delivery based on engine load, temperature, and atmospheric conditions, yielding improvements of 5-8% in power output while maintaining emissions compliance.

Ignition timing adjustments offer substantial performance gains when properly executed. The LT1 benefits from advanced timing in certain RPM ranges, but requires careful monitoring to prevent detonation. Modern engine management systems allow for variable timing maps that can be adjusted according to fuel quality, boost pressure (if applicable), and operating temperatures. Professional tuners typically find a 2-3 degree advance over factory settings yields optimal results when using premium fuel.

Air intake optimization significantly impacts LT1 performance. Cold air intake systems that effectively isolate the intake charge from engine bay heat can provide temperature reductions of 20-30°F, resulting in denser air and increased power. Complementing this with properly sized mass airflow sensors and throttle bodies (typically 58-62mm for modified applications) ensures the engine can breathe efficiently throughout its operating range.

Exhaust system tuning represents another critical optimization area. Headers with 1.75-1.875 inch primary tubes, properly matched to a 3-inch exhaust system with minimal back pressure, can unlock 15-25 additional horsepower. The exhaust scavenging effect, when properly tuned through header length and collector design, enhances cylinder evacuation and improves volumetric efficiency across the powerband.

Electronic control module (ECM) programming ties these physical modifications together. Modern flash tuning allows for comprehensive adjustments to fuel delivery, ignition timing, variable valve timing parameters, and torque management systems. Professional tuners utilize closed-loop feedback from wideband oxygen sensors to maintain optimal air-fuel ratios (typically 12.8:1 for maximum power, 13.2:1 for balanced performance) throughout the RPM range, while also adjusting transmission shift points and torque converter lockup strategies for optimal power delivery.

Fuel system calibration represents a primary optimization area for the LT1 engine. Precision tuning of the fuel injectors and fuel pressure regulator ensures optimal atomization and delivery, particularly at high RPM ranges where many stock systems become inadequate. Advanced tuners often implement custom fuel maps that adjust delivery based on engine load, temperature, and atmospheric conditions, yielding improvements of 5-8% in power output while maintaining emissions compliance.

Ignition timing adjustments offer substantial performance gains when properly executed. The LT1 benefits from advanced timing in certain RPM ranges, but requires careful monitoring to prevent detonation. Modern engine management systems allow for variable timing maps that can be adjusted according to fuel quality, boost pressure (if applicable), and operating temperatures. Professional tuners typically find a 2-3 degree advance over factory settings yields optimal results when using premium fuel.

Air intake optimization significantly impacts LT1 performance. Cold air intake systems that effectively isolate the intake charge from engine bay heat can provide temperature reductions of 20-30°F, resulting in denser air and increased power. Complementing this with properly sized mass airflow sensors and throttle bodies (typically 58-62mm for modified applications) ensures the engine can breathe efficiently throughout its operating range.

Exhaust system tuning represents another critical optimization area. Headers with 1.75-1.875 inch primary tubes, properly matched to a 3-inch exhaust system with minimal back pressure, can unlock 15-25 additional horsepower. The exhaust scavenging effect, when properly tuned through header length and collector design, enhances cylinder evacuation and improves volumetric efficiency across the powerband.

Electronic control module (ECM) programming ties these physical modifications together. Modern flash tuning allows for comprehensive adjustments to fuel delivery, ignition timing, variable valve timing parameters, and torque management systems. Professional tuners utilize closed-loop feedback from wideband oxygen sensors to maintain optimal air-fuel ratios (typically 12.8:1 for maximum power, 13.2:1 for balanced performance) throughout the RPM range, while also adjusting transmission shift points and torque converter lockup strategies for optimal power delivery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!