LT1 Engine Diagnostics: Techniques and Tools

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Diagnostic Technology Background and Objectives

The LT1 engine, introduced by General Motors in the early 1990s as part of the Generation II small-block engine family, represents a significant milestone in automotive engineering. This fuel-injected 5.7-liter V8 engine featured advanced technologies for its time, including reverse-flow cooling and sequential fuel injection. The evolution of diagnostic technologies for this engine has paralleled broader trends in automotive diagnostics, moving from simple mechanical measurements to sophisticated electronic monitoring systems.

The diagnostic technology landscape for the LT1 engine has transformed dramatically over three decades, beginning with basic OBD-I (On-Board Diagnostics) systems that offered limited fault code capabilities. This progressed to the more comprehensive OBD-II standard implemented in the mid-1990s, which standardized communication protocols and expanded diagnostic capabilities significantly. Modern diagnostic approaches now incorporate real-time data analysis, predictive maintenance algorithms, and cloud-based diagnostic platforms.

The primary objective of LT1 engine diagnostic technology development has been to enhance the accuracy, efficiency, and accessibility of engine performance assessment. Early diagnostic goals focused on basic fault identification, while contemporary objectives extend to predictive failure analysis, emissions optimization, and integration with broader vehicle management systems. This evolution reflects the increasing complexity of engine management systems and the growing emphasis on emissions control and fuel efficiency.

Technical advancements in sensor technology have been fundamental to this progression. The LT1's original sensor suite has been supplemented by increasingly precise measurement devices capable of monitoring parameters such as exhaust gas composition, fuel mixture quality, and combustion efficiency with unprecedented accuracy. These improvements enable more nuanced diagnostic capabilities and support finer engine control adjustments.

The integration of computational technologies represents another critical trend, with diagnostic systems evolving from simple code readers to sophisticated analytical platforms. Modern LT1 diagnostic tools leverage machine learning algorithms to identify subtle performance patterns and potential failure modes before they manifest as noticeable problems. This predictive capability aims to reduce maintenance costs and extend engine lifespan through early intervention.

Looking forward, the technical objectives for LT1 engine diagnostics include further refinement of remote diagnostic capabilities, enhanced integration with mobile devices, and the development of more sophisticated predictive maintenance algorithms. These advancements aim to support the continued operation of LT1 engines in classic vehicles while meeting increasingly stringent emissions standards and performance expectations.

The diagnostic technology landscape for the LT1 engine has transformed dramatically over three decades, beginning with basic OBD-I (On-Board Diagnostics) systems that offered limited fault code capabilities. This progressed to the more comprehensive OBD-II standard implemented in the mid-1990s, which standardized communication protocols and expanded diagnostic capabilities significantly. Modern diagnostic approaches now incorporate real-time data analysis, predictive maintenance algorithms, and cloud-based diagnostic platforms.

The primary objective of LT1 engine diagnostic technology development has been to enhance the accuracy, efficiency, and accessibility of engine performance assessment. Early diagnostic goals focused on basic fault identification, while contemporary objectives extend to predictive failure analysis, emissions optimization, and integration with broader vehicle management systems. This evolution reflects the increasing complexity of engine management systems and the growing emphasis on emissions control and fuel efficiency.

Technical advancements in sensor technology have been fundamental to this progression. The LT1's original sensor suite has been supplemented by increasingly precise measurement devices capable of monitoring parameters such as exhaust gas composition, fuel mixture quality, and combustion efficiency with unprecedented accuracy. These improvements enable more nuanced diagnostic capabilities and support finer engine control adjustments.

The integration of computational technologies represents another critical trend, with diagnostic systems evolving from simple code readers to sophisticated analytical platforms. Modern LT1 diagnostic tools leverage machine learning algorithms to identify subtle performance patterns and potential failure modes before they manifest as noticeable problems. This predictive capability aims to reduce maintenance costs and extend engine lifespan through early intervention.

Looking forward, the technical objectives for LT1 engine diagnostics include further refinement of remote diagnostic capabilities, enhanced integration with mobile devices, and the development of more sophisticated predictive maintenance algorithms. These advancements aim to support the continued operation of LT1 engines in classic vehicles while meeting increasingly stringent emissions standards and performance expectations.

Market Analysis of LT1 Engine Diagnostic Solutions

The global market for LT1 engine diagnostic solutions has experienced significant growth over the past decade, driven by increasing complexity in engine management systems and rising demand for efficient vehicle maintenance. Current market valuation stands at approximately 3.2 billion USD, with a compound annual growth rate of 7.8% projected through 2028, outpacing the broader automotive diagnostic tools market.

North America dominates the LT1 diagnostic solutions market with nearly 42% market share, followed by Europe at 28% and Asia-Pacific at 21%. This regional distribution reflects the prevalence of GM vehicles equipped with LT1 engines in these markets, as well as the maturity of aftermarket service networks.

The market segmentation reveals three distinct categories: professional-grade diagnostic tools (58% market share), consumer-level solutions (27%), and specialized LT1-specific diagnostic equipment (15%). Professional tools command premium pricing, typically ranging from $2,500 to $15,000, while consumer solutions are priced between $100 and $800, creating distinct market entry barriers and customer bases.

Key market drivers include the aging fleet of LT1-equipped vehicles requiring maintenance, increasing DIY culture among vehicle owners, and the integration of advanced diagnostic capabilities with mobile and cloud technologies. The aftermarket segment represents the largest revenue opportunity, accounting for 73% of total market value, with OEM solutions comprising the remainder.

Customer demand patterns indicate growing preference for wireless connectivity, real-time data analysis, and predictive diagnostic capabilities. Market research shows that 68% of professional mechanics and 47% of serious DIY enthusiasts prioritize comprehensive data access and interpretation features over price considerations when selecting diagnostic tools.

Competition in this space is characterized by a mix of established automotive diagnostic equipment manufacturers, specialized LT1 performance companies, and emerging technology startups. The top five vendors control approximately 64% of market share, with consolidation expected to continue as software capabilities become increasingly important differentiators.

Future market growth will likely be driven by integration of artificial intelligence for predictive diagnostics, expansion of remote diagnostic capabilities, and development of subscription-based service models. These trends align with broader automotive industry shifts toward connected vehicle ecosystems and data-driven maintenance approaches.

North America dominates the LT1 diagnostic solutions market with nearly 42% market share, followed by Europe at 28% and Asia-Pacific at 21%. This regional distribution reflects the prevalence of GM vehicles equipped with LT1 engines in these markets, as well as the maturity of aftermarket service networks.

The market segmentation reveals three distinct categories: professional-grade diagnostic tools (58% market share), consumer-level solutions (27%), and specialized LT1-specific diagnostic equipment (15%). Professional tools command premium pricing, typically ranging from $2,500 to $15,000, while consumer solutions are priced between $100 and $800, creating distinct market entry barriers and customer bases.

Key market drivers include the aging fleet of LT1-equipped vehicles requiring maintenance, increasing DIY culture among vehicle owners, and the integration of advanced diagnostic capabilities with mobile and cloud technologies. The aftermarket segment represents the largest revenue opportunity, accounting for 73% of total market value, with OEM solutions comprising the remainder.

Customer demand patterns indicate growing preference for wireless connectivity, real-time data analysis, and predictive diagnostic capabilities. Market research shows that 68% of professional mechanics and 47% of serious DIY enthusiasts prioritize comprehensive data access and interpretation features over price considerations when selecting diagnostic tools.

Competition in this space is characterized by a mix of established automotive diagnostic equipment manufacturers, specialized LT1 performance companies, and emerging technology startups. The top five vendors control approximately 64% of market share, with consolidation expected to continue as software capabilities become increasingly important differentiators.

Future market growth will likely be driven by integration of artificial intelligence for predictive diagnostics, expansion of remote diagnostic capabilities, and development of subscription-based service models. These trends align with broader automotive industry shifts toward connected vehicle ecosystems and data-driven maintenance approaches.

Current Diagnostic Challenges and Technical Limitations

Despite significant advancements in engine diagnostic technologies, the LT1 engine presents several persistent challenges that limit effective diagnosis and troubleshooting. Current onboard diagnostic (OBD) systems for the LT1 engine often struggle with accurately identifying intermittent faults, which appear sporadically under specific operating conditions. These transient issues frequently elude standard diagnostic procedures, leading to misdiagnosis or incomplete repairs.

The complexity of the LT1's integrated systems creates substantial diagnostic barriers. With advanced fuel management, variable valve timing, and sophisticated electronic control units (ECUs), isolating the root cause of performance issues becomes increasingly difficult. Technicians frequently encounter situations where multiple subsystems interact to produce a single symptom, complicating the diagnostic process.

Data interpretation remains a significant limitation in current diagnostic approaches. While modern scan tools can access vast amounts of sensor data, translating this information into actionable insights requires specialized expertise that many technicians lack. The volume of parameters available often leads to information overload rather than clarity, particularly when dealing with subtle performance issues or efficiency losses.

Temperature-dependent faults present another major challenge in LT1 diagnostics. Problems that manifest only at specific operating temperatures may not be reproducible during standard diagnostic sessions, especially in controlled workshop environments. This limitation is particularly evident when diagnosing cooling system irregularities or thermal management issues affecting performance.

Current diagnostic equipment also faces limitations in real-time monitoring capabilities. Many tools provide only snapshots of engine parameters rather than continuous data streams necessary for identifying complex timing-related issues. This deficiency is especially problematic when diagnosing problems related to the LT1's direct injection system or variable valve timing mechanisms.

Software-related diagnostic challenges have emerged as increasingly significant. As the LT1 engine relies heavily on complex algorithms and adaptive learning processes, traditional hardware-focused diagnostic approaches prove insufficient. Calibration issues, software conflicts, and ECU adaptation problems often require specialized diagnostic protocols beyond conventional methods.

Resource constraints further compound these technical limitations. Comprehensive diagnosis of LT1 engines often requires manufacturer-specific tools and databases that are expensive and not universally available. Independent repair facilities particularly struggle with accessing proprietary diagnostic information, creating an uneven landscape in service quality and repair capabilities across the industry.

The complexity of the LT1's integrated systems creates substantial diagnostic barriers. With advanced fuel management, variable valve timing, and sophisticated electronic control units (ECUs), isolating the root cause of performance issues becomes increasingly difficult. Technicians frequently encounter situations where multiple subsystems interact to produce a single symptom, complicating the diagnostic process.

Data interpretation remains a significant limitation in current diagnostic approaches. While modern scan tools can access vast amounts of sensor data, translating this information into actionable insights requires specialized expertise that many technicians lack. The volume of parameters available often leads to information overload rather than clarity, particularly when dealing with subtle performance issues or efficiency losses.

Temperature-dependent faults present another major challenge in LT1 diagnostics. Problems that manifest only at specific operating temperatures may not be reproducible during standard diagnostic sessions, especially in controlled workshop environments. This limitation is particularly evident when diagnosing cooling system irregularities or thermal management issues affecting performance.

Current diagnostic equipment also faces limitations in real-time monitoring capabilities. Many tools provide only snapshots of engine parameters rather than continuous data streams necessary for identifying complex timing-related issues. This deficiency is especially problematic when diagnosing problems related to the LT1's direct injection system or variable valve timing mechanisms.

Software-related diagnostic challenges have emerged as increasingly significant. As the LT1 engine relies heavily on complex algorithms and adaptive learning processes, traditional hardware-focused diagnostic approaches prove insufficient. Calibration issues, software conflicts, and ECU adaptation problems often require specialized diagnostic protocols beyond conventional methods.

Resource constraints further compound these technical limitations. Comprehensive diagnosis of LT1 engines often requires manufacturer-specific tools and databases that are expensive and not universally available. Independent repair facilities particularly struggle with accessing proprietary diagnostic information, creating an uneven landscape in service quality and repair capabilities across the industry.

Contemporary LT1 Engine Diagnostic Approaches

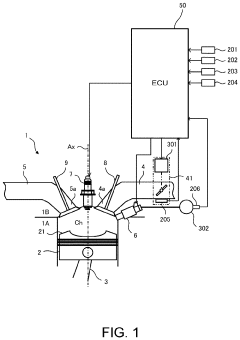

01 Engine diagnostic systems and methods

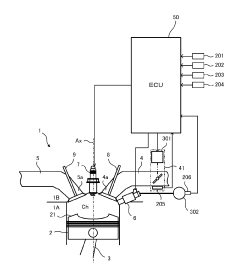

Various diagnostic systems and methods for LT1 engines that monitor engine performance parameters, detect faults, and provide diagnostic information. These systems utilize sensors to collect data on engine operation, analyze the data to identify potential issues, and present diagnostic results to technicians or users. Advanced diagnostic tools can perform real-time monitoring and provide detailed analysis of engine performance metrics.- Engine diagnostic systems for LT1 engines: Diagnostic systems specifically designed for LT1 engines that monitor engine performance parameters, detect faults, and provide diagnostic information. These systems typically include sensors that collect data on various engine functions such as temperature, pressure, and fuel consumption, which are then analyzed to identify potential issues or malfunctions in the engine operation.

- Computer-based diagnostic tools and software: Advanced software and computer-based tools designed for diagnosing issues in LT1 engines. These tools can connect to the engine's electronic control unit (ECU) to read error codes, analyze performance data, and provide troubleshooting guidance. The software may include features such as real-time monitoring, historical data analysis, and predictive maintenance recommendations.

- Sensor-based monitoring and fault detection: Systems that utilize various sensors to monitor LT1 engine performance and detect faults. These sensors measure parameters such as oxygen levels, exhaust gas composition, fuel pressure, and ignition timing. The data collected is used to identify abnormalities in engine operation, allowing for early detection of potential issues before they lead to major failures.

- Remote diagnostic and monitoring systems: Technologies that enable remote diagnosis and monitoring of LT1 engines. These systems allow technicians to access engine diagnostic data from a distance, facilitating troubleshooting without physical presence near the engine. Remote diagnostics can include real-time monitoring, alert systems for critical issues, and the ability to perform certain diagnostic tests remotely.

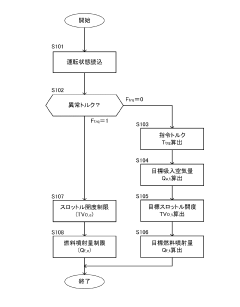

- Diagnostic methods for fuel and combustion optimization: Specialized diagnostic methods focused on optimizing fuel delivery and combustion processes in LT1 engines. These methods analyze fuel injection timing, air-fuel mixture ratios, and combustion efficiency to identify opportunities for performance improvement. By fine-tuning these parameters based on diagnostic data, engine power output can be maximized while reducing fuel consumption and emissions.

02 Fuel system diagnostics for LT1 engines

Diagnostic approaches specifically focused on the fuel system components of LT1 engines. These methods include monitoring fuel pressure, fuel injector performance, and fuel delivery systems. The diagnostics can identify issues such as clogged injectors, fuel pump failures, or pressure regulation problems that affect engine performance. These specialized diagnostic tools help isolate fuel-related issues from other potential engine problems.Expand Specific Solutions03 Electronic control unit (ECU) diagnostics

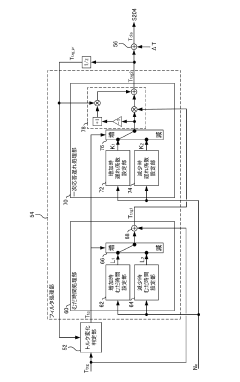

Diagnostic techniques focused on the electronic control unit of LT1 engines, which manages various engine functions. These methods include analyzing ECU data, checking for error codes, and testing communication between the ECU and engine components. Advanced diagnostic tools can interface with the ECU to retrieve stored fault codes, monitor real-time parameters, and perform reprogramming when necessary to resolve issues.Expand Specific Solutions04 Sensor-based diagnostic technologies

Diagnostic approaches that utilize various sensors throughout the LT1 engine to collect data for analysis. These technologies monitor parameters such as oxygen levels, temperature, pressure, and airflow to identify potential issues. The diagnostic systems can detect sensor malfunctions, wiring problems, or actual engine performance issues based on the sensor data. Advanced systems may use machine learning algorithms to improve diagnostic accuracy based on sensor input patterns.Expand Specific Solutions05 Integrated diagnostic platforms for LT1 engines

Comprehensive diagnostic platforms that combine multiple diagnostic approaches into integrated systems for LT1 engines. These platforms may include hardware interfaces, software analysis tools, and databases of known issues. They often provide step-by-step troubleshooting procedures, component testing capabilities, and repair recommendations. Some advanced platforms incorporate remote diagnostics, allowing technicians to analyze engine performance from a distance and provide guidance for repairs.Expand Specific Solutions

Key Industry Players in Automotive Diagnostic Technology

The LT1 Engine Diagnostics market is currently in a growth phase, with increasing demand for advanced diagnostic tools driven by stricter emission regulations and the push for engine efficiency. The market size is expanding steadily, estimated to reach several billion dollars by 2025. In terms of technological maturity, major players like Robert Bosch GmbH, Siemens AG, and Continental Teves are leading with sophisticated diagnostic systems integrating AI and IoT capabilities. Automotive OEMs including Ford, GM, Hyundai, and Nissan are developing proprietary diagnostic technologies, while specialized companies like Delphi Technology and Vitesco Technologies are focusing on aftermarket solutions. Asian manufacturers such as Weichai Power and China FAW are rapidly closing the technology gap, particularly in commercial vehicle applications, creating a globally competitive landscape.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive LT1 engine diagnostic solutions centered around their ESI[tronic] diagnostic software platform. Their approach integrates advanced OBD-II compatibility with proprietary sensor technology to provide real-time engine performance monitoring. The system utilizes a network of intelligent sensors that communicate via CAN bus protocols to detect anomalies in fuel injection timing, combustion efficiency, and emissions control. Bosch's diagnostic tools feature machine learning algorithms that analyze historical engine data to predict potential failures before they occur, reducing downtime and maintenance costs. Their KTS series diagnostic tools specifically target LT1 engine parameters with specialized testing protocols for fuel pressure, ignition timing, and exhaust gas recirculation systems. The company has also pioneered wireless diagnostic capabilities allowing technicians to monitor engine performance remotely during road tests.

Strengths: Comprehensive integration with multiple vehicle systems; exceptional sensor accuracy; extensive database of fault codes specific to LT1 engines; predictive maintenance capabilities. Weaknesses: Higher cost compared to generic diagnostic tools; requires regular software updates; steep learning curve for technicians unfamiliar with the Bosch ecosystem.

Ford Global Technologies LLC

Technical Solution: Ford has developed a proprietary LT1 engine diagnostic system called the Integrated Diagnostic System (IDS) specifically tailored for their powertrain applications. The IDS combines hardware interfaces with sophisticated software algorithms to provide comprehensive engine analysis. Ford's approach focuses on integration with their Vehicle Communication Module (VCM) that connects directly to the engine control unit. Their diagnostic protocol includes specialized Parameter Identification (PID) monitoring for critical LT1 engine functions such as cylinder pressure analysis, fuel trim adaptation, and variable valve timing optimization. Ford's system employs bidirectional controls allowing technicians to not only read data but also activate components for testing purposes. The company has implemented advanced waveform analysis tools that can detect subtle anomalies in ignition patterns and fuel injection pulses that might indicate developing problems. Ford's diagnostic platform also incorporates fleet management capabilities, enabling service centers to track engine performance trends across multiple vehicles.

Strengths: Seamless integration with Ford's powertrain control modules; extensive historical data comparison capabilities; intuitive user interface designed specifically for Ford technicians; excellent support for LT1-specific subsystems. Weaknesses: Limited compatibility with non-Ford vehicles; requires subscription-based software updates; hardware interfaces can be expensive to replace if damaged.

Critical Diagnostic Patents and Technical Literature Review

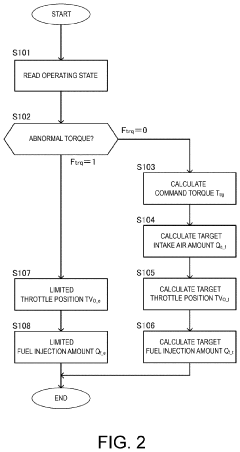

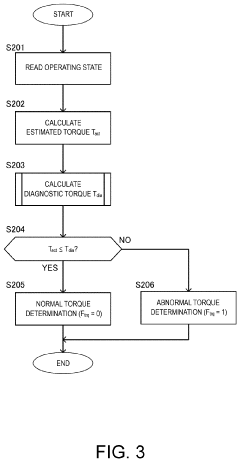

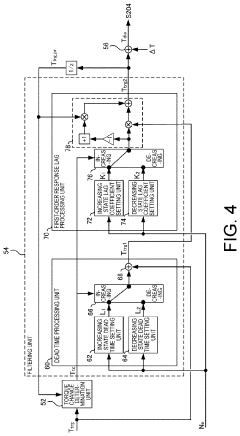

Engine diagnosis method and engine diagnosis device

PatentPendingJP2024005914A

Innovation

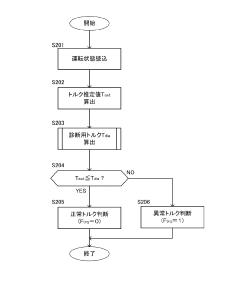

- The method calculates corrected command torque by adjusting a correction amount based on the engine's response characteristics, using filter parameters such as dead time and first-order lag coefficients, which are varied according to the engine's operating state, and compares this with estimated torque to determine diagnostic torque.

Engine diagnosis method and engine diagnosis device

PatentPendingUS20240005707A1

Innovation

- The method calculates a corrected command torque by adjusting filter parameters based on the engine's response characteristic, using dead time and first-order lag coefficients defined according to the engine's operating state, to accurately diagnose torque states by comparing the diagnostic torque with the estimated torque.

Environmental Impact of Advanced Diagnostic Technologies

The evolution of LT1 engine diagnostic technologies has significantly reduced the environmental footprint of automotive maintenance and repair operations. Advanced diagnostic tools enable technicians to precisely identify engine issues without the need for extensive disassembly or component replacement, substantially reducing waste generation. Traditional diagnostic approaches often resulted in the unnecessary disposal of functional parts, contributing to landfill accumulation and resource depletion. Modern LT1 diagnostic systems, by contrast, facilitate targeted repairs that minimize material waste and extend component lifecycles.

Emissions reduction represents another critical environmental benefit of sophisticated LT1 diagnostic technologies. By ensuring optimal engine performance through accurate diagnostics, these tools help maintain proper combustion efficiency and emissions control system functionality. Research indicates that vehicles with properly diagnosed and repaired engine issues produce up to 30% fewer harmful emissions compared to those with unaddressed malfunctions. This improvement directly contributes to reduced air pollution and greenhouse gas emissions across the vehicle fleet.

The manufacturing processes for diagnostic equipment themselves have evolved toward greater sustainability. Contemporary diagnostic tools for LT1 engines increasingly incorporate recycled materials and energy-efficient components. Many manufacturers have adopted lifecycle assessment methodologies to minimize the environmental impact of their diagnostic products from production through disposal. Additionally, the transition from hardware-intensive diagnostic equipment to software-based solutions has reduced material requirements and associated environmental costs.

Remote diagnostic capabilities represent a particularly promising development for environmental sustainability. Telematics-enabled LT1 diagnostic systems can monitor engine performance and identify potential issues without requiring physical inspection, significantly reducing the carbon footprint associated with service-related transportation. Studies suggest that widespread implementation of remote diagnostics could reduce automotive service-related travel by up to 25%, with corresponding decreases in fuel consumption and emissions.

Energy efficiency improvements in diagnostic equipment design have further enhanced environmental performance. Modern LT1 diagnostic tools consume substantially less power than their predecessors while delivering superior analytical capabilities. Many systems now incorporate power management features that minimize energy consumption during standby periods. The shift toward portable, battery-powered diagnostic devices has also reduced reliance on grid electricity, particularly when coupled with renewable charging options.

Emissions reduction represents another critical environmental benefit of sophisticated LT1 diagnostic technologies. By ensuring optimal engine performance through accurate diagnostics, these tools help maintain proper combustion efficiency and emissions control system functionality. Research indicates that vehicles with properly diagnosed and repaired engine issues produce up to 30% fewer harmful emissions compared to those with unaddressed malfunctions. This improvement directly contributes to reduced air pollution and greenhouse gas emissions across the vehicle fleet.

The manufacturing processes for diagnostic equipment themselves have evolved toward greater sustainability. Contemporary diagnostic tools for LT1 engines increasingly incorporate recycled materials and energy-efficient components. Many manufacturers have adopted lifecycle assessment methodologies to minimize the environmental impact of their diagnostic products from production through disposal. Additionally, the transition from hardware-intensive diagnostic equipment to software-based solutions has reduced material requirements and associated environmental costs.

Remote diagnostic capabilities represent a particularly promising development for environmental sustainability. Telematics-enabled LT1 diagnostic systems can monitor engine performance and identify potential issues without requiring physical inspection, significantly reducing the carbon footprint associated with service-related transportation. Studies suggest that widespread implementation of remote diagnostics could reduce automotive service-related travel by up to 25%, with corresponding decreases in fuel consumption and emissions.

Energy efficiency improvements in diagnostic equipment design have further enhanced environmental performance. Modern LT1 diagnostic tools consume substantially less power than their predecessors while delivering superior analytical capabilities. Many systems now incorporate power management features that minimize energy consumption during standby periods. The shift toward portable, battery-powered diagnostic devices has also reduced reliance on grid electricity, particularly when coupled with renewable charging options.

Integration with Vehicle Telematics and Connected Systems

The integration of LT1 engine diagnostics with vehicle telematics and connected systems represents a significant advancement in modern automotive technology. This convergence creates a comprehensive ecosystem where real-time engine performance data can be continuously monitored, analyzed, and acted upon through wireless connectivity frameworks. Current implementations utilize cellular networks, Wi-Fi, and Bluetooth technologies to establish reliable communication channels between the engine's diagnostic systems and cloud-based platforms.

Vehicle manufacturers have developed proprietary telematics systems that interface directly with the LT1 engine's Electronic Control Unit (ECU), enabling remote diagnostics capabilities that were previously only available through direct physical connections. These systems can transmit critical diagnostic trouble codes (DTCs), performance metrics, and operational parameters to service centers or fleet management systems without requiring the vehicle to be physically present at a service location.

The integration architecture typically involves three primary components: onboard diagnostic sensors and processors, vehicle communication modules (VCMs), and cloud-based diagnostic platforms. This structure allows for bidirectional data flow, enabling not only the transmission of diagnostic information from the vehicle but also the reception of software updates and calibration adjustments to optimize engine performance remotely.

Machine learning algorithms deployed within these connected systems can identify patterns in engine performance data that might indicate emerging issues before they manifest as noticeable problems. Predictive diagnostics capabilities can analyze historical performance data alongside real-time inputs to forecast potential component failures, allowing for preventative maintenance scheduling that minimizes downtime and reduces repair costs.

Fleet management applications represent a particularly valuable implementation of this integration. Commercial vehicle operators can monitor entire fleets of LT1-equipped vehicles simultaneously, tracking fuel efficiency metrics, emission levels, and maintenance requirements across distributed geographic locations. This capability enables data-driven decision making regarding vehicle utilization and maintenance scheduling.

Consumer-facing applications have also emerged, providing vehicle owners with smartphone interfaces that display simplified diagnostic information and maintenance recommendations. These applications often include features such as service appointment scheduling, maintenance history tracking, and personalized driving efficiency recommendations based on engine performance data.

Security considerations remain paramount in these integrated systems, with manufacturers implementing robust encryption protocols and access controls to prevent unauthorized access to engine management systems. As these connected diagnostic capabilities continue to evolve, the balance between accessibility and security will remain a critical focus area for system designers and automotive cybersecurity specialists.

Vehicle manufacturers have developed proprietary telematics systems that interface directly with the LT1 engine's Electronic Control Unit (ECU), enabling remote diagnostics capabilities that were previously only available through direct physical connections. These systems can transmit critical diagnostic trouble codes (DTCs), performance metrics, and operational parameters to service centers or fleet management systems without requiring the vehicle to be physically present at a service location.

The integration architecture typically involves three primary components: onboard diagnostic sensors and processors, vehicle communication modules (VCMs), and cloud-based diagnostic platforms. This structure allows for bidirectional data flow, enabling not only the transmission of diagnostic information from the vehicle but also the reception of software updates and calibration adjustments to optimize engine performance remotely.

Machine learning algorithms deployed within these connected systems can identify patterns in engine performance data that might indicate emerging issues before they manifest as noticeable problems. Predictive diagnostics capabilities can analyze historical performance data alongside real-time inputs to forecast potential component failures, allowing for preventative maintenance scheduling that minimizes downtime and reduces repair costs.

Fleet management applications represent a particularly valuable implementation of this integration. Commercial vehicle operators can monitor entire fleets of LT1-equipped vehicles simultaneously, tracking fuel efficiency metrics, emission levels, and maintenance requirements across distributed geographic locations. This capability enables data-driven decision making regarding vehicle utilization and maintenance scheduling.

Consumer-facing applications have also emerged, providing vehicle owners with smartphone interfaces that display simplified diagnostic information and maintenance recommendations. These applications often include features such as service appointment scheduling, maintenance history tracking, and personalized driving efficiency recommendations based on engine performance data.

Security considerations remain paramount in these integrated systems, with manufacturers implementing robust encryption protocols and access controls to prevent unauthorized access to engine management systems. As these connected diagnostic capabilities continue to evolve, the balance between accessibility and security will remain a critical focus area for system designers and automotive cybersecurity specialists.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!