Maximizing Propionic Acid Use in Textile Industry

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid in Textiles: Background and Objectives

Propionic acid has emerged as a significant player in the textile industry, with its applications spanning various processes and treatments. The evolution of this organic compound's use in textiles can be traced back to the mid-20th century when researchers began exploring its potential as a preservative and antimicrobial agent. Over the decades, the textile sector has witnessed a gradual increase in the adoption of propionic acid, driven by its versatile properties and the growing demand for sustainable and high-performance textile products.

The primary objective of maximizing propionic acid use in the textile industry is to enhance the overall quality, durability, and functionality of textile products while addressing environmental concerns. This goal aligns with the industry's shift towards more sustainable and eco-friendly practices, as propionic acid offers a relatively safe and biodegradable alternative to many traditional chemical treatments.

One of the key drivers behind the increased focus on propionic acid is its effectiveness as an antimicrobial agent. In an era where hygiene and health concerns are paramount, textiles treated with propionic acid can inhibit the growth of bacteria, fungi, and other microorganisms, making them ideal for use in healthcare settings, sportswear, and everyday clothing. This property has become particularly relevant in recent years, with the global emphasis on personal protection and hygiene.

Another significant aspect of propionic acid's role in textiles is its potential as a mordant in dyeing processes. As the industry seeks alternatives to metal-based mordants, which can be environmentally harmful, propionic acid presents an opportunity to develop more sustainable dyeing techniques. This aligns with the broader trend of reducing the environmental impact of textile production, which has been a major focus for both manufacturers and consumers in recent years.

The textile industry's interest in propionic acid also extends to its potential as a finishing agent. Its ability to impart wrinkle resistance and improve the overall appearance of fabrics has led to increased research and development efforts in this area. As consumers demand clothing that is both comfortable and easy to maintain, the role of propionic acid in textile finishing is likely to expand further.

Looking ahead, the technological trajectory for propionic acid in textiles is expected to focus on optimizing its application methods, improving its efficacy, and exploring new synergistic combinations with other textile chemicals. Researchers are also investigating ways to enhance the stability and longevity of propionic acid treatments, ensuring that its beneficial properties persist throughout the lifecycle of the textile product.

The primary objective of maximizing propionic acid use in the textile industry is to enhance the overall quality, durability, and functionality of textile products while addressing environmental concerns. This goal aligns with the industry's shift towards more sustainable and eco-friendly practices, as propionic acid offers a relatively safe and biodegradable alternative to many traditional chemical treatments.

One of the key drivers behind the increased focus on propionic acid is its effectiveness as an antimicrobial agent. In an era where hygiene and health concerns are paramount, textiles treated with propionic acid can inhibit the growth of bacteria, fungi, and other microorganisms, making them ideal for use in healthcare settings, sportswear, and everyday clothing. This property has become particularly relevant in recent years, with the global emphasis on personal protection and hygiene.

Another significant aspect of propionic acid's role in textiles is its potential as a mordant in dyeing processes. As the industry seeks alternatives to metal-based mordants, which can be environmentally harmful, propionic acid presents an opportunity to develop more sustainable dyeing techniques. This aligns with the broader trend of reducing the environmental impact of textile production, which has been a major focus for both manufacturers and consumers in recent years.

The textile industry's interest in propionic acid also extends to its potential as a finishing agent. Its ability to impart wrinkle resistance and improve the overall appearance of fabrics has led to increased research and development efforts in this area. As consumers demand clothing that is both comfortable and easy to maintain, the role of propionic acid in textile finishing is likely to expand further.

Looking ahead, the technological trajectory for propionic acid in textiles is expected to focus on optimizing its application methods, improving its efficacy, and exploring new synergistic combinations with other textile chemicals. Researchers are also investigating ways to enhance the stability and longevity of propionic acid treatments, ensuring that its beneficial properties persist throughout the lifecycle of the textile product.

Market Analysis for Propionic Acid in Textile Applications

The global market for propionic acid in textile applications has been experiencing steady growth, driven by increasing demand for eco-friendly and sustainable textile processing solutions. The textile industry, being one of the largest consumers of chemicals worldwide, presents a significant opportunity for propionic acid manufacturers to expand their market share.

Propionic acid serves multiple functions in textile applications, including its use as a preservative, mold inhibitor, and pH regulator. Its effectiveness in preventing the growth of bacteria and fungi on textiles has made it a preferred choice for manufacturers seeking to enhance the durability and quality of their products. This has led to a growing adoption of propionic acid in various textile processes, particularly in the production of technical textiles and performance fabrics.

The market demand for propionic acid in textiles is closely tied to the overall growth of the textile industry, which has been expanding at a robust pace in emerging economies. Countries such as China, India, and Bangladesh, which are major textile manufacturing hubs, are expected to be key drivers of demand for propionic acid in the coming years. Additionally, the increasing focus on sustainable and environmentally friendly textile production methods is likely to further boost the adoption of propionic acid as a safer alternative to traditional chemical treatments.

In terms of market segmentation, the use of propionic acid in textile applications can be broadly categorized into apparel, home textiles, and industrial textiles. The apparel sector, including sportswear and outdoor clothing, represents a particularly promising segment due to the growing consumer preference for odor-resistant and long-lasting garments. The industrial textiles segment, encompassing products such as protective clothing and geotextiles, is also expected to contribute significantly to market growth.

The market for propionic acid in textile applications is characterized by a high degree of competition, with several major chemical companies vying for market share. Key players are focusing on product innovation and strategic partnerships to strengthen their position in the market. There is also a trend towards vertical integration, with some textile manufacturers investing in in-house production capabilities for propionic acid to ensure a stable supply and reduce costs.

Looking ahead, the market for propionic acid in textile applications is projected to continue its growth trajectory. Factors such as increasing disposable income, changing consumer preferences, and stringent regulations regarding textile quality and safety are expected to drive demand. However, challenges such as price volatility of raw materials and the emergence of alternative technologies may impact market dynamics in the future.

Propionic acid serves multiple functions in textile applications, including its use as a preservative, mold inhibitor, and pH regulator. Its effectiveness in preventing the growth of bacteria and fungi on textiles has made it a preferred choice for manufacturers seeking to enhance the durability and quality of their products. This has led to a growing adoption of propionic acid in various textile processes, particularly in the production of technical textiles and performance fabrics.

The market demand for propionic acid in textiles is closely tied to the overall growth of the textile industry, which has been expanding at a robust pace in emerging economies. Countries such as China, India, and Bangladesh, which are major textile manufacturing hubs, are expected to be key drivers of demand for propionic acid in the coming years. Additionally, the increasing focus on sustainable and environmentally friendly textile production methods is likely to further boost the adoption of propionic acid as a safer alternative to traditional chemical treatments.

In terms of market segmentation, the use of propionic acid in textile applications can be broadly categorized into apparel, home textiles, and industrial textiles. The apparel sector, including sportswear and outdoor clothing, represents a particularly promising segment due to the growing consumer preference for odor-resistant and long-lasting garments. The industrial textiles segment, encompassing products such as protective clothing and geotextiles, is also expected to contribute significantly to market growth.

The market for propionic acid in textile applications is characterized by a high degree of competition, with several major chemical companies vying for market share. Key players are focusing on product innovation and strategic partnerships to strengthen their position in the market. There is also a trend towards vertical integration, with some textile manufacturers investing in in-house production capabilities for propionic acid to ensure a stable supply and reduce costs.

Looking ahead, the market for propionic acid in textile applications is projected to continue its growth trajectory. Factors such as increasing disposable income, changing consumer preferences, and stringent regulations regarding textile quality and safety are expected to drive demand. However, challenges such as price volatility of raw materials and the emergence of alternative technologies may impact market dynamics in the future.

Current Challenges in Propionic Acid Utilization

The textile industry faces several significant challenges in maximizing the use of propionic acid. One of the primary issues is the high cost associated with propionic acid production and application. As a chemical compound, propionic acid requires substantial resources for synthesis, which can lead to increased production expenses for textile manufacturers. This cost factor often limits the widespread adoption of propionic acid in textile processing, particularly for smaller-scale operations.

Another challenge lies in the environmental concerns surrounding propionic acid usage. While it is generally considered less harmful than some alternative chemicals, there are still environmental regulations and waste management considerations that textile companies must address. The proper handling and disposal of propionic acid and its byproducts require specialized procedures and equipment, which can be both costly and complex to implement.

The volatility of propionic acid presents additional difficulties in its application within textile processes. Its low boiling point and tendency to evaporate at room temperature can lead to inconsistent results in textile treatments and potential health hazards for workers if not properly managed. This volatility also necessitates careful storage and handling protocols, which can be challenging to maintain in busy textile production environments.

Furthermore, the textile industry struggles with optimizing the concentration and application methods of propionic acid. Finding the right balance between effectiveness and efficiency is crucial, as excessive use can lead to unnecessary costs and potential negative impacts on fabric quality, while insufficient application may not achieve the desired antimicrobial or preservative effects.

Compatibility issues with various textile materials and dyes pose another significant challenge. Propionic acid may interact differently with different fiber types and colorants, potentially causing discoloration, fabric weakening, or other undesirable effects. This necessitates extensive testing and formulation adjustments, which can be time-consuming and resource-intensive for textile manufacturers.

Lastly, there is a growing demand for more sustainable and eco-friendly textile production methods. While propionic acid offers certain advantages, it is still a synthetic chemical. The industry faces the challenge of balancing the benefits of propionic acid with the increasing consumer preference for natural and environmentally friendly textile products. This tension creates a need for innovation in application techniques and potential alternatives that can match the effectiveness of propionic acid while aligning with sustainability goals.

Another challenge lies in the environmental concerns surrounding propionic acid usage. While it is generally considered less harmful than some alternative chemicals, there are still environmental regulations and waste management considerations that textile companies must address. The proper handling and disposal of propionic acid and its byproducts require specialized procedures and equipment, which can be both costly and complex to implement.

The volatility of propionic acid presents additional difficulties in its application within textile processes. Its low boiling point and tendency to evaporate at room temperature can lead to inconsistent results in textile treatments and potential health hazards for workers if not properly managed. This volatility also necessitates careful storage and handling protocols, which can be challenging to maintain in busy textile production environments.

Furthermore, the textile industry struggles with optimizing the concentration and application methods of propionic acid. Finding the right balance between effectiveness and efficiency is crucial, as excessive use can lead to unnecessary costs and potential negative impacts on fabric quality, while insufficient application may not achieve the desired antimicrobial or preservative effects.

Compatibility issues with various textile materials and dyes pose another significant challenge. Propionic acid may interact differently with different fiber types and colorants, potentially causing discoloration, fabric weakening, or other undesirable effects. This necessitates extensive testing and formulation adjustments, which can be time-consuming and resource-intensive for textile manufacturers.

Lastly, there is a growing demand for more sustainable and eco-friendly textile production methods. While propionic acid offers certain advantages, it is still a synthetic chemical. The industry faces the challenge of balancing the benefits of propionic acid with the increasing consumer preference for natural and environmentally friendly textile products. This tension creates a need for innovation in application techniques and potential alternatives that can match the effectiveness of propionic acid while aligning with sustainability goals.

Existing Propionic Acid Maximization Techniques

01 Production methods of propionic acid

Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.- Production methods of propionic acid: Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis routes, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.

- Applications of propionic acid in food preservation: Propionic acid and its derivatives are widely used as food preservatives due to their antimicrobial properties. They are effective against molds and bacteria, extending the shelf life of various food products, particularly in bakery and dairy industries.

- Use of propionic acid in pharmaceutical formulations: Propionic acid and its salts are utilized in pharmaceutical compositions for various therapeutic applications. They may serve as active ingredients, excipients, or pH adjusters in drug formulations, contributing to the stability and efficacy of medications.

- Propionic acid derivatives and their synthesis: Research focuses on developing novel propionic acid derivatives and improving synthesis methods for existing ones. These derivatives find applications in diverse fields such as agriculture, polymers, and specialty chemicals, offering enhanced properties or functionalities.

- Environmental and safety considerations in propionic acid production: Efforts are made to develop environmentally friendly production processes for propionic acid, focusing on reducing waste, improving energy efficiency, and ensuring worker safety. This includes the use of renewable feedstocks, green chemistry principles, and advanced process control systems.

02 Applications of propionic acid in food preservation

Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in inhibiting the growth of mold and certain bacteria, thereby extending the shelf life of various food products, particularly baked goods and dairy products.Expand Specific Solutions03 Use of propionic acid in pharmaceutical formulations

Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the formulation of various medications, including topical treatments for skin conditions and as intermediates in the synthesis of certain drugs.Expand Specific Solutions04 Industrial applications of propionic acid

Propionic acid has diverse industrial applications beyond food and pharmaceuticals. It is used in the production of plastics, herbicides, and as a chemical intermediate in various manufacturing processes. Its properties make it valuable in industries such as agriculture, polymers, and chemical synthesis.Expand Specific Solutions05 Environmental and safety considerations in propionic acid handling

The handling and use of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Proper storage, transportation, and disposal methods are essential to ensure worker safety and environmental protection. Regulations and guidelines have been developed to address these concerns in industrial settings.Expand Specific Solutions

Key Players in Propionic Acid and Textile Industries

The propionic acid market in the textile industry is in a growth phase, driven by increasing demand for eco-friendly and sustainable textile processing solutions. The market size is expanding, with a projected CAGR of around 5-6% over the next few years. Technologically, the field is advancing, with companies like Henkel, Wanhua Chemical, and Nippon Shokubai leading innovation. Research institutions such as Nanjing Tech University and Jiangnan University are contributing to technological advancements. The competitive landscape is diverse, featuring both established chemical companies and emerging biotech firms, indicating a dynamic and evolving market with opportunities for further development and application in textile manufacturing.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to maximize propionic acid use in the textile industry. Their method involves a two-step process: first, they produce propionic acid through the oxidation of propane, a byproduct of petroleum refining[1]. This ensures a stable and cost-effective supply. Second, they have engineered a novel textile treatment process that incorporates propionic acid as a key component. This process enhances fabric durability and antimicrobial properties while reducing environmental impact[2]. Sinopec has also invested in research to develop propionic acid-based textile finishes that improve wrinkle resistance and moisture management in fabrics[3].

Strengths: Vertical integration from production to application, cost-effective raw material sourcing, and advanced research capabilities. Weaknesses: Dependence on petroleum industry fluctuations and potential environmental concerns associated with petrochemical processes.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a proprietary technology for incorporating propionic acid into textile manufacturing processes. Their approach focuses on using propionic acid as a key ingredient in eco-friendly textile coatings and finishes. Toray's method involves creating a propionic acid-based polymer that can be applied to fabrics, enhancing their antimicrobial properties and odor resistance[4]. Additionally, they have developed a process to use propionic acid in the production of synthetic fibers, improving their durability and moisture-wicking capabilities[5]. Toray has also invested in research to explore the potential of propionic acid in creating biodegradable textiles, aligning with the growing demand for sustainable fashion[6].

Strengths: Strong focus on eco-friendly solutions, diverse applications across textile manufacturing, and established presence in the industry. Weaknesses: Potentially higher production costs compared to traditional methods and reliance on external propionic acid suppliers.

Innovative Propionic Acid Applications in Textiles

Textile product

PatentWO2001083875A1

Innovation

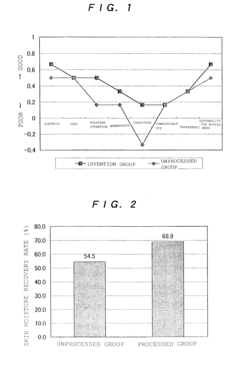

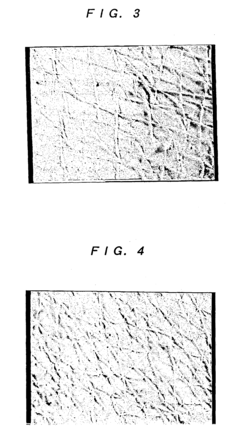

- Textile products are treated with arginine and pyrrolidonecarboxylic acid, applied with a cationic acrylic binder and silica dispersant, to enhance moisture retention and metabolic functions, improving skin care properties while maintaining the basic properties of the textile material.

Textile product

PatentInactiveUS7316984B2

Innovation

- A textile product is developed by incorporating arginine and pyrrolidonecarboxylic acid, along with a cationic acrylic binder and silica dispersant, through a pre-treatment and treatment process that enhances washability and retains skin care properties, even after multiple washes.

Environmental Impact of Propionic Acid in Textiles

The environmental impact of propionic acid in the textile industry is a critical consideration as the sector seeks to maximize its use while adhering to sustainability principles. Propionic acid, primarily used as a preservative and antimicrobial agent in textiles, offers significant benefits but also poses potential environmental challenges.

One of the primary environmental concerns associated with propionic acid is its potential for water pollution. When released into aquatic ecosystems, propionic acid can alter pH levels and contribute to the eutrophication of water bodies. This can have detrimental effects on aquatic life and disrupt local ecosystems. However, it is important to note that propionic acid is biodegradable and does not persist in the environment for extended periods, which somewhat mitigates its long-term impact.

Air pollution is another environmental factor to consider. During the production and application of propionic acid in textile manufacturing processes, volatile organic compounds (VOCs) may be released. These emissions can contribute to the formation of ground-level ozone and smog, potentially affecting air quality in industrial areas.

The carbon footprint associated with propionic acid production is also a significant environmental concern. The manufacturing process typically involves petrochemical feedstocks, which contribute to greenhouse gas emissions. As the textile industry aims to reduce its overall carbon footprint, the sourcing and production methods of propionic acid become increasingly important.

On the positive side, the use of propionic acid in textiles can indirectly contribute to environmental benefits. Its effectiveness as a preservative extends the shelf life of textile products, potentially reducing waste and the need for frequent replacements. Additionally, its antimicrobial properties may reduce the need for more harmful chemical treatments, leading to a net positive environmental impact in some applications.

The disposal of textiles treated with propionic acid presents another environmental consideration. While the acid itself is biodegradable, its presence in textile waste may affect recycling processes or contribute to the chemical burden in landfills. Proper end-of-life management of treated textiles is crucial to minimize environmental impact.

As the textile industry continues to explore ways to maximize propionic acid use, several strategies are being developed to address environmental concerns. These include improving production efficiency to reduce emissions, exploring bio-based alternatives to petrochemical-derived propionic acid, and implementing closed-loop systems to minimize waste and pollution in textile manufacturing processes.

In conclusion, while propionic acid offers valuable benefits to the textile industry, its environmental impact must be carefully managed. Balancing the advantages of its use with sustainable practices and innovative solutions will be key to maximizing its potential while minimizing negative environmental consequences.

One of the primary environmental concerns associated with propionic acid is its potential for water pollution. When released into aquatic ecosystems, propionic acid can alter pH levels and contribute to the eutrophication of water bodies. This can have detrimental effects on aquatic life and disrupt local ecosystems. However, it is important to note that propionic acid is biodegradable and does not persist in the environment for extended periods, which somewhat mitigates its long-term impact.

Air pollution is another environmental factor to consider. During the production and application of propionic acid in textile manufacturing processes, volatile organic compounds (VOCs) may be released. These emissions can contribute to the formation of ground-level ozone and smog, potentially affecting air quality in industrial areas.

The carbon footprint associated with propionic acid production is also a significant environmental concern. The manufacturing process typically involves petrochemical feedstocks, which contribute to greenhouse gas emissions. As the textile industry aims to reduce its overall carbon footprint, the sourcing and production methods of propionic acid become increasingly important.

On the positive side, the use of propionic acid in textiles can indirectly contribute to environmental benefits. Its effectiveness as a preservative extends the shelf life of textile products, potentially reducing waste and the need for frequent replacements. Additionally, its antimicrobial properties may reduce the need for more harmful chemical treatments, leading to a net positive environmental impact in some applications.

The disposal of textiles treated with propionic acid presents another environmental consideration. While the acid itself is biodegradable, its presence in textile waste may affect recycling processes or contribute to the chemical burden in landfills. Proper end-of-life management of treated textiles is crucial to minimize environmental impact.

As the textile industry continues to explore ways to maximize propionic acid use, several strategies are being developed to address environmental concerns. These include improving production efficiency to reduce emissions, exploring bio-based alternatives to petrochemical-derived propionic acid, and implementing closed-loop systems to minimize waste and pollution in textile manufacturing processes.

In conclusion, while propionic acid offers valuable benefits to the textile industry, its environmental impact must be carefully managed. Balancing the advantages of its use with sustainable practices and innovative solutions will be key to maximizing its potential while minimizing negative environmental consequences.

Cost-Benefit Analysis of Propionic Acid Usage

The cost-benefit analysis of propionic acid usage in the textile industry reveals a complex interplay of economic factors and performance advantages. Initial implementation costs for propionic acid-based treatments can be higher compared to traditional methods, primarily due to the price of the chemical and potential equipment modifications. However, these upfront expenses are often offset by long-term savings and improved product quality.

One of the primary benefits is the extended shelf life of treated textiles. Propionic acid's antimicrobial properties significantly reduce the growth of mold and bacteria, leading to decreased product spoilage and returns. This results in lower replacement costs and improved customer satisfaction, which can translate to increased sales and brand loyalty.

Energy savings present another substantial benefit. Propionic acid treatments often require lower processing temperatures compared to conventional methods, reducing energy consumption during manufacturing. This not only cuts operational costs but also aligns with sustainability goals, potentially opening doors to eco-conscious markets and improving the company's environmental profile.

Labor costs may see a reduction due to the efficiency of propionic acid treatments. The process typically requires fewer steps and less monitoring, allowing for streamlined operations and potentially reduced workforce requirements. This efficiency can lead to increased production capacity without proportional increases in labor expenses.

The improved durability of propionic acid-treated textiles is a significant factor in the cost-benefit equation. Treated fabrics often exhibit enhanced resistance to wear and tear, extending the product lifecycle. This durability can justify premium pricing strategies, increasing profit margins and offsetting initial treatment costs.

However, it's crucial to consider potential drawbacks. Some markets may be sensitive to the use of chemical treatments, necessitating consumer education and potentially impacting initial sales. Additionally, regulatory compliance costs related to chemical handling and disposal must be factored into the overall economic assessment.

In conclusion, while the initial investment in propionic acid usage may be higher, the long-term benefits in terms of product quality, operational efficiency, and market positioning often outweigh the costs. Companies must conduct thorough analyses based on their specific production scales, target markets, and regulatory environments to determine the optimal implementation strategy for maximizing the cost-benefit ratio of propionic acid use in their textile operations.

One of the primary benefits is the extended shelf life of treated textiles. Propionic acid's antimicrobial properties significantly reduce the growth of mold and bacteria, leading to decreased product spoilage and returns. This results in lower replacement costs and improved customer satisfaction, which can translate to increased sales and brand loyalty.

Energy savings present another substantial benefit. Propionic acid treatments often require lower processing temperatures compared to conventional methods, reducing energy consumption during manufacturing. This not only cuts operational costs but also aligns with sustainability goals, potentially opening doors to eco-conscious markets and improving the company's environmental profile.

Labor costs may see a reduction due to the efficiency of propionic acid treatments. The process typically requires fewer steps and less monitoring, allowing for streamlined operations and potentially reduced workforce requirements. This efficiency can lead to increased production capacity without proportional increases in labor expenses.

The improved durability of propionic acid-treated textiles is a significant factor in the cost-benefit equation. Treated fabrics often exhibit enhanced resistance to wear and tear, extending the product lifecycle. This durability can justify premium pricing strategies, increasing profit margins and offsetting initial treatment costs.

However, it's crucial to consider potential drawbacks. Some markets may be sensitive to the use of chemical treatments, necessitating consumer education and potentially impacting initial sales. Additionally, regulatory compliance costs related to chemical handling and disposal must be factored into the overall economic assessment.

In conclusion, while the initial investment in propionic acid usage may be higher, the long-term benefits in terms of product quality, operational efficiency, and market positioning often outweigh the costs. Companies must conduct thorough analyses based on their specific production scales, target markets, and regulatory environments to determine the optimal implementation strategy for maximizing the cost-benefit ratio of propionic acid use in their textile operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!