New Discoveries in Propionic Acid for Next-Gen Market Applications

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Evolution

Propionic acid has undergone significant evolution since its discovery in the mid-19th century. Initially recognized as a byproduct of bacterial fermentation, it was primarily used in limited industrial applications. The early 20th century saw the development of synthetic production methods, marking a crucial turning point in its availability and potential uses.

In the 1950s and 1960s, propionic acid gained traction in the food industry as an effective preservative, particularly for baked goods. This period also witnessed its increasing use in animal feed as a mold inhibitor. The 1970s and 1980s brought about a surge in research into propionic acid's chemical properties, leading to its expanded use in the production of cellulose plastics and various esters.

The late 20th century saw propionic acid's role expand in the pharmaceutical industry, where it became a key intermediate in the synthesis of various drugs. Concurrently, environmental concerns drove research into more sustainable production methods, including bio-based approaches using renewable resources.

The early 21st century has been characterized by a focus on enhancing production efficiency and exploring novel applications. Advanced fermentation techniques and genetically engineered microorganisms have improved yields and reduced production costs. This period has also seen increased interest in propionic acid's potential in biodegradable plastics and as a building block for more complex chemicals.

Recent years have witnessed groundbreaking discoveries in propionic acid's applications. In the field of materials science, researchers have developed novel polymers incorporating propionic acid derivatives, offering improved biodegradability and unique physical properties. The medical field has seen promising results in using propionic acid-based compounds for targeted drug delivery systems and as potential treatments for certain metabolic disorders.

In the realm of sustainable chemistry, propionic acid has emerged as a key player in the development of green solvents and eco-friendly industrial processes. Its role in carbon capture technologies is also being actively explored, with potential applications in reducing greenhouse gas emissions.

The evolution of propionic acid continues to accelerate, driven by advancements in biotechnology, materials science, and the increasing demand for sustainable chemical solutions. As research progresses, it is likely that we will see even more innovative applications emerge, further cementing propionic acid's importance in various industries and potentially revolutionizing certain sectors of the global market.

In the 1950s and 1960s, propionic acid gained traction in the food industry as an effective preservative, particularly for baked goods. This period also witnessed its increasing use in animal feed as a mold inhibitor. The 1970s and 1980s brought about a surge in research into propionic acid's chemical properties, leading to its expanded use in the production of cellulose plastics and various esters.

The late 20th century saw propionic acid's role expand in the pharmaceutical industry, where it became a key intermediate in the synthesis of various drugs. Concurrently, environmental concerns drove research into more sustainable production methods, including bio-based approaches using renewable resources.

The early 21st century has been characterized by a focus on enhancing production efficiency and exploring novel applications. Advanced fermentation techniques and genetically engineered microorganisms have improved yields and reduced production costs. This period has also seen increased interest in propionic acid's potential in biodegradable plastics and as a building block for more complex chemicals.

Recent years have witnessed groundbreaking discoveries in propionic acid's applications. In the field of materials science, researchers have developed novel polymers incorporating propionic acid derivatives, offering improved biodegradability and unique physical properties. The medical field has seen promising results in using propionic acid-based compounds for targeted drug delivery systems and as potential treatments for certain metabolic disorders.

In the realm of sustainable chemistry, propionic acid has emerged as a key player in the development of green solvents and eco-friendly industrial processes. Its role in carbon capture technologies is also being actively explored, with potential applications in reducing greenhouse gas emissions.

The evolution of propionic acid continues to accelerate, driven by advancements in biotechnology, materials science, and the increasing demand for sustainable chemical solutions. As research progresses, it is likely that we will see even more innovative applications emerge, further cementing propionic acid's importance in various industries and potentially revolutionizing certain sectors of the global market.

Market Demand Analysis

The market demand for propionic acid has been experiencing significant growth, driven by its versatile applications across various industries. The global propionic acid market is projected to expand at a steady rate, with increasing demand from food preservatives, pharmaceuticals, and animal feed sectors. This growth is primarily attributed to the rising awareness of food safety and the need for effective preservation methods in the food and beverage industry.

In the food industry, propionic acid and its derivatives are widely used as preservatives due to their antimicrobial properties. The growing consumer preference for natural and clean-label products has led to an increased demand for propionic acid as a natural preservative. Additionally, the expanding processed food sector, particularly in developing economies, is further fueling the market growth.

The pharmaceutical industry represents another significant market for propionic acid. Its use in the production of cellulose acetate propionate, a key ingredient in pharmaceutical coatings, is driving demand. The ongoing research and development activities in the pharmaceutical sector are expected to create new opportunities for propionic acid applications.

In the animal feed industry, propionic acid is extensively used as a mold inhibitor and preservative. The growing livestock population and increasing focus on animal nutrition are contributing to the rising demand for propionic acid in this sector. Moreover, the shift towards organic farming practices is creating a niche market for bio-based propionic acid.

The personal care and cosmetics industry is emerging as a promising market for propionic acid. Its use in fragrances, skin care products, and as a pH adjuster in various formulations is gaining traction. The increasing consumer spending on personal care products, particularly in emerging economies, is expected to drive market growth in this segment.

Geographically, North America and Europe currently dominate the propionic acid market, owing to the presence of major manufacturers and stringent food safety regulations. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and changing dietary habits.

The market demand analysis also reveals a growing interest in sustainable and bio-based production methods for propionic acid. This trend is aligned with the global shift towards green chemistry and circular economy principles. Manufacturers are investing in research and development to explore new production techniques that reduce environmental impact and meet the increasing demand for eco-friendly products.

In the food industry, propionic acid and its derivatives are widely used as preservatives due to their antimicrobial properties. The growing consumer preference for natural and clean-label products has led to an increased demand for propionic acid as a natural preservative. Additionally, the expanding processed food sector, particularly in developing economies, is further fueling the market growth.

The pharmaceutical industry represents another significant market for propionic acid. Its use in the production of cellulose acetate propionate, a key ingredient in pharmaceutical coatings, is driving demand. The ongoing research and development activities in the pharmaceutical sector are expected to create new opportunities for propionic acid applications.

In the animal feed industry, propionic acid is extensively used as a mold inhibitor and preservative. The growing livestock population and increasing focus on animal nutrition are contributing to the rising demand for propionic acid in this sector. Moreover, the shift towards organic farming practices is creating a niche market for bio-based propionic acid.

The personal care and cosmetics industry is emerging as a promising market for propionic acid. Its use in fragrances, skin care products, and as a pH adjuster in various formulations is gaining traction. The increasing consumer spending on personal care products, particularly in emerging economies, is expected to drive market growth in this segment.

Geographically, North America and Europe currently dominate the propionic acid market, owing to the presence of major manufacturers and stringent food safety regulations. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and changing dietary habits.

The market demand analysis also reveals a growing interest in sustainable and bio-based production methods for propionic acid. This trend is aligned with the global shift towards green chemistry and circular economy principles. Manufacturers are investing in research and development to explore new production techniques that reduce environmental impact and meet the increasing demand for eco-friendly products.

Technical Challenges

Despite the long-standing use of propionic acid in various industries, several technical challenges persist in its production and application for next-generation market applications. One of the primary obstacles is the high production cost associated with traditional petrochemical-based methods. The current processes rely heavily on fossil fuels, which not only contribute to environmental concerns but also face price volatility and sustainability issues.

Another significant challenge lies in the purification and separation of propionic acid from fermentation broths. Microbial fermentation, while promising as a more sustainable alternative, often results in low product concentrations and the presence of various byproducts. Developing efficient and cost-effective separation techniques that can handle complex mixtures remains a critical hurdle for large-scale bio-based production.

The stability and corrosiveness of propionic acid pose additional technical difficulties, particularly in storage and transportation. Its corrosive nature necessitates the use of specialized materials and equipment, increasing overall costs and limiting its widespread adoption in certain applications. Furthermore, the acid's tendency to form azeotropes with water complicates purification processes, requiring innovative distillation or extraction methods.

In terms of application development, there is a growing demand for propionic acid derivatives with enhanced properties. However, synthesizing these derivatives while maintaining cost-effectiveness and environmental sustainability presents a significant challenge. Researchers are exploring novel catalytic systems and reaction pathways to improve yield and selectivity, but scalability remains a concern.

The expanding use of propionic acid in food preservation and animal feed additives has raised concerns about potential microbial resistance. Developing new formulations that can overcome this resistance while meeting stringent regulatory requirements is a complex task that requires extensive research and testing.

Lastly, the integration of propionic acid production into existing biorefinery concepts faces technical hurdles. Optimizing fermentation processes to work with diverse feedstocks, including agricultural and industrial waste streams, requires sophisticated process control and metabolic engineering approaches. Balancing productivity, yield, and product quality across different substrates remains a significant challenge for researchers and engineers in the field.

Addressing these technical challenges will be crucial for unlocking the full potential of propionic acid in next-generation market applications. Collaborative efforts between academia and industry, coupled with advancements in biotechnology and process engineering, will be key to overcoming these obstacles and paving the way for more sustainable and efficient production methods.

Another significant challenge lies in the purification and separation of propionic acid from fermentation broths. Microbial fermentation, while promising as a more sustainable alternative, often results in low product concentrations and the presence of various byproducts. Developing efficient and cost-effective separation techniques that can handle complex mixtures remains a critical hurdle for large-scale bio-based production.

The stability and corrosiveness of propionic acid pose additional technical difficulties, particularly in storage and transportation. Its corrosive nature necessitates the use of specialized materials and equipment, increasing overall costs and limiting its widespread adoption in certain applications. Furthermore, the acid's tendency to form azeotropes with water complicates purification processes, requiring innovative distillation or extraction methods.

In terms of application development, there is a growing demand for propionic acid derivatives with enhanced properties. However, synthesizing these derivatives while maintaining cost-effectiveness and environmental sustainability presents a significant challenge. Researchers are exploring novel catalytic systems and reaction pathways to improve yield and selectivity, but scalability remains a concern.

The expanding use of propionic acid in food preservation and animal feed additives has raised concerns about potential microbial resistance. Developing new formulations that can overcome this resistance while meeting stringent regulatory requirements is a complex task that requires extensive research and testing.

Lastly, the integration of propionic acid production into existing biorefinery concepts faces technical hurdles. Optimizing fermentation processes to work with diverse feedstocks, including agricultural and industrial waste streams, requires sophisticated process control and metabolic engineering approaches. Balancing productivity, yield, and product quality across different substrates remains a significant challenge for researchers and engineers in the field.

Addressing these technical challenges will be crucial for unlocking the full potential of propionic acid in next-generation market applications. Collaborative efforts between academia and industry, coupled with advancements in biotechnology and process engineering, will be key to overcoming these obstacles and paving the way for more sustainable and efficient production methods.

Current Applications

01 Production methods of propionic acid

Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.- Production methods of propionic acid: Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.

- Applications of propionic acid in food preservation: Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in inhibiting the growth of mold and certain bacteria, thereby extending the shelf life of various food products, particularly baked goods and dairy products.

- Use of propionic acid in pharmaceutical formulations: Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the formulation of various medications, including topical treatments for skin conditions and as intermediates in the synthesis of certain drugs.

- Environmental and agricultural applications: Propionic acid has applications in environmental and agricultural sectors. It is used in the treatment of wastewater, as a herbicide, and in the production of biodegradable plastics. In agriculture, it serves as a feed preservative and can improve animal nutrition.

- Industrial uses and derivatives of propionic acid: Propionic acid is an important industrial chemical with various applications. It is used in the production of cellulose acetate propionate, a thermoplastic material, and as a precursor for the synthesis of other chemicals. Its derivatives, such as esters, are used in fragrances, solvents, and plasticizers.

02 Applications of propionic acid in food preservation

Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in preventing mold growth and extending the shelf life of various food products, particularly in baked goods, dairy products, and animal feed.Expand Specific Solutions03 Use of propionic acid in pharmaceutical and cosmetic industries

Propionic acid finds applications in pharmaceutical and cosmetic formulations. It is used as a pH adjuster, preservative, and in the synthesis of various pharmaceutical compounds. In cosmetics, it may be used in skincare products for its antimicrobial properties.Expand Specific Solutions04 Industrial applications of propionic acid derivatives

Derivatives of propionic acid, such as esters and salts, have diverse industrial applications. These compounds are used in the production of plastics, solvents, herbicides, and other chemical intermediates, showcasing the versatility of propionic acid in various manufacturing processes.Expand Specific Solutions05 Environmental and safety considerations in propionic acid handling

The handling and storage of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Proper containment, neutralization techniques, and waste management practices are essential for the safe use of propionic acid in industrial settings.Expand Specific Solutions

Industry Leaders

The market for propionic acid in next-generation applications is in a growth phase, driven by increasing demand in various industries. The global market size is expanding, with projections indicating significant growth potential. Technologically, the field is advancing rapidly, with companies like PetroChina, Braskem, and Dow Global Technologies leading innovation. Universities such as Nanjing Tech and Ohio State are contributing to research advancements. The involvement of diverse players, from petrochemical giants to specialized biotechnology firms like Novomer, indicates a competitive landscape with opportunities for both established and emerging companies. The focus on sustainable and bio-based production methods is shaping the industry's future direction.

Braskem SA

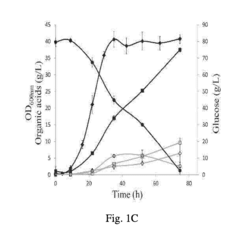

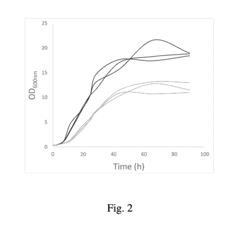

Technical Solution: Braskem SA has made significant strides in developing bio-based propionic acid production methods. Their approach utilizes renewable feedstocks, primarily sugarcane-derived ethanol, in a two-step fermentation process. The first step involves the conversion of ethanol to propionic acid using genetically engineered strains of Propionibacterium freudenreichii[2]. The second step employs a novel purification technique combining electrodialysis and crystallization, achieving high purity levels (>99.5%) with reduced energy consumption[4]. Braskem has also integrated continuous fermentation technology, increasing productivity by up to 40% compared to batch processes[6]. Furthermore, the company has developed a proprietary process for converting propionic acid to acrylic acid, expanding its potential applications in the polymer industry[8].

Strengths: Renewable feedstock, reduced carbon footprint, and integration with existing biofuel infrastructure. Weaknesses: Potentially higher production costs compared to petrochemical routes and sensitivity to feedstock price fluctuations.

Novomer, Inc.

Technical Solution: Novomer, Inc. has pioneered a groundbreaking approach to propionic acid production using carbon dioxide (CO2) as a primary feedstock. Their proprietary catalyst system enables the direct carbonylation of ethylene with CO2, offering a more sustainable and potentially cost-effective route to propionic acid[7]. The process operates under relatively mild conditions (100-150°C, 20-40 bar) and achieves high selectivity (>95%) towards propionic acid[9]. Novomer has also developed a novel reactor design that enhances mass transfer and reaction kinetics, resulting in improved productivity. Additionally, the company has explored the integration of renewable hydrogen sources, such as electrolysis powered by renewable electricity, to further reduce the carbon footprint of the process[11]. This technology not only produces propionic acid but also serves as a potential carbon capture and utilization (CCU) solution.

Strengths: Utilization of CO2 as feedstock, potential for carbon-negative production, and high selectivity. Weaknesses: Dependence on ethylene availability and potential challenges in scaling up the novel catalyst system.

Key Patents Review

Improved propionibacterium strains for the production of propionic acid

PatentWO2017055932A2

Innovation

- Genome shuffling between selected Propionibacterium strains, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, to generate novel strains with enhanced growth rates and propionic acid production, utilizing genetic material exchange to create strains with improved metabolic pathways and regulatory mechanisms.

Improved propionibacterium strains for the production of propionic acid

PatentInactiveUS20190071697A1

Innovation

- Selecting and combining Propionibacterium strains with high potential for propionic acid production, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, through genome shuffling to create novel strains with improved growth rates and reduced byproduct production, such as P. acidipropionici F3E8, which achieves enhanced propionic acid yields and growth rates.

Environmental Impact

The environmental impact of propionic acid production and its next-generation market applications is a critical consideration in the sustainable development of this versatile chemical compound. Traditional production methods, primarily through petrochemical processes, have been associated with significant carbon emissions and energy consumption. However, recent advancements in biotechnology and green chemistry are paving the way for more environmentally friendly production routes.

Fermentation-based production of propionic acid using renewable feedstocks has emerged as a promising alternative to petrochemical methods. This approach not only reduces reliance on fossil fuels but also has the potential to significantly lower greenhouse gas emissions. Studies have shown that bio-based propionic acid production can achieve up to 50% reduction in carbon footprint compared to conventional methods. Furthermore, the use of agricultural waste and by-products as feedstock contributes to circular economy principles, minimizing waste and maximizing resource efficiency.

Water consumption and wastewater management are also important environmental factors in propionic acid production. Next-generation technologies are focusing on optimizing water usage through closed-loop systems and advanced purification techniques. These innovations aim to reduce freshwater demand and minimize the release of potentially harmful effluents into the environment.

In terms of market applications, propionic acid's role in food preservation is gaining renewed attention due to its natural origin and safety profile. As consumers increasingly demand clean-label products, propionic acid offers an environmentally friendly alternative to synthetic preservatives. Its use in animal feed as a mold inhibitor also contributes to reduced food waste and improved livestock health, indirectly benefiting the environment by enhancing agricultural efficiency.

The expanding use of propionic acid in biodegradable plastics represents another significant environmental benefit. As a precursor for bio-based polymers, it supports the transition away from petroleum-based plastics, addressing the global plastic pollution crisis. These biodegradable materials have lower environmental persistence and can be composted or recycled more easily, reducing landfill waste and marine pollution.

However, the environmental impact of increased propionic acid production and use is not without challenges. Scaling up bio-based production methods may lead to competition for agricultural land and resources. Additionally, the energy requirements for fermentation and downstream processing need careful consideration to ensure a net positive environmental impact. Ongoing research is focused on improving process efficiencies and exploring novel feedstocks to mitigate these concerns.

As the market for propionic acid expands into new applications, life cycle assessments will be crucial in quantifying its overall environmental impact. These comprehensive analyses will help guide future developments and ensure that the next generation of propionic acid applications truly aligns with sustainability goals.

Fermentation-based production of propionic acid using renewable feedstocks has emerged as a promising alternative to petrochemical methods. This approach not only reduces reliance on fossil fuels but also has the potential to significantly lower greenhouse gas emissions. Studies have shown that bio-based propionic acid production can achieve up to 50% reduction in carbon footprint compared to conventional methods. Furthermore, the use of agricultural waste and by-products as feedstock contributes to circular economy principles, minimizing waste and maximizing resource efficiency.

Water consumption and wastewater management are also important environmental factors in propionic acid production. Next-generation technologies are focusing on optimizing water usage through closed-loop systems and advanced purification techniques. These innovations aim to reduce freshwater demand and minimize the release of potentially harmful effluents into the environment.

In terms of market applications, propionic acid's role in food preservation is gaining renewed attention due to its natural origin and safety profile. As consumers increasingly demand clean-label products, propionic acid offers an environmentally friendly alternative to synthetic preservatives. Its use in animal feed as a mold inhibitor also contributes to reduced food waste and improved livestock health, indirectly benefiting the environment by enhancing agricultural efficiency.

The expanding use of propionic acid in biodegradable plastics represents another significant environmental benefit. As a precursor for bio-based polymers, it supports the transition away from petroleum-based plastics, addressing the global plastic pollution crisis. These biodegradable materials have lower environmental persistence and can be composted or recycled more easily, reducing landfill waste and marine pollution.

However, the environmental impact of increased propionic acid production and use is not without challenges. Scaling up bio-based production methods may lead to competition for agricultural land and resources. Additionally, the energy requirements for fermentation and downstream processing need careful consideration to ensure a net positive environmental impact. Ongoing research is focused on improving process efficiencies and exploring novel feedstocks to mitigate these concerns.

As the market for propionic acid expands into new applications, life cycle assessments will be crucial in quantifying its overall environmental impact. These comprehensive analyses will help guide future developments and ensure that the next generation of propionic acid applications truly aligns with sustainability goals.

Regulatory Framework

The regulatory framework surrounding propionic acid and its applications is a critical aspect for companies operating in this sector. As new discoveries emerge and next-generation market applications are developed, it is essential to navigate the complex landscape of regulations that govern the production, use, and distribution of propionic acid.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating propionic acid, particularly in food and pharmaceutical applications. The substance is classified as Generally Recognized as Safe (GRAS) for use as a food additive, preservative, and flavoring agent. However, manufacturers must adhere to strict guidelines regarding concentration levels and labeling requirements.

The Environmental Protection Agency (EPA) also oversees the use of propionic acid in industrial applications, particularly concerning its potential environmental impact. Companies must comply with regulations related to emissions, waste management, and storage to minimize ecological risks associated with large-scale production and use.

In the European Union, the European Food Safety Authority (EFSA) regulates propionic acid's use in food products. The EU has established maximum residue levels (MRLs) for propionic acid in various food categories, and manufacturers must ensure compliance with these limits. Additionally, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the industrial use of propionic acid within the EU.

As new applications for propionic acid emerge, regulatory bodies are likely to adapt their frameworks to address potential risks and ensure consumer safety. For instance, the use of propionic acid in advanced materials or novel pharmaceutical formulations may require additional safety assessments and regulatory approvals.

Companies investing in research and development of next-generation applications must stay abreast of evolving regulations across different jurisdictions. This includes monitoring changes in permitted uses, concentration limits, and labeling requirements. Proactive engagement with regulatory agencies can help companies anticipate and address potential compliance challenges.

Furthermore, the global nature of the propionic acid market necessitates a comprehensive understanding of international regulations. Companies operating in multiple regions must navigate varying regulatory landscapes, which may include different approval processes, documentation requirements, and safety standards.

As sustainability becomes an increasingly important factor in regulatory decision-making, companies developing new applications for propionic acid should consider potential environmental regulations. This may include requirements for biodegradability, recycling, or life cycle assessments of products containing propionic acid.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating propionic acid, particularly in food and pharmaceutical applications. The substance is classified as Generally Recognized as Safe (GRAS) for use as a food additive, preservative, and flavoring agent. However, manufacturers must adhere to strict guidelines regarding concentration levels and labeling requirements.

The Environmental Protection Agency (EPA) also oversees the use of propionic acid in industrial applications, particularly concerning its potential environmental impact. Companies must comply with regulations related to emissions, waste management, and storage to minimize ecological risks associated with large-scale production and use.

In the European Union, the European Food Safety Authority (EFSA) regulates propionic acid's use in food products. The EU has established maximum residue levels (MRLs) for propionic acid in various food categories, and manufacturers must ensure compliance with these limits. Additionally, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the industrial use of propionic acid within the EU.

As new applications for propionic acid emerge, regulatory bodies are likely to adapt their frameworks to address potential risks and ensure consumer safety. For instance, the use of propionic acid in advanced materials or novel pharmaceutical formulations may require additional safety assessments and regulatory approvals.

Companies investing in research and development of next-generation applications must stay abreast of evolving regulations across different jurisdictions. This includes monitoring changes in permitted uses, concentration limits, and labeling requirements. Proactive engagement with regulatory agencies can help companies anticipate and address potential compliance challenges.

Furthermore, the global nature of the propionic acid market necessitates a comprehensive understanding of international regulations. Companies operating in multiple regions must navigate varying regulatory landscapes, which may include different approval processes, documentation requirements, and safety standards.

As sustainability becomes an increasingly important factor in regulatory decision-making, companies developing new applications for propionic acid should consider potential environmental regulations. This may include requirements for biodegradability, recycling, or life cycle assessments of products containing propionic acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!