Propionic Acid Advancements in Food Preservatives

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Evolution and Objectives

Propionic acid has been a cornerstone in food preservation for decades, with its journey beginning in the early 20th century. Initially discovered as a natural byproduct of bacterial fermentation, its potential as a preservative was quickly recognized. The evolution of propionic acid in food preservation has been marked by continuous advancements in production methods, application techniques, and understanding of its antimicrobial properties.

In the 1930s, propionic acid was first synthesized on an industrial scale, paving the way for its widespread use in food preservation. The following decades saw significant improvements in production efficiency and purity, making it more accessible and cost-effective for the food industry. By the 1960s, propionic acid had become a staple in bakery products, particularly for preventing mold growth in bread and other baked goods.

The 1980s and 1990s witnessed a surge in research focused on understanding the mechanisms of propionic acid's antimicrobial activity. This period was crucial in establishing its efficacy against various food spoilage organisms and pathogens, expanding its application beyond bakery products to dairy, meat, and other food categories.

Recent years have seen a shift towards developing more sustainable and natural preservation methods. This trend has led to increased interest in propionic acid produced through fermentation processes, aligning with consumer demands for clean label products. Simultaneously, there has been a focus on enhancing the efficacy of propionic acid through synergistic combinations with other preservatives and innovative delivery systems.

The primary objectives in the advancement of propionic acid as a food preservative are multifaceted. Firstly, there is a drive to improve its antimicrobial potency while minimizing the required dosage, thereby reducing potential impacts on taste and aroma. Secondly, researchers are exploring ways to extend its shelf-life efficacy, particularly in challenging food matrices with high water activity or pH levels.

Another key objective is to develop propionic acid derivatives or formulations that offer broader spectrum antimicrobial activity, potentially addressing emerging food safety concerns. Additionally, there is a growing emphasis on enhancing the sustainability of propionic acid production, with efforts directed towards bio-based manufacturing processes and the use of renewable resources.

As the food industry continues to evolve, the objectives for propionic acid advancements also include improving its compatibility with other food ingredients and processing technologies. This includes developing heat-stable formulations for use in thermally processed foods and exploring encapsulation techniques for controlled release in complex food systems.

In the 1930s, propionic acid was first synthesized on an industrial scale, paving the way for its widespread use in food preservation. The following decades saw significant improvements in production efficiency and purity, making it more accessible and cost-effective for the food industry. By the 1960s, propionic acid had become a staple in bakery products, particularly for preventing mold growth in bread and other baked goods.

The 1980s and 1990s witnessed a surge in research focused on understanding the mechanisms of propionic acid's antimicrobial activity. This period was crucial in establishing its efficacy against various food spoilage organisms and pathogens, expanding its application beyond bakery products to dairy, meat, and other food categories.

Recent years have seen a shift towards developing more sustainable and natural preservation methods. This trend has led to increased interest in propionic acid produced through fermentation processes, aligning with consumer demands for clean label products. Simultaneously, there has been a focus on enhancing the efficacy of propionic acid through synergistic combinations with other preservatives and innovative delivery systems.

The primary objectives in the advancement of propionic acid as a food preservative are multifaceted. Firstly, there is a drive to improve its antimicrobial potency while minimizing the required dosage, thereby reducing potential impacts on taste and aroma. Secondly, researchers are exploring ways to extend its shelf-life efficacy, particularly in challenging food matrices with high water activity or pH levels.

Another key objective is to develop propionic acid derivatives or formulations that offer broader spectrum antimicrobial activity, potentially addressing emerging food safety concerns. Additionally, there is a growing emphasis on enhancing the sustainability of propionic acid production, with efforts directed towards bio-based manufacturing processes and the use of renewable resources.

As the food industry continues to evolve, the objectives for propionic acid advancements also include improving its compatibility with other food ingredients and processing technologies. This includes developing heat-stable formulations for use in thermally processed foods and exploring encapsulation techniques for controlled release in complex food systems.

Food Preservation Market Analysis

The food preservation market has experienced significant growth in recent years, driven by increasing consumer demand for convenience foods, extended shelf life, and food safety. The global food preservatives market was valued at approximately $2.5 billion in 2020 and is projected to reach $3.2 billion by 2025, growing at a CAGR of around 4.5% during the forecast period. This growth is primarily attributed to the rising need for food security, changing lifestyles, and the expansion of the food and beverage industry.

Propionic acid, as a key player in the food preservatives sector, has gained substantial traction due to its effectiveness in inhibiting mold growth and extending the shelf life of various food products. The market for propionic acid in food preservation applications is expected to witness robust growth, with a projected CAGR of 5.2% from 2021 to 2026. This growth is fueled by the increasing adoption of propionic acid in bakery products, dairy items, and animal feed preservation.

The bakery segment dominates the propionic acid market in food preservation, accounting for over 40% of the total market share. This is due to the widespread use of propionic acid and its salts in preventing mold growth in bread, pastries, and other baked goods. The dairy industry follows closely, with propionic acid being utilized in cheese production to inhibit the growth of propionibacteria and other microorganisms.

Geographically, North America and Europe are the leading markets for propionic acid in food preservation, collectively accounting for over 60% of the global market share. This dominance is attributed to stringent food safety regulations, high consumer awareness, and the presence of major food processing companies in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, changing dietary habits, and increasing disposable incomes.

The market is characterized by the presence of several key players, including BASF SE, Dow Inc., Eastman Chemical Company, and Perstorp Holding AB. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios. For instance, recent advancements in encapsulation technologies have led to the development of controlled-release propionic acid formulations, offering improved efficacy and longer-lasting preservation effects.

Propionic acid, as a key player in the food preservatives sector, has gained substantial traction due to its effectiveness in inhibiting mold growth and extending the shelf life of various food products. The market for propionic acid in food preservation applications is expected to witness robust growth, with a projected CAGR of 5.2% from 2021 to 2026. This growth is fueled by the increasing adoption of propionic acid in bakery products, dairy items, and animal feed preservation.

The bakery segment dominates the propionic acid market in food preservation, accounting for over 40% of the total market share. This is due to the widespread use of propionic acid and its salts in preventing mold growth in bread, pastries, and other baked goods. The dairy industry follows closely, with propionic acid being utilized in cheese production to inhibit the growth of propionibacteria and other microorganisms.

Geographically, North America and Europe are the leading markets for propionic acid in food preservation, collectively accounting for over 60% of the global market share. This dominance is attributed to stringent food safety regulations, high consumer awareness, and the presence of major food processing companies in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, changing dietary habits, and increasing disposable incomes.

The market is characterized by the presence of several key players, including BASF SE, Dow Inc., Eastman Chemical Company, and Perstorp Holding AB. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios. For instance, recent advancements in encapsulation technologies have led to the development of controlled-release propionic acid formulations, offering improved efficacy and longer-lasting preservation effects.

Current Challenges in Propionic Acid Usage

Despite the widespread use of propionic acid as a food preservative, several challenges persist in its application, hindering its full potential in the food industry. One of the primary concerns is the strong odor associated with propionic acid, which can negatively impact the sensory properties of food products. This pungent smell limits its use in certain food categories, particularly those where flavor profiles are crucial.

Another significant challenge is the relatively high concentration required for effective antimicrobial action. This not only increases the cost of preservation but also raises concerns about potential health effects of long-term consumption of foods with high propionic acid content. Regulatory bodies in various countries have set maximum permissible levels, which sometimes restrict its use in certain food products.

The corrosive nature of propionic acid poses challenges in handling and storage. It requires specialized equipment and safety measures, increasing operational costs for food manufacturers. Additionally, its corrosive properties can potentially affect packaging materials, leading to concerns about product shelf life and safety.

Propionic acid's effectiveness is also pH-dependent, with its antimicrobial activity decreasing in less acidic environments. This limitation narrows its application range and necessitates careful formulation in food products with varying pH levels. Furthermore, some microorganisms have shown resistance to propionic acid over time, reducing its long-term efficacy as a preservative.

The environmental impact of propionic acid production and disposal is another growing concern. Traditional production methods often involve petrochemical processes, which are not sustainable in the long term. There is an increasing demand for more environmentally friendly production methods and bio-based alternatives.

Lastly, consumer trends towards 'clean label' and natural products present a challenge for synthetic preservatives like propionic acid. There is a growing preference for natural antimicrobials, putting pressure on the food industry to find alternatives or develop natural sources of propionic acid.

These challenges collectively drive the need for innovative solutions in propionic acid usage as a food preservative. Addressing these issues requires multidisciplinary approaches, involving advancements in chemistry, microbiology, food technology, and sustainable production methods.

Another significant challenge is the relatively high concentration required for effective antimicrobial action. This not only increases the cost of preservation but also raises concerns about potential health effects of long-term consumption of foods with high propionic acid content. Regulatory bodies in various countries have set maximum permissible levels, which sometimes restrict its use in certain food products.

The corrosive nature of propionic acid poses challenges in handling and storage. It requires specialized equipment and safety measures, increasing operational costs for food manufacturers. Additionally, its corrosive properties can potentially affect packaging materials, leading to concerns about product shelf life and safety.

Propionic acid's effectiveness is also pH-dependent, with its antimicrobial activity decreasing in less acidic environments. This limitation narrows its application range and necessitates careful formulation in food products with varying pH levels. Furthermore, some microorganisms have shown resistance to propionic acid over time, reducing its long-term efficacy as a preservative.

The environmental impact of propionic acid production and disposal is another growing concern. Traditional production methods often involve petrochemical processes, which are not sustainable in the long term. There is an increasing demand for more environmentally friendly production methods and bio-based alternatives.

Lastly, consumer trends towards 'clean label' and natural products present a challenge for synthetic preservatives like propionic acid. There is a growing preference for natural antimicrobials, putting pressure on the food industry to find alternatives or develop natural sources of propionic acid.

These challenges collectively drive the need for innovative solutions in propionic acid usage as a food preservative. Addressing these issues requires multidisciplinary approaches, involving advancements in chemistry, microbiology, food technology, and sustainable production methods.

Existing Propionic Acid Applications

01 Antimicrobial effectiveness of propionic acid

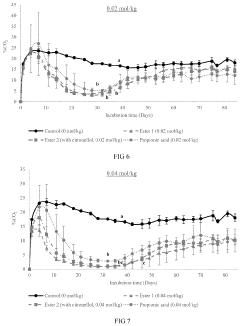

Propionic acid demonstrates effective antimicrobial properties, making it suitable for use as a preservative in various applications. It inhibits the growth of mold, yeast, and certain bacteria, extending the shelf life of products. The effectiveness of propionic acid as a preservative is attributed to its ability to lower pH and disrupt microbial cell membranes.- Antimicrobial effectiveness of propionic acid: Propionic acid demonstrates effective antimicrobial properties, making it suitable for use as a preservative in various applications. It inhibits the growth of molds, yeasts, and certain bacteria, thereby extending the shelf life of products. The effectiveness of propionic acid as a preservative is attributed to its ability to lower pH and disrupt microbial cell membranes.

- Synergistic preservation with propionic acid combinations: Combining propionic acid with other preservatives or compounds can enhance its preservation effectiveness. Synergistic effects have been observed when propionic acid is used in conjunction with other organic acids, salts, or antimicrobial agents. These combinations can provide broader spectrum protection against various microorganisms and improve overall preservation efficacy.

- Application of propionic acid in food preservation: Propionic acid is widely used as a food preservative due to its effectiveness in preventing spoilage. It is particularly useful in bakery products, dairy items, and animal feed. The acid helps maintain product quality by inhibiting mold growth and extending shelf life. Its natural occurrence in some foods also makes it a preferred choice for clean label preservation.

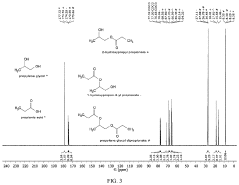

- Propionic acid derivatives for enhanced preservation: Derivatives of propionic acid, such as propionates and esters, have been developed to improve preservation effectiveness. These modified forms can offer advantages like increased solubility, better stability, or targeted antimicrobial activity. Some derivatives may also provide additional benefits such as improved taste profiles or reduced odor in preserved products.

- Controlled release systems for propionic acid preservation: Innovative delivery systems have been developed to enhance the preservation effectiveness of propionic acid. These include encapsulation techniques, slow-release formulations, and incorporation into polymeric matrices. Such systems allow for sustained antimicrobial activity, improved distribution within the product, and potentially reduced overall acid usage while maintaining preservation efficacy.

02 Synergistic preservation with propionic acid combinations

Combining propionic acid with other preservatives or compounds can enhance its preservation effectiveness. Synergistic effects have been observed when propionic acid is used in conjunction with other organic acids, salts, or antimicrobial agents. These combinations can provide broader spectrum protection against various microorganisms and improve overall preservation efficacy.Expand Specific Solutions03 Application of propionic acid in food preservation

Propionic acid is widely used as a food preservative due to its effectiveness in preventing spoilage. It is particularly useful in bakery products, dairy items, and animal feed. The acid helps maintain product quality, extend shelf life, and prevent the growth of harmful microorganisms in food products.Expand Specific Solutions04 Propionic acid derivatives for enhanced preservation

Derivatives of propionic acid, such as propionates and esters, have been developed to improve preservation effectiveness. These modified forms can offer advantages such as improved solubility, stability, or targeted antimicrobial activity. Some derivatives may also have reduced odor or taste impact compared to the parent compound.Expand Specific Solutions05 Controlled release systems for propionic acid preservation

Controlled release systems have been developed to optimize the preservation effectiveness of propionic acid. These systems allow for the gradual release of the preservative, maintaining its concentration at effective levels over extended periods. This approach can enhance the long-term preservation efficacy and reduce the overall amount of preservative required.Expand Specific Solutions

Key Players in Food Preservative Industry

The propionic acid market for food preservatives is in a mature growth stage, with a global market size estimated to be over $1 billion. The technology is well-established, with major players like BASF, Dow, and Eastman dominating production. However, there's ongoing innovation in application methods and natural alternatives. Companies like Kemin Industries and Novozymes are developing bio-based propionic acid solutions, while BASF and Dow continue to improve synthetic production processes. Universities such as Jiangnan University and The Ohio State University are conducting research to enhance propionic acid's efficacy and sustainability in food preservation applications.

BASF Corp.

Technical Solution: BASF has developed advanced propionic acid-based preservatives for food applications. Their technology focuses on optimizing the antimicrobial efficacy of propionic acid through synergistic combinations with other organic acids and salts. BASF's approach involves microencapsulation techniques to improve the stability and controlled release of propionic acid in various food matrices. This allows for extended shelf life and improved food safety[1]. Additionally, BASF has invested in green chemistry methods to produce propionic acid from renewable resources, reducing the environmental impact of their preservatives[3].

Strengths: High efficacy, improved stability, and controlled release. Environmentally friendly production methods. Weaknesses: Potentially higher cost due to advanced formulation techniques.

Kemin Industries, Inc.

Technical Solution: Kemin Industries has developed a proprietary blend of propionic acid and other organic acids for food preservation. Their technology focuses on creating synergistic effects between different acids to enhance antimicrobial activity. Kemin's formulations are designed to be effective at lower pH levels, allowing for broader application in acidic food products. They have also developed buffered propionic acid solutions that maintain efficacy while minimizing corrosion in processing equipment[2]. Kemin's research has shown that their propionic acid blends can extend shelf life by up to 40% in certain bakery products compared to traditional preservatives[4].

Strengths: Enhanced efficacy in acidic conditions, reduced equipment corrosion, significant shelf life extension. Weaknesses: May have limitations in non-acidic food applications.

Innovative Propionic Acid Formulations

Compositions containing organic acids and their esters to prevent mold contamination in animal feed

PatentPendingUS20230189803A1

Innovation

- Development of carboxylic acid esters of monopropylene glycol with short-chain fatty acids, combined with propionic esters and salts, to create a composition that inhibits mold growth effectively while reducing volatility and corrosiveness, and improving odor, thereby providing long-term protection and enhanced storage properties.

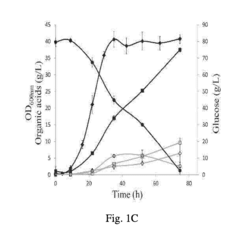

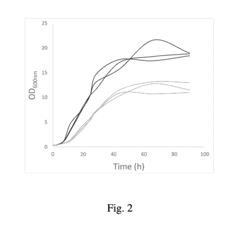

Improved propionibacterium strains for the production of propionic acid

PatentInactiveUS20190071697A1

Innovation

- Selecting and combining Propionibacterium strains with high potential for propionic acid production, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, through genome shuffling to create novel strains with improved growth rates and reduced byproduct production, such as P. acidipropionici F3E8, which achieves enhanced propionic acid yields and growth rates.

Regulatory Framework for Food Preservatives

The regulatory framework for food preservatives, including propionic acid, is a complex and evolving landscape that varies across different regions and countries. In the United States, the Food and Drug Administration (FDA) oversees the regulation of food additives, including preservatives. Propionic acid and its salts are generally recognized as safe (GRAS) for use in food products, with specific limitations on usage levels depending on the food category.

The European Union (EU) has established a comprehensive regulatory system for food additives through the European Food Safety Authority (EFSA). Propionic acid and propionates are approved for use in various food categories under Regulation (EC) No 1333/2008. The EU regularly reviews and updates its list of approved additives based on new scientific evidence and risk assessments.

In Asia, countries like Japan and China have their own regulatory bodies and approval processes for food preservatives. The Japanese Ministry of Health, Labour and Welfare regulates food additives, while in China, the National Health Commission oversees food safety regulations. Both countries have approved the use of propionic acid and its salts in certain food products, with specific limitations.

International organizations, such as the Joint FAO/WHO Expert Committee on Food Additives (JECFA), play a crucial role in establishing global standards and guidelines for food additives. JECFA has evaluated propionic acid and its salts, providing recommendations on acceptable daily intake (ADI) and maximum use levels in various food categories.

The regulatory framework also addresses labeling requirements for food products containing preservatives. In many jurisdictions, manufacturers are required to list propionic acid or its salts on product labels, either by name or by their E-number (E280 for propionic acid). This transparency allows consumers to make informed choices about the products they purchase.

As advancements in propionic acid technology continue, regulatory bodies must adapt their frameworks to accommodate new formulations, applications, and safety data. This may involve reassessing existing regulations, conducting additional safety evaluations, and potentially expanding or restricting the use of propionic acid-based preservatives in certain food categories.

The global nature of the food industry necessitates harmonization efforts between different regulatory bodies to facilitate international trade while maintaining high food safety standards. Initiatives like the Codex Alimentarius Commission work towards developing international food standards, guidelines, and codes of practice to promote fair trade practices and consumer protection.

The European Union (EU) has established a comprehensive regulatory system for food additives through the European Food Safety Authority (EFSA). Propionic acid and propionates are approved for use in various food categories under Regulation (EC) No 1333/2008. The EU regularly reviews and updates its list of approved additives based on new scientific evidence and risk assessments.

In Asia, countries like Japan and China have their own regulatory bodies and approval processes for food preservatives. The Japanese Ministry of Health, Labour and Welfare regulates food additives, while in China, the National Health Commission oversees food safety regulations. Both countries have approved the use of propionic acid and its salts in certain food products, with specific limitations.

International organizations, such as the Joint FAO/WHO Expert Committee on Food Additives (JECFA), play a crucial role in establishing global standards and guidelines for food additives. JECFA has evaluated propionic acid and its salts, providing recommendations on acceptable daily intake (ADI) and maximum use levels in various food categories.

The regulatory framework also addresses labeling requirements for food products containing preservatives. In many jurisdictions, manufacturers are required to list propionic acid or its salts on product labels, either by name or by their E-number (E280 for propionic acid). This transparency allows consumers to make informed choices about the products they purchase.

As advancements in propionic acid technology continue, regulatory bodies must adapt their frameworks to accommodate new formulations, applications, and safety data. This may involve reassessing existing regulations, conducting additional safety evaluations, and potentially expanding or restricting the use of propionic acid-based preservatives in certain food categories.

The global nature of the food industry necessitates harmonization efforts between different regulatory bodies to facilitate international trade while maintaining high food safety standards. Initiatives like the Codex Alimentarius Commission work towards developing international food standards, guidelines, and codes of practice to promote fair trade practices and consumer protection.

Environmental Impact of Propionic Acid Production

The production of propionic acid, a widely used food preservative, has significant environmental implications that warrant careful consideration. The traditional petrochemical-based production methods have been associated with substantial carbon emissions and energy consumption. However, recent advancements in biotechnological processes have shown promise in reducing the environmental footprint of propionic acid production.

Fermentation-based production methods, utilizing renewable biomass feedstocks, have emerged as a more sustainable alternative. These processes typically employ propionibacteria or other microorganisms to convert sugars or other organic compounds into propionic acid. This approach not only reduces reliance on fossil fuels but also potentially decreases greenhouse gas emissions. Studies have shown that bio-based production can lead to a 30-50% reduction in carbon footprint compared to conventional petrochemical routes.

Water usage and wastewater management are critical environmental factors in propionic acid production. Traditional methods often require significant water inputs and generate effluents that need extensive treatment. Biotechnological processes, while generally more water-efficient, still face challenges in wastewater handling. Innovative water recycling systems and advanced treatment technologies are being developed to address these issues, aiming to minimize water consumption and improve the quality of discharged effluents.

The impact on land use and biodiversity is another important consideration, particularly for bio-based production methods that rely on agricultural feedstocks. There are concerns about potential competition with food crops and the expansion of cultivated land. To mitigate these issues, research is focusing on utilizing non-food biomass sources, such as agricultural residues and waste streams, as feedstocks for propionic acid production.

Energy efficiency in production processes is a key area for environmental improvement. Both traditional and biotechnological methods are being optimized to reduce energy consumption. This includes the development of more efficient fermentation processes, improved separation and purification techniques, and the integration of renewable energy sources in production facilities.

The end-of-life fate of propionic acid and its derivatives in food products also has environmental implications. As a biodegradable compound, propionic acid generally has a lower environmental persistence compared to some synthetic preservatives. However, its widespread use necessitates a comprehensive understanding of its ecological impact, including potential effects on aquatic ecosystems when released into the environment.

In conclusion, while propionic acid production has historically had significant environmental impacts, ongoing advancements are driving the industry towards more sustainable practices. The shift towards bio-based production methods, coupled with improvements in process efficiency and waste management, holds promise for reducing the overall environmental footprint of this important food preservative.

Fermentation-based production methods, utilizing renewable biomass feedstocks, have emerged as a more sustainable alternative. These processes typically employ propionibacteria or other microorganisms to convert sugars or other organic compounds into propionic acid. This approach not only reduces reliance on fossil fuels but also potentially decreases greenhouse gas emissions. Studies have shown that bio-based production can lead to a 30-50% reduction in carbon footprint compared to conventional petrochemical routes.

Water usage and wastewater management are critical environmental factors in propionic acid production. Traditional methods often require significant water inputs and generate effluents that need extensive treatment. Biotechnological processes, while generally more water-efficient, still face challenges in wastewater handling. Innovative water recycling systems and advanced treatment technologies are being developed to address these issues, aiming to minimize water consumption and improve the quality of discharged effluents.

The impact on land use and biodiversity is another important consideration, particularly for bio-based production methods that rely on agricultural feedstocks. There are concerns about potential competition with food crops and the expansion of cultivated land. To mitigate these issues, research is focusing on utilizing non-food biomass sources, such as agricultural residues and waste streams, as feedstocks for propionic acid production.

Energy efficiency in production processes is a key area for environmental improvement. Both traditional and biotechnological methods are being optimized to reduce energy consumption. This includes the development of more efficient fermentation processes, improved separation and purification techniques, and the integration of renewable energy sources in production facilities.

The end-of-life fate of propionic acid and its derivatives in food products also has environmental implications. As a biodegradable compound, propionic acid generally has a lower environmental persistence compared to some synthetic preservatives. However, its widespread use necessitates a comprehensive understanding of its ecological impact, including potential effects on aquatic ecosystems when released into the environment.

In conclusion, while propionic acid production has historically had significant environmental impacts, ongoing advancements are driving the industry towards more sustainable practices. The shift towards bio-based production methods, coupled with improvements in process efficiency and waste management, holds promise for reducing the overall environmental footprint of this important food preservative.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!