Propionic Acid Energy Efficiency in Chemical Industries

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Tech Evolution and Objectives

Propionic acid has been a significant component in the chemical industry for decades, with its applications spanning from food preservatives to pharmaceuticals and polymers. The evolution of propionic acid production technology has been driven by the need for increased energy efficiency and sustainability in chemical processes.

In the early stages, propionic acid was primarily produced through petrochemical routes, such as the oxidation of propanol or the carbonylation of ethylene. These methods, while effective, were energy-intensive and relied heavily on fossil fuel feedstocks. As environmental concerns grew and energy costs increased, the industry began to shift towards more sustainable and energy-efficient production methods.

The development of bio-based production routes marked a significant milestone in propionic acid technology. Fermentation processes using propionibacteria emerged as a promising alternative, offering a renewable pathway to propionic acid production. This biological approach not only reduced dependency on petrochemical feedstocks but also presented opportunities for improved energy efficiency through process integration and waste valorization.

Recent years have seen a focus on hybrid processes that combine chemical and biological routes, aiming to leverage the strengths of both approaches. These integrated systems seek to optimize energy utilization across the entire production chain, from feedstock preparation to product purification.

The current technological landscape is characterized by a drive towards process intensification and the application of advanced control strategies. Innovations in reactor design, such as microreactors and continuous flow systems, have enabled more precise control over reaction conditions, leading to improved yields and reduced energy consumption.

Looking forward, the objectives for propionic acid technology in chemical industries are multifaceted. A primary goal is to further enhance energy efficiency throughout the production process, with a particular emphasis on reducing the energy requirements for separation and purification steps, which often account for a significant portion of the overall energy consumption.

Another key objective is the development of catalysts that can operate at lower temperatures and pressures, thereby reducing the energy input required for the chemical conversion processes. This includes exploring novel heterogeneous catalysts and biocatalysts that can facilitate more selective and energy-efficient reactions.

The integration of renewable energy sources into propionic acid production systems is also a critical target. This involves designing processes that can effectively utilize intermittent energy sources such as solar and wind power, potentially through the use of energy storage technologies or smart grid integration.

Ultimately, the overarching aim is to establish propionic acid production methods that align with the principles of green chemistry and circular economy. This entails not only improving energy efficiency but also minimizing waste generation, maximizing atom economy, and exploring opportunities for carbon capture and utilization within the production process.

In the early stages, propionic acid was primarily produced through petrochemical routes, such as the oxidation of propanol or the carbonylation of ethylene. These methods, while effective, were energy-intensive and relied heavily on fossil fuel feedstocks. As environmental concerns grew and energy costs increased, the industry began to shift towards more sustainable and energy-efficient production methods.

The development of bio-based production routes marked a significant milestone in propionic acid technology. Fermentation processes using propionibacteria emerged as a promising alternative, offering a renewable pathway to propionic acid production. This biological approach not only reduced dependency on petrochemical feedstocks but also presented opportunities for improved energy efficiency through process integration and waste valorization.

Recent years have seen a focus on hybrid processes that combine chemical and biological routes, aiming to leverage the strengths of both approaches. These integrated systems seek to optimize energy utilization across the entire production chain, from feedstock preparation to product purification.

The current technological landscape is characterized by a drive towards process intensification and the application of advanced control strategies. Innovations in reactor design, such as microreactors and continuous flow systems, have enabled more precise control over reaction conditions, leading to improved yields and reduced energy consumption.

Looking forward, the objectives for propionic acid technology in chemical industries are multifaceted. A primary goal is to further enhance energy efficiency throughout the production process, with a particular emphasis on reducing the energy requirements for separation and purification steps, which often account for a significant portion of the overall energy consumption.

Another key objective is the development of catalysts that can operate at lower temperatures and pressures, thereby reducing the energy input required for the chemical conversion processes. This includes exploring novel heterogeneous catalysts and biocatalysts that can facilitate more selective and energy-efficient reactions.

The integration of renewable energy sources into propionic acid production systems is also a critical target. This involves designing processes that can effectively utilize intermittent energy sources such as solar and wind power, potentially through the use of energy storage technologies or smart grid integration.

Ultimately, the overarching aim is to establish propionic acid production methods that align with the principles of green chemistry and circular economy. This entails not only improving energy efficiency but also minimizing waste generation, maximizing atom economy, and exploring opportunities for carbon capture and utilization within the production process.

Market Analysis for Energy-Efficient Propionic Acid

The global market for energy-efficient propionic acid production is experiencing significant growth, driven by increasing demand for sustainable chemical processes and stringent environmental regulations. Propionic acid, a versatile chemical compound used in various industries, has seen a steady rise in consumption, particularly in food preservation, animal feed, and pharmaceuticals. The market size for propionic acid was valued at approximately $1.5 billion in 2020 and is projected to reach $2.1 billion by 2025, with a compound annual growth rate (CAGR) of 6.8%.

The demand for energy-efficient production methods is particularly strong in regions with high energy costs and strict environmental policies, such as Europe and North America. These regions are leading the adoption of advanced technologies to reduce energy consumption and carbon emissions in chemical manufacturing processes. Asia-Pacific, especially China and India, is emerging as a key growth market due to rapid industrialization and increasing awareness of sustainable production practices.

Key factors driving the market for energy-efficient propionic acid include the rising costs of energy, growing environmental concerns, and the need for improved production efficiency. Industries are increasingly focusing on reducing their carbon footprint and operational costs, making energy-efficient processes a priority. The food and beverage industry, which accounts for a significant portion of propionic acid consumption, is particularly interested in sustainable production methods to meet consumer demands for eco-friendly products.

The market is also influenced by technological advancements in production processes. Innovations in catalysis, process intensification, and heat integration are creating opportunities for more energy-efficient production routes. For instance, the development of novel catalysts that operate at lower temperatures and pressures is gaining traction, as it significantly reduces energy requirements in the production process.

Regulatory pressures are another crucial factor shaping the market. Governments worldwide are implementing stricter regulations on industrial emissions and energy consumption, incentivizing companies to invest in energy-efficient technologies. This regulatory landscape is expected to continue driving the adoption of energy-efficient production methods in the propionic acid industry.

However, the market faces challenges such as high initial investment costs for upgrading existing production facilities and the technical complexities associated with implementing new energy-efficient technologies. These factors may slow down the adoption rate, particularly among small and medium-sized enterprises.

In conclusion, the market analysis indicates a strong growth potential for energy-efficient propionic acid production. The industry is poised for significant transformation as it balances increasing demand with the need for sustainable and cost-effective production methods. Companies that can successfully develop and implement energy-efficient technologies are likely to gain a competitive edge in this evolving market landscape.

The demand for energy-efficient production methods is particularly strong in regions with high energy costs and strict environmental policies, such as Europe and North America. These regions are leading the adoption of advanced technologies to reduce energy consumption and carbon emissions in chemical manufacturing processes. Asia-Pacific, especially China and India, is emerging as a key growth market due to rapid industrialization and increasing awareness of sustainable production practices.

Key factors driving the market for energy-efficient propionic acid include the rising costs of energy, growing environmental concerns, and the need for improved production efficiency. Industries are increasingly focusing on reducing their carbon footprint and operational costs, making energy-efficient processes a priority. The food and beverage industry, which accounts for a significant portion of propionic acid consumption, is particularly interested in sustainable production methods to meet consumer demands for eco-friendly products.

The market is also influenced by technological advancements in production processes. Innovations in catalysis, process intensification, and heat integration are creating opportunities for more energy-efficient production routes. For instance, the development of novel catalysts that operate at lower temperatures and pressures is gaining traction, as it significantly reduces energy requirements in the production process.

Regulatory pressures are another crucial factor shaping the market. Governments worldwide are implementing stricter regulations on industrial emissions and energy consumption, incentivizing companies to invest in energy-efficient technologies. This regulatory landscape is expected to continue driving the adoption of energy-efficient production methods in the propionic acid industry.

However, the market faces challenges such as high initial investment costs for upgrading existing production facilities and the technical complexities associated with implementing new energy-efficient technologies. These factors may slow down the adoption rate, particularly among small and medium-sized enterprises.

In conclusion, the market analysis indicates a strong growth potential for energy-efficient propionic acid production. The industry is poised for significant transformation as it balances increasing demand with the need for sustainable and cost-effective production methods. Companies that can successfully develop and implement energy-efficient technologies are likely to gain a competitive edge in this evolving market landscape.

Current Challenges in Propionic Acid Production

The production of propionic acid in chemical industries faces several significant challenges that impact its energy efficiency and overall sustainability. One of the primary issues is the high energy consumption associated with traditional production methods. The current dominant process, which involves the oxidation of propionaldehyde, requires substantial thermal energy input, leading to increased operational costs and environmental concerns.

Another challenge lies in the separation and purification stages of propionic acid production. The conventional distillation processes used to isolate and purify the acid are energy-intensive, often accounting for a large portion of the total energy consumption in the production chain. This not only affects the economic viability of the process but also contributes to its carbon footprint.

The use of fossil fuel-based feedstocks in propionic acid production presents both economic and environmental challenges. Fluctuations in petroleum prices can significantly impact production costs, while the reliance on non-renewable resources raises sustainability concerns. This dependence on fossil fuels also contributes to the overall carbon emissions associated with propionic acid manufacturing.

Catalyst efficiency remains a critical challenge in improving the energy profile of propionic acid production. Current catalytic systems often suffer from low selectivity and rapid deactivation, necessitating frequent regeneration or replacement. This not only increases energy consumption but also leads to production downtime and additional material costs.

The management of byproducts and waste streams in propionic acid production processes poses another significant challenge. Inefficient handling of these streams can result in energy losses and environmental issues. Developing more effective methods for byproduct utilization or waste stream treatment is crucial for enhancing overall process efficiency.

Scale-up challenges also persist in implementing more energy-efficient technologies for propionic acid production. Many promising lab-scale innovations struggle to maintain their efficiency and economic viability when scaled to industrial production levels. This gap between research and practical application hinders the adoption of potentially game-changing technologies in the industry.

Lastly, the integration of renewable energy sources into propionic acid production processes remains a challenge. While there is growing interest in utilizing green energy to power chemical production, the intermittent nature of many renewable sources and the high energy demands of propionic acid synthesis create obstacles in achieving a seamless and reliable integration.

Another challenge lies in the separation and purification stages of propionic acid production. The conventional distillation processes used to isolate and purify the acid are energy-intensive, often accounting for a large portion of the total energy consumption in the production chain. This not only affects the economic viability of the process but also contributes to its carbon footprint.

The use of fossil fuel-based feedstocks in propionic acid production presents both economic and environmental challenges. Fluctuations in petroleum prices can significantly impact production costs, while the reliance on non-renewable resources raises sustainability concerns. This dependence on fossil fuels also contributes to the overall carbon emissions associated with propionic acid manufacturing.

Catalyst efficiency remains a critical challenge in improving the energy profile of propionic acid production. Current catalytic systems often suffer from low selectivity and rapid deactivation, necessitating frequent regeneration or replacement. This not only increases energy consumption but also leads to production downtime and additional material costs.

The management of byproducts and waste streams in propionic acid production processes poses another significant challenge. Inefficient handling of these streams can result in energy losses and environmental issues. Developing more effective methods for byproduct utilization or waste stream treatment is crucial for enhancing overall process efficiency.

Scale-up challenges also persist in implementing more energy-efficient technologies for propionic acid production. Many promising lab-scale innovations struggle to maintain their efficiency and economic viability when scaled to industrial production levels. This gap between research and practical application hinders the adoption of potentially game-changing technologies in the industry.

Lastly, the integration of renewable energy sources into propionic acid production processes remains a challenge. While there is growing interest in utilizing green energy to power chemical production, the intermittent nature of many renewable sources and the high energy demands of propionic acid synthesis create obstacles in achieving a seamless and reliable integration.

Energy-Efficient Solutions in Propionic Acid Synthesis

01 Energy-efficient production of propionic acid

Various methods and processes have been developed to improve the energy efficiency in the production of propionic acid. These include optimized fermentation techniques, advanced catalytic processes, and innovative reactor designs that reduce energy consumption and increase yield.- Improved production methods for propionic acid: Advanced production methods for propionic acid focus on enhancing energy efficiency. These techniques may involve optimized fermentation processes, innovative catalysts, or novel reactor designs that reduce energy consumption while maintaining or improving yield.

- Energy-efficient purification and separation techniques: Developing energy-efficient purification and separation methods for propionic acid production is crucial. These may include advanced distillation techniques, membrane separation, or other novel approaches that minimize energy use in the isolation and purification stages.

- Utilization of renewable energy sources: Incorporating renewable energy sources in propionic acid production processes can significantly improve overall energy efficiency. This may involve the use of solar, wind, or biomass energy to power production facilities or specific process steps.

- Process integration and heat recovery systems: Implementing process integration techniques and heat recovery systems can enhance the energy efficiency of propionic acid production. This involves optimizing heat exchange between process streams and utilizing waste heat from one process to power another, reducing overall energy consumption.

- Continuous flow processes for energy-efficient production: Developing continuous flow processes for propionic acid production can lead to improved energy efficiency compared to batch processes. These methods allow for better control of reaction conditions, reduced energy consumption, and increased productivity.

02 Utilization of waste heat in propionic acid production

Techniques for recovering and utilizing waste heat generated during the production of propionic acid have been implemented to enhance overall energy efficiency. This includes heat integration systems and the use of heat exchangers to capture and reuse thermal energy from various process streams.Expand Specific Solutions03 Improved catalysts for energy-efficient propionic acid synthesis

Development of novel catalysts and catalyst systems that enable more energy-efficient synthesis of propionic acid. These catalysts often operate at lower temperatures or pressures, reducing the overall energy requirements of the production process.Expand Specific Solutions04 Membrane-based separation for energy-efficient purification

Implementation of membrane-based separation technologies for the purification of propionic acid, which can significantly reduce energy consumption compared to traditional distillation methods. These processes often involve pervaporation or other selective membrane techniques.Expand Specific Solutions05 Process intensification for improved energy efficiency

Application of process intensification techniques to enhance the energy efficiency of propionic acid production. This includes the use of microreactors, continuous flow processes, and integrated reaction-separation systems that minimize energy losses and improve overall process efficiency.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The propionic acid energy efficiency market in chemical industries is in a growth phase, driven by increasing demand for sustainable and cost-effective production methods. The global market size is expanding, with key players like BASF, Dow Chemical, and Eastman Chemical leading innovations. Technological maturity varies, with established companies like China Petroleum & Chemical Corp. and PetroChina Co., Ltd. focusing on large-scale production, while newer entrants such as Evonik Operations GmbH and LG Chem Ltd. are developing novel catalysts and process improvements. Research institutions like The Ohio State University and The University of Queensland are contributing to advancements in energy-efficient synthesis routes, indicating a dynamic and evolving technological landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to improve propionic acid energy efficiency in chemical industries. Their method involves a novel catalytic process that utilizes a heterogeneous catalyst system, combining metal oxides and zeolites[1]. This system enhances the selective oxidation of propane to propionic acid, significantly reducing energy consumption. The process operates at lower temperatures (around 250-300°C) compared to traditional methods, which typically require temperatures above 400°C[3]. Additionally, Sinopec has implemented advanced heat integration techniques, recovering and reusing waste heat from various stages of the production process, further improving overall energy efficiency[5].

Strengths: Lower operating temperatures, improved selectivity, and enhanced heat recovery lead to significant energy savings. Weaknesses: May require initial capital investment for catalyst development and process modification.

Evonik Operations GmbH

Technical Solution: Evonik has developed a bio-based production method for propionic acid, focusing on improving energy efficiency in chemical industries. Their approach utilizes genetically engineered microorganisms to produce propionic acid through fermentation of renewable feedstocks[2]. The process operates at near-ambient temperatures and pressures, significantly reducing energy requirements compared to traditional petrochemical routes. Evonik's method incorporates advanced bioreactor designs with optimized mixing and heat transfer capabilities, enhancing overall process efficiency[4]. Furthermore, they have implemented a novel downstream processing technique that combines membrane separation and crystallization, reducing energy consumption in the purification stage by up to 30%[6].

Strengths: Low energy input due to mild operating conditions, utilization of renewable resources, and efficient purification process. Weaknesses: Potential challenges in scaling up bioprocesses and maintaining consistent product quality.

Innovative Patents for Propionic Acid Energy Efficiency

Method for Improving Acid tolerance of Propionibacterium acdipropionici

PatentInactiveUS20140178952A1

Innovation

- Adding arginine and/or aspartic acid to the culture medium during the cultivation of Propionibacterium acdipropionici to enhance acid tolerance and propionic acid productivity.

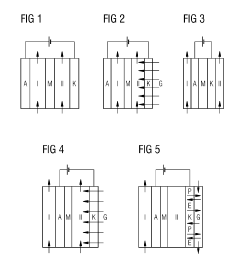

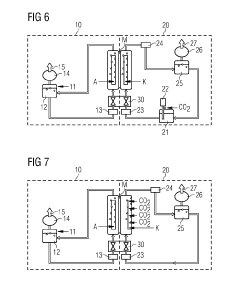

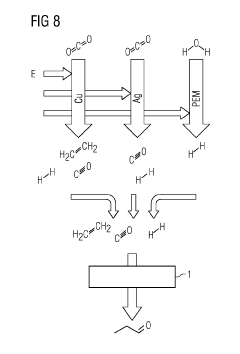

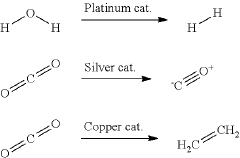

Production of Propanol, Propionaldehyde, and/or Propionic Acid From Carbon Dioxide, Water, and Electrical Energy

PatentInactiveUS20190249317A1

Innovation

- A process involving the electrolysis of CO2 to produce CO and C2H4, followed by reaction with H2 to form propanol and/or propionaldehyde, or with H2O to form propionic acid, utilizing waste heat from electrolyzers and specific cathodes like copper, silver, and gold to enhance efficiency and minimize stages.

Environmental Impact and Sustainability Considerations

The production and use of propionic acid in chemical industries have significant environmental implications and sustainability considerations. As industries strive for energy efficiency, it is crucial to assess the environmental impact of propionic acid production and explore sustainable alternatives.

One of the primary environmental concerns associated with propionic acid production is greenhouse gas emissions. Traditional manufacturing processes often rely on fossil fuel-based feedstocks and energy-intensive reactions, contributing to carbon dioxide emissions. To address this issue, researchers are exploring bio-based production methods using renewable resources, such as biomass fermentation. These alternative approaches have the potential to reduce the carbon footprint of propionic acid production significantly.

Water consumption and wastewater generation are also important environmental factors to consider. Conventional production methods may require substantial amounts of water for cooling and separation processes, leading to increased water stress in water-scarce regions. Additionally, the discharge of untreated or inadequately treated wastewater can result in water pollution and ecosystem disruption. Implementing water recycling systems and advanced wastewater treatment technologies can help mitigate these impacts and improve overall water efficiency.

The use of hazardous chemicals in propionic acid production poses risks to both human health and the environment. Proper handling, storage, and disposal of these substances are essential to prevent accidental releases and minimize potential contamination. Developing safer alternatives and implementing green chemistry principles can contribute to reducing the environmental and health risks associated with propionic acid production.

Energy efficiency improvements in propionic acid production can lead to significant environmental benefits. Optimizing reaction conditions, implementing heat recovery systems, and utilizing more efficient catalysts can reduce energy consumption and associated emissions. Furthermore, the integration of renewable energy sources, such as solar or wind power, into production facilities can further decrease the reliance on fossil fuels and enhance sustainability.

Life cycle assessment (LCA) studies are valuable tools for evaluating the overall environmental impact of propionic acid production. These assessments consider the entire product lifecycle, from raw material extraction to end-of-life disposal, providing a comprehensive understanding of the environmental footprint. LCA results can guide decision-making processes and help identify areas for improvement in terms of sustainability.

As the chemical industry moves towards circular economy principles, exploring opportunities for recycling and reusing propionic acid becomes increasingly important. Developing efficient recovery and purification techniques can minimize waste generation and reduce the demand for virgin raw materials. Additionally, investigating potential applications for by-products and waste streams can create value-added products and improve overall resource efficiency.

One of the primary environmental concerns associated with propionic acid production is greenhouse gas emissions. Traditional manufacturing processes often rely on fossil fuel-based feedstocks and energy-intensive reactions, contributing to carbon dioxide emissions. To address this issue, researchers are exploring bio-based production methods using renewable resources, such as biomass fermentation. These alternative approaches have the potential to reduce the carbon footprint of propionic acid production significantly.

Water consumption and wastewater generation are also important environmental factors to consider. Conventional production methods may require substantial amounts of water for cooling and separation processes, leading to increased water stress in water-scarce regions. Additionally, the discharge of untreated or inadequately treated wastewater can result in water pollution and ecosystem disruption. Implementing water recycling systems and advanced wastewater treatment technologies can help mitigate these impacts and improve overall water efficiency.

The use of hazardous chemicals in propionic acid production poses risks to both human health and the environment. Proper handling, storage, and disposal of these substances are essential to prevent accidental releases and minimize potential contamination. Developing safer alternatives and implementing green chemistry principles can contribute to reducing the environmental and health risks associated with propionic acid production.

Energy efficiency improvements in propionic acid production can lead to significant environmental benefits. Optimizing reaction conditions, implementing heat recovery systems, and utilizing more efficient catalysts can reduce energy consumption and associated emissions. Furthermore, the integration of renewable energy sources, such as solar or wind power, into production facilities can further decrease the reliance on fossil fuels and enhance sustainability.

Life cycle assessment (LCA) studies are valuable tools for evaluating the overall environmental impact of propionic acid production. These assessments consider the entire product lifecycle, from raw material extraction to end-of-life disposal, providing a comprehensive understanding of the environmental footprint. LCA results can guide decision-making processes and help identify areas for improvement in terms of sustainability.

As the chemical industry moves towards circular economy principles, exploring opportunities for recycling and reusing propionic acid becomes increasingly important. Developing efficient recovery and purification techniques can minimize waste generation and reduce the demand for virgin raw materials. Additionally, investigating potential applications for by-products and waste streams can create value-added products and improve overall resource efficiency.

Regulatory Framework for Chemical Process Efficiency

The regulatory framework for chemical process efficiency plays a crucial role in shaping the energy efficiency landscape for propionic acid production in chemical industries. Governments and international organizations have implemented various policies and standards to promote sustainable practices and reduce environmental impact.

At the global level, the Paris Agreement serves as a cornerstone for climate action, encouraging nations to set ambitious targets for reducing greenhouse gas emissions. This agreement has led to the development of more stringent regulations on energy consumption and efficiency in industrial processes, including propionic acid production.

In the European Union, the Industrial Emissions Directive (IED) sets strict limits on emissions from chemical plants and mandates the use of Best Available Techniques (BAT) to ensure optimal energy efficiency. The EU Emissions Trading System (ETS) further incentivizes companies to reduce their carbon footprint by putting a price on carbon emissions.

The United States Environmental Protection Agency (EPA) has established the Energy Star program, which provides guidelines and certifications for energy-efficient industrial processes. Additionally, the Department of Energy's Better Plants program offers resources and technical assistance to help manufacturers improve their energy efficiency.

In China, the Energy Conservation Law and the Cleaner Production Promotion Law form the basis for energy efficiency regulations in the chemical industry. These laws set targets for energy consumption reduction and promote the adoption of cleaner production technologies.

International standards such as ISO 50001 for Energy Management Systems provide a framework for organizations to continuously improve their energy performance. Many countries have incorporated these standards into their national regulations, creating a more harmonized approach to energy efficiency.

Specific to propionic acid production, regulatory bodies often require companies to conduct regular energy audits and implement energy management plans. These regulations may include mandatory reporting of energy consumption data and the setting of industry-specific benchmarks for energy efficiency.

Financial incentives and tax breaks are frequently used by governments to encourage investment in energy-efficient technologies. For instance, accelerated depreciation schemes for energy-efficient equipment or grants for research and development of novel energy-saving processes in propionic acid production.

As the global focus on sustainability intensifies, regulatory frameworks are evolving to include more comprehensive life cycle assessments of chemical processes. This holistic approach considers the energy efficiency of the entire production chain, from raw material extraction to end-of-life disposal or recycling of propionic acid products.

At the global level, the Paris Agreement serves as a cornerstone for climate action, encouraging nations to set ambitious targets for reducing greenhouse gas emissions. This agreement has led to the development of more stringent regulations on energy consumption and efficiency in industrial processes, including propionic acid production.

In the European Union, the Industrial Emissions Directive (IED) sets strict limits on emissions from chemical plants and mandates the use of Best Available Techniques (BAT) to ensure optimal energy efficiency. The EU Emissions Trading System (ETS) further incentivizes companies to reduce their carbon footprint by putting a price on carbon emissions.

The United States Environmental Protection Agency (EPA) has established the Energy Star program, which provides guidelines and certifications for energy-efficient industrial processes. Additionally, the Department of Energy's Better Plants program offers resources and technical assistance to help manufacturers improve their energy efficiency.

In China, the Energy Conservation Law and the Cleaner Production Promotion Law form the basis for energy efficiency regulations in the chemical industry. These laws set targets for energy consumption reduction and promote the adoption of cleaner production technologies.

International standards such as ISO 50001 for Energy Management Systems provide a framework for organizations to continuously improve their energy performance. Many countries have incorporated these standards into their national regulations, creating a more harmonized approach to energy efficiency.

Specific to propionic acid production, regulatory bodies often require companies to conduct regular energy audits and implement energy management plans. These regulations may include mandatory reporting of energy consumption data and the setting of industry-specific benchmarks for energy efficiency.

Financial incentives and tax breaks are frequently used by governments to encourage investment in energy-efficient technologies. For instance, accelerated depreciation schemes for energy-efficient equipment or grants for research and development of novel energy-saving processes in propionic acid production.

As the global focus on sustainability intensifies, regulatory frameworks are evolving to include more comprehensive life cycle assessments of chemical processes. This holistic approach considers the energy efficiency of the entire production chain, from raw material extraction to end-of-life disposal or recycling of propionic acid products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!