Propionic Acid in Biomaterials: Latest Research Endeavors

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Biomaterials: Background and Objectives

Propionic acid has emerged as a significant player in the field of biomaterials, attracting increasing attention from researchers and industry professionals alike. This organic compound, naturally occurring in various biological processes, has demonstrated remarkable potential for diverse applications in biomaterials science. The journey of propionic acid in this domain traces back to its initial recognition as a metabolic byproduct, evolving into a versatile component in biomaterial development.

The evolution of propionic acid's role in biomaterials has been driven by the growing demand for sustainable and biocompatible materials across multiple sectors, including medicine, agriculture, and environmental science. As global concerns about environmental sustainability and biocompatibility continue to rise, propionic acid has positioned itself as a promising candidate for addressing these challenges. Its natural origin and biodegradability align well with the principles of green chemistry and circular economy, making it an attractive option for researchers and manufacturers alike.

Recent years have witnessed a surge in research activities focused on harnessing the unique properties of propionic acid for biomaterial applications. Scientists have been exploring its potential in areas such as drug delivery systems, tissue engineering scaffolds, and antimicrobial coatings. The compound's ability to modulate material properties, enhance biocompatibility, and impart specific functionalities has opened up new avenues for innovation in biomaterials design.

The primary objectives of current research endeavors in propionic acid biomaterials are multifaceted. Researchers aim to develop novel biomaterials with enhanced performance characteristics, leveraging the unique chemical and biological properties of propionic acid. This includes improving the mechanical strength, degradation profiles, and bioactivity of materials for specific applications. Additionally, there is a strong focus on optimizing the synthesis and processing methods to ensure scalability and cost-effectiveness, crucial factors for commercial viability.

Another key objective is to elucidate the underlying mechanisms of propionic acid's interactions with biological systems. Understanding these interactions at the molecular and cellular levels is essential for designing safer and more effective biomaterials. Researchers are also exploring the potential synergies between propionic acid and other biomolecules or synthetic compounds to create hybrid materials with superior properties.

As the field progresses, there is an increasing emphasis on translational research, aiming to bridge the gap between laboratory discoveries and practical applications. This involves addressing challenges related to regulatory compliance, manufacturing scalability, and clinical validation of propionic acid-based biomaterials. The ultimate goal is to develop innovative biomaterial solutions that can address unmet needs in healthcare, environmental remediation, and sustainable manufacturing.

The evolution of propionic acid's role in biomaterials has been driven by the growing demand for sustainable and biocompatible materials across multiple sectors, including medicine, agriculture, and environmental science. As global concerns about environmental sustainability and biocompatibility continue to rise, propionic acid has positioned itself as a promising candidate for addressing these challenges. Its natural origin and biodegradability align well with the principles of green chemistry and circular economy, making it an attractive option for researchers and manufacturers alike.

Recent years have witnessed a surge in research activities focused on harnessing the unique properties of propionic acid for biomaterial applications. Scientists have been exploring its potential in areas such as drug delivery systems, tissue engineering scaffolds, and antimicrobial coatings. The compound's ability to modulate material properties, enhance biocompatibility, and impart specific functionalities has opened up new avenues for innovation in biomaterials design.

The primary objectives of current research endeavors in propionic acid biomaterials are multifaceted. Researchers aim to develop novel biomaterials with enhanced performance characteristics, leveraging the unique chemical and biological properties of propionic acid. This includes improving the mechanical strength, degradation profiles, and bioactivity of materials for specific applications. Additionally, there is a strong focus on optimizing the synthesis and processing methods to ensure scalability and cost-effectiveness, crucial factors for commercial viability.

Another key objective is to elucidate the underlying mechanisms of propionic acid's interactions with biological systems. Understanding these interactions at the molecular and cellular levels is essential for designing safer and more effective biomaterials. Researchers are also exploring the potential synergies between propionic acid and other biomolecules or synthetic compounds to create hybrid materials with superior properties.

As the field progresses, there is an increasing emphasis on translational research, aiming to bridge the gap between laboratory discoveries and practical applications. This involves addressing challenges related to regulatory compliance, manufacturing scalability, and clinical validation of propionic acid-based biomaterials. The ultimate goal is to develop innovative biomaterial solutions that can address unmet needs in healthcare, environmental remediation, and sustainable manufacturing.

Market Analysis for Propionic Acid-Based Biomaterials

The market for propionic acid-based biomaterials is experiencing significant growth, driven by increasing demand for sustainable and eco-friendly alternatives in various industries. This market segment is particularly gaining traction in sectors such as packaging, agriculture, and healthcare, where biodegradable and biocompatible materials are highly sought after.

In the packaging industry, propionic acid-based biomaterials are emerging as a viable solution to address the growing concerns over plastic pollution. These materials offer comparable performance to traditional plastics while being biodegradable, making them an attractive option for environmentally conscious consumers and businesses. The food packaging sector, in particular, is showing keen interest in these materials due to their antimicrobial properties, which can help extend the shelf life of products.

The agriculture sector is another key market for propionic acid-based biomaterials. These materials are being utilized in the development of controlled-release fertilizers and pesticides, offering more efficient and environmentally friendly alternatives to conventional products. The ability of these biomaterials to degrade naturally in soil without leaving harmful residues is a significant advantage, aligning with the global push towards sustainable farming practices.

In the healthcare industry, propionic acid-based biomaterials are finding applications in wound dressings, drug delivery systems, and tissue engineering scaffolds. The biocompatibility and antimicrobial properties of these materials make them particularly suitable for medical applications. The growing emphasis on personalized medicine and regenerative therapies is expected to further drive demand in this sector.

Market analysts project a compound annual growth rate (CAGR) for propionic acid-based biomaterials that outpaces many traditional materials. This growth is attributed to increasing environmental regulations, consumer awareness, and corporate sustainability initiatives. However, challenges such as higher production costs compared to conventional materials and the need for further research to improve material properties remain.

The market landscape is characterized by a mix of established chemical companies diversifying into biomaterials and innovative startups focusing exclusively on sustainable solutions. Collaborations between industry players and research institutions are becoming more common, accelerating the development and commercialization of new propionic acid-based biomaterials.

Geographically, North America and Europe are currently leading the market, with stringent environmental regulations and high consumer awareness driving adoption. However, Asia-Pacific is expected to emerge as a significant market in the coming years, fueled by rapid industrialization, growing environmental concerns, and supportive government policies promoting sustainable materials.

In the packaging industry, propionic acid-based biomaterials are emerging as a viable solution to address the growing concerns over plastic pollution. These materials offer comparable performance to traditional plastics while being biodegradable, making them an attractive option for environmentally conscious consumers and businesses. The food packaging sector, in particular, is showing keen interest in these materials due to their antimicrobial properties, which can help extend the shelf life of products.

The agriculture sector is another key market for propionic acid-based biomaterials. These materials are being utilized in the development of controlled-release fertilizers and pesticides, offering more efficient and environmentally friendly alternatives to conventional products. The ability of these biomaterials to degrade naturally in soil without leaving harmful residues is a significant advantage, aligning with the global push towards sustainable farming practices.

In the healthcare industry, propionic acid-based biomaterials are finding applications in wound dressings, drug delivery systems, and tissue engineering scaffolds. The biocompatibility and antimicrobial properties of these materials make them particularly suitable for medical applications. The growing emphasis on personalized medicine and regenerative therapies is expected to further drive demand in this sector.

Market analysts project a compound annual growth rate (CAGR) for propionic acid-based biomaterials that outpaces many traditional materials. This growth is attributed to increasing environmental regulations, consumer awareness, and corporate sustainability initiatives. However, challenges such as higher production costs compared to conventional materials and the need for further research to improve material properties remain.

The market landscape is characterized by a mix of established chemical companies diversifying into biomaterials and innovative startups focusing exclusively on sustainable solutions. Collaborations between industry players and research institutions are becoming more common, accelerating the development and commercialization of new propionic acid-based biomaterials.

Geographically, North America and Europe are currently leading the market, with stringent environmental regulations and high consumer awareness driving adoption. However, Asia-Pacific is expected to emerge as a significant market in the coming years, fueled by rapid industrialization, growing environmental concerns, and supportive government policies promoting sustainable materials.

Current Challenges in Propionic Acid Biomaterial Research

Despite significant advancements in propionic acid biomaterial research, several challenges persist, hindering the full realization of its potential in various applications. One of the primary obstacles is the high production cost of propionic acid from renewable resources. Current bioprocesses often yield low concentrations and productivity, making it economically unviable for large-scale production. This necessitates the development of more efficient fermentation processes and the engineering of robust microbial strains capable of withstanding higher acid concentrations.

Another significant challenge lies in the purification and recovery of propionic acid from fermentation broths. Traditional separation methods, such as distillation and liquid-liquid extraction, are energy-intensive and often result in product loss. Innovative separation technologies, such as membrane-based processes or in situ product recovery systems, need to be optimized to enhance the overall efficiency and reduce operational costs.

The incorporation of propionic acid into biomaterials presents its own set of challenges. The acid's corrosive nature can lead to degradation of certain materials, limiting its use in specific applications. Researchers are working on developing novel formulations and composite materials that can withstand the acidic environment while maintaining desired properties. Additionally, ensuring the controlled release of propionic acid from biomaterials for antimicrobial or preservation purposes remains a complex task, requiring advanced encapsulation techniques and smart delivery systems.

Scalability and reproducibility of propionic acid-based biomaterials pose another hurdle. Laboratory-scale successes often face difficulties when translated to industrial production. Maintaining consistent quality, properties, and performance of these materials at larger scales requires extensive process optimization and quality control measures.

Environmental concerns and sustainability issues also present challenges in propionic acid biomaterial research. While propionic acid itself is biodegradable, the production processes and some of its derivatives may have environmental impacts. Developing greener synthesis routes, minimizing waste generation, and ensuring the complete biodegradability of final products are crucial areas that need attention.

Regulatory hurdles and safety assessments for novel propionic acid-based biomaterials, especially in medical and food-related applications, can be time-consuming and costly. Researchers must navigate complex regulatory frameworks and provide comprehensive safety data to gain approval for commercial use.

Lastly, the limited understanding of the long-term effects and potential toxicity of propionic acid and its derivatives in certain biomaterial applications necessitates further in-depth studies. This is particularly crucial for biomedical applications where the materials interact directly with biological systems over extended periods.

Another significant challenge lies in the purification and recovery of propionic acid from fermentation broths. Traditional separation methods, such as distillation and liquid-liquid extraction, are energy-intensive and often result in product loss. Innovative separation technologies, such as membrane-based processes or in situ product recovery systems, need to be optimized to enhance the overall efficiency and reduce operational costs.

The incorporation of propionic acid into biomaterials presents its own set of challenges. The acid's corrosive nature can lead to degradation of certain materials, limiting its use in specific applications. Researchers are working on developing novel formulations and composite materials that can withstand the acidic environment while maintaining desired properties. Additionally, ensuring the controlled release of propionic acid from biomaterials for antimicrobial or preservation purposes remains a complex task, requiring advanced encapsulation techniques and smart delivery systems.

Scalability and reproducibility of propionic acid-based biomaterials pose another hurdle. Laboratory-scale successes often face difficulties when translated to industrial production. Maintaining consistent quality, properties, and performance of these materials at larger scales requires extensive process optimization and quality control measures.

Environmental concerns and sustainability issues also present challenges in propionic acid biomaterial research. While propionic acid itself is biodegradable, the production processes and some of its derivatives may have environmental impacts. Developing greener synthesis routes, minimizing waste generation, and ensuring the complete biodegradability of final products are crucial areas that need attention.

Regulatory hurdles and safety assessments for novel propionic acid-based biomaterials, especially in medical and food-related applications, can be time-consuming and costly. Researchers must navigate complex regulatory frameworks and provide comprehensive safety data to gain approval for commercial use.

Lastly, the limited understanding of the long-term effects and potential toxicity of propionic acid and its derivatives in certain biomaterial applications necessitates further in-depth studies. This is particularly crucial for biomedical applications where the materials interact directly with biological systems over extended periods.

Current Propionic Acid Biomaterial Solutions

01 Production methods of propionic acid

Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis routes, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.- Production methods of propionic acid: Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis routes, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.

- Applications of propionic acid in food preservation: Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective against molds and some bacteria, extending the shelf life of various food products, particularly in bakery items and dairy products.

- Use of propionic acid in pharmaceutical formulations: Propionic acid and its derivatives find applications in pharmaceutical formulations. They are used as excipients, pH adjusters, and in some cases, as active pharmaceutical ingredients for various therapeutic purposes.

- Propionic acid in polymer and chemical synthesis: Propionic acid serves as a precursor or intermediate in the synthesis of various polymers and chemicals. It is used in the production of cellulose plastics, perfumes, and other industrial chemicals, contributing to the development of new materials and compounds.

- Environmental and safety considerations in propionic acid handling: The handling, storage, and disposal of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Innovations in this area focus on developing safer handling methods, reducing environmental risks, and improving workplace safety in industries using propionic acid.

02 Applications of propionic acid in food preservation

Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective against molds and bacteria, extending the shelf life of various food products, particularly in bakery goods and dairy products.Expand Specific Solutions03 Use of propionic acid in pharmaceutical formulations

Propionic acid and its derivatives are utilized in pharmaceutical formulations for various purposes, including as active ingredients, excipients, or pH adjusters. They may be incorporated into topical, oral, or injectable medications.Expand Specific Solutions04 Propionic acid in polymer and plastic industries

Propionic acid serves as a precursor or additive in the production of various polymers and plastics. It can be used in the synthesis of cellulose-based plastics, as a plasticizer, or as a component in polymer coatings and adhesives.Expand Specific Solutions05 Environmental and agricultural applications of propionic acid

Propionic acid finds applications in environmental and agricultural sectors, including use as a herbicide, soil treatment agent, and in the production of biodegradable materials. It also plays a role in animal feed preservation and as a growth promoter in livestock.Expand Specific Solutions

Key Players in Propionic Acid Biomaterial Industry

The research on propionic acid in biomaterials is currently in an emerging phase, with growing interest from both academia and industry. The market for this technology is expanding, driven by the increasing demand for sustainable and bio-based materials. While the market size is still relatively small, it shows significant potential for growth. The technology's maturity is progressing, with key players like Nanjing Tech University, Chongqing University of Technology, and Jiangnan University leading academic research. Companies such as Arkema France SA, Evonik Operations GmbH, and LG Chem Ltd. are actively involved in industrial applications, indicating a transition from laboratory-scale to commercial development. This competitive landscape suggests a dynamic field with opportunities for innovation and market expansion.

Arkema France SA

Technical Solution: Arkema France SA has developed a novel approach for incorporating propionic acid into biomaterials, focusing on biodegradable polymers. Their research involves the synthesis of propionic acid-based monomers that can be polymerized to form environmentally friendly materials with enhanced properties. The company has successfully created a range of propionic acid-modified polylactic acid (PLA) composites, which exhibit improved thermal stability and mechanical strength compared to conventional PLA [1]. These materials show potential for applications in packaging, medical devices, and agricultural films. Arkema's process also includes the development of catalysts that enable efficient polymerization of propionic acid-derived monomers, resulting in high-molecular-weight polymers with controlled architectures [3].

Strengths: Improved material properties, wide range of applications, and environmentally friendly. Weaknesses: Potentially higher production costs and limited scalability of the process.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has made significant strides in utilizing propionic acid for biomaterial production, particularly in the field of resorbable implants. Their research focuses on developing propionic acid-based copolymers that offer controlled degradation rates and improved biocompatibility. Evonik has successfully created a series of propionic acid-modified poly(lactide-co-glycolide) (PLGA) materials that demonstrate enhanced cell adhesion and proliferation properties [2]. These materials have shown promise in tissue engineering applications, particularly for bone and cartilage regeneration. The company has also developed a proprietary process for incorporating propionic acid into their RESOMER® line of bioresorbable polymers, which allows for fine-tuning of material properties such as degradation rate and mechanical strength [4].

Strengths: Tailored degradation rates, improved biocompatibility, and established product line. Weaknesses: Limited to medical applications and potential regulatory hurdles.

Innovative Propionic Acid Biomaterial Technologies

Improved propionibacterium strains for the production of propionic acid

PatentWO2017055932A2

Innovation

- Genome shuffling between selected Propionibacterium strains, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, to generate novel strains with enhanced growth rates and propionic acid production, utilizing genetic material exchange to create strains with improved metabolic pathways and regulatory mechanisms.

Bioproduction of Propionic Acid from Levulinic Acid by Utilizing Recombinant Pseudomonas putida

PatentInactiveKR1020240029628A

Innovation

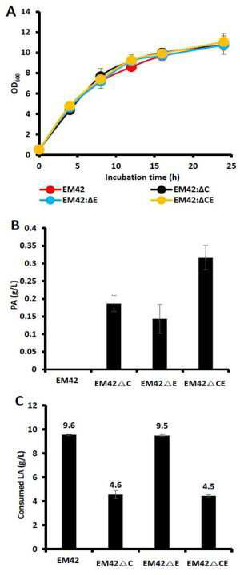

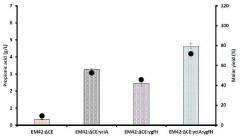

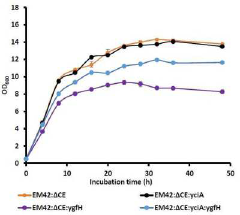

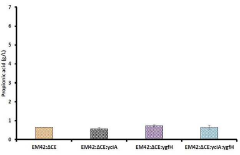

- A transgenic Pseudomonas putida strain is developed by deleting prpC and prpE genes and expressing yciA and ygfH genes, utilizing levulinic acid as a substrate to enhance propionic acid production through a levulinic acid-inducible expression system, optimizing the metabolic pathway to improve titer and yield.

Environmental Impact of Propionic Acid Biomaterials

The environmental impact of propionic acid biomaterials has garnered significant attention in recent years due to the growing emphasis on sustainable and eco-friendly alternatives to traditional petroleum-based materials. Propionic acid, a naturally occurring carboxylic acid, has shown promise in various biomaterial applications, offering potential environmental benefits over conventional materials.

One of the primary environmental advantages of propionic acid biomaterials is their biodegradability. Unlike many synthetic polymers that persist in the environment for extended periods, propionic acid-based materials can be broken down by natural processes, reducing long-term environmental accumulation. This characteristic is particularly valuable in applications such as packaging, where single-use plastics have become a major environmental concern.

The production of propionic acid biomaterials also presents opportunities for reduced carbon footprint compared to traditional petrochemical-based materials. When derived from renewable resources, such as biomass or agricultural waste, propionic acid production can contribute to a circular economy model, minimizing reliance on fossil fuels and potentially lowering greenhouse gas emissions associated with material manufacturing.

However, it is essential to consider the entire life cycle of propionic acid biomaterials when assessing their environmental impact. While the end-of-life phase may show improvements in terms of biodegradability, the production process and resource requirements must be carefully evaluated. Factors such as land use, water consumption, and energy requirements for biomass cultivation and processing can influence the overall environmental profile of these materials.

Recent research has focused on optimizing the production methods for propionic acid biomaterials to enhance their environmental performance. Efforts have been made to develop more efficient fermentation processes, utilizing waste streams as feedstocks, and improving the yield and purity of propionic acid production. These advancements aim to reduce the environmental footprint associated with the manufacturing stage.

The potential for propionic acid biomaterials to replace or complement existing materials in various applications also contributes to their environmental impact assessment. In sectors such as food packaging, medical devices, and agricultural products, the adoption of these biomaterials could lead to reduced environmental pollution and improved waste management practices.

Nevertheless, challenges remain in fully realizing the environmental benefits of propionic acid biomaterials. Issues such as scalability, cost-effectiveness, and performance characteristics compared to traditional materials need to be addressed to ensure widespread adoption and meaningful environmental impact. Additionally, the development of appropriate end-of-life management systems, including composting and recycling infrastructure, is crucial to maximize the environmental advantages of these materials.

One of the primary environmental advantages of propionic acid biomaterials is their biodegradability. Unlike many synthetic polymers that persist in the environment for extended periods, propionic acid-based materials can be broken down by natural processes, reducing long-term environmental accumulation. This characteristic is particularly valuable in applications such as packaging, where single-use plastics have become a major environmental concern.

The production of propionic acid biomaterials also presents opportunities for reduced carbon footprint compared to traditional petrochemical-based materials. When derived from renewable resources, such as biomass or agricultural waste, propionic acid production can contribute to a circular economy model, minimizing reliance on fossil fuels and potentially lowering greenhouse gas emissions associated with material manufacturing.

However, it is essential to consider the entire life cycle of propionic acid biomaterials when assessing their environmental impact. While the end-of-life phase may show improvements in terms of biodegradability, the production process and resource requirements must be carefully evaluated. Factors such as land use, water consumption, and energy requirements for biomass cultivation and processing can influence the overall environmental profile of these materials.

Recent research has focused on optimizing the production methods for propionic acid biomaterials to enhance their environmental performance. Efforts have been made to develop more efficient fermentation processes, utilizing waste streams as feedstocks, and improving the yield and purity of propionic acid production. These advancements aim to reduce the environmental footprint associated with the manufacturing stage.

The potential for propionic acid biomaterials to replace or complement existing materials in various applications also contributes to their environmental impact assessment. In sectors such as food packaging, medical devices, and agricultural products, the adoption of these biomaterials could lead to reduced environmental pollution and improved waste management practices.

Nevertheless, challenges remain in fully realizing the environmental benefits of propionic acid biomaterials. Issues such as scalability, cost-effectiveness, and performance characteristics compared to traditional materials need to be addressed to ensure widespread adoption and meaningful environmental impact. Additionally, the development of appropriate end-of-life management systems, including composting and recycling infrastructure, is crucial to maximize the environmental advantages of these materials.

Regulatory Framework for Biomaterial Applications

The regulatory framework for biomaterial applications involving propionic acid is a complex and evolving landscape. As the use of propionic acid in biomaterials continues to expand, regulatory bodies worldwide are adapting their guidelines to ensure safety, efficacy, and quality control.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biomaterials containing propionic acid. The FDA's Center for Devices and Radiological Health (CDRH) oversees medical devices incorporating these biomaterials, while the Center for Drug Evaluation and Research (CDER) regulates drug-related applications. The regulatory pathway depends on the intended use and classification of the biomaterial product.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations have significant implications for biomaterials containing propionic acid, particularly in terms of clinical evidence requirements and post-market surveillance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates biomaterials under the Pharmaceutical and Medical Device Act. The PMDA has specific guidelines for the evaluation of biomaterials, including those containing propionic acid, with a focus on biocompatibility and long-term safety.

International standards, such as those developed by the International Organization for Standardization (ISO), play a crucial role in harmonizing regulatory approaches across different regions. ISO 10993 series, which addresses the biological evaluation of medical devices, is particularly relevant for biomaterials containing propionic acid.

Regulatory bodies are increasingly focusing on the sustainability and environmental impact of biomaterials. This trend is likely to influence future regulations concerning propionic acid-based biomaterials, particularly in terms of biodegradability and eco-toxicity assessments.

As research in propionic acid biomaterials advances, regulators are adapting to new applications and potential risks. There is a growing emphasis on personalized medicine and 3D-printed biomaterials, which may lead to more tailored regulatory approaches for propionic acid-containing products.

Manufacturers and researchers working with propionic acid in biomaterials must navigate this complex regulatory landscape. Compliance with Good Manufacturing Practices (GMP) and Quality Management Systems (QMS) is essential, as is ongoing communication with regulatory bodies throughout the product development lifecycle.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biomaterials containing propionic acid. The FDA's Center for Devices and Radiological Health (CDRH) oversees medical devices incorporating these biomaterials, while the Center for Drug Evaluation and Research (CDER) regulates drug-related applications. The regulatory pathway depends on the intended use and classification of the biomaterial product.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations have significant implications for biomaterials containing propionic acid, particularly in terms of clinical evidence requirements and post-market surveillance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates biomaterials under the Pharmaceutical and Medical Device Act. The PMDA has specific guidelines for the evaluation of biomaterials, including those containing propionic acid, with a focus on biocompatibility and long-term safety.

International standards, such as those developed by the International Organization for Standardization (ISO), play a crucial role in harmonizing regulatory approaches across different regions. ISO 10993 series, which addresses the biological evaluation of medical devices, is particularly relevant for biomaterials containing propionic acid.

Regulatory bodies are increasingly focusing on the sustainability and environmental impact of biomaterials. This trend is likely to influence future regulations concerning propionic acid-based biomaterials, particularly in terms of biodegradability and eco-toxicity assessments.

As research in propionic acid biomaterials advances, regulators are adapting to new applications and potential risks. There is a growing emphasis on personalized medicine and 3D-printed biomaterials, which may lead to more tailored regulatory approaches for propionic acid-containing products.

Manufacturers and researchers working with propionic acid in biomaterials must navigate this complex regulatory landscape. Compliance with Good Manufacturing Practices (GMP) and Quality Management Systems (QMS) is essential, as is ongoing communication with regulatory bodies throughout the product development lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!