Propionic Acid in Biotechnology: Current & Emerging Applications

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Biotech Evolution and Objectives

Propionic acid has emerged as a versatile compound in biotechnology, with its applications evolving significantly over the past decades. Initially recognized for its antimicrobial properties, propionic acid's role in biotechnology has expanded to encompass a wide range of industries, including food preservation, pharmaceuticals, and sustainable chemical production.

The evolution of propionic acid in biotechnology can be traced back to its discovery in the mid-19th century. Early applications focused primarily on its use as a food preservative, particularly in baked goods and dairy products. As research progressed, scientists began to uncover the potential of propionic acid in various biotechnological processes.

In recent years, the biotechnological applications of propionic acid have experienced rapid growth, driven by advancements in fermentation technologies and the increasing demand for sustainable alternatives to petrochemical-derived products. The development of more efficient microbial strains and improved bioprocessing techniques has led to enhanced production capabilities and expanded applications.

One of the key objectives in propionic acid biotechnology is to optimize its production through fermentation processes. Researchers are focusing on developing high-yield microbial strains, improving fermentation conditions, and enhancing downstream processing to increase productivity and reduce costs. This effort aims to make bio-based propionic acid more competitive with its petrochemical counterpart.

Another important goal is to explore novel applications of propionic acid in emerging fields such as bioplastics, biofuels, and green solvents. The potential of propionic acid as a platform chemical for the synthesis of various value-added products is being actively investigated, with the aim of creating new markets and reducing reliance on fossil-based resources.

Environmental sustainability is a crucial objective in the evolution of propionic acid biotechnology. Efforts are underway to develop more eco-friendly production processes, reduce energy consumption, and minimize waste generation. This aligns with the broader trend towards green chemistry and sustainable manufacturing practices in the biotechnology sector.

As the field continues to advance, researchers are also exploring the integration of propionic acid production with other bioprocesses, such as waste valorization and biorefinery concepts. This holistic approach aims to create synergies between different biotechnological processes, maximizing resource utilization and economic viability.

The evolution of propionic acid in biotechnology can be traced back to its discovery in the mid-19th century. Early applications focused primarily on its use as a food preservative, particularly in baked goods and dairy products. As research progressed, scientists began to uncover the potential of propionic acid in various biotechnological processes.

In recent years, the biotechnological applications of propionic acid have experienced rapid growth, driven by advancements in fermentation technologies and the increasing demand for sustainable alternatives to petrochemical-derived products. The development of more efficient microbial strains and improved bioprocessing techniques has led to enhanced production capabilities and expanded applications.

One of the key objectives in propionic acid biotechnology is to optimize its production through fermentation processes. Researchers are focusing on developing high-yield microbial strains, improving fermentation conditions, and enhancing downstream processing to increase productivity and reduce costs. This effort aims to make bio-based propionic acid more competitive with its petrochemical counterpart.

Another important goal is to explore novel applications of propionic acid in emerging fields such as bioplastics, biofuels, and green solvents. The potential of propionic acid as a platform chemical for the synthesis of various value-added products is being actively investigated, with the aim of creating new markets and reducing reliance on fossil-based resources.

Environmental sustainability is a crucial objective in the evolution of propionic acid biotechnology. Efforts are underway to develop more eco-friendly production processes, reduce energy consumption, and minimize waste generation. This aligns with the broader trend towards green chemistry and sustainable manufacturing practices in the biotechnology sector.

As the field continues to advance, researchers are also exploring the integration of propionic acid production with other bioprocesses, such as waste valorization and biorefinery concepts. This holistic approach aims to create synergies between different biotechnological processes, maximizing resource utilization and economic viability.

Market Analysis for Propionic Acid in Biotechnology

The global market for propionic acid in biotechnology applications has been experiencing steady growth, driven by increasing demand in various sectors such as food and feed preservation, pharmaceuticals, and cosmetics. The market size for propionic acid in biotechnology was valued at approximately $1.3 billion in 2020 and is projected to reach $1.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.7% during the forecast period.

The food and feed preservation segment dominates the market, accounting for over 60% of the total market share. This is primarily due to the rising demand for natural preservatives in the food industry and the growing awareness of food safety among consumers. Propionic acid's effectiveness in inhibiting mold growth and extending shelf life has made it a preferred choice for manufacturers.

In the pharmaceutical sector, propionic acid is gaining traction as a key ingredient in the production of various medications, particularly those used to treat fungal infections and skin disorders. This segment is expected to witness the highest growth rate, with a CAGR of 8.2% from 2020 to 2025, driven by increasing healthcare expenditure and the development of novel drug formulations.

The cosmetics industry is another significant consumer of propionic acid, utilizing it in the production of personal care products such as shampoos, lotions, and creams. The market in this sector is anticipated to grow at a CAGR of 5.9% during the forecast period, fueled by the rising demand for natural and organic personal care products.

Geographically, North America and Europe are the leading markets for propionic acid in biotechnology, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.5% from 2020 to 2025, due to rapid industrialization, increasing disposable income, and growing awareness of food safety in countries like China and India.

Key market players in the propionic acid biotechnology sector include BASF SE, Dow Inc., Eastman Chemical Company, and Perstorp Holding AB. These companies are focusing on research and development to expand their product portfolios and improve production efficiency. Additionally, strategic partnerships and collaborations are being formed to strengthen market presence and cater to the growing demand across various applications.

The food and feed preservation segment dominates the market, accounting for over 60% of the total market share. This is primarily due to the rising demand for natural preservatives in the food industry and the growing awareness of food safety among consumers. Propionic acid's effectiveness in inhibiting mold growth and extending shelf life has made it a preferred choice for manufacturers.

In the pharmaceutical sector, propionic acid is gaining traction as a key ingredient in the production of various medications, particularly those used to treat fungal infections and skin disorders. This segment is expected to witness the highest growth rate, with a CAGR of 8.2% from 2020 to 2025, driven by increasing healthcare expenditure and the development of novel drug formulations.

The cosmetics industry is another significant consumer of propionic acid, utilizing it in the production of personal care products such as shampoos, lotions, and creams. The market in this sector is anticipated to grow at a CAGR of 5.9% during the forecast period, fueled by the rising demand for natural and organic personal care products.

Geographically, North America and Europe are the leading markets for propionic acid in biotechnology, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.5% from 2020 to 2025, due to rapid industrialization, increasing disposable income, and growing awareness of food safety in countries like China and India.

Key market players in the propionic acid biotechnology sector include BASF SE, Dow Inc., Eastman Chemical Company, and Perstorp Holding AB. These companies are focusing on research and development to expand their product portfolios and improve production efficiency. Additionally, strategic partnerships and collaborations are being formed to strengthen market presence and cater to the growing demand across various applications.

Current Challenges in Propionic Acid Biotechnology

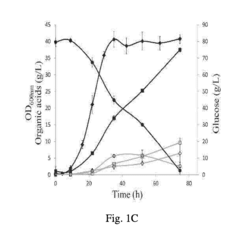

Despite the promising potential of propionic acid in biotechnology, several significant challenges hinder its widespread adoption and efficient production. One of the primary obstacles is the low yield and productivity of current fermentation processes. The microbial production of propionic acid often results in relatively low concentrations, typically ranging from 20 to 40 g/L, which is insufficient for economically viable industrial-scale production.

Another major challenge is the inhibitory effect of propionic acid on the producing microorganisms. As the concentration of propionic acid increases during fermentation, it begins to inhibit cell growth and metabolism, leading to reduced productivity and yield. This product inhibition phenomenon necessitates the development of more robust microbial strains or innovative fermentation strategies to overcome this limitation.

The high cost of downstream processing and purification also presents a significant hurdle. Separating propionic acid from the fermentation broth and achieving the required purity for various applications can be energy-intensive and expensive. Current separation methods, such as liquid-liquid extraction or electrodialysis, often struggle to achieve high recovery rates while maintaining cost-effectiveness.

Furthermore, the substrate utilization efficiency in propionic acid fermentation remains suboptimal. Many of the current production processes rely on relatively expensive carbon sources, which impacts the overall economics of the process. Developing microbial strains capable of efficiently utilizing low-cost, renewable feedstocks is crucial for improving the economic viability of bio-based propionic acid production.

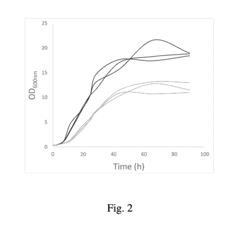

The lack of genetically well-characterized and easily manipulable propionic acid-producing microorganisms poses another challenge. While Propionibacterium species are the primary producers, their genetic tools and metabolic engineering strategies are not as well-developed as those for model organisms like Escherichia coli or Saccharomyces cerevisiae. This limitation hampers efforts to optimize strains for enhanced production through metabolic engineering approaches.

Scaling up propionic acid production from laboratory to industrial levels presents additional challenges. Maintaining optimal fermentation conditions, such as pH and temperature control, becomes more complex at larger scales. Moreover, ensuring consistent product quality and addressing issues related to contamination and process stability are critical concerns that need to be addressed for successful industrial implementation.

Lastly, the environmental impact of propionic acid production through biotechnological routes requires careful consideration. While bio-based production offers potential sustainability benefits, issues such as water consumption, waste generation, and energy use in the fermentation and downstream processing stages need to be optimized to ensure a truly environmentally friendly production process.

Another major challenge is the inhibitory effect of propionic acid on the producing microorganisms. As the concentration of propionic acid increases during fermentation, it begins to inhibit cell growth and metabolism, leading to reduced productivity and yield. This product inhibition phenomenon necessitates the development of more robust microbial strains or innovative fermentation strategies to overcome this limitation.

The high cost of downstream processing and purification also presents a significant hurdle. Separating propionic acid from the fermentation broth and achieving the required purity for various applications can be energy-intensive and expensive. Current separation methods, such as liquid-liquid extraction or electrodialysis, often struggle to achieve high recovery rates while maintaining cost-effectiveness.

Furthermore, the substrate utilization efficiency in propionic acid fermentation remains suboptimal. Many of the current production processes rely on relatively expensive carbon sources, which impacts the overall economics of the process. Developing microbial strains capable of efficiently utilizing low-cost, renewable feedstocks is crucial for improving the economic viability of bio-based propionic acid production.

The lack of genetically well-characterized and easily manipulable propionic acid-producing microorganisms poses another challenge. While Propionibacterium species are the primary producers, their genetic tools and metabolic engineering strategies are not as well-developed as those for model organisms like Escherichia coli or Saccharomyces cerevisiae. This limitation hampers efforts to optimize strains for enhanced production through metabolic engineering approaches.

Scaling up propionic acid production from laboratory to industrial levels presents additional challenges. Maintaining optimal fermentation conditions, such as pH and temperature control, becomes more complex at larger scales. Moreover, ensuring consistent product quality and addressing issues related to contamination and process stability are critical concerns that need to be addressed for successful industrial implementation.

Lastly, the environmental impact of propionic acid production through biotechnological routes requires careful consideration. While bio-based production offers potential sustainability benefits, issues such as water consumption, waste generation, and energy use in the fermentation and downstream processing stages need to be optimized to ensure a truly environmentally friendly production process.

Current Biotech Applications of Propionic Acid

01 Production methods of propionic acid

Various methods for producing propionic acid are described, including fermentation processes, chemical synthesis routes, and catalytic reactions. These methods aim to improve yield, efficiency, and purity of propionic acid production for industrial applications.- Production methods of propionic acid: Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.

- Applications of propionic acid in food preservation: Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in preventing mold growth and extending the shelf life of various food products, particularly in baked goods, dairy products, and animal feed.

- Use of propionic acid in pharmaceutical industry: Propionic acid and its derivatives find applications in the pharmaceutical industry. They are used in the synthesis of various drugs, as intermediates in the production of active pharmaceutical ingredients, and in some cases, as components of drug formulations.

- Environmental and industrial applications: Propionic acid is utilized in various environmental and industrial applications. These include its use as a chemical intermediate in the production of plastics, herbicides, and other industrial chemicals. It also finds applications in wastewater treatment and as a solvent in certain industrial processes.

- Purification and recovery of propionic acid: Various methods and processes have been developed for the purification and recovery of propionic acid from reaction mixtures or fermentation broths. These techniques may involve distillation, extraction, or other separation processes to obtain high-purity propionic acid for commercial use.

02 Applications of propionic acid in food preservation

Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective against molds and some bacteria, extending the shelf life of various food products, particularly in bakery items and dairy products.Expand Specific Solutions03 Use of propionic acid in pharmaceutical formulations

Propionic acid and its derivatives find applications in pharmaceutical formulations. They are used as excipients, pH adjusters, and in some cases, as active pharmaceutical ingredients for various therapeutic purposes.Expand Specific Solutions04 Propionic acid in polymer and chemical synthesis

Propionic acid serves as a precursor or intermediate in the synthesis of various polymers and chemicals. It is used in the production of cellulose acetate propionate, herbicides, and other industrial chemicals, contributing to the development of new materials and compounds.Expand Specific Solutions05 Environmental and safety considerations in propionic acid handling

The handling, storage, and disposal of propionic acid require specific safety measures due to its corrosive nature and potential environmental impact. Innovations in this area focus on developing safer handling methods, reducing environmental risks, and improving workplace safety in industries using propionic acid.Expand Specific Solutions

Key Players in Propionic Acid Biotechnology

The propionic acid biotechnology market is in a growth phase, driven by increasing demand for sustainable and bio-based products across various industries. The market size is expanding, with applications in food preservation, animal feed, and pharmaceuticals. Technological maturity varies, with established players like Dow Global Technologies and Rohm & Haas Co. leading in industrial-scale production. Academic institutions such as Jiangnan University and The Ohio State University are advancing research in novel applications and production methods. Emerging companies like Exelixis, Inc. and Evonik Operations GmbH are focusing on innovative biotechnological approaches to improve efficiency and expand the range of applications, indicating a dynamic and competitive landscape with potential for further growth and technological advancements.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed advanced fermentation processes for propionic acid production using genetically engineered microorganisms. Their approach involves metabolic engineering of Propionibacterium strains to enhance yield and productivity. The company has implemented a two-stage fermentation process, where the first stage focuses on biomass accumulation, followed by a second stage optimized for propionic acid production[1]. This method has reportedly achieved titers of over 100 g/L of propionic acid. Additionally, Dow has explored the use of renewable feedstocks, such as glycerol and lignocellulosic biomass, to improve the sustainability of their propionic acid production process[2].

Strengths: High production titers, use of renewable feedstocks, and advanced metabolic engineering techniques. Weaknesses: Potential high costs associated with genetically engineered strains and two-stage fermentation process.

Evonik Operations GmbH

Technical Solution: Evonik has developed a novel biotechnological process for producing propionic acid using engineered Escherichia coli strains. Their approach focuses on redirecting metabolic flux towards propionic acid production by overexpressing key enzymes and eliminating competing pathways. The company has reported achieving propionic acid yields of up to 0.8 g/g glucose, which is significantly higher than traditional fermentation methods[3]. Evonik's process also incorporates in situ product recovery techniques to mitigate product inhibition and improve overall productivity. Furthermore, they have explored the integration of their biotechnological process with existing chemical production facilities to create a hybrid production system that leverages the strengths of both biological and chemical synthesis[4].

Strengths: High yield, innovative strain engineering, and integration with existing chemical processes. Weaknesses: Potential scalability challenges and reliance on genetically modified organisms.

Innovative Research in Propionic Acid Biotechnology

Improved propionibacterium strains for the production of propionic acid

PatentWO2017055932A2

Innovation

- Genome shuffling between selected Propionibacterium strains, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, to generate novel strains with enhanced growth rates and propionic acid production, utilizing genetic material exchange to create strains with improved metabolic pathways and regulatory mechanisms.

Improved propionibacterium strains for the production of propionic acid

PatentInactiveUS20190071697A1

Innovation

- Selecting and combining Propionibacterium strains with high potential for propionic acid production, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, through genome shuffling to create novel strains with improved growth rates and reduced byproduct production, such as P. acidipropionici F3E8, which achieves enhanced propionic acid yields and growth rates.

Regulatory Framework for Propionic Acid in Biotech

The regulatory framework for propionic acid in biotechnology is a complex and evolving landscape that encompasses various aspects of its production, use, and safety. At the global level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) provide guidelines for the safe use of propionic acid in food and feed applications. These guidelines are often adopted or adapted by national regulatory bodies.

In the United States, the Food and Drug Administration (FDA) regulates propionic acid under the Federal Food, Drug, and Cosmetic Act. It is classified as Generally Recognized as Safe (GRAS) for use as a food additive and preservative. The Environmental Protection Agency (EPA) also oversees its use in non-food applications, particularly in industrial and agricultural settings.

The European Union has established comprehensive regulations for propionic acid through the European Food Safety Authority (EFSA). The EU Regulation No 1333/2008 on food additives sets specific conditions for its use in food products. Additionally, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs its industrial applications.

In Asia, countries like China and Japan have their own regulatory frameworks. The National Medical Products Administration (NMPA) in China and the Ministry of Health, Labour and Welfare in Japan oversee the use of propionic acid in food and pharmaceutical applications.

Biotechnological production of propionic acid is subject to additional regulations related to genetically modified organisms (GMOs) and bioprocessing. These regulations vary significantly between countries and regions, with some nations having more stringent controls on GMO-derived products than others.

Safety data sheets (SDS) and product labeling requirements are crucial components of the regulatory framework. Manufacturers and distributors must provide detailed information on the properties, hazards, and safe handling procedures for propionic acid.

As the biotechnology industry continues to advance, regulatory bodies are adapting their frameworks to address new production methods and applications. This includes the development of guidelines for novel fermentation processes and the use of engineered microorganisms in propionic acid production.

The regulatory landscape also extends to environmental considerations, with increasing focus on sustainable production methods and waste management in the biotechnological production of propionic acid. This reflects a growing trend towards circular economy principles in industrial biotechnology.

In the United States, the Food and Drug Administration (FDA) regulates propionic acid under the Federal Food, Drug, and Cosmetic Act. It is classified as Generally Recognized as Safe (GRAS) for use as a food additive and preservative. The Environmental Protection Agency (EPA) also oversees its use in non-food applications, particularly in industrial and agricultural settings.

The European Union has established comprehensive regulations for propionic acid through the European Food Safety Authority (EFSA). The EU Regulation No 1333/2008 on food additives sets specific conditions for its use in food products. Additionally, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs its industrial applications.

In Asia, countries like China and Japan have their own regulatory frameworks. The National Medical Products Administration (NMPA) in China and the Ministry of Health, Labour and Welfare in Japan oversee the use of propionic acid in food and pharmaceutical applications.

Biotechnological production of propionic acid is subject to additional regulations related to genetically modified organisms (GMOs) and bioprocessing. These regulations vary significantly between countries and regions, with some nations having more stringent controls on GMO-derived products than others.

Safety data sheets (SDS) and product labeling requirements are crucial components of the regulatory framework. Manufacturers and distributors must provide detailed information on the properties, hazards, and safe handling procedures for propionic acid.

As the biotechnology industry continues to advance, regulatory bodies are adapting their frameworks to address new production methods and applications. This includes the development of guidelines for novel fermentation processes and the use of engineered microorganisms in propionic acid production.

The regulatory landscape also extends to environmental considerations, with increasing focus on sustainable production methods and waste management in the biotechnological production of propionic acid. This reflects a growing trend towards circular economy principles in industrial biotechnology.

Environmental Impact of Propionic Acid Biotechnology

The environmental impact of propionic acid biotechnology is a critical consideration as this field continues to expand. The production of propionic acid through biotechnological processes offers several environmental advantages over traditional petrochemical-based methods. Primarily, it reduces reliance on fossil fuels, thereby decreasing greenhouse gas emissions associated with production.

Biotechnological production of propionic acid typically utilizes renewable feedstocks such as glucose, glycerol, or agricultural waste products. This approach promotes a circular economy and reduces the carbon footprint of the production process. Furthermore, the use of microorganisms for production often requires less energy input compared to chemical synthesis, contributing to overall energy efficiency.

However, the environmental benefits are not without challenges. The fermentation processes used in biotechnological production can generate significant amounts of wastewater. This effluent may contain organic compounds and residual nutrients that require treatment before discharge. Proper wastewater management is essential to prevent eutrophication and other water pollution issues.

Another environmental consideration is the potential for genetically modified organisms (GMOs) used in some biotechnological processes. While GMOs can enhance production efficiency, their use raises concerns about potential ecological impacts if accidentally released into the environment. Strict containment and disposal protocols are necessary to mitigate these risks.

Land use is another factor to consider. As demand for bio-based propionic acid grows, there may be increased pressure on agricultural land to produce feedstocks. This could potentially lead to land-use changes and associated environmental impacts, such as deforestation or loss of biodiversity if not managed sustainably.

On the positive side, propionic acid itself has applications that can contribute to environmental sustainability. Its use as a food preservative can extend the shelf life of products, potentially reducing food waste. In agriculture, it serves as an effective mold inhibitor in animal feed, which can improve livestock health and reduce the need for antibiotics, thereby mitigating antibiotic resistance concerns.

As the biotechnology industry continues to innovate, there is potential for further environmental improvements. Research into more efficient microbial strains, optimized fermentation processes, and novel feedstock utilization could enhance the environmental profile of propionic acid production. Additionally, the development of closed-loop systems and biorefinery concepts could maximize resource efficiency and minimize waste generation.

Biotechnological production of propionic acid typically utilizes renewable feedstocks such as glucose, glycerol, or agricultural waste products. This approach promotes a circular economy and reduces the carbon footprint of the production process. Furthermore, the use of microorganisms for production often requires less energy input compared to chemical synthesis, contributing to overall energy efficiency.

However, the environmental benefits are not without challenges. The fermentation processes used in biotechnological production can generate significant amounts of wastewater. This effluent may contain organic compounds and residual nutrients that require treatment before discharge. Proper wastewater management is essential to prevent eutrophication and other water pollution issues.

Another environmental consideration is the potential for genetically modified organisms (GMOs) used in some biotechnological processes. While GMOs can enhance production efficiency, their use raises concerns about potential ecological impacts if accidentally released into the environment. Strict containment and disposal protocols are necessary to mitigate these risks.

Land use is another factor to consider. As demand for bio-based propionic acid grows, there may be increased pressure on agricultural land to produce feedstocks. This could potentially lead to land-use changes and associated environmental impacts, such as deforestation or loss of biodiversity if not managed sustainably.

On the positive side, propionic acid itself has applications that can contribute to environmental sustainability. Its use as a food preservative can extend the shelf life of products, potentially reducing food waste. In agriculture, it serves as an effective mold inhibitor in animal feed, which can improve livestock health and reduce the need for antibiotics, thereby mitigating antibiotic resistance concerns.

As the biotechnology industry continues to innovate, there is potential for further environmental improvements. Research into more efficient microbial strains, optimized fermentation processes, and novel feedstock utilization could enhance the environmental profile of propionic acid production. Additionally, the development of closed-loop systems and biorefinery concepts could maximize resource efficiency and minimize waste generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!