Propionic Acid: Unlocking Future Biotechnological Techniques

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Evolution

Propionic acid has undergone a significant evolution in the field of biotechnology, transforming from a simple organic compound to a key player in various industrial applications. Initially discovered in the mid-19th century as a byproduct of bacterial fermentation, propionic acid's potential remained largely untapped for decades.

The early 20th century marked the beginning of propionic acid's industrial production, primarily through petrochemical processes. However, it wasn't until the latter half of the century that its biotechnological significance began to emerge. The 1960s and 1970s saw increased research into microbial production methods, laying the groundwork for future bio-based manufacturing techniques.

The 1980s and 1990s witnessed a surge in understanding the metabolic pathways involved in propionic acid production by microorganisms. This period was characterized by the identification and characterization of key enzymes and genes responsible for its biosynthesis. Concurrently, advancements in fermentation technology and process engineering paved the way for more efficient microbial production methods.

The turn of the millennium brought about a paradigm shift in propionic acid production. With growing environmental concerns and the push for sustainable practices, bio-based production methods gained traction. The development of genetically engineered strains of bacteria and yeast capable of producing propionic acid at higher yields became a focal point of research.

In recent years, the evolution of propionic acid in biotechnology has accelerated dramatically. The advent of systems biology and metabolic engineering has enabled researchers to optimize microbial strains for enhanced production. Synthetic biology approaches have led to the creation of novel biosynthetic pathways, expanding the potential applications of propionic acid beyond traditional uses.

The integration of artificial intelligence and machine learning in biotechnology has further propelled propionic acid's evolution. These technologies have facilitated the rapid screening of microbial strains, prediction of optimal fermentation conditions, and design of more efficient production processes. As a result, bio-based propionic acid production has become increasingly competitive with traditional petrochemical methods.

Looking ahead, the evolution of propionic acid in biotechnology shows no signs of slowing down. Emerging trends include the development of continuous fermentation processes, the exploration of alternative feedstocks for microbial production, and the creation of propionic acid-derived high-value compounds. As biotechnology continues to advance, propionic acid is poised to play an even more significant role in various industries, from food preservation to bioplastics production, cementing its position as a versatile and sustainable chemical building block.

The early 20th century marked the beginning of propionic acid's industrial production, primarily through petrochemical processes. However, it wasn't until the latter half of the century that its biotechnological significance began to emerge. The 1960s and 1970s saw increased research into microbial production methods, laying the groundwork for future bio-based manufacturing techniques.

The 1980s and 1990s witnessed a surge in understanding the metabolic pathways involved in propionic acid production by microorganisms. This period was characterized by the identification and characterization of key enzymes and genes responsible for its biosynthesis. Concurrently, advancements in fermentation technology and process engineering paved the way for more efficient microbial production methods.

The turn of the millennium brought about a paradigm shift in propionic acid production. With growing environmental concerns and the push for sustainable practices, bio-based production methods gained traction. The development of genetically engineered strains of bacteria and yeast capable of producing propionic acid at higher yields became a focal point of research.

In recent years, the evolution of propionic acid in biotechnology has accelerated dramatically. The advent of systems biology and metabolic engineering has enabled researchers to optimize microbial strains for enhanced production. Synthetic biology approaches have led to the creation of novel biosynthetic pathways, expanding the potential applications of propionic acid beyond traditional uses.

The integration of artificial intelligence and machine learning in biotechnology has further propelled propionic acid's evolution. These technologies have facilitated the rapid screening of microbial strains, prediction of optimal fermentation conditions, and design of more efficient production processes. As a result, bio-based propionic acid production has become increasingly competitive with traditional petrochemical methods.

Looking ahead, the evolution of propionic acid in biotechnology shows no signs of slowing down. Emerging trends include the development of continuous fermentation processes, the exploration of alternative feedstocks for microbial production, and the creation of propionic acid-derived high-value compounds. As biotechnology continues to advance, propionic acid is poised to play an even more significant role in various industries, from food preservation to bioplastics production, cementing its position as a versatile and sustainable chemical building block.

Market Demand Analysis

The market demand for propionic acid has been steadily increasing, driven by its diverse applications across various industries. In the food and beverage sector, propionic acid serves as a crucial preservative, extending the shelf life of baked goods, dairy products, and processed foods. This application has seen significant growth due to the rising consumer demand for convenience foods and the need for longer-lasting products in global supply chains.

The animal feed industry represents another major market for propionic acid. As a feed preservative, it prevents mold growth and bacterial contamination, ensuring the quality and safety of animal nutrition. With the expanding livestock industry and increasing focus on animal health, the demand for propionic acid in this sector continues to grow.

In the pharmaceutical and personal care industries, propionic acid finds applications as an intermediate in the production of various drugs, cosmetics, and fragrances. The growing health consciousness and personal care trends worldwide contribute to the increased demand in these sectors.

The chemical industry utilizes propionic acid as a precursor for the production of cellulose acetate propionate, a material used in various applications such as eyeglass frames, tool handles, and automotive parts. The expanding automotive and consumer goods industries drive the demand for this derivative.

Geographically, North America and Europe have traditionally been the largest markets for propionic acid, owing to their well-established food and beverage industries and stringent regulations on food safety. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by increasing industrialization, population growth, and changing dietary habits.

The global propionic acid market is projected to experience substantial growth in the coming years. Factors such as urbanization, rising disposable incomes, and the shift towards processed and packaged foods in developing economies contribute to this growth trajectory. Additionally, the increasing awareness of food safety and the need for sustainable preservation methods further boost the demand for propionic acid.

As biotechnological techniques for propionic acid production advance, there is potential for market expansion through cost reduction and improved production efficiency. This could lead to broader applications and penetration into new market segments, further driving demand growth.

The animal feed industry represents another major market for propionic acid. As a feed preservative, it prevents mold growth and bacterial contamination, ensuring the quality and safety of animal nutrition. With the expanding livestock industry and increasing focus on animal health, the demand for propionic acid in this sector continues to grow.

In the pharmaceutical and personal care industries, propionic acid finds applications as an intermediate in the production of various drugs, cosmetics, and fragrances. The growing health consciousness and personal care trends worldwide contribute to the increased demand in these sectors.

The chemical industry utilizes propionic acid as a precursor for the production of cellulose acetate propionate, a material used in various applications such as eyeglass frames, tool handles, and automotive parts. The expanding automotive and consumer goods industries drive the demand for this derivative.

Geographically, North America and Europe have traditionally been the largest markets for propionic acid, owing to their well-established food and beverage industries and stringent regulations on food safety. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by increasing industrialization, population growth, and changing dietary habits.

The global propionic acid market is projected to experience substantial growth in the coming years. Factors such as urbanization, rising disposable incomes, and the shift towards processed and packaged foods in developing economies contribute to this growth trajectory. Additionally, the increasing awareness of food safety and the need for sustainable preservation methods further boost the demand for propionic acid.

As biotechnological techniques for propionic acid production advance, there is potential for market expansion through cost reduction and improved production efficiency. This could lead to broader applications and penetration into new market segments, further driving demand growth.

Technical Challenges

The development of propionic acid as a key component in future biotechnological techniques faces several significant challenges. One of the primary obstacles is the low yield and productivity of current production methods. Traditional fermentation processes using propionibacteria often result in limited product concentrations, typically below 50 g/L, which is insufficient for large-scale industrial applications.

Another major challenge lies in the high production costs associated with propionic acid synthesis. The expensive substrates required for fermentation, coupled with energy-intensive downstream processing, make it difficult to compete with petrochemical-based production methods. This economic barrier hinders the widespread adoption of bio-based propionic acid in various industries.

The selectivity and purity of propionic acid production also present technical hurdles. Fermentation processes often generate byproducts such as acetic acid and succinic acid, which complicate the separation and purification steps. Developing efficient and cost-effective separation techniques to achieve high-purity propionic acid remains a critical challenge for researchers and engineers.

Metabolic engineering of microorganisms for enhanced propionic acid production faces its own set of challenges. While genetic modifications can potentially improve yield and productivity, the complex metabolic pathways involved in propionic acid biosynthesis make it difficult to predict and control the effects of genetic alterations. Balancing cellular metabolism to maximize propionic acid production while maintaining cell viability is an ongoing challenge.

The scalability of biotechnological processes for propionic acid production is another significant hurdle. Moving from laboratory-scale experiments to industrial-scale production often encounters issues related to process stability, contamination control, and maintaining consistent product quality. Developing robust and scalable fermentation processes that can operate continuously and reliably is crucial for commercial viability.

Environmental concerns and sustainability issues also pose challenges to the development of propionic acid biotechnology. While bio-based production methods are generally considered more environmentally friendly than petrochemical routes, there are still concerns about the carbon footprint of large-scale fermentation processes, water usage, and waste management. Addressing these sustainability challenges is essential for the long-term viability of biotechnological propionic acid production.

Lastly, regulatory hurdles and market acceptance present non-technical challenges that must be overcome. Ensuring compliance with food and pharmaceutical regulations, particularly for high-purity grades of propionic acid, requires significant investment in quality control and documentation. Additionally, convincing industries to switch from established petrochemical-based sources to bio-based alternatives may require demonstrating clear economic and environmental benefits.

Another major challenge lies in the high production costs associated with propionic acid synthesis. The expensive substrates required for fermentation, coupled with energy-intensive downstream processing, make it difficult to compete with petrochemical-based production methods. This economic barrier hinders the widespread adoption of bio-based propionic acid in various industries.

The selectivity and purity of propionic acid production also present technical hurdles. Fermentation processes often generate byproducts such as acetic acid and succinic acid, which complicate the separation and purification steps. Developing efficient and cost-effective separation techniques to achieve high-purity propionic acid remains a critical challenge for researchers and engineers.

Metabolic engineering of microorganisms for enhanced propionic acid production faces its own set of challenges. While genetic modifications can potentially improve yield and productivity, the complex metabolic pathways involved in propionic acid biosynthesis make it difficult to predict and control the effects of genetic alterations. Balancing cellular metabolism to maximize propionic acid production while maintaining cell viability is an ongoing challenge.

The scalability of biotechnological processes for propionic acid production is another significant hurdle. Moving from laboratory-scale experiments to industrial-scale production often encounters issues related to process stability, contamination control, and maintaining consistent product quality. Developing robust and scalable fermentation processes that can operate continuously and reliably is crucial for commercial viability.

Environmental concerns and sustainability issues also pose challenges to the development of propionic acid biotechnology. While bio-based production methods are generally considered more environmentally friendly than petrochemical routes, there are still concerns about the carbon footprint of large-scale fermentation processes, water usage, and waste management. Addressing these sustainability challenges is essential for the long-term viability of biotechnological propionic acid production.

Lastly, regulatory hurdles and market acceptance present non-technical challenges that must be overcome. Ensuring compliance with food and pharmaceutical regulations, particularly for high-purity grades of propionic acid, requires significant investment in quality control and documentation. Additionally, convincing industries to switch from established petrochemical-based sources to bio-based alternatives may require demonstrating clear economic and environmental benefits.

Current Production Methods

01 Production methods of propionic acid

Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.- Production methods of propionic acid: Various methods are employed for the production of propionic acid, including fermentation processes, chemical synthesis, and catalytic reactions. These methods often involve the use of specific microorganisms, catalysts, or chemical precursors to efficiently produce propionic acid on an industrial scale.

- Applications of propionic acid in food preservation: Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in preventing mold growth and extending the shelf life of various food products, particularly in baked goods, dairy products, and animal feed.

- Use of propionic acid in pharmaceutical and cosmetic industries: Propionic acid finds applications in the pharmaceutical and cosmetic industries. It is used as a precursor in the synthesis of certain drugs and as a pH adjuster in various formulations. In cosmetics, it serves as a preservative and can help maintain product stability.

- Environmental and industrial applications of propionic acid: Propionic acid has various environmental and industrial applications. It is used in the production of cellulose acetate propionate, a biodegradable plastic. Additionally, it serves as a raw material in the manufacture of herbicides, plasticizers, and other industrial chemicals.

- Purification and recovery processes for propionic acid: Various purification and recovery processes are employed to obtain high-quality propionic acid from reaction mixtures or fermentation broths. These processes may include distillation, extraction, crystallization, or membrane separation techniques to achieve the desired purity and yield of propionic acid.

02 Applications of propionic acid in food preservation

Propionic acid and its salts are widely used as food preservatives due to their antimicrobial properties. They are effective in preventing mold growth and extending the shelf life of various food products, particularly in baked goods, dairy products, and animal feed.Expand Specific Solutions03 Use of propionic acid in pharmaceutical and cosmetic industries

Propionic acid finds applications in the pharmaceutical and cosmetic industries. It is used as a precursor in the synthesis of certain drugs and as a pH adjuster in various formulations. In cosmetics, it may be used as a preservative or in the production of other cosmetic ingredients.Expand Specific Solutions04 Environmental and industrial applications of propionic acid

Propionic acid has various environmental and industrial applications. It is used in the production of cellulose acetate propionate, a biodegradable plastic. Additionally, it finds use in herbicides, solvents, and as a raw material in the production of other chemicals.Expand Specific Solutions05 Purification and recovery methods for propionic acid

Various techniques are employed for the purification and recovery of propionic acid from reaction mixtures or fermentation broths. These methods may include distillation, extraction, crystallization, or membrane-based separation processes to obtain high-purity propionic acid for commercial use.Expand Specific Solutions

Industry Leaders

The propionic acid biotechnology market is in a growth phase, driven by increasing demand for sustainable production methods and applications in various industries. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with key players like Jiangnan University, The Ohio State University, and Zhejiang University leading academic research. Companies such as Bristol Myers Squibb, AbbVie, and Dow Global Technologies are investing in industrial applications, while research institutions like CSIR and KRIBB are contributing to fundamental advancements. The involvement of diverse stakeholders, from academia to industry, indicates a maturing technology landscape with promising future developments in propionic acid biotechnology.

Jiangnan University

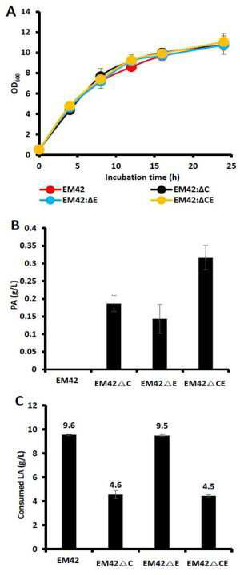

Technical Solution: Jiangnan University has developed a novel biotechnological approach for propionic acid production using engineered Propionibacterium freudenreichii strains. Their method involves metabolic engineering to enhance the glycerol utilization pathway and optimize the electron transfer chain. This results in improved propionic acid yield and productivity. The university has also explored co-fermentation strategies using mixed substrates to further increase production efficiency[1][3]. Additionally, they have implemented advanced fermentation techniques, including fed-batch and continuous fermentation processes, to maximize propionic acid titers[2].

Strengths: Expertise in metabolic engineering and fermentation optimization. Weaknesses: May face challenges in scaling up to industrial production levels.

Cargill, Inc.

Technical Solution: Cargill has developed a proprietary biotechnological process for producing bio-based propionic acid using renewable feedstocks. Their approach utilizes genetically engineered microorganisms, likely Propionibacterium or Escherichia coli strains, optimized for high-yield propionic acid production. The company has invested in large-scale fermentation facilities and downstream processing technologies to purify the bio-based propionic acid to meet industry standards[4]. Cargill's process incorporates advanced process control systems and continuous fermentation techniques to maintain consistent product quality and maximize productivity[5].

Strengths: Strong industrial scale-up capabilities and established market presence. Weaknesses: May face competition from petrochemical-based propionic acid producers.

Key Innovations

Method for Improving Acid tolerance of Propionibacterium acdipropionici

PatentInactiveUS20140178952A1

Innovation

- Adding arginine and/or aspartic acid to the culture medium during the cultivation of Propionibacterium acdipropionici to enhance acid tolerance and propionic acid productivity.

Bioproduction of Propionic Acid from Levulinic Acid by Utilizing Recombinant Pseudomonas putida

PatentInactiveKR1020240029628A

Innovation

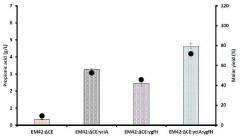

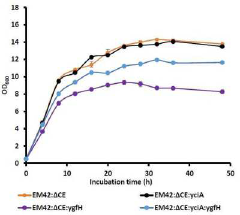

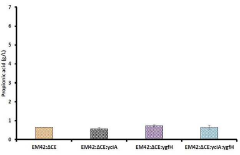

- A transgenic Pseudomonas putida strain is developed by deleting prpC and prpE genes and expressing yciA and ygfH genes, utilizing levulinic acid as a substrate to enhance propionic acid production through a levulinic acid-inducible expression system, optimizing the metabolic pathway to improve titer and yield.

Regulatory Framework

The regulatory framework surrounding propionic acid and its biotechnological applications is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of propionic acid in food and pharmaceutical applications. The FDA has classified propionic acid as Generally Recognized as Safe (GRAS) for use as a food preservative, allowing its widespread application in the food industry.

The Environmental Protection Agency (EPA) also regulates propionic acid under the Toxic Substances Control Act (TSCA), particularly concerning its production and potential environmental impacts. Manufacturers must comply with EPA guidelines for chemical handling, storage, and disposal to ensure environmental safety and worker protection.

In the European Union, the European Food Safety Authority (EFSA) has evaluated propionic acid and its salts, confirming their safety for use as food additives. The EU has established specific purity criteria and maximum levels for propionic acid in various food products through Regulation (EC) No 1333/2008 on food additives.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international standards for food additives, including propionic acid. These standards help harmonize regulations across countries and facilitate international trade.

As biotechnological techniques for propionic acid production advance, regulatory bodies are adapting their frameworks to address new challenges. For instance, the use of genetically modified organisms (GMOs) in propionic acid production is subject to stringent regulations in many countries. In the EU, Directive 2001/18/EC governs the deliberate release of GMOs into the environment, while in the US, the Coordinated Framework for Regulation of Biotechnology involves multiple agencies in overseeing biotechnology products.

Emerging applications of propionic acid in areas such as bioplastics and biofuels may require new regulatory considerations. Regulatory bodies are increasingly focusing on sustainability and circular economy principles, which may influence future regulations on propionic acid production and use.

As the biotechnology sector continues to evolve, it is crucial for stakeholders to stay informed about regulatory changes and engage in dialogue with regulatory bodies to ensure compliance and foster innovation in propionic acid applications.

The Environmental Protection Agency (EPA) also regulates propionic acid under the Toxic Substances Control Act (TSCA), particularly concerning its production and potential environmental impacts. Manufacturers must comply with EPA guidelines for chemical handling, storage, and disposal to ensure environmental safety and worker protection.

In the European Union, the European Food Safety Authority (EFSA) has evaluated propionic acid and its salts, confirming their safety for use as food additives. The EU has established specific purity criteria and maximum levels for propionic acid in various food products through Regulation (EC) No 1333/2008 on food additives.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international standards for food additives, including propionic acid. These standards help harmonize regulations across countries and facilitate international trade.

As biotechnological techniques for propionic acid production advance, regulatory bodies are adapting their frameworks to address new challenges. For instance, the use of genetically modified organisms (GMOs) in propionic acid production is subject to stringent regulations in many countries. In the EU, Directive 2001/18/EC governs the deliberate release of GMOs into the environment, while in the US, the Coordinated Framework for Regulation of Biotechnology involves multiple agencies in overseeing biotechnology products.

Emerging applications of propionic acid in areas such as bioplastics and biofuels may require new regulatory considerations. Regulatory bodies are increasingly focusing on sustainability and circular economy principles, which may influence future regulations on propionic acid production and use.

As the biotechnology sector continues to evolve, it is crucial for stakeholders to stay informed about regulatory changes and engage in dialogue with regulatory bodies to ensure compliance and foster innovation in propionic acid applications.

Environmental Impact

The production and use of propionic acid through biotechnological techniques have significant environmental implications. One of the primary advantages is the potential reduction in greenhouse gas emissions compared to traditional petrochemical-based production methods. Biotechnological processes often utilize renewable feedstocks, such as agricultural waste or biomass, which can lead to a more sustainable production cycle and reduced carbon footprint.

However, the environmental impact of propionic acid production through biotechnology is not without challenges. The fermentation processes involved can generate wastewater containing organic compounds and nutrients, which require proper treatment before disposal. Additionally, the energy requirements for maintaining optimal fermentation conditions and downstream processing can be substantial, potentially offsetting some of the environmental benefits if not managed efficiently.

The use of genetically modified organisms (GMOs) in propionic acid production raises concerns about potential ecological risks. While strict containment measures are typically in place, the release of these organisms into the environment could have unforeseen consequences on local ecosystems. This necessitates rigorous safety protocols and ongoing environmental monitoring.

On the positive side, propionic acid produced through biotechnological means can contribute to the development of more environmentally friendly products. Its applications in food preservation can extend shelf life and reduce food waste, indirectly lowering the environmental impact of food production and distribution. In agriculture, its use as a mold inhibitor in animal feed can improve livestock health and reduce the need for antibiotics, potentially mitigating the environmental issues associated with antibiotic resistance.

The scalability of biotechnological production methods for propionic acid also presents environmental considerations. As production increases to meet growing demand, there may be increased pressure on land use for feedstock cultivation. This could potentially lead to competition with food crops or contribute to deforestation if not managed sustainably.

Lifecycle assessments of propionic acid production through biotechnology have shown promising results in terms of reduced environmental impact compared to traditional methods. However, these assessments often highlight areas for improvement, such as optimizing energy use in production facilities and developing more efficient separation and purification techniques to minimize waste and resource consumption.

In conclusion, while biotechnological production of propionic acid offers several environmental advantages, it is crucial to continually assess and mitigate potential negative impacts. Ongoing research and development in this field should focus on enhancing the sustainability of production processes, minimizing waste generation, and ensuring the safe containment of genetically modified organisms used in production.

However, the environmental impact of propionic acid production through biotechnology is not without challenges. The fermentation processes involved can generate wastewater containing organic compounds and nutrients, which require proper treatment before disposal. Additionally, the energy requirements for maintaining optimal fermentation conditions and downstream processing can be substantial, potentially offsetting some of the environmental benefits if not managed efficiently.

The use of genetically modified organisms (GMOs) in propionic acid production raises concerns about potential ecological risks. While strict containment measures are typically in place, the release of these organisms into the environment could have unforeseen consequences on local ecosystems. This necessitates rigorous safety protocols and ongoing environmental monitoring.

On the positive side, propionic acid produced through biotechnological means can contribute to the development of more environmentally friendly products. Its applications in food preservation can extend shelf life and reduce food waste, indirectly lowering the environmental impact of food production and distribution. In agriculture, its use as a mold inhibitor in animal feed can improve livestock health and reduce the need for antibiotics, potentially mitigating the environmental issues associated with antibiotic resistance.

The scalability of biotechnological production methods for propionic acid also presents environmental considerations. As production increases to meet growing demand, there may be increased pressure on land use for feedstock cultivation. This could potentially lead to competition with food crops or contribute to deforestation if not managed sustainably.

Lifecycle assessments of propionic acid production through biotechnology have shown promising results in terms of reduced environmental impact compared to traditional methods. However, these assessments often highlight areas for improvement, such as optimizing energy use in production facilities and developing more efficient separation and purification techniques to minimize waste and resource consumption.

In conclusion, while biotechnological production of propionic acid offers several environmental advantages, it is crucial to continually assess and mitigate potential negative impacts. Ongoing research and development in this field should focus on enhancing the sustainability of production processes, minimizing waste generation, and ensuring the safe containment of genetically modified organisms used in production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!