Advanced Sealing Technologies For Turbine Engine Technology

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Sealing Technologies Background And Goals

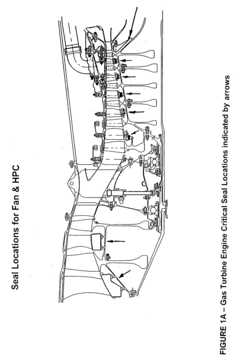

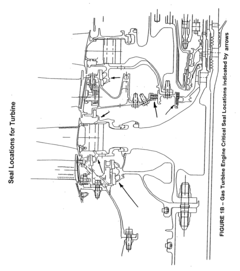

Under the background of turbine engine technology, advanced sealing technologies have evolved significantly. The primary goal is to enhance engine efficiency, reliability, and longevity by minimizing leakage and maintaining optimal pressure and temperature conditions. Historically, sealing technologies have transitioned from basic mechanical seals to sophisticated materials and designs, such as brush seals, labyrinth seals, and advanced ceramic coatings. These advancements aim to address the challenges posed by high temperatures, pressures, and rotational speeds inherent in turbine engines. The evolution of these technologies reflects a continuous effort to improve performance, reduce maintenance costs, and meet stringent regulatory standards.

Advanced Sealing Technologies Market Demand Analysis

### Advanced Sealing Technologies Market Demand Analysis

**Market Demand Overview**

The demand for advanced sealing technologies in turbine engines is driven by the need for improved efficiency, reliability, and performance. These technologies are crucial in minimizing leakage, reducing maintenance costs, and enhancing the overall lifespan of turbine engines.

**Industry Growth Drivers**

- Increasing adoption of turbine engines in aviation and power generation sectors.

- Stringent environmental regulations pushing for reduced emissions and fuel consumption.

- Technological advancements leading to the development of more durable and efficient sealing solutions.

- Development of high-temperature resistant materials to withstand extreme operating conditions.

- Integration of smart sealing technologies for real-time monitoring and predictive maintenance.

- Adoption of additive manufacturing techniques for customized sealing solutions.

- High initial costs and complexity of advanced sealing technologies.

- Need for continuous innovation to meet evolving industry standards and requirements.

- Opportunities in developing eco-friendly and sustainable sealing solutions.

Advanced Sealing Technologies Status And Challenges

### Advanced Sealing Technologies Status And Challenges

**Current Status:**

- **Technological Maturity:** Advanced sealing technologies for turbine engines have seen significant advancements, focusing on high-temperature resistance, durability, and efficiency.

- **Material Innovations:** Development of new materials like ceramics, advanced polymers, and metal alloys to enhance sealing performance under extreme conditions.

**Challenges:**

- **Thermal Management:** Managing high temperatures and thermal cycling without compromising seal integrity.

- **Wear and Tear:** Prolonged exposure to harsh environments leads to material degradation and reduced lifespan.

- **Manufacturing Complexity:** Precision manufacturing and maintaining tight tolerances are critical yet challenging.

- **Cost Efficiency:** Balancing high-performance requirements with cost-effective production methods.

**Geographical Distribution:**

- **Global Leaders:** Predominantly led by companies in the US, Europe, and Japan, with significant contributions from emerging markets in Asia.

- **Research Hubs:** Major research and development activities are concentrated in regions with strong aerospace and defense industries.

Advanced Sealing Technologies Current Technical Solutions

01 Use of advanced materials for sealing

Advanced materials like high-performance elastomers, composites, and specialized coatings enhance sealing efficiency by providing superior resistance to wear, temperature, and chemicals.- Use of advanced materials for sealing: Elastomers, composites, and high-performance polymers enhance sealing efficiency by offering superior resistance to temperature, pressure, and chemicals.

- Innovative sealing designs: Multi-lip seals, labyrinth seals, and dynamic seals reduce leakage, enhance durability, and maintain performance under varying conditions.

- Application of coatings and surface treatments: Plasma coatings, fluoropolymer coatings, and surface texturing reduce friction, wear, and corrosion, enhancing seal longevity and efficiency.

- Integration of smart technologies: Sensors and monitoring systems provide real-time data for predictive maintenance and early detection of failures, improving sealing efficiency.

- Use of hybrid sealing systems: Hybrid systems combine mechanical and elastomeric seals to achieve higher efficiency, leveraging the strengths of each component for robust solutions.

02 Design improvements in sealing mechanisms

Innovative designs, including multi-layered seals and optimized geometries, significantly enhance sealing efficiency under various conditions.Expand Specific Solutions03 Enhanced sealing techniques for dynamic applications

Specialized techniques like adaptive seals and self-lubricating materials maintain efficiency in dynamic applications, preventing leakage.Expand Specific Solutions04 Integration of smart technologies in sealing systems

Smart technologies, such as sensors and monitoring systems, provide real-time data for predictive maintenance and immediate response to seal failures.Expand Specific Solutions05 Application-specific sealing solutions

Customizing seal materials, designs, and configurations for specific applications improves sealing efficiency in various industries.Expand Specific Solutions

Advanced Sealing Technologies Main Player Analysis

The competitive landscape for advanced sealing technologies in turbine engine technology includes industry giants and specialized companies. Key players like United Technologies Corp., General Electric Company, and Rolls-Royce Plc leverage extensive R&D capabilities. Companies like Stein Seal Co. and Beijing Aerospace Propulsion Institute add specialized expertise, enhancing innovation. The market is competitive, with continuous advancements aimed at improving performance and reliability.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced sealing technologies for turbine engines, focusing on high-temperature resistant materials and innovative sealing designs to enhance engine efficiency and durability.

Strength: High-temperature resistance. Weakness: High production cost.

General Electric Company

Technical Solution: General Electric Company offers advanced sealing solutions for turbine engines, including abradable seals and brush seals, which improve sealing performance and reduce leakage.

Strength: Improved sealing performance. Weakness: Complex maintenance.

Advanced Sealing Technologies Key Technology Interpretation

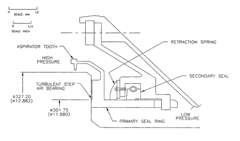

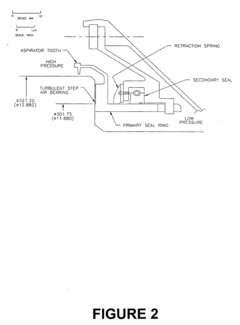

Air riding seal

PatentInactiveUS20070007730A1

Innovation

- The use of a hydrostatic gas film to create non-contact seals that reduce secondary cooling flows and parasitic leakages.

- The design of non-contact seals specifically for high temperature and high-speed turbine applications.

- Demonstrated improvement in performance and efficiency in gas turbine engines through the use of these non-contact seals.

Advanced Sealing Technologies Environmental Impact Analysis

Advanced sealing technologies for turbine engines significantly impact the environment. These technologies aim to enhance engine efficiency, reduce fuel consumption, and lower emissions. By improving sealing mechanisms, engines can operate at higher temperatures and pressures, leading to better performance and reduced environmental footprint. However, the production and disposal of advanced sealing materials may pose environmental challenges. Sustainable practices in material selection, manufacturing, and recycling are crucial to mitigate negative impacts. Overall, advanced sealing technologies offer substantial environmental benefits by promoting cleaner and more efficient turbine engine operations.

Advanced Sealing Technologies Regulatory And Compliance Considerations

Regulatory and compliance considerations for advanced sealing technologies in turbine engine technology involve understanding and adhering to stringent industry standards and regulations. These include environmental regulations, safety standards, and performance criteria set by aviation authorities such as the FAA and EASA. Compliance ensures that sealing technologies meet required durability, efficiency, and safety benchmarks. Additionally, manufacturers must stay updated with evolving regulations and certification processes to maintain market competitiveness and avoid legal repercussions. Effective compliance strategies involve continuous monitoring, rigorous testing, and documentation to ensure all sealing solutions align with regulatory expectations and industry best practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!