Improving Sealing In Turbine Engine Technology

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

Under the background of turbine engine technology, the primary goal is to enhance sealing mechanisms to improve efficiency and reliability. Historically, turbine engines have evolved significantly, with advancements in materials and design playing crucial roles. The focus now is on minimizing leakage and optimizing sealing to withstand extreme temperatures and pressures. This involves exploring new materials, advanced manufacturing techniques, and innovative design approaches. The objective is to achieve superior sealing performance, thereby enhancing overall engine efficiency, reducing maintenance costs, and extending the operational lifespan of turbine engines.

Turbine Engine Market Demand Analysis

Turbine engines are critical in various industries, including aviation, power generation, and marine propulsion. The demand for turbine engines is driven by several factors:

**Increasing Air Travel:** The rise in global air travel boosts the demand for efficient and reliable turbine engines. Airlines seek engines that offer better fuel efficiency and lower emissions.

**Power Generation Needs:** Turbine engines are essential for power plants, especially in regions with growing energy demands. They provide a reliable and efficient means of generating electricity.

**Industrial Applications:** Turbine engines are used in various industrial applications, including oil and gas extraction, where they power compressors and pumps.

**Environmental Regulations:** Stricter environmental regulations push for cleaner and more efficient turbine engines. This drives innovation and demand for advanced sealing technologies to reduce emissions and improve performance.

**Technological Advancements:** Continuous advancements in materials and engineering techniques enhance turbine engine performance, making them more attractive to various industries.

**Military and Defense:** Turbine engines are crucial for military aircraft and naval vessels, driving demand in the defense sector.

**Economic Growth:** Economic development in emerging markets increases the need for transportation and energy, further boosting turbine engine demand.

**Replacement and Upgrades:** Aging infrastructure and the need for more efficient engines lead to replacement and upgrade cycles, sustaining market demand.

**Increasing Air Travel:** The rise in global air travel boosts the demand for efficient and reliable turbine engines. Airlines seek engines that offer better fuel efficiency and lower emissions.

**Power Generation Needs:** Turbine engines are essential for power plants, especially in regions with growing energy demands. They provide a reliable and efficient means of generating electricity.

**Industrial Applications:** Turbine engines are used in various industrial applications, including oil and gas extraction, where they power compressors and pumps.

**Environmental Regulations:** Stricter environmental regulations push for cleaner and more efficient turbine engines. This drives innovation and demand for advanced sealing technologies to reduce emissions and improve performance.

**Technological Advancements:** Continuous advancements in materials and engineering techniques enhance turbine engine performance, making them more attractive to various industries.

**Military and Defense:** Turbine engines are crucial for military aircraft and naval vessels, driving demand in the defense sector.

**Economic Growth:** Economic development in emerging markets increases the need for transportation and energy, further boosting turbine engine demand.

**Replacement and Upgrades:** Aging infrastructure and the need for more efficient engines lead to replacement and upgrade cycles, sustaining market demand.

Turbine Engine Technology Status and Challenges

### Turbine Engine Technology Status and Challenges

**Current Status:**

- Turbine engine technology has advanced significantly, focusing on efficiency, durability, and environmental impact.

- Modern engines incorporate advanced materials, cooling techniques, and aerodynamic designs.

**Challenges:**

- **Sealing Issues:** Maintaining effective seals under high temperatures and pressures is critical.

- **Material Limitations:** High-performance materials are expensive and challenging to manufacture.

- **Thermal Management:** Efficiently managing heat to prevent component degradation.

- **Environmental Regulations:** Meeting stringent emission standards while maintaining performance.

- **Cost Efficiency:** Balancing advanced technology with cost-effective production.

**Geographical Distribution:**

- **North America and Europe:** Leading in research and development, with significant investments in innovation.

- **Asia:** Rapidly growing market with increasing capabilities in manufacturing and technology adoption.

Turbine Engine Current Technical Solutions

01 Advanced sealing materials

Utilization of advanced materials for sealing in turbine engines to enhance durability and performance under extreme conditions.- Advanced sealing materials: Utilization of advanced materials like ceramics and high-temperature alloys to improve sealing performance and durability.

- Innovative seal designs: Development of novel seal designs like labyrinth and brush seals to optimize sealing efficiency and minimize leakage.

- Sealing technologies for specific engine components: Specialized sealing technologies for specific turbine engine components like rotor-stator interfaces and blade tips.

- Enhanced sealing methods: Adoption of advanced methods like thermal barrier coatings and plasma spraying to improve sealing effectiveness and longevity.

- Sealing solutions for environmental protection: Development of sealing solutions to reduce emissions and improve environmental compliance by minimizing leakage of harmful gases.

02 Innovative sealing designs

Development of innovative sealing designs to improve efficiency and reliability by minimizing leakage and optimizing the sealing interface.Expand Specific Solutions03 Sealing techniques for high-temperature applications

Techniques for maintaining seal integrity in high-temperature applications within turbine engines.Expand Specific Solutions04 Sealing solutions for reducing emissions

Sealing solutions aimed at reducing emissions by improving sealing efficiency to minimize the escape of harmful gases.Expand Specific Solutions05 Sealing systems for enhanced maintenance

Sealing systems designed for easier maintenance and longer service intervals, reducing downtime and maintenance costs.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for turbine engine sealing technology includes industry leaders and specialized companies. The market is mature with advancements in materials and engineering, driven by demand in aerospace and energy sectors. Key players like United Technologies Corp., General Electric Technology GmbH, Rolls-Royce Plc, and Safran Aircraft Engines SAS lead with high technical maturity and R&D capabilities. Emerging players like Stein Seal Co. and Turbo Systems Switzerland AG also innovate in sealing technologies.

United Technologies Corp.

Technical Solution: United Technologies Corp. develops advanced sealing technologies for turbine engines, focusing on high-temperature resistant materials and innovative designs to enhance efficiency and durability.

Strength: High-temperature resistance. Weakness: High development cost.

General Electric Technology GmbH

Technical Solution: General Electric Technology GmbH offers advanced ceramic and metallic seals for turbine engines, emphasizing durability and performance under extreme conditions to reduce maintenance and extend engine life.

Strength: Durability under extreme conditions. Weakness: Complex manufacturing process.

Turbine Engine Key Technology Interpretation

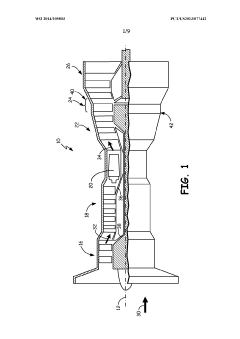

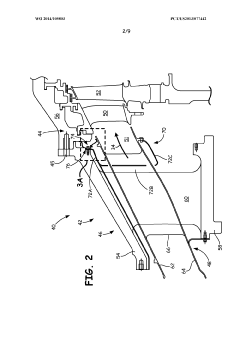

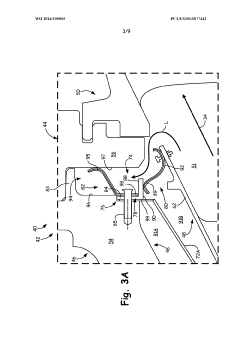

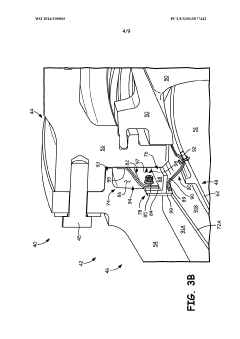

Gas turbine seal assembly and seal support

PatentWO2014105803A1

Innovation

- The use of a seal support ring and finger seals to provide a tight seal and prevent air leakage between different parts of the engine.

- Positioning seals in various parts of the engine, such as the turbine exhaust case and outer case sections, to ensure comprehensive sealing and prevent air leakage.

- Improved engine efficiency, reduced fuel consumption, and enhanced overall performance due to effective sealing mechanisms.

Turbine Engine Sealing Improvement Economic Analysis

The economic analysis of improving sealing in turbine engine technology focuses on cost-benefit evaluation. Enhanced sealing can lead to increased efficiency, reduced fuel consumption, and lower emissions, which translate into operational cost savings and environmental benefits. However, the initial investment in advanced materials and manufacturing processes must be considered. The market demand for more efficient and eco-friendly engines drives innovation, making the investment potentially lucrative. Analyzing the return on investment (ROI) involves comparing the upfront costs with long-term savings and market advantages, ensuring that the economic benefits outweigh the expenditures.

Turbine Engine Sealing Improvement Policy and Regulatory Impact

The improvement of sealing in turbine engine technology is significantly influenced by policies and regulations. Regulatory bodies set stringent standards for emissions, efficiency, and safety, driving innovation in sealing technologies to meet these requirements. Policies promoting environmental sustainability push for advancements in materials and designs that enhance sealing performance, reduce leakage, and improve overall engine efficiency. Compliance with these regulations ensures competitive advantage and market acceptance. Thus, understanding and aligning with policy and regulatory frameworks is crucial for developing effective sealing solutions in turbine engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!