Steering Wheel Materials: Sustainable and Durable Choices

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Materials Evolution and Objectives

The evolution of steering wheel materials has been driven by the automotive industry's pursuit of safety, comfort, and sustainability. Initially, steering wheels were crafted from wood, which provided a natural and aesthetically pleasing appearance. However, as vehicle safety standards became more stringent, manufacturers shifted towards more durable and impact-resistant materials.

In the mid-20th century, metal frames covered with hard plastics became the norm, offering improved strength and durability. This transition marked a significant step in steering wheel design, prioritizing safety over aesthetics. The introduction of polyurethane foam in the 1970s revolutionized steering wheel comfort, providing a softer grip and better insulation against vibrations.

The late 20th century saw the widespread adoption of leather-wrapped steering wheels, particularly in luxury vehicles. This trend combined the tactile comfort of leather with the underlying strength of synthetic materials, enhancing both the driving experience and perceived vehicle quality.

Recent years have witnessed a growing emphasis on sustainability in automotive design. This shift has led to the exploration of eco-friendly alternatives to traditional steering wheel materials. Manufacturers are now investigating plant-based polymers, recycled plastics, and other sustainable materials that can meet the rigorous safety and durability standards required for steering wheels.

The primary objective in steering wheel material research is to develop sustainable and durable solutions that do not compromise on safety or comfort. This goal aligns with broader industry trends towards reducing environmental impact and meeting increasingly stringent regulations on vehicle emissions and lifecycle sustainability.

Key objectives include:

1. Identifying renewable and biodegradable materials that can withstand the wear and tear of daily use.

2. Developing recycling processes for end-of-life steering wheels to minimize waste.

3. Improving the durability of sustainable materials to match or exceed that of traditional options.

4. Enhancing the tactile properties of eco-friendly materials to maintain or improve driver comfort and control.

5. Reducing the carbon footprint associated with steering wheel production and disposal.

As the automotive industry continues to evolve, the focus on sustainable and durable materials for steering wheels represents a critical area of research and development. This pursuit not only addresses environmental concerns but also drives innovation in material science, potentially leading to breakthroughs that could be applied across various automotive components and beyond.

In the mid-20th century, metal frames covered with hard plastics became the norm, offering improved strength and durability. This transition marked a significant step in steering wheel design, prioritizing safety over aesthetics. The introduction of polyurethane foam in the 1970s revolutionized steering wheel comfort, providing a softer grip and better insulation against vibrations.

The late 20th century saw the widespread adoption of leather-wrapped steering wheels, particularly in luxury vehicles. This trend combined the tactile comfort of leather with the underlying strength of synthetic materials, enhancing both the driving experience and perceived vehicle quality.

Recent years have witnessed a growing emphasis on sustainability in automotive design. This shift has led to the exploration of eco-friendly alternatives to traditional steering wheel materials. Manufacturers are now investigating plant-based polymers, recycled plastics, and other sustainable materials that can meet the rigorous safety and durability standards required for steering wheels.

The primary objective in steering wheel material research is to develop sustainable and durable solutions that do not compromise on safety or comfort. This goal aligns with broader industry trends towards reducing environmental impact and meeting increasingly stringent regulations on vehicle emissions and lifecycle sustainability.

Key objectives include:

1. Identifying renewable and biodegradable materials that can withstand the wear and tear of daily use.

2. Developing recycling processes for end-of-life steering wheels to minimize waste.

3. Improving the durability of sustainable materials to match or exceed that of traditional options.

4. Enhancing the tactile properties of eco-friendly materials to maintain or improve driver comfort and control.

5. Reducing the carbon footprint associated with steering wheel production and disposal.

As the automotive industry continues to evolve, the focus on sustainable and durable materials for steering wheels represents a critical area of research and development. This pursuit not only addresses environmental concerns but also drives innovation in material science, potentially leading to breakthroughs that could be applied across various automotive components and beyond.

Market Demand for Sustainable Automotive Interiors

The automotive industry is witnessing a significant shift towards sustainability, driven by increasing environmental awareness and stringent regulations. This trend has created a growing market demand for sustainable automotive interiors, including steering wheels. Consumers are becoming more conscious of the environmental impact of their vehicle choices, leading to a preference for eco-friendly materials and production processes.

The steering wheel, as a crucial touchpoint between the driver and the vehicle, has become a focal point for sustainability efforts. Manufacturers are responding to this demand by exploring innovative materials and production techniques that reduce environmental impact while maintaining or improving durability and performance. This shift is not only driven by consumer preferences but also by regulatory pressures aimed at reducing the automotive industry's carbon footprint.

Market research indicates that a substantial portion of car buyers are willing to pay a premium for vehicles with sustainable interiors. This willingness is particularly pronounced among younger generations and in markets with strong environmental consciousness. The demand for sustainable steering wheels is expected to grow at a compound annual growth rate (CAGR) of several percentage points over the next five years, outpacing the overall automotive market growth.

Luxury and electric vehicle segments are leading the adoption of sustainable materials in steering wheels, setting trends that are gradually permeating into mainstream vehicle categories. This trickle-down effect is accelerating the market expansion for sustainable steering wheel materials across various price points and vehicle types.

The push for sustainability in steering wheels is not limited to the materials used but extends to the entire lifecycle of the product. Consumers and regulators are increasingly interested in recyclability, end-of-life disposal, and the overall carbon footprint of steering wheel production. This holistic approach to sustainability is reshaping the supply chain and manufacturing processes in the automotive industry.

Moreover, the demand for sustainable steering wheels is intertwined with the broader trend of vehicle electrification. As electric vehicles gain market share, there is an increased emphasis on aligning the sustainability of the powertrain with that of the vehicle's interior components, including the steering wheel. This synergy is creating new opportunities for material innovation and market growth in the sustainable automotive interior sector.

The steering wheel, as a crucial touchpoint between the driver and the vehicle, has become a focal point for sustainability efforts. Manufacturers are responding to this demand by exploring innovative materials and production techniques that reduce environmental impact while maintaining or improving durability and performance. This shift is not only driven by consumer preferences but also by regulatory pressures aimed at reducing the automotive industry's carbon footprint.

Market research indicates that a substantial portion of car buyers are willing to pay a premium for vehicles with sustainable interiors. This willingness is particularly pronounced among younger generations and in markets with strong environmental consciousness. The demand for sustainable steering wheels is expected to grow at a compound annual growth rate (CAGR) of several percentage points over the next five years, outpacing the overall automotive market growth.

Luxury and electric vehicle segments are leading the adoption of sustainable materials in steering wheels, setting trends that are gradually permeating into mainstream vehicle categories. This trickle-down effect is accelerating the market expansion for sustainable steering wheel materials across various price points and vehicle types.

The push for sustainability in steering wheels is not limited to the materials used but extends to the entire lifecycle of the product. Consumers and regulators are increasingly interested in recyclability, end-of-life disposal, and the overall carbon footprint of steering wheel production. This holistic approach to sustainability is reshaping the supply chain and manufacturing processes in the automotive industry.

Moreover, the demand for sustainable steering wheels is intertwined with the broader trend of vehicle electrification. As electric vehicles gain market share, there is an increased emphasis on aligning the sustainability of the powertrain with that of the vehicle's interior components, including the steering wheel. This synergy is creating new opportunities for material innovation and market growth in the sustainable automotive interior sector.

Current Challenges in Steering Wheel Material Sustainability

The steering wheel industry faces significant challenges in developing sustainable and durable materials that meet both environmental and performance requirements. One of the primary issues is the reliance on petroleum-based materials, such as polyurethane and polyvinyl chloride (PVC), which are not biodegradable and contribute to environmental pollution. These materials also have a limited lifespan, leading to frequent replacements and increased waste generation.

Another challenge is the need for materials that can withstand extreme temperature variations and prolonged exposure to UV radiation without degrading or losing their structural integrity. This is particularly crucial for steering wheels, as they are constantly exposed to sunlight and temperature fluctuations inside vehicles. Current materials often suffer from discoloration, cracking, or peeling over time, compromising both aesthetics and safety.

The industry also struggles with finding sustainable alternatives that can match the tactile feel and grip of traditional materials. Steering wheels require a specific texture and level of friction to ensure safe and comfortable handling, which many eco-friendly materials have yet to replicate effectively. This balance between sustainability and performance remains a significant hurdle for manufacturers.

Additionally, there is a growing demand for antimicrobial properties in steering wheel materials, especially in the wake of global health concerns. Developing sustainable materials that also possess inherent antimicrobial qualities without relying on harmful chemical treatments presents a complex challenge for researchers and manufacturers alike.

The cost factor also poses a substantial obstacle in the transition to more sustainable materials. Many eco-friendly alternatives currently available are significantly more expensive than traditional materials, making it difficult for manufacturers to adopt them without increasing product prices substantially. This economic barrier slows down the industry's shift towards more sustainable practices.

Lastly, the lack of standardized testing and certification processes for sustainable steering wheel materials creates uncertainty in the market. Without clear guidelines and benchmarks, it becomes challenging for manufacturers to validate the environmental claims and performance characteristics of new materials, hindering innovation and adoption of truly sustainable solutions.

Another challenge is the need for materials that can withstand extreme temperature variations and prolonged exposure to UV radiation without degrading or losing their structural integrity. This is particularly crucial for steering wheels, as they are constantly exposed to sunlight and temperature fluctuations inside vehicles. Current materials often suffer from discoloration, cracking, or peeling over time, compromising both aesthetics and safety.

The industry also struggles with finding sustainable alternatives that can match the tactile feel and grip of traditional materials. Steering wheels require a specific texture and level of friction to ensure safe and comfortable handling, which many eco-friendly materials have yet to replicate effectively. This balance between sustainability and performance remains a significant hurdle for manufacturers.

Additionally, there is a growing demand for antimicrobial properties in steering wheel materials, especially in the wake of global health concerns. Developing sustainable materials that also possess inherent antimicrobial qualities without relying on harmful chemical treatments presents a complex challenge for researchers and manufacturers alike.

The cost factor also poses a substantial obstacle in the transition to more sustainable materials. Many eco-friendly alternatives currently available are significantly more expensive than traditional materials, making it difficult for manufacturers to adopt them without increasing product prices substantially. This economic barrier slows down the industry's shift towards more sustainable practices.

Lastly, the lack of standardized testing and certification processes for sustainable steering wheel materials creates uncertainty in the market. Without clear guidelines and benchmarks, it becomes challenging for manufacturers to validate the environmental claims and performance characteristics of new materials, hindering innovation and adoption of truly sustainable solutions.

Existing Sustainable Steering Wheel Material Solutions

01 Use of sustainable and eco-friendly materials

Steering wheels are being manufactured using sustainable and eco-friendly materials to reduce environmental impact. These materials include recycled plastics, bio-based polymers, and natural fibers. The use of such materials not only improves sustainability but also maintains the durability and performance of the steering wheel.- Use of sustainable and eco-friendly materials: Steering wheels are being manufactured using sustainable and eco-friendly materials to reduce environmental impact. These materials include recycled plastics, bio-based polymers, and natural fibers. The use of such materials not only improves sustainability but also maintains the durability and performance of the steering wheel.

- Advanced composite materials for enhanced durability: Innovative composite materials are being utilized in steering wheel construction to improve durability and longevity. These composites often combine lightweight materials with high-strength fibers, resulting in steering wheels that are resistant to wear, temperature fluctuations, and impact. The use of these materials also contributes to overall vehicle weight reduction.

- Smart materials for adaptive functionality: Integration of smart materials in steering wheels allows for adaptive functionality and improved durability. These materials can change properties in response to external stimuli, such as temperature or pressure, enhancing grip, comfort, and overall steering wheel lifespan. Some smart materials also have self-healing properties, further extending the product's durability.

- Coating technologies for increased lifespan: Advanced coating technologies are being applied to steering wheel materials to enhance their durability and resistance to wear. These coatings can protect against UV radiation, chemical exposure, and physical abrasion. Some coatings also provide antimicrobial properties, contributing to the overall hygiene and longevity of the steering wheel.

- Modular and replaceable component design: Steering wheels are being designed with modular and replaceable components to improve sustainability and extend overall product life. This approach allows for easy repair and replacement of worn parts without the need to replace the entire steering wheel. It also facilitates the integration of new technologies and materials as they become available.

02 Advanced composite materials for enhanced durability

Innovative composite materials are being developed to improve the durability of steering wheels. These materials combine lightweight properties with high strength and resistance to wear and tear. The use of advanced composites helps extend the lifespan of steering wheels while maintaining optimal performance and safety standards.Expand Specific Solutions03 Smart materials for adaptive functionality

Integration of smart materials in steering wheel design allows for adaptive functionality and improved durability. These materials can respond to various stimuli, such as temperature or pressure, to enhance grip, comfort, and overall performance. The use of smart materials contributes to the longevity of the steering wheel by adapting to different driving conditions.Expand Specific Solutions04 Nanotechnology-enhanced materials for improved properties

Nanotechnology is being applied to steering wheel materials to enhance their properties. Nanoparticles and nanostructures are incorporated into the base materials to improve strength, wear resistance, and overall durability. This technology also allows for the development of self-cleaning and antimicrobial surfaces, contributing to the sustainability and longevity of the steering wheel.Expand Specific Solutions05 Modular and replaceable components for extended lifespan

Steering wheel designs are incorporating modular and replaceable components to extend the overall lifespan of the product. This approach allows for easy maintenance, repair, and replacement of worn-out parts without the need to replace the entire steering wheel. The modular design contributes to sustainability by reducing waste and improving the longevity of the steering system.Expand Specific Solutions

Key Players in Automotive Interior Materials

The research on sustainable and durable materials for steering wheels is in a growth phase, with increasing market demand driven by automotive industry trends towards sustainability and durability. The global market size for automotive steering wheel materials is expanding, fueled by rising vehicle production and consumer preferences for high-quality interiors. Technologically, the field is advancing rapidly, with companies like Autoliv Development AB, ZF Automotive Safety Germany GmbH, and Hyundai Motor Co., Ltd. leading innovation. These firms are developing new materials and manufacturing processes to enhance steering wheel durability, sustainability, and performance. Established automotive giants such as Honda Motor Co., Ltd. and BMW AG are also investing heavily in this area, indicating the technology's growing maturity and strategic importance in the automotive sector.

Autoliv Development AB

Technical Solution: Autoliv has developed a sustainable steering wheel concept using bio-based materials. Their approach involves using renewable resources such as flax fibers and bio-resins to create a lightweight yet durable steering wheel structure. The company has implemented a lifecycle assessment to ensure the environmental impact is minimized from production to end-of-life[1]. Additionally, Autoliv has incorporated recycled materials into non-structural components of the steering wheel, further enhancing its sustainability credentials[2]. The durability of these materials has been tested to meet automotive industry standards, with accelerated aging tests showing comparable performance to traditional materials[3].

Strengths: Reduced environmental impact, lightweight design, meets industry durability standards. Weaknesses: Potentially higher production costs, limited long-term performance data compared to traditional materials.

ZF Automotive Safety Germany GmbH

Technical Solution: ZF has developed a range of sustainable materials for steering wheels, focusing on both environmental impact and durability. Their research includes the use of recycled carbon fibers in the steering wheel core, which provides strength and reduces weight while repurposing waste materials[4]. ZF has also explored the use of bio-based polyurethane foams for the outer layer, derived from plant-based oils, which offer comparable comfort and durability to traditional petroleum-based foams[5]. The company has implemented a modular design approach, allowing for easier disassembly and recycling at the end of the product's life. Durability testing has shown that these sustainable materials can withstand temperature extremes, UV exposure, and repeated use cycles typical in automotive applications[6].

Strengths: Innovative use of recycled and bio-based materials, modular design for improved recyclability, proven durability in automotive conditions. Weaknesses: Potential cost increases, may require adjustments to existing manufacturing processes.

Innovative Eco-friendly Steering Wheel Material Technologies

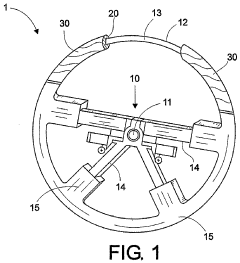

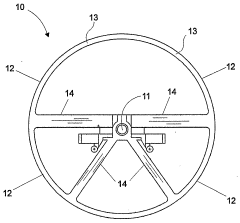

Automobile steering wheel

PatentWO1996031567A1

Innovation

- A thermoplastic elastomer composition comprising polyethylene resin, a styrene block copolymer, and optionally a partially crosslinked polyolefinic thermoplastic elastomer, providing a soft, low-specific-gravity, recyclable, and wear-resistant material for steering wheels.

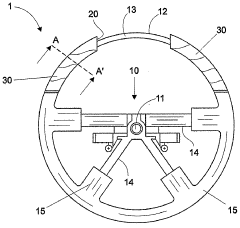

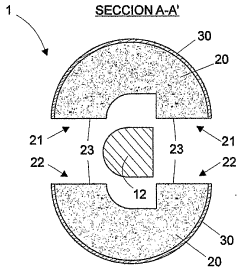

Steering wheel that has an intermediate cork cover and method for obtaining same

PatentWO2007116236A1

Innovation

- A steering wheel with an intermediate cork cover that is formed by mixing cork particles with a curable polyurethane resin and molded into complementary halves, which can be easily shaped for ergonomic designs and features a decorative layer for aesthetics, providing a low-cost, durable, and comfortable grip.

Life Cycle Assessment of Steering Wheel Materials

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of steering wheel materials throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, use phase, and end-of-life disposal or recycling. For steering wheels, the assessment typically focuses on materials such as polyurethane, leather, wood, and various synthetic composites.

The raw material extraction phase considers the environmental consequences of obtaining the primary components for steering wheel production. This includes the energy consumption, water usage, and emissions associated with mining or harvesting activities. For instance, leather production involves significant water consumption and potential chemical pollution, while synthetic materials may require energy-intensive petroleum extraction processes.

Manufacturing processes are scrutinized for their energy efficiency, waste generation, and emissions. The production of steering wheels often involves molding, cutting, and assembly operations, each contributing to the overall environmental footprint. Advanced manufacturing techniques, such as 3D printing or precision molding, may offer opportunities for reducing material waste and energy consumption.

The use phase of steering wheel materials is particularly important due to the long lifespan of vehicles. Durability and resistance to wear are critical factors, as materials that degrade quickly may require premature replacement, increasing the overall environmental impact. Additionally, the weight of the steering wheel can influence fuel consumption over the vehicle's lifetime, making lightweight yet durable materials increasingly attractive.

End-of-life considerations focus on the recyclability or biodegradability of steering wheel materials. Traditional materials like leather present challenges in recycling, while certain synthetic composites may offer improved recyclability. The potential for material recovery and reuse is a key factor in reducing the overall environmental impact of steering wheel production.

LCA studies on steering wheel materials often reveal trade-offs between different environmental impacts. For example, a material with low production emissions might have poor durability, leading to increased replacement frequency. These assessments help manufacturers and designers make informed decisions, balancing performance requirements with environmental considerations.

Emerging sustainable materials, such as bio-based polymers or recycled composites, are increasingly being evaluated through LCA. These materials offer potential advantages in terms of reduced carbon footprint and improved end-of-life options. However, their overall environmental impact must be carefully assessed to ensure they truly offer improvements across the entire lifecycle.

The raw material extraction phase considers the environmental consequences of obtaining the primary components for steering wheel production. This includes the energy consumption, water usage, and emissions associated with mining or harvesting activities. For instance, leather production involves significant water consumption and potential chemical pollution, while synthetic materials may require energy-intensive petroleum extraction processes.

Manufacturing processes are scrutinized for their energy efficiency, waste generation, and emissions. The production of steering wheels often involves molding, cutting, and assembly operations, each contributing to the overall environmental footprint. Advanced manufacturing techniques, such as 3D printing or precision molding, may offer opportunities for reducing material waste and energy consumption.

The use phase of steering wheel materials is particularly important due to the long lifespan of vehicles. Durability and resistance to wear are critical factors, as materials that degrade quickly may require premature replacement, increasing the overall environmental impact. Additionally, the weight of the steering wheel can influence fuel consumption over the vehicle's lifetime, making lightweight yet durable materials increasingly attractive.

End-of-life considerations focus on the recyclability or biodegradability of steering wheel materials. Traditional materials like leather present challenges in recycling, while certain synthetic composites may offer improved recyclability. The potential for material recovery and reuse is a key factor in reducing the overall environmental impact of steering wheel production.

LCA studies on steering wheel materials often reveal trade-offs between different environmental impacts. For example, a material with low production emissions might have poor durability, leading to increased replacement frequency. These assessments help manufacturers and designers make informed decisions, balancing performance requirements with environmental considerations.

Emerging sustainable materials, such as bio-based polymers or recycled composites, are increasingly being evaluated through LCA. These materials offer potential advantages in terms of reduced carbon footprint and improved end-of-life options. However, their overall environmental impact must be carefully assessed to ensure they truly offer improvements across the entire lifecycle.

Regulatory Framework for Automotive Sustainability

The regulatory framework for automotive sustainability plays a crucial role in shaping the development and implementation of sustainable and durable materials for steering wheels. As governments worldwide increasingly focus on environmental protection and resource conservation, automotive manufacturers are compelled to adapt their practices and materials to meet stringent regulations.

In the European Union, the End-of-Life Vehicles (ELV) Directive sets targets for the reuse, recycling, and recovery of materials from vehicles. This directive directly impacts the choice of materials for steering wheels, encouraging manufacturers to use recyclable and recoverable materials. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation restricts the use of certain hazardous substances in automotive components, including steering wheels.

The United States Environmental Protection Agency (EPA) has established Corporate Average Fuel Economy (CAFE) standards, which indirectly influence material selection for steering wheels. As automakers strive to reduce vehicle weight to meet fuel efficiency targets, they are incentivized to use lightweight, sustainable materials in all components, including steering wheels.

In Asia, countries like Japan and South Korea have implemented their own regulations promoting automotive sustainability. Japan's Automobile Recycling Law mandates the recycling of end-of-life vehicles, while South Korea's Resource Circulation Act encourages the use of eco-friendly materials in vehicle production.

Global initiatives such as the United Nations Sustainable Development Goals (SDGs) also impact the regulatory landscape for automotive sustainability. SDG 12, which focuses on responsible consumption and production, has led to increased pressure on automotive manufacturers to adopt sustainable practices throughout their supply chains.

The regulatory framework also extends to labeling and certification requirements. For instance, the ISO 14001 environmental management standard is widely adopted in the automotive industry, influencing material selection and production processes for components like steering wheels.

As regulations continue to evolve, automotive manufacturers must stay ahead of the curve by investing in research and development of sustainable and durable materials for steering wheels. This includes exploring bio-based materials, advanced recycling technologies, and innovative manufacturing processes that minimize environmental impact while maintaining or improving performance and durability.

The regulatory landscape for automotive sustainability is dynamic, with new regulations and standards emerging regularly. Manufacturers must maintain a proactive approach to compliance, anticipating future regulatory changes and adapting their material selection and production processes accordingly. This forward-thinking approach not only ensures compliance but also positions companies as leaders in sustainable automotive manufacturing.

In the European Union, the End-of-Life Vehicles (ELV) Directive sets targets for the reuse, recycling, and recovery of materials from vehicles. This directive directly impacts the choice of materials for steering wheels, encouraging manufacturers to use recyclable and recoverable materials. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation restricts the use of certain hazardous substances in automotive components, including steering wheels.

The United States Environmental Protection Agency (EPA) has established Corporate Average Fuel Economy (CAFE) standards, which indirectly influence material selection for steering wheels. As automakers strive to reduce vehicle weight to meet fuel efficiency targets, they are incentivized to use lightweight, sustainable materials in all components, including steering wheels.

In Asia, countries like Japan and South Korea have implemented their own regulations promoting automotive sustainability. Japan's Automobile Recycling Law mandates the recycling of end-of-life vehicles, while South Korea's Resource Circulation Act encourages the use of eco-friendly materials in vehicle production.

Global initiatives such as the United Nations Sustainable Development Goals (SDGs) also impact the regulatory landscape for automotive sustainability. SDG 12, which focuses on responsible consumption and production, has led to increased pressure on automotive manufacturers to adopt sustainable practices throughout their supply chains.

The regulatory framework also extends to labeling and certification requirements. For instance, the ISO 14001 environmental management standard is widely adopted in the automotive industry, influencing material selection and production processes for components like steering wheels.

As regulations continue to evolve, automotive manufacturers must stay ahead of the curve by investing in research and development of sustainable and durable materials for steering wheels. This includes exploring bio-based materials, advanced recycling technologies, and innovative manufacturing processes that minimize environmental impact while maintaining or improving performance and durability.

The regulatory landscape for automotive sustainability is dynamic, with new regulations and standards emerging regularly. Manufacturers must maintain a proactive approach to compliance, anticipating future regulatory changes and adapting their material selection and production processes accordingly. This forward-thinking approach not only ensures compliance but also positions companies as leaders in sustainable automotive manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!