Steering Wheel Developments: Enhancing Thermal Comfort

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Thermal Evolution and Objectives

The evolution of steering wheel thermal comfort technology has been a significant focus in the automotive industry over the past few decades. Initially, steering wheels were simple mechanical devices designed solely for vehicle control. However, as consumer expectations for comfort and luxury in vehicles increased, manufacturers began to explore ways to enhance the driving experience through thermal management of the steering wheel.

The first major breakthrough in this field came in the late 1990s with the introduction of heated steering wheels. This technology utilized embedded heating elements within the wheel to provide warmth during cold weather conditions. The primary objective was to improve driver comfort and safety by reducing the time needed for hands to warm up, thereby enhancing grip and control.

As the technology progressed, the focus shifted from merely providing heat to offering a more comprehensive thermal management system. By the mid-2000s, manufacturers began experimenting with cooling technologies for steering wheels, recognizing the need for comfort in hot climates as well. This led to the development of ventilated steering wheels, which use small fans or air circulation systems to reduce heat and moisture buildup.

The current technological landscape is characterized by a push towards more advanced and efficient thermal management systems. Modern steering wheels often incorporate both heating and cooling capabilities, with the ability to rapidly adjust temperatures based on ambient conditions and driver preferences. The integration of smart sensors and adaptive control systems has further enhanced the precision and effectiveness of these thermal comfort features.

Looking forward, the objectives for steering wheel thermal technology are multifaceted. There is a strong emphasis on improving energy efficiency, particularly in the context of electric vehicles where power consumption is a critical factor. Researchers are exploring novel materials and designs that can provide better insulation and more uniform heat distribution while minimizing energy use.

Another key objective is the development of more personalized and responsive systems. This includes the integration of biometric sensors to detect the driver's body temperature and adjust the steering wheel temperature accordingly. Additionally, there is growing interest in incorporating haptic feedback and touch-sensitive surfaces into thermal management systems, allowing for more intuitive control and customization.

As vehicles become increasingly autonomous, the role of the steering wheel is also evolving. Future objectives may include developing thermal comfort technologies that can seamlessly transition between manual and autonomous driving modes, adapting to different user needs and preferences in various scenarios.

The first major breakthrough in this field came in the late 1990s with the introduction of heated steering wheels. This technology utilized embedded heating elements within the wheel to provide warmth during cold weather conditions. The primary objective was to improve driver comfort and safety by reducing the time needed for hands to warm up, thereby enhancing grip and control.

As the technology progressed, the focus shifted from merely providing heat to offering a more comprehensive thermal management system. By the mid-2000s, manufacturers began experimenting with cooling technologies for steering wheels, recognizing the need for comfort in hot climates as well. This led to the development of ventilated steering wheels, which use small fans or air circulation systems to reduce heat and moisture buildup.

The current technological landscape is characterized by a push towards more advanced and efficient thermal management systems. Modern steering wheels often incorporate both heating and cooling capabilities, with the ability to rapidly adjust temperatures based on ambient conditions and driver preferences. The integration of smart sensors and adaptive control systems has further enhanced the precision and effectiveness of these thermal comfort features.

Looking forward, the objectives for steering wheel thermal technology are multifaceted. There is a strong emphasis on improving energy efficiency, particularly in the context of electric vehicles where power consumption is a critical factor. Researchers are exploring novel materials and designs that can provide better insulation and more uniform heat distribution while minimizing energy use.

Another key objective is the development of more personalized and responsive systems. This includes the integration of biometric sensors to detect the driver's body temperature and adjust the steering wheel temperature accordingly. Additionally, there is growing interest in incorporating haptic feedback and touch-sensitive surfaces into thermal management systems, allowing for more intuitive control and customization.

As vehicles become increasingly autonomous, the role of the steering wheel is also evolving. Future objectives may include developing thermal comfort technologies that can seamlessly transition between manual and autonomous driving modes, adapting to different user needs and preferences in various scenarios.

Market Analysis for Heated Steering Wheels

The market for heated steering wheels has experienced significant growth in recent years, driven by increasing consumer demand for comfort and luxury features in vehicles. This trend is particularly pronounced in regions with cold climates, where heated steering wheels provide a tangible improvement in driver comfort during winter months.

The global heated steering wheel market was valued at approximately $1.5 billion in 2020 and is projected to reach $2.8 billion by 2027, growing at a CAGR of 9.3% during the forecast period. This growth is attributed to several factors, including the rising adoption of premium vehicles, increasing disposable income in emerging economies, and a growing emphasis on driver comfort and safety.

North America and Europe currently dominate the heated steering wheel market, accounting for over 70% of the global market share. This is due to the prevalence of cold weather conditions and the high penetration of luxury vehicles in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing vehicle production and rising consumer preferences for comfort features in countries like China and Japan.

The market is segmented based on vehicle type, with passenger cars holding the largest market share. Within the passenger car segment, luxury vehicles have the highest adoption rate of heated steering wheels, often offering them as standard features. However, there is a growing trend of heated steering wheels being introduced in mid-range and even some economy vehicles as optional equipment, expanding the potential market.

In terms of sales channels, OEM (Original Equipment Manufacturer) installations dominate the market, accounting for over 80% of sales. This is because heated steering wheels are typically integrated into the vehicle during the manufacturing process. The aftermarket segment, while smaller, is showing steady growth as consumers seek to upgrade their existing vehicles with comfort features.

Key market drivers include technological advancements in heating systems, increasing integration of smart features in steering wheels, and growing consumer awareness of the benefits of heated steering wheels in terms of comfort and safety. Additionally, the trend towards electric vehicles is expected to positively impact the market, as these vehicles often prioritize comfort features to differentiate themselves in the competitive automotive landscape.

However, the market also faces challenges, such as the high cost of heated steering wheels, which can limit their adoption in lower-priced vehicle segments. Additionally, concerns about the impact on battery life in electric vehicles and the need for standardization in heating technology across different vehicle models present obstacles to market growth.

The global heated steering wheel market was valued at approximately $1.5 billion in 2020 and is projected to reach $2.8 billion by 2027, growing at a CAGR of 9.3% during the forecast period. This growth is attributed to several factors, including the rising adoption of premium vehicles, increasing disposable income in emerging economies, and a growing emphasis on driver comfort and safety.

North America and Europe currently dominate the heated steering wheel market, accounting for over 70% of the global market share. This is due to the prevalence of cold weather conditions and the high penetration of luxury vehicles in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing vehicle production and rising consumer preferences for comfort features in countries like China and Japan.

The market is segmented based on vehicle type, with passenger cars holding the largest market share. Within the passenger car segment, luxury vehicles have the highest adoption rate of heated steering wheels, often offering them as standard features. However, there is a growing trend of heated steering wheels being introduced in mid-range and even some economy vehicles as optional equipment, expanding the potential market.

In terms of sales channels, OEM (Original Equipment Manufacturer) installations dominate the market, accounting for over 80% of sales. This is because heated steering wheels are typically integrated into the vehicle during the manufacturing process. The aftermarket segment, while smaller, is showing steady growth as consumers seek to upgrade their existing vehicles with comfort features.

Key market drivers include technological advancements in heating systems, increasing integration of smart features in steering wheels, and growing consumer awareness of the benefits of heated steering wheels in terms of comfort and safety. Additionally, the trend towards electric vehicles is expected to positively impact the market, as these vehicles often prioritize comfort features to differentiate themselves in the competitive automotive landscape.

However, the market also faces challenges, such as the high cost of heated steering wheels, which can limit their adoption in lower-priced vehicle segments. Additionally, concerns about the impact on battery life in electric vehicles and the need for standardization in heating technology across different vehicle models present obstacles to market growth.

Current Thermal Technologies and Challenges

The current landscape of steering wheel thermal technologies presents a mix of established solutions and emerging innovations, each with its own set of challenges. Traditional heating systems, which have been in use for decades, typically employ resistive heating elements embedded within the steering wheel rim. These systems provide reliable warmth but often suffer from slow response times and uneven heat distribution. Additionally, they can be energy-intensive, potentially impacting vehicle efficiency, especially in electric vehicles where power management is crucial.

More recent advancements have introduced thermoelectric devices based on the Peltier effect. These systems offer both heating and cooling capabilities, providing a more comprehensive thermal comfort solution. However, they face challenges in terms of energy efficiency and the complexity of integration into existing steering wheel designs. The need for both hot and cold sides in Peltier devices often requires intricate heat management systems, adding to the overall cost and weight of the steering wheel assembly.

Another emerging technology in this field is the use of conductive fabrics and coatings. These materials can be integrated into the steering wheel cover to provide more uniform heating. While promising, they currently face durability issues, especially under the constant stress and wear that steering wheels endure. Ensuring consistent performance over the vehicle's lifetime remains a significant challenge for this technology.

Climate-controlled steering wheels, which incorporate small vents to blow heated or cooled air, represent another innovative approach. These systems offer rapid temperature adjustment but face challenges in terms of noise generation and the complexity of integrating air channels within the limited space of a steering wheel.

A common challenge across all these technologies is the need for precise and responsive temperature control. Current sensor technologies and control algorithms often struggle to accurately detect and respond to the driver's thermal comfort needs, leading to suboptimal user experiences. This is particularly challenging given the variability in individual preferences and the dynamic nature of in-vehicle environments.

Power management and energy efficiency remain overarching concerns, especially as the automotive industry shifts towards electrification. Steering wheel thermal systems must balance comfort with energy consumption, a challenge that becomes more pronounced in electric vehicles where every watt of power usage directly impacts range.

Lastly, the integration of these thermal technologies with other emerging steering wheel features, such as touch-sensitive controls, haptic feedback systems, and airbag deployment mechanisms, presents significant design and engineering challenges. Ensuring that thermal comfort solutions do not compromise safety, functionality, or ergonomics is a complex task that requires careful consideration and innovative approaches.

More recent advancements have introduced thermoelectric devices based on the Peltier effect. These systems offer both heating and cooling capabilities, providing a more comprehensive thermal comfort solution. However, they face challenges in terms of energy efficiency and the complexity of integration into existing steering wheel designs. The need for both hot and cold sides in Peltier devices often requires intricate heat management systems, adding to the overall cost and weight of the steering wheel assembly.

Another emerging technology in this field is the use of conductive fabrics and coatings. These materials can be integrated into the steering wheel cover to provide more uniform heating. While promising, they currently face durability issues, especially under the constant stress and wear that steering wheels endure. Ensuring consistent performance over the vehicle's lifetime remains a significant challenge for this technology.

Climate-controlled steering wheels, which incorporate small vents to blow heated or cooled air, represent another innovative approach. These systems offer rapid temperature adjustment but face challenges in terms of noise generation and the complexity of integrating air channels within the limited space of a steering wheel.

A common challenge across all these technologies is the need for precise and responsive temperature control. Current sensor technologies and control algorithms often struggle to accurately detect and respond to the driver's thermal comfort needs, leading to suboptimal user experiences. This is particularly challenging given the variability in individual preferences and the dynamic nature of in-vehicle environments.

Power management and energy efficiency remain overarching concerns, especially as the automotive industry shifts towards electrification. Steering wheel thermal systems must balance comfort with energy consumption, a challenge that becomes more pronounced in electric vehicles where every watt of power usage directly impacts range.

Lastly, the integration of these thermal technologies with other emerging steering wheel features, such as touch-sensitive controls, haptic feedback systems, and airbag deployment mechanisms, presents significant design and engineering challenges. Ensuring that thermal comfort solutions do not compromise safety, functionality, or ergonomics is a complex task that requires careful consideration and innovative approaches.

Existing Heated Steering Wheel Solutions

01 Heating and cooling systems for steering wheels

Steering wheels can be equipped with integrated heating and cooling systems to provide thermal comfort to drivers. These systems may use various technologies such as thermoelectric elements, fluid circulation, or air ventilation to regulate the temperature of the steering wheel surface, ensuring a comfortable grip in different weather conditions.- Heating and cooling systems for steering wheels: Steering wheels can be equipped with integrated heating and cooling systems to provide thermal comfort for drivers. These systems may include heating elements, cooling channels, or thermoelectric devices embedded within the steering wheel structure. The temperature can be adjusted based on user preferences or ambient conditions, ensuring a comfortable grip in various weather conditions.

- Thermal sensors and adaptive control: Advanced steering wheel thermal comfort systems incorporate sensors to detect the temperature of the wheel surface and the driver's hands. These sensors provide input to adaptive control systems that automatically adjust the heating or cooling to maintain optimal comfort. The system may also consider factors such as ambient temperature and humidity to fine-tune its operation.

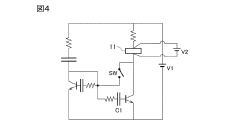

- Energy-efficient thermal management: To improve energy efficiency, steering wheel thermal comfort systems may employ smart power management techniques. These can include zonal heating or cooling, where only the areas in contact with the driver's hands are actively controlled. Additionally, the system may use predictive algorithms to anticipate thermal needs based on driving patterns or scheduled trips, optimizing energy consumption.

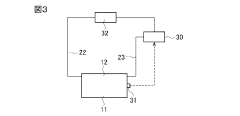

- Integration with vehicle climate control: Steering wheel thermal comfort systems can be integrated with the vehicle's overall climate control system. This integration allows for coordinated operation, ensuring that the steering wheel temperature complements the cabin environment. It may also enable features such as preconditioning the steering wheel temperature before the driver enters the vehicle, enhancing overall comfort.

- Ergonomic design for thermal comfort: The physical design of the steering wheel plays a crucial role in thermal comfort. This includes the selection of materials with appropriate thermal properties, such as those that don't become too hot or cold to touch in extreme temperatures. The wheel's shape and surface texture may also be optimized to enhance grip and comfort while facilitating effective heat transfer between the wheel and the driver's hands.

02 Thermal sensors and adaptive control

Advanced steering wheel thermal comfort systems incorporate temperature sensors and adaptive control algorithms. These sensors detect the ambient temperature and the driver's hand temperature, allowing the system to automatically adjust the steering wheel temperature for optimal comfort. The adaptive control can also learn user preferences over time.Expand Specific Solutions03 Energy-efficient thermal management

To improve energy efficiency, some steering wheel thermal comfort systems employ smart power management techniques. These may include zonal heating or cooling, where only the areas in contact with the driver's hands are temperature-controlled, or the use of energy-recuperation systems to minimize power consumption while maintaining comfort.Expand Specific Solutions04 Integration with vehicle climate control

Steering wheel thermal comfort systems can be integrated with the vehicle's overall climate control system. This integration allows for coordinated temperature management throughout the vehicle, enhancing overall driver comfort and potentially improving energy efficiency by balancing the thermal load across different vehicle systems.Expand Specific Solutions05 Materials and surface treatments for thermal comfort

Innovative materials and surface treatments are used to enhance the thermal properties of steering wheels. These may include thermally conductive or insulating materials, phase-change materials that absorb or release heat, or specially textured surfaces that improve grip and thermal sensation. Such materials can improve thermal comfort even without active heating or cooling systems.Expand Specific Solutions

Key Automotive Thermal Solution Providers

The steering wheel thermal comfort technology market is in a growth phase, with increasing demand for enhanced driver experience and vehicle comfort. The market size is expanding as automakers integrate advanced thermal management systems into their vehicles. Technological maturity varies among key players, with companies like Autoliv Development AB, Hyundai Motor Co., and Toyoda Gosei Co. leading in innovation. Established automotive giants such as Mercedes-Benz Group AG, BMW AG, and Ford Global Technologies are also investing heavily in this area. Emerging players like ZF Automotive Safety Germany GmbH and Valeo Schalter und Sensoren GmbH are contributing to market competitiveness with specialized solutions, indicating a dynamic and evolving landscape in steering wheel thermal comfort technology.

Honda Motor Co., Ltd.

Technical Solution: Honda has focused on developing a steering wheel thermal comfort system that prioritizes energy efficiency and rapid response. Their approach utilizes a thin-film heating element that covers the entire steering wheel surface, providing uniform heat distribution[10]. For cooling, Honda has implemented a novel microfluidic cooling system that circulates a temperature-controlled fluid through channels within the steering wheel structure[11]. This system allows for quick temperature adjustments while maintaining a consistent surface feel. Honda has also integrated their thermal comfort system with their driver attention monitoring system, automatically adjusting the steering wheel temperature based on detected driver fatigue levels to help maintain alertness[12]. Furthermore, the company has developed an eco-mode for their system that optimizes energy usage based on the vehicle's overall power consumption, making it particularly suitable for their hybrid and electric vehicle lineup.

Strengths: Energy-efficient design, integration with driver attention systems, and uniform temperature distribution. Weaknesses: Potential complexity in the microfluidic system and higher initial development costs.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has introduced a sophisticated steering wheel thermal comfort system as part of their ENERGIZING Comfort package. Their approach combines traditional heating elements with advanced air circulation technology. The system uses micro-perforations in the leather covering of the steering wheel, through which warm or cool air can be circulated[4]. This allows for more uniform temperature distribution and faster comfort adjustment. Mercedes has also integrated capacitive sensors to detect hand presence, activating the system only when needed to conserve energy[5]. Furthermore, the company has developed a predictive comfort algorithm that learns driver preferences over time and adjusts settings automatically based on factors such as outside temperature and vehicle climate control settings[6].

Strengths: Innovative air circulation technology, energy-efficient operation, and personalized comfort settings. Weaknesses: Potentially higher manufacturing costs and increased system complexity.

Innovative Thermal Management Patents

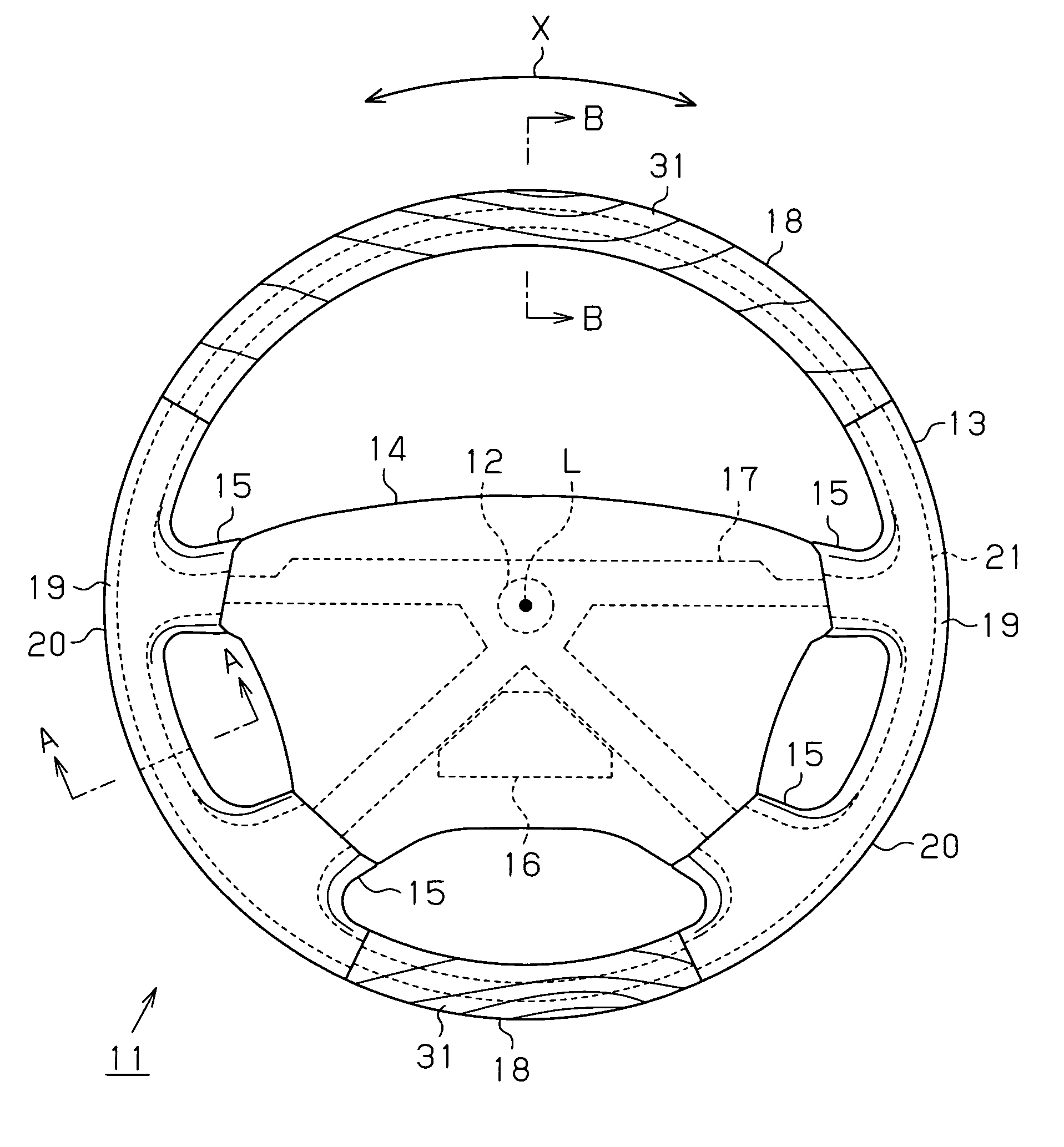

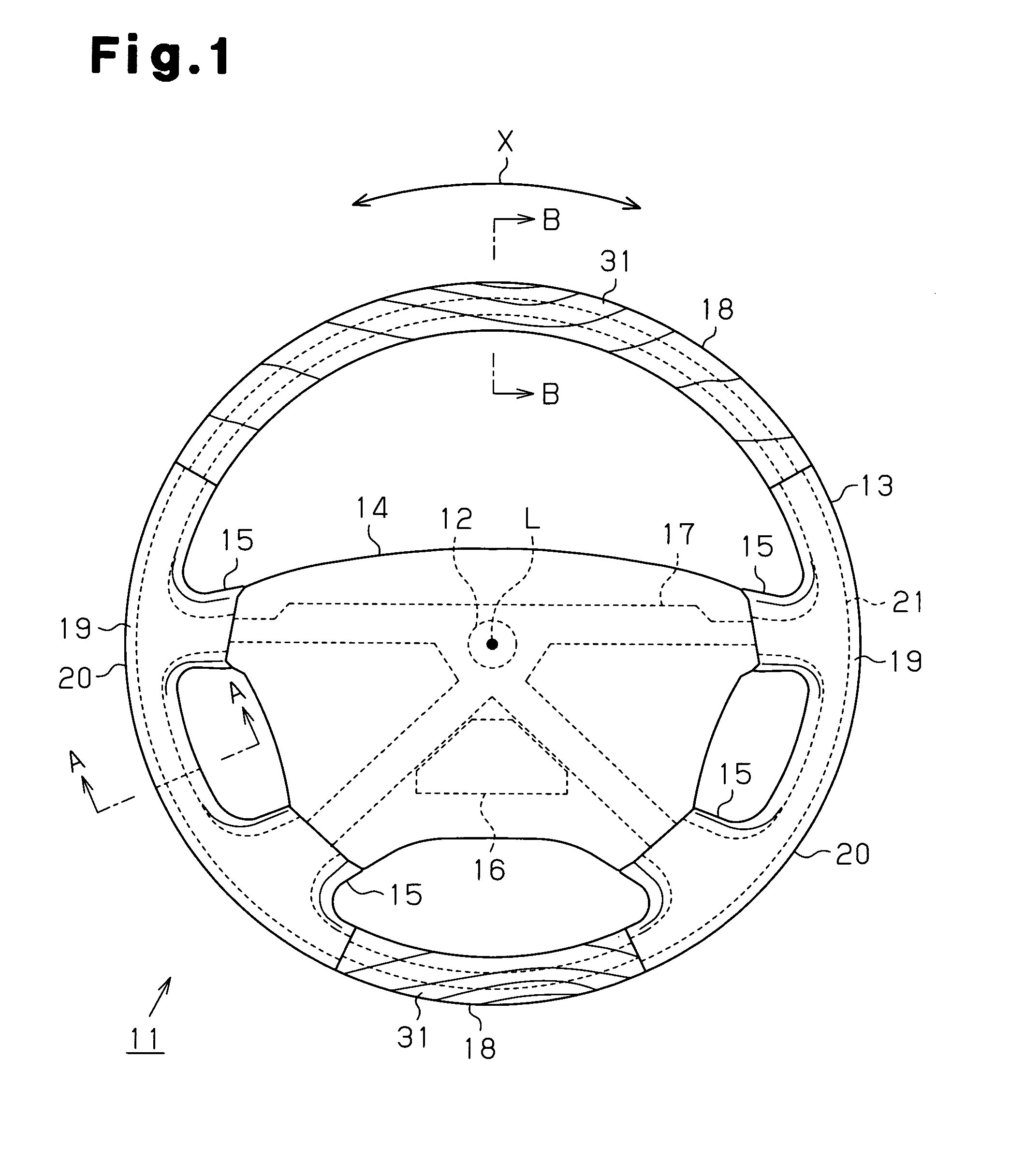

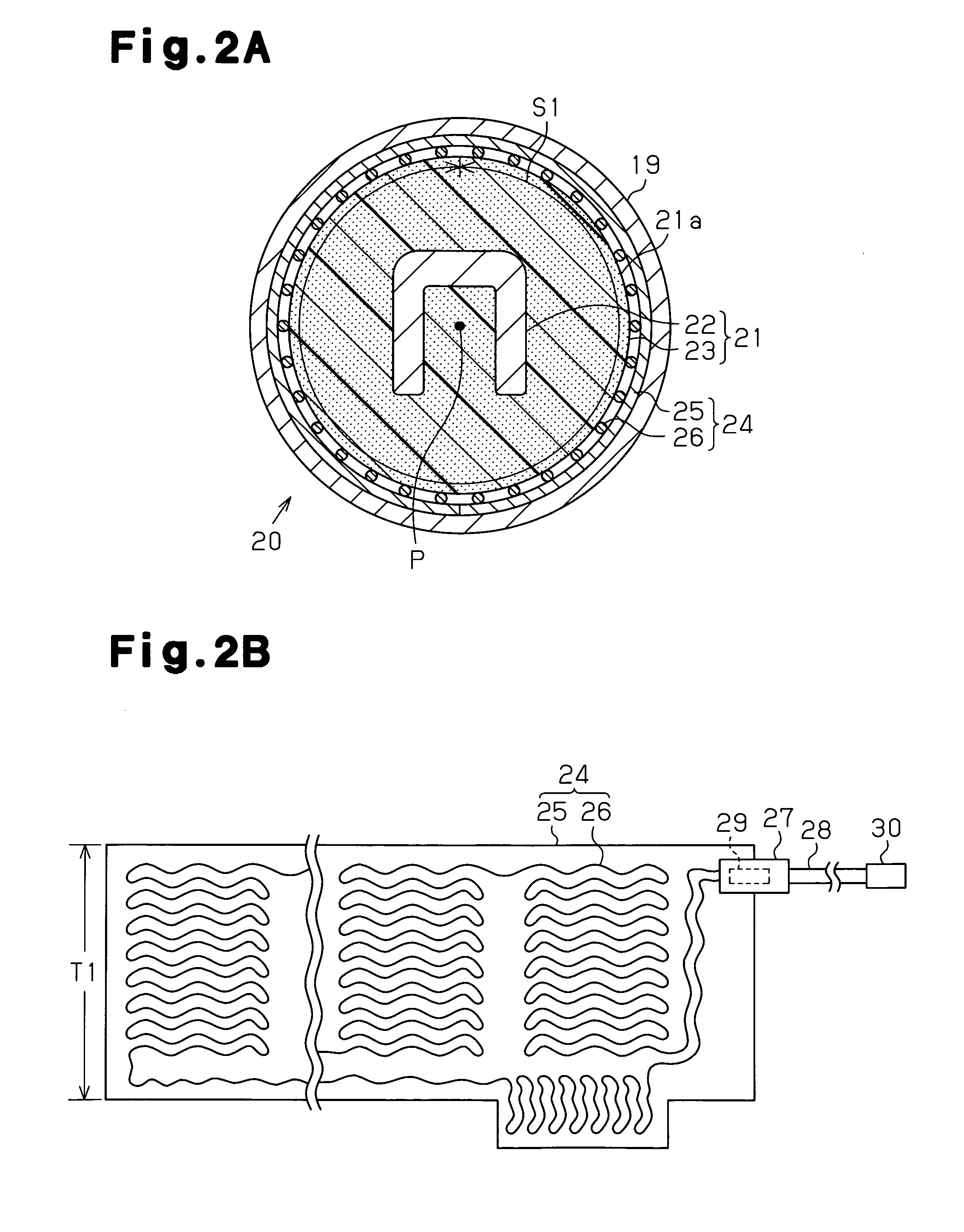

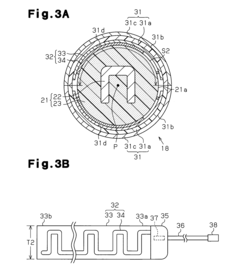

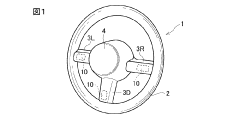

Steering wheel

PatentInactiveUS8330079B2

Innovation

- A steering wheel design featuring a rim with both leather-covered and wood-grain portions, each equipped with independent temperature adjusters and a control section that uses thermistors and heating wires to maintain a uniform surface temperature, ensuring that both materials are heated to a comfortable level.

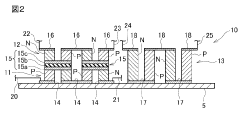

Steering having temperature adjustment device

PatentActiveJP2018199476A

Innovation

- A steering wheel with integrated thermoelectric conversion elements for cooling and heating, where one element dissipates heat to another to generate power, which is used to operate devices like displays, fans, and lighting, with temperature control and power management systems.

Energy Efficiency in Automotive Heating Systems

Energy efficiency in automotive heating systems has become a critical focus in the automotive industry, driven by the need to reduce overall vehicle energy consumption and improve range in electric vehicles. Traditional heating systems in vehicles rely heavily on waste heat from the internal combustion engine, which is not available in electric vehicles. This has led to the development of more efficient heating solutions that can operate without compromising the vehicle's energy reserves.

One of the primary approaches to improving energy efficiency in automotive heating systems is the implementation of heat pump technology. Heat pumps work by transferring heat from the outside environment into the vehicle cabin, rather than generating heat directly. This process is significantly more energy-efficient than resistive heating elements, which convert electricity directly into heat. Heat pumps can achieve a coefficient of performance (COP) of 3 or higher, meaning they can produce three units of heat energy for every unit of electrical energy consumed.

Another innovative solution is the use of infrared heating panels. These panels emit infrared radiation that directly warms occupants and surfaces within the vehicle, rather than heating the air. This targeted heating approach can reduce energy consumption by up to 30% compared to traditional forced-air systems. Infrared heating also provides more immediate comfort to passengers, as it does not rely on air circulation to distribute warmth.

Zonal heating systems have also emerged as an energy-efficient alternative. By dividing the vehicle cabin into separate climate zones, these systems allow for precise temperature control in occupied areas while reducing or eliminating heating in unoccupied spaces. This targeted approach can significantly reduce overall energy consumption, especially in larger vehicles or when not all seats are occupied.

The integration of smart climate control systems further enhances energy efficiency. These systems use advanced sensors and algorithms to optimize heating based on factors such as occupancy, sun load, and individual passenger preferences. By continuously adjusting the heating output to match real-time conditions, smart systems can minimize energy waste while maintaining optimal comfort levels.

Thermal management of the entire vehicle system has also become a key focus for improving heating efficiency. This holistic approach involves recovering waste heat from various vehicle components, such as the battery pack in electric vehicles or the powertrain in hybrid vehicles. By utilizing this recovered heat for cabin warming, the overall energy demand for heating can be substantially reduced.

As the automotive industry continues to prioritize energy efficiency, these innovative heating solutions are likely to evolve further. Future developments may include the integration of phase-change materials for thermal energy storage, advanced insulation technologies to reduce heat loss, and the use of artificial intelligence to predict and prepare for heating needs based on user habits and environmental conditions.

One of the primary approaches to improving energy efficiency in automotive heating systems is the implementation of heat pump technology. Heat pumps work by transferring heat from the outside environment into the vehicle cabin, rather than generating heat directly. This process is significantly more energy-efficient than resistive heating elements, which convert electricity directly into heat. Heat pumps can achieve a coefficient of performance (COP) of 3 or higher, meaning they can produce three units of heat energy for every unit of electrical energy consumed.

Another innovative solution is the use of infrared heating panels. These panels emit infrared radiation that directly warms occupants and surfaces within the vehicle, rather than heating the air. This targeted heating approach can reduce energy consumption by up to 30% compared to traditional forced-air systems. Infrared heating also provides more immediate comfort to passengers, as it does not rely on air circulation to distribute warmth.

Zonal heating systems have also emerged as an energy-efficient alternative. By dividing the vehicle cabin into separate climate zones, these systems allow for precise temperature control in occupied areas while reducing or eliminating heating in unoccupied spaces. This targeted approach can significantly reduce overall energy consumption, especially in larger vehicles or when not all seats are occupied.

The integration of smart climate control systems further enhances energy efficiency. These systems use advanced sensors and algorithms to optimize heating based on factors such as occupancy, sun load, and individual passenger preferences. By continuously adjusting the heating output to match real-time conditions, smart systems can minimize energy waste while maintaining optimal comfort levels.

Thermal management of the entire vehicle system has also become a key focus for improving heating efficiency. This holistic approach involves recovering waste heat from various vehicle components, such as the battery pack in electric vehicles or the powertrain in hybrid vehicles. By utilizing this recovered heat for cabin warming, the overall energy demand for heating can be substantially reduced.

As the automotive industry continues to prioritize energy efficiency, these innovative heating solutions are likely to evolve further. Future developments may include the integration of phase-change materials for thermal energy storage, advanced insulation technologies to reduce heat loss, and the use of artificial intelligence to predict and prepare for heating needs based on user habits and environmental conditions.

User Experience and Safety Considerations

The integration of thermal comfort features in steering wheels represents a significant advancement in automotive design, directly impacting user experience and safety. As drivers interact with the steering wheel more than any other vehicle control, its thermal properties play a crucial role in overall comfort and driving performance.

Thermal comfort in steering wheels addresses the issue of temperature extremes, which can significantly affect driver comfort and concentration. In cold weather, a chilly steering wheel can cause discomfort and reduce tactile sensitivity, potentially compromising control. Conversely, in hot conditions, an overheated steering wheel can lead to sweaty palms and reduced grip. By implementing heating and cooling technologies, manufacturers can maintain an optimal temperature range, enhancing the driving experience across various climatic conditions.

From a safety perspective, thermal comfort features contribute to maintaining driver alertness and reducing fatigue. Comfortable hand temperatures help sustain proper blood circulation, which is essential for maintaining reflexes and reaction times. This is particularly important during long drives or in challenging weather conditions where driver fatigue can pose significant safety risks.

The user experience is further enhanced by the customization options that thermal comfort features offer. Advanced systems allow drivers to set their preferred temperature, creating a personalized comfort zone. This level of customization not only improves satisfaction but also accommodates individual preferences and potential medical needs, such as arthritis or circulation issues that may be exacerbated by temperature extremes.

However, the implementation of thermal comfort features must be carefully balanced with other safety considerations. The integration of heating and cooling elements should not compromise the structural integrity or grip properties of the steering wheel. Manufacturers must ensure that these features do not introduce new safety risks, such as electrical hazards or reduced tactile feedback.

Moreover, the user interface for controlling these features must be intuitive and minimally distracting. Poorly designed controls could lead to driver distraction, potentially offsetting the safety benefits of improved comfort. Therefore, ergonomic design and seamless integration of controls are paramount in maximizing both safety and user experience.

In conclusion, the development of thermally comfortable steering wheels represents a convergence of user experience enhancement and safety considerations. By addressing the physiological needs of drivers and providing a more comfortable interface with the vehicle, these advancements have the potential to significantly improve both the enjoyment and safety of driving. As this technology continues to evolve, it will be crucial to maintain a careful balance between comfort innovation and fundamental safety principles.

Thermal comfort in steering wheels addresses the issue of temperature extremes, which can significantly affect driver comfort and concentration. In cold weather, a chilly steering wheel can cause discomfort and reduce tactile sensitivity, potentially compromising control. Conversely, in hot conditions, an overheated steering wheel can lead to sweaty palms and reduced grip. By implementing heating and cooling technologies, manufacturers can maintain an optimal temperature range, enhancing the driving experience across various climatic conditions.

From a safety perspective, thermal comfort features contribute to maintaining driver alertness and reducing fatigue. Comfortable hand temperatures help sustain proper blood circulation, which is essential for maintaining reflexes and reaction times. This is particularly important during long drives or in challenging weather conditions where driver fatigue can pose significant safety risks.

The user experience is further enhanced by the customization options that thermal comfort features offer. Advanced systems allow drivers to set their preferred temperature, creating a personalized comfort zone. This level of customization not only improves satisfaction but also accommodates individual preferences and potential medical needs, such as arthritis or circulation issues that may be exacerbated by temperature extremes.

However, the implementation of thermal comfort features must be carefully balanced with other safety considerations. The integration of heating and cooling elements should not compromise the structural integrity or grip properties of the steering wheel. Manufacturers must ensure that these features do not introduce new safety risks, such as electrical hazards or reduced tactile feedback.

Moreover, the user interface for controlling these features must be intuitive and minimally distracting. Poorly designed controls could lead to driver distraction, potentially offsetting the safety benefits of improved comfort. Therefore, ergonomic design and seamless integration of controls are paramount in maximizing both safety and user experience.

In conclusion, the development of thermally comfortable steering wheels represents a convergence of user experience enhancement and safety considerations. By addressing the physiological needs of drivers and providing a more comfortable interface with the vehicle, these advancements have the potential to significantly improve both the enjoyment and safety of driving. As this technology continues to evolve, it will be crucial to maintain a careful balance between comfort innovation and fundamental safety principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!