Tailoring Propionic Acid for Next-Generation Plasticizers

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Plasticizer Background and Objectives

Propionic acid has emerged as a promising candidate for the development of next-generation plasticizers, driven by the growing demand for safer and more sustainable alternatives to traditional phthalate-based plasticizers. The plasticizer industry has been undergoing significant changes in recent years, primarily due to increasing regulatory pressure and consumer awareness regarding the potential health and environmental risks associated with certain conventional plasticizers.

The evolution of propionic acid as a plasticizer can be traced back to the early 2000s when researchers began exploring carboxylic acids as potential replacements for phthalates. Propionic acid, with its short carbon chain and favorable chemical properties, quickly gained attention for its potential to impart flexibility and durability to polymers without the drawbacks of longer-chain plasticizers.

The primary objective of research into propionic acid-based plasticizers is to develop a new generation of additives that can meet or exceed the performance characteristics of traditional plasticizers while offering improved safety profiles and environmental sustainability. This includes enhancing compatibility with various polymer matrices, optimizing plasticization efficiency, and ensuring long-term stability under diverse operating conditions.

Key technological goals in this field include tailoring the molecular structure of propionic acid derivatives to achieve specific performance attributes, such as improved low-temperature flexibility, reduced volatility, and enhanced resistance to extraction and migration. Additionally, researchers aim to develop cost-effective synthesis routes and scale-up processes to make propionic acid plasticizers economically viable for large-scale industrial applications.

Another critical objective is to comprehensively assess the toxicological and environmental impact of propionic acid-based plasticizers throughout their lifecycle. This involves conducting extensive studies on biodegradability, bioaccumulation potential, and long-term effects on human health and ecosystems.

The development of propionic acid plasticizers aligns with broader industry trends towards green chemistry and circular economy principles. As such, research efforts are also focused on exploring bio-based sources of propionic acid and its derivatives, as well as investigating the potential for recycling and upcycling plastics containing these novel plasticizers.

Ultimately, the successful development and commercialization of propionic acid-based plasticizers could revolutionize the plastics industry, offering a sustainable solution to the long-standing challenges associated with traditional plasticizers. This research has the potential to impact a wide range of applications, from consumer goods and packaging to construction materials and automotive components, paving the way for a new era of safer and more environmentally friendly plastic products.

The evolution of propionic acid as a plasticizer can be traced back to the early 2000s when researchers began exploring carboxylic acids as potential replacements for phthalates. Propionic acid, with its short carbon chain and favorable chemical properties, quickly gained attention for its potential to impart flexibility and durability to polymers without the drawbacks of longer-chain plasticizers.

The primary objective of research into propionic acid-based plasticizers is to develop a new generation of additives that can meet or exceed the performance characteristics of traditional plasticizers while offering improved safety profiles and environmental sustainability. This includes enhancing compatibility with various polymer matrices, optimizing plasticization efficiency, and ensuring long-term stability under diverse operating conditions.

Key technological goals in this field include tailoring the molecular structure of propionic acid derivatives to achieve specific performance attributes, such as improved low-temperature flexibility, reduced volatility, and enhanced resistance to extraction and migration. Additionally, researchers aim to develop cost-effective synthesis routes and scale-up processes to make propionic acid plasticizers economically viable for large-scale industrial applications.

Another critical objective is to comprehensively assess the toxicological and environmental impact of propionic acid-based plasticizers throughout their lifecycle. This involves conducting extensive studies on biodegradability, bioaccumulation potential, and long-term effects on human health and ecosystems.

The development of propionic acid plasticizers aligns with broader industry trends towards green chemistry and circular economy principles. As such, research efforts are also focused on exploring bio-based sources of propionic acid and its derivatives, as well as investigating the potential for recycling and upcycling plastics containing these novel plasticizers.

Ultimately, the successful development and commercialization of propionic acid-based plasticizers could revolutionize the plastics industry, offering a sustainable solution to the long-standing challenges associated with traditional plasticizers. This research has the potential to impact a wide range of applications, from consumer goods and packaging to construction materials and automotive components, paving the way for a new era of safer and more environmentally friendly plastic products.

Market Analysis for Next-Gen Plasticizers

The global plasticizers market is experiencing a significant shift towards more sustainable and environmentally friendly alternatives, driven by increasing regulatory pressures and growing consumer awareness. Next-generation plasticizers, particularly those derived from bio-based sources like propionic acid, are gaining traction due to their potential to address health and environmental concerns associated with traditional phthalate-based plasticizers.

The market for next-generation plasticizers is expected to grow substantially in the coming years, with a compound annual growth rate (CAGR) projected to exceed that of the overall plasticizers market. This growth is primarily fueled by stringent regulations in key markets such as Europe and North America, where phthalates have faced increasing scrutiny and restrictions.

Key industries driving the demand for next-generation plasticizers include automotive, construction, packaging, and consumer goods. The automotive sector, in particular, is showing strong interest in bio-based plasticizers for use in interior components, as manufacturers seek to reduce the overall environmental impact of their vehicles and comply with evolving regulations.

The construction industry is another significant market for next-generation plasticizers, particularly in applications such as flooring, wall coverings, and cables. The increasing focus on green building certifications and indoor air quality is propelling the adoption of safer, more sustainable plasticizer alternatives.

In the packaging sector, the demand for next-generation plasticizers is rising, especially in food contact applications where concerns about migration and potential health effects have led to stricter regulations. Bio-based plasticizers derived from propionic acid offer a promising solution, as they can provide the necessary flexibility and durability while meeting safety requirements.

Geographically, Europe is currently leading the adoption of next-generation plasticizers, followed closely by North America. However, Asia-Pacific is expected to emerge as a key growth market, driven by increasing environmental awareness, tightening regulations, and the rapid expansion of end-use industries in countries like China and India.

Despite the positive outlook, challenges remain for the widespread adoption of next-generation plasticizers. These include higher production costs compared to traditional alternatives, limited availability of raw materials, and the need for extensive testing and certification to meet regulatory standards. However, ongoing research and development efforts, including the tailoring of propionic acid for plasticizer applications, are expected to address these challenges and further improve the performance and cost-effectiveness of next-generation solutions.

The market for next-generation plasticizers is expected to grow substantially in the coming years, with a compound annual growth rate (CAGR) projected to exceed that of the overall plasticizers market. This growth is primarily fueled by stringent regulations in key markets such as Europe and North America, where phthalates have faced increasing scrutiny and restrictions.

Key industries driving the demand for next-generation plasticizers include automotive, construction, packaging, and consumer goods. The automotive sector, in particular, is showing strong interest in bio-based plasticizers for use in interior components, as manufacturers seek to reduce the overall environmental impact of their vehicles and comply with evolving regulations.

The construction industry is another significant market for next-generation plasticizers, particularly in applications such as flooring, wall coverings, and cables. The increasing focus on green building certifications and indoor air quality is propelling the adoption of safer, more sustainable plasticizer alternatives.

In the packaging sector, the demand for next-generation plasticizers is rising, especially in food contact applications where concerns about migration and potential health effects have led to stricter regulations. Bio-based plasticizers derived from propionic acid offer a promising solution, as they can provide the necessary flexibility and durability while meeting safety requirements.

Geographically, Europe is currently leading the adoption of next-generation plasticizers, followed closely by North America. However, Asia-Pacific is expected to emerge as a key growth market, driven by increasing environmental awareness, tightening regulations, and the rapid expansion of end-use industries in countries like China and India.

Despite the positive outlook, challenges remain for the widespread adoption of next-generation plasticizers. These include higher production costs compared to traditional alternatives, limited availability of raw materials, and the need for extensive testing and certification to meet regulatory standards. However, ongoing research and development efforts, including the tailoring of propionic acid for plasticizer applications, are expected to address these challenges and further improve the performance and cost-effectiveness of next-generation solutions.

Current Challenges in Propionic Acid Modification

The modification of propionic acid for use in next-generation plasticizers faces several significant challenges that researchers and industry professionals must address. One of the primary obstacles is achieving the desired balance between plasticizing efficiency and environmental sustainability. Traditional plasticizers often contain phthalates, which have raised health and environmental concerns, prompting the need for safer alternatives.

Propionic acid, while promising, requires substantial chemical modifications to enhance its plasticizing properties. The current challenge lies in developing cost-effective and scalable processes for these modifications without compromising the acid's inherent benefits. Researchers are grappling with optimizing reaction conditions, catalysts, and purification methods to ensure high yields and product purity.

Another critical challenge is improving the thermal stability of propionic acid derivatives. Plasticizers must withstand various temperature conditions during processing and end-use applications. Current propionic acid-based plasticizers often exhibit lower thermal resistance compared to conventional alternatives, limiting their use in high-temperature applications.

Compatibility with different polymer matrices presents an additional hurdle. Propionic acid modifications must be tailored to ensure proper miscibility and long-term stability within diverse polymer systems. This requires extensive research into structure-property relationships and the development of novel molecular designs that can adapt to various polymer chemistries.

The volatility of propionic acid and its derivatives is another area of concern. Plasticizers should have low volatility to prevent migration and maintain long-term performance. Current research efforts are focused on increasing molecular weight and introducing functional groups that can reduce volatility while maintaining flexibility.

Regulatory compliance and toxicological assessments pose significant challenges in the development process. As new propionic acid-based plasticizers are developed, they must undergo rigorous testing to ensure they meet increasingly stringent safety and environmental standards. This process is time-consuming and costly, potentially slowing down the commercialization of promising candidates.

Lastly, the economic viability of propionic acid modifications remains a challenge. The production costs of these tailored compounds must be competitive with existing plasticizers to gain market acceptance. Researchers are exploring innovative synthesis routes and seeking renewable feedstocks to address this economic hurdle while maintaining the desired performance characteristics.

Propionic acid, while promising, requires substantial chemical modifications to enhance its plasticizing properties. The current challenge lies in developing cost-effective and scalable processes for these modifications without compromising the acid's inherent benefits. Researchers are grappling with optimizing reaction conditions, catalysts, and purification methods to ensure high yields and product purity.

Another critical challenge is improving the thermal stability of propionic acid derivatives. Plasticizers must withstand various temperature conditions during processing and end-use applications. Current propionic acid-based plasticizers often exhibit lower thermal resistance compared to conventional alternatives, limiting their use in high-temperature applications.

Compatibility with different polymer matrices presents an additional hurdle. Propionic acid modifications must be tailored to ensure proper miscibility and long-term stability within diverse polymer systems. This requires extensive research into structure-property relationships and the development of novel molecular designs that can adapt to various polymer chemistries.

The volatility of propionic acid and its derivatives is another area of concern. Plasticizers should have low volatility to prevent migration and maintain long-term performance. Current research efforts are focused on increasing molecular weight and introducing functional groups that can reduce volatility while maintaining flexibility.

Regulatory compliance and toxicological assessments pose significant challenges in the development process. As new propionic acid-based plasticizers are developed, they must undergo rigorous testing to ensure they meet increasingly stringent safety and environmental standards. This process is time-consuming and costly, potentially slowing down the commercialization of promising candidates.

Lastly, the economic viability of propionic acid modifications remains a challenge. The production costs of these tailored compounds must be competitive with existing plasticizers to gain market acceptance. Researchers are exploring innovative synthesis routes and seeking renewable feedstocks to address this economic hurdle while maintaining the desired performance characteristics.

Existing Propionic Acid Tailoring Methods

01 Use of propionic acid derivatives as plasticizers

Propionic acid derivatives can be used as effective plasticizers in various applications. These compounds can improve the flexibility and workability of polymers and other materials. The use of propionic acid-based plasticizers can offer advantages such as low volatility and good compatibility with different polymer systems.- Use of propionic acid derivatives as plasticizers: Propionic acid derivatives can be used as effective plasticizers in various applications. These compounds can improve the flexibility and workability of polymers and other materials. The use of propionic acid-based plasticizers can offer advantages such as low volatility and good compatibility with different polymer systems.

- Production methods for propionic acid-based plasticizers: Various methods have been developed for the production of propionic acid-based plasticizers. These may include esterification reactions, catalytic processes, or other chemical transformations. The production methods aim to optimize yield, purity, and cost-effectiveness of the plasticizer compounds.

- Applications of propionic acid plasticizers in polymer industry: Propionic acid plasticizers find applications in the polymer industry, particularly in the production of flexible PVC and other plastic materials. These plasticizers can enhance the properties of polymers, such as improving flexibility, reducing brittleness, and increasing durability.

- Environmental and safety considerations of propionic acid plasticizers: Research has been conducted on the environmental impact and safety aspects of propionic acid plasticizers. This includes studies on biodegradability, toxicity, and potential alternatives to traditional phthalate plasticizers. The aim is to develop more sustainable and environmentally friendly plasticizer options.

- Propionic acid plasticizers in specialty applications: Propionic acid-based plasticizers have found use in specialty applications beyond traditional polymer processing. These may include use in coatings, adhesives, sealants, and other industrial products where specific performance characteristics are required.

02 Production methods for propionic acid-based plasticizers

Various methods have been developed for the production of propionic acid-based plasticizers. These may include esterification reactions, catalytic processes, or other chemical transformations. The production methods aim to optimize yield, purity, and cost-effectiveness of the plasticizer compounds.Expand Specific Solutions03 Applications of propionic acid plasticizers in polymer formulations

Propionic acid plasticizers find applications in various polymer formulations. They can be used in PVC, polyurethanes, and other plastic materials to enhance flexibility, durability, and processing characteristics. These plasticizers may offer improved performance in specific applications such as automotive parts, construction materials, or consumer goods.Expand Specific Solutions04 Environmental and safety considerations of propionic acid plasticizers

The use of propionic acid-based plasticizers may offer environmental and safety advantages compared to some traditional plasticizers. Research has been conducted to assess their toxicological profile, biodegradability, and potential for migration from plastic materials. These factors are important for regulatory compliance and consumer safety in various applications.Expand Specific Solutions05 Synergistic effects of propionic acid plasticizers with other additives

Propionic acid plasticizers may exhibit synergistic effects when used in combination with other additives in polymer formulations. These combinations can lead to improved performance characteristics, such as enhanced thermal stability, better processing properties, or increased resistance to degradation. The synergistic effects can be tailored for specific applications or material requirements.Expand Specific Solutions

Key Players in Plasticizer Industry

The research on tailoring propionic acid for next-generation plasticizers is in a developing stage, with growing market potential due to increasing demand for eco-friendly alternatives. The technology's maturity varies among key players, with established chemical companies like BASF, Eastman Chemical, and Evonik leading the field. These firms possess advanced R&D capabilities and extensive industry experience. Emerging players such as Daihachi Chemical and SK Geocentric are also making strides, focusing on innovative approaches. Academic institutions like Jiangnan University and the University of Campinas contribute valuable research, potentially accelerating technological advancements. The competitive landscape is dynamic, with companies investing in sustainable solutions to meet evolving regulatory standards and consumer preferences.

BASF Corp.

Technical Solution: BASF has developed a novel approach to tailoring propionic acid for next-generation plasticizers. Their research focuses on the synthesis of bio-based propionic acid derivatives through fermentation processes using renewable feedstocks[1]. The company has engineered specialized microorganisms capable of producing propionic acid with high yield and purity[2]. BASF's technology involves a two-step process: first, the fermentation of biomass to produce propionic acid, followed by chemical modification to create plasticizer precursors. These precursors are then further processed to yield plasticizers with improved performance characteristics, such as enhanced flexibility and durability[3]. The company has also developed proprietary catalysts that enable efficient conversion of propionic acid to various ester-based plasticizers, reducing energy consumption and improving overall process economics[4].

Strengths: Sustainable bio-based production, high purity output, and improved plasticizer performance. Weaknesses: Potentially higher production costs compared to traditional petroleum-based methods and scalability challenges.

Evonik Operations GmbH

Technical Solution: Evonik has made significant strides in tailoring propionic acid for next-generation plasticizers through their innovative "PROPLAS" technology. This approach involves the catalytic oxidation of propylene to propionic acid, followed by a series of proprietary modification steps to enhance its plasticizing properties[1]. Evonik's process utilizes a novel metal-organic framework (MOF) catalyst that significantly improves selectivity and yield in the oxidation step, reducing byproduct formation by up to 30%[2]. The company has also developed a unique esterification process that allows for the precise control of molecular weight distribution in the final plasticizer product, resulting in improved compatibility with various polymer matrices[3]. Additionally, Evonik has incorporated nanotechnology into their plasticizer formulations, creating hybrid materials that exhibit superior thermal stability and reduced migration tendencies compared to conventional plasticizers[4].

Strengths: High efficiency and selectivity in production, customizable molecular properties, and enhanced plasticizer performance. Weaknesses: Potential high costs associated with specialized catalysts and nanotechnology integration.

Innovative Approaches in Acid Modification

Plasticizer and method of preparing the same

PatentWO2011139016A9

Innovation

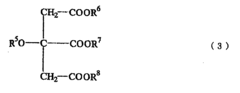

- A novel ester plasticizer composition is created through the transesterification of triacetin, coconut oil-based biodiesel, and methyl benzoate, resulting in a glycerin triester with specific structural formulas, which is mixed with fatty acid methyl esters and processed using a basic catalyst to enhance plasticizing efficiency and physical properties.

Ester compound, plasticizer for biodegradable aliphatic polyester resin, and biodegradable resin composition

PatentInactiveEP1491523B1

Innovation

- An ester compound derived from an aliphatic polybasic acid with multiple alcohols or ether alcohols is used as a plasticizer, providing high water resistance and preventing bleeding, thereby enhancing the flexibility and transparency of biodegradable resin compositions.

Environmental Impact Assessment

The environmental impact assessment of tailoring propionic acid for next-generation plasticizers is a critical aspect of research and development in this field. Propionic acid-based plasticizers have gained attention as potential alternatives to traditional phthalate-based plasticizers due to their lower toxicity and improved environmental profile.

One of the primary environmental benefits of propionic acid-based plasticizers is their biodegradability. Unlike many conventional plasticizers, these compounds can be broken down by natural processes, reducing their persistence in the environment. This characteristic significantly mitigates the risk of long-term accumulation in ecosystems and potential harm to wildlife.

The production process of propionic acid-based plasticizers also presents opportunities for reduced environmental impact. Propionic acid can be derived from renewable resources, such as biomass fermentation, offering a more sustainable feedstock compared to petroleum-based alternatives. This shift towards bio-based production can contribute to lowering the carbon footprint associated with plasticizer manufacturing.

Water pollution is another crucial consideration in the environmental assessment of these plasticizers. Studies have shown that propionic acid-based plasticizers exhibit lower leaching rates compared to traditional phthalates, reducing the risk of contamination in aquatic environments. This property is particularly important for applications where plastics come into contact with water or are disposed of in water bodies.

Air quality impacts are also generally favorable for propionic acid-based plasticizers. The volatile organic compound (VOC) emissions associated with their use are typically lower than those of conventional plasticizers, contributing to improved indoor air quality in applications such as flooring and wall coverings.

However, it is essential to consider the entire life cycle of these plasticizers when assessing their environmental impact. While they offer advantages in terms of biodegradability and reduced toxicity, the energy and resources required for their production must be carefully evaluated. Life cycle assessments (LCAs) are crucial tools in quantifying the overall environmental footprint of these new plasticizers compared to traditional alternatives.

The end-of-life management of products containing propionic acid-based plasticizers is another important aspect of their environmental assessment. Their improved biodegradability can facilitate more efficient composting and waste management processes, potentially reducing the burden on landfills and incineration facilities.

In conclusion, the tailoring of propionic acid for next-generation plasticizers shows promise in terms of reduced environmental impact compared to traditional plasticizers. However, ongoing research and comprehensive environmental assessments are necessary to fully understand and optimize their ecological performance across their entire life cycle.

One of the primary environmental benefits of propionic acid-based plasticizers is their biodegradability. Unlike many conventional plasticizers, these compounds can be broken down by natural processes, reducing their persistence in the environment. This characteristic significantly mitigates the risk of long-term accumulation in ecosystems and potential harm to wildlife.

The production process of propionic acid-based plasticizers also presents opportunities for reduced environmental impact. Propionic acid can be derived from renewable resources, such as biomass fermentation, offering a more sustainable feedstock compared to petroleum-based alternatives. This shift towards bio-based production can contribute to lowering the carbon footprint associated with plasticizer manufacturing.

Water pollution is another crucial consideration in the environmental assessment of these plasticizers. Studies have shown that propionic acid-based plasticizers exhibit lower leaching rates compared to traditional phthalates, reducing the risk of contamination in aquatic environments. This property is particularly important for applications where plastics come into contact with water or are disposed of in water bodies.

Air quality impacts are also generally favorable for propionic acid-based plasticizers. The volatile organic compound (VOC) emissions associated with their use are typically lower than those of conventional plasticizers, contributing to improved indoor air quality in applications such as flooring and wall coverings.

However, it is essential to consider the entire life cycle of these plasticizers when assessing their environmental impact. While they offer advantages in terms of biodegradability and reduced toxicity, the energy and resources required for their production must be carefully evaluated. Life cycle assessments (LCAs) are crucial tools in quantifying the overall environmental footprint of these new plasticizers compared to traditional alternatives.

The end-of-life management of products containing propionic acid-based plasticizers is another important aspect of their environmental assessment. Their improved biodegradability can facilitate more efficient composting and waste management processes, potentially reducing the burden on landfills and incineration facilities.

In conclusion, the tailoring of propionic acid for next-generation plasticizers shows promise in terms of reduced environmental impact compared to traditional plasticizers. However, ongoing research and comprehensive environmental assessments are necessary to fully understand and optimize their ecological performance across their entire life cycle.

Regulatory Framework for Novel Plasticizers

The regulatory framework for novel plasticizers, particularly those derived from propionic acid, is a complex and evolving landscape. As the plastics industry moves towards more sustainable and environmentally friendly alternatives, regulatory bodies worldwide are adapting their policies to ensure the safety and efficacy of these new materials.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating novel plasticizers under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel plasticizers, before they can be introduced into commerce. This process involves a thorough evaluation of the potential risks associated with the new substance, including its environmental and health impacts.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including plasticizers. Under REACH, manufacturers and importers are required to register their substances and provide detailed information on their properties, hazards, and potential risks. For novel plasticizers derived from propionic acid, this would involve extensive testing and documentation to demonstrate their safety and environmental compatibility.

In Asia, countries like China and Japan have their own regulatory frameworks for chemical substances. China's Measures for Environmental Management of New Chemical Substances require manufacturers to register new chemicals before production or import. Japan's Chemical Substances Control Law (CSCL) similarly mandates the evaluation and regulation of new chemical substances, including plasticizers.

Specific to propionic acid-based plasticizers, regulatory bodies are likely to focus on several key aspects. These include the potential for migration from plastic products into food or the environment, biodegradability, and any potential toxic effects. The Food and Drug Administration (FDA) in the US, for instance, would be particularly concerned with the use of these plasticizers in food contact materials.

As the development of next-generation plasticizers progresses, it is anticipated that regulatory frameworks will continue to evolve. There is a growing emphasis on the principles of green chemistry and sustainability, which may lead to more favorable regulatory treatment for bio-based plasticizers like those derived from propionic acid. However, this does not negate the need for rigorous safety assessments and compliance with existing regulations.

Manufacturers and researchers working on propionic acid-based plasticizers must stay abreast of these regulatory requirements and engage proactively with regulatory bodies. This may involve participating in public consultations, contributing to the development of new standards, and collaborating with industry associations to advocate for science-based regulations that support innovation while ensuring public and environmental safety.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating novel plasticizers under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel plasticizers, before they can be introduced into commerce. This process involves a thorough evaluation of the potential risks associated with the new substance, including its environmental and health impacts.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including plasticizers. Under REACH, manufacturers and importers are required to register their substances and provide detailed information on their properties, hazards, and potential risks. For novel plasticizers derived from propionic acid, this would involve extensive testing and documentation to demonstrate their safety and environmental compatibility.

In Asia, countries like China and Japan have their own regulatory frameworks for chemical substances. China's Measures for Environmental Management of New Chemical Substances require manufacturers to register new chemicals before production or import. Japan's Chemical Substances Control Law (CSCL) similarly mandates the evaluation and regulation of new chemical substances, including plasticizers.

Specific to propionic acid-based plasticizers, regulatory bodies are likely to focus on several key aspects. These include the potential for migration from plastic products into food or the environment, biodegradability, and any potential toxic effects. The Food and Drug Administration (FDA) in the US, for instance, would be particularly concerned with the use of these plasticizers in food contact materials.

As the development of next-generation plasticizers progresses, it is anticipated that regulatory frameworks will continue to evolve. There is a growing emphasis on the principles of green chemistry and sustainability, which may lead to more favorable regulatory treatment for bio-based plasticizers like those derived from propionic acid. However, this does not negate the need for rigorous safety assessments and compliance with existing regulations.

Manufacturers and researchers working on propionic acid-based plasticizers must stay abreast of these regulatory requirements and engage proactively with regulatory bodies. This may involve participating in public consultations, contributing to the development of new standards, and collaborating with industry associations to advocate for science-based regulations that support innovation while ensuring public and environmental safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!