Turbine Engine Technology With A Focus On Speeding Up The Flow

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

## Directory: 技术背景与目标

Turbine engine technology has undergone significant advancements since its inception, primarily driven by the need for more efficient and powerful engines in aviation and power generation. The primary goal is to enhance the speed of the airflow through the turbine, which directly impacts the engine's efficiency and performance. Historically, the development of turbine engines has focused on improving materials, aerodynamics, and cooling techniques to withstand higher temperatures and pressures. Recent trends indicate a shift towards integrating advanced computational methods and materials science to push the boundaries of turbine performance further. By accelerating the airflow, the aim is to achieve higher thrust-to-weight ratios, reduced fuel consumption, and lower emissions, aligning with the industry's goals for sustainability and efficiency.

Turbine Engine Market Demand Analysis

### Turbine Engine Market Demand Analysis

**Growing Demand for Efficient Engines**

The demand for turbine engines is increasing due to the need for more efficient and environmentally friendly engines. This is driven by stricter emission regulations and the push for sustainable aviation.

**Aerospace Industry Expansion**

The aerospace industry is expanding, with a significant rise in air travel and cargo transport. This growth necessitates advanced turbine engines that offer higher performance and reliability.

**Military Applications**

Military applications also drive the demand for turbine engines, with a focus on enhancing speed, agility, and operational efficiency of aircraft.

**Energy Sector Needs**

In the energy sector, turbine engines are crucial for power generation. The shift towards renewable energy sources and the need for efficient backup power systems boost the demand for advanced turbine technologies.

**Technological Advancements**

Continuous technological advancements in materials, aerodynamics, and thermodynamics are propelling the development of next-generation turbine engines, meeting the market's evolving needs.

**Regional Market Dynamics**

The market demand varies regionally, with North America and Europe leading in technological adoption, while Asia-Pacific shows rapid growth due to increasing industrialization and urbanization.

**Competitive Landscape**

The competitive landscape is shaped by major players investing in R&D to innovate and capture market share, ensuring they meet the rising demand for high-performance turbine engines.

Turbine Engine Technology Status and Challenges

### Turbine Engine Technology Status and Challenges

**Current Development Status**:

- Turbine engine technology has seen significant advancements in efficiency, power output, and environmental impact.

- Key innovations include high-temperature materials, advanced cooling techniques, and improved aerodynamics.

**Major Challenges**:

- Increasing the speed of airflow through the turbine remains a critical challenge.

- High operational temperatures and pressures demand materials with exceptional thermal and mechanical properties.

- Noise reduction and emission control are ongoing concerns, requiring continuous innovation.

**Geographical Distribution**:

- Leading research and development are concentrated in the US, Europe, and Asia, with notable contributions from companies and research institutions in these regions.

**Technical Constraints**:

- Material limitations hinder the ability to withstand extreme conditions.

- Balancing performance improvements with environmental regulations is complex.

- Integration of new technologies into existing systems poses significant engineering challenges.

Turbine Engine Current Technical Solutions

01 Optimization of turbine blade design

Optimize turbine blade design to improve flow speed and efficiency by modifying blade shape, angle, and materials to reduce drag and enhance aerodynamic performance.- Optimization of turbine blade design: Optimize turbine blade design to improve flow speed and efficiency by modifying blade shape, angle, and materials to reduce drag and enhance aerodynamic performance.

- Use of advanced cooling techniques: Employ advanced cooling techniques like film cooling and internal cooling channels to manage turbine blade temperatures, maintaining optimal performance and preventing overheating.

- Implementation of variable geometry components: Use variable geometry components like adjustable vanes and nozzles to control flow speed and direction, allowing real-time adjustments for optimal performance under different conditions.

- Enhancement of combustion efficiency: Improve combustion efficiency with advanced fuel injection systems, optimized combustion chamber designs, and better air-fuel mixing to achieve higher flow speeds and better overall efficiency.

- Application of high-performance materials: Use high-performance materials like advanced alloys and ceramics to enhance turbine component durability and performance, withstanding higher temperatures and stresses for improved flow speed and efficiency.

02 Use of advanced materials

Use advanced materials like high-temperature alloys and composites in turbine engines to withstand higher flow speeds and temperatures, improving performance and durability.Expand Specific Solutions03 Implementation of cooling techniques

Implement cooling techniques like internal cooling channels and thermal barrier coatings to manage heat and maintain optimal flow speeds without compromising engine integrity.Expand Specific Solutions04 Enhancement of combustion efficiency

Improve combustion efficiency with better fuel-air mixing, advanced combustion chamber designs, and optimized fuel injection systems for higher flow speeds and overall engine performance.Expand Specific Solutions05 Aerodynamic improvements in turbine components

Make aerodynamic improvements in turbine components using shrouds, seals, and optimized stator and rotor designs to reduce losses and increase flow speed within the turbine engine.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for turbine engine technology is marked by established leaders and emerging players. Key players like General Electric Company, Rolls-Royce Plc, Safran Aircraft Engines SAS, and Mitsubishi Power Ltd. drive innovation with their advanced R&D capabilities. The market is expected to grow with increasing demand for efficient turbine engines in aerospace and energy sectors.

General Electric Company

Technical Solution: General Electric develops advanced turbine engine technologies with high-efficiency compressors and advanced cooling techniques.

Strength: High efficiency and advanced cooling. Weakness: High cost and complexity.

Rolls-Royce Plc

Technical Solution: Rolls-Royce focuses on high-speed turbine engines with innovations in aerodynamic design and materials.

Strength: Cutting-edge aerodynamic design. Weakness: Long development cycles.

Turbine Engine Key Technology Interpretation

Axial turbine

PatentActiveUS8308421B2

Innovation

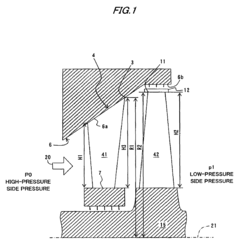

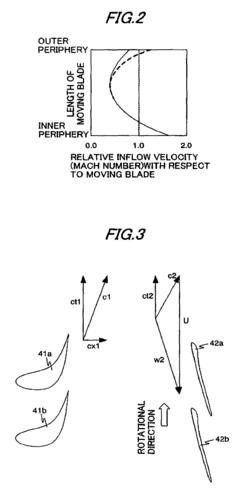

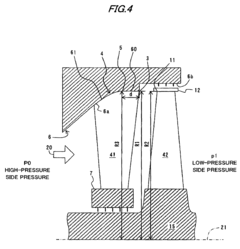

- The outlet flow path is designed to be taller than the inlet flow path, increasing the pressure of the working fluid as it passes through the turbine stages.

- The stationary blade is designed with a higher radial height at its outlet than at its inlet, suppressing the relative velocity of the flow entering the moving blade.

- A portion of the intersection line between the turbine and the outer peripheral portion of the stationary blade extends in the direction of the central axis of the turbine, reducing the likelihood of shock waves.

Turbine Engine Flow Speed Improvement Economic Analysis

The economic analysis of improving turbine engine flow speed focuses on evaluating the cost-benefit aspects of enhancing flow dynamics. This involves assessing the financial implications of adopting advanced technologies to increase flow speed, including initial investment, operational costs, and potential savings. Additionally, it examines the impact on fuel efficiency, maintenance expenses, and overall engine performance. The analysis also considers market demand for high-speed turbine engines and potential revenue growth. By balancing costs with anticipated benefits, the analysis aims to provide a comprehensive understanding of the economic viability and strategic value of such technological advancements.

Turbine Engine Flow Speed Improvement Policy and Regulatory Impact

The research on turbine engine technology, focusing on speeding up the flow, must consider policy and regulatory impacts. Regulations on emissions, noise, and fuel efficiency significantly influence technological advancements. Compliance with international standards, such as those set by ICAO and FAA, is crucial. Policies promoting green technologies and sustainability drive innovation towards more efficient and environmentally friendly engines. Additionally, government incentives and funding for research can accelerate development. Understanding these regulatory frameworks helps in aligning technological goals with legal requirements, ensuring market readiness and competitive advantage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!