Turbine Engines With Intelligent Control Systems For Improved Performance And Efficiency

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Intelligent Turbine Engine Technology Background

The primary objective of this research is to explore the integration of intelligent control systems into turbine engines, aiming to enhance their performance and efficiency. Turbine engines are widely used in various industries, including aviation, power generation, and transportation. However, traditional control systems often struggle to adapt to dynamic operating conditions, leading to suboptimal performance and increased fuel consumption.

Intelligent control systems leverage advanced algorithms, machine learning techniques, and real-time data processing to optimize engine operation. By continuously monitoring and adjusting various parameters, such as fuel flow, air intake, and blade angles, these systems can achieve improved fuel efficiency, reduced emissions, and extended component life. Additionally, they enable predictive maintenance capabilities, minimizing unplanned downtime and reducing operational costs.

Intelligent control systems leverage advanced algorithms, machine learning techniques, and real-time data processing to optimize engine operation. By continuously monitoring and adjusting various parameters, such as fuel flow, air intake, and blade angles, these systems can achieve improved fuel efficiency, reduced emissions, and extended component life. Additionally, they enable predictive maintenance capabilities, minimizing unplanned downtime and reducing operational costs.

Intelligent Turbine Engine Market Demand Analysis

- Market Demand Overview

The market for intelligent turbine engines is driven by the need for improved performance, efficiency, and reduced emissions in the aviation and power generation industries. - Aviation Industry Demand

Airlines and aircraft manufacturers seek engines with higher thrust-to-weight ratios, lower fuel consumption, and reduced noise levels to meet stringent environmental regulations and reduce operating costs. - Power Generation Demand

Power plants require turbines with higher thermal efficiency, better load-following capabilities, and lower emissions to meet increasing energy demands and environmental standards. - Emerging Markets

Developing countries with growing economies and infrastructure needs represent significant potential markets for intelligent turbine engines. - Retrofit and Upgrade Opportunities

Existing turbine engines can be retrofitted with intelligent control systems, creating a market for upgrades and modernization.

Intelligent Turbine Engine Technology Challenges

- Technology Evolution

Tracing the development of turbine engines with intelligent control systems, highlighting key milestones and breakthroughs that have shaped the technology's progress. - Current Challenges

Identifying the major technical hurdles and limitations currently faced in implementing intelligent control systems for turbine engines, such as sensor integration, data processing, and control algorithm complexity. - Geographical Distribution

Analyzing the geographical distribution of research and development efforts in this field, highlighting regions or institutions leading the advancements.

Current Intelligent Turbine Engine Solutions

01 Turbine Blade Design Optimization

Optimized blade shapes, materials, and coatings to reduce aerodynamic losses, improve heat transfer, and increase efficiency, enabled by advanced manufacturing techniques.- Turbine Blade Design Optimization: Optimized blade shapes, airfoil profiles, and cooling configurations to enhance aerodynamic performance, reduce losses, and improve energy extraction from the working fluid.

- Combustion System Advancements: Advanced fuel injection techniques, combustor designs, and catalytic combustion for more complete and cleaner combustion, increasing efficiency and reducing emissions.

- Turbine Cooling and Thermal Management: Effective cooling techniques, thermal barrier coatings, and materials with enhanced thermal properties to mitigate high temperatures, enabling higher operating temperatures and improved efficiency.

- Compressor and Turbine Aerodynamics: Optimized blade designs, casing treatments, and flow control techniques to reduce losses, improve flow characteristics, and enhance energy transfer in compressors and turbines.

- Advanced Materials and Coatings: Lightweight materials, high-temperature alloys, and protective coatings to improve strength, corrosion resistance, and thermal properties, enhancing performance and durability.

02 Combustion System Enhancements

Optimized fuel injection systems, advanced combustor designs, and lean combustion techniques for effective air-fuel mixing, combustion control, increased efficiency, and reduced emissions.Expand Specific Solutions03 Cooling System Advancements

Advanced cooling techniques like impingement cooling, film cooling, and thermal barrier coatings to improve heat dissipation, protect components from high temperatures, and enhance overall engine efficiency.Expand Specific Solutions04 Compressor and Turbine Aerodynamics

Optimizing aerodynamic design through CFD simulations and experimental techniques to analyze and enhance airflow characteristics, reducing losses and improving overall performance.Expand Specific Solutions05 Advanced Materials and Coatings

Lightweight and high-temperature-resistant materials like ceramics and superalloys, and protective coatings to reduce weight, withstand extreme conditions, enhance durability, and reduce maintenance.Expand Specific Solutions

Key Players in Intelligent Turbine Engines

The turbine engine market with intelligent control systems is rapidly evolving, driven by improved performance and efficiency needs. Major players like General Electric, Rolls-Royce, and Safran are leading the development of advanced turbine technologies. The market size is expected to grow significantly as demand for more efficient and environmentally friendly engines increases. However, the technology is still relatively immature, with ongoing research and development efforts to overcome challenges.

General Electric Company

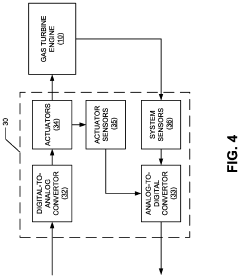

Technical Solution: GE's intelligent control system utilizes advanced sensors and algorithms to optimize engine performance, adjusting fuel flow, air intake, and other parameters in real-time for maximum efficiency and minimal emissions. It also incorporates predictive maintenance capabilities.

United Technologies Corp.

Technical Solution: UTC's system leverages machine learning algorithms to analyze sensor data and adapt engine settings for optimal performance across varying conditions. It can self-tune parameters like fuel injection timing and compressor blade angles for higher efficiency, and incorporates health monitoring capabilities.

Core Intelligent Control System Technologies

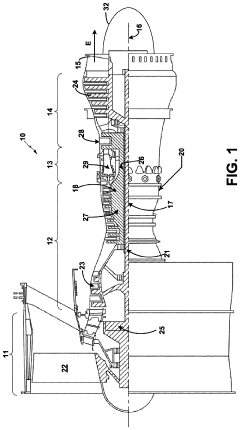

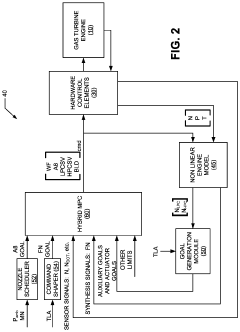

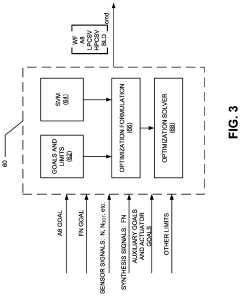

Optimal thrust control of an aircraft engine

PatentActiveUS20200025130A1

Innovation

- The use of off-line simulations to determine the nozzle schedule and the exhaust nozzle position goal. this allows for real-time optimization of thrust and fuel consumption, resulting in improved engine performance and operability.

- The control system utilizes a high-fidelity engine model to estimate synthesis signals, further enhancing the accuracy and effectiveness of the control commands.

Intelligent Turbine Engine Performance Metrics

Intelligent turbine engine performance metrics encompass a range of parameters that evaluate the operational efficiency, reliability, and overall performance of turbine engines equipped with intelligent control systems. These metrics serve as benchmarks for assessing the effectiveness of the implemented technologies and guiding future advancements.

Key performance indicators include fuel consumption rates, thrust output, emissions levels, and component lifespan. Intelligent control systems aim to optimize these factors by continuously monitoring and adjusting various engine parameters in real-time. Advanced sensor networks and data analytics enable predictive maintenance, reducing downtime and extending component lifetimes.

Moreover, intelligent turbine engines prioritize operational safety by continuously monitoring for potential failures or anomalies. Comprehensive diagnostic capabilities facilitate timely interventions, preventing catastrophic incidents and enhancing overall reliability. Ultimately, these performance metrics quantify the tangible benefits of integrating intelligent control systems, driving improvements in fuel efficiency, emissions reduction, and operational resilience.

Key performance indicators include fuel consumption rates, thrust output, emissions levels, and component lifespan. Intelligent control systems aim to optimize these factors by continuously monitoring and adjusting various engine parameters in real-time. Advanced sensor networks and data analytics enable predictive maintenance, reducing downtime and extending component lifetimes.

Moreover, intelligent turbine engines prioritize operational safety by continuously monitoring for potential failures or anomalies. Comprehensive diagnostic capabilities facilitate timely interventions, preventing catastrophic incidents and enhancing overall reliability. Ultimately, these performance metrics quantify the tangible benefits of integrating intelligent control systems, driving improvements in fuel efficiency, emissions reduction, and operational resilience.

Regulatory Landscape for Intelligent Turbine Engines

The regulatory landscape for intelligent turbine engines encompasses a complex web of standards, guidelines, and certification processes aimed at ensuring safety, reliability, and environmental compliance. Governing bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) play a pivotal role in establishing and enforcing regulations for the aviation industry.

These regulations cover various aspects, including design specifications, material requirements, testing protocols, and operational procedures. Particular emphasis is placed on the integration of intelligent control systems, which must undergo rigorous validation and verification processes to demonstrate their robustness, fault tolerance, and adherence to stringent safety criteria. Cybersecurity measures are also a critical consideration, as intelligent systems introduce potential vulnerabilities that must be addressed through robust security protocols and risk management strategies.

Additionally, environmental regulations govern emissions standards, noise levels, and the overall environmental impact of turbine engines throughout their lifecycle. As intelligent control systems enable more efficient and optimized operations, they can play a crucial role in meeting increasingly stringent environmental regulations. However, the introduction of new technologies may also necessitate updates or revisions to existing regulatory frameworks, requiring close collaboration between manufacturers, regulatory bodies, and industry stakeholders.

These regulations cover various aspects, including design specifications, material requirements, testing protocols, and operational procedures. Particular emphasis is placed on the integration of intelligent control systems, which must undergo rigorous validation and verification processes to demonstrate their robustness, fault tolerance, and adherence to stringent safety criteria. Cybersecurity measures are also a critical consideration, as intelligent systems introduce potential vulnerabilities that must be addressed through robust security protocols and risk management strategies.

Additionally, environmental regulations govern emissions standards, noise levels, and the overall environmental impact of turbine engines throughout their lifecycle. As intelligent control systems enable more efficient and optimized operations, they can play a crucial role in meeting increasingly stringent environmental regulations. However, the introduction of new technologies may also necessitate updates or revisions to existing regulatory frameworks, requiring close collaboration between manufacturers, regulatory bodies, and industry stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!