SEM-EDS Light Elements: Windowless Detectors, Background And Absorption Effects

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SEM-EDS Light Element Detection Background and Objectives

Scanning Electron Microscopy coupled with Energy Dispersive X-ray Spectroscopy (SEM-EDS) has evolved significantly since its inception in the 1960s, becoming an indispensable analytical technique for materials characterization. The detection of light elements (atomic number less than 11) has historically presented significant challenges due to their low-energy X-ray emissions, which are easily absorbed by conventional detector windows and atmospheric conditions.

The evolution of SEM-EDS technology has been marked by several key milestones, including the transition from Si(Li) detectors to Silicon Drift Detectors (SDDs), improvements in detector resolution, and the development of windowless or ultra-thin window detectors specifically designed to enhance light element detection capabilities. These advancements have progressively expanded the analytical capabilities of SEM-EDS systems, enabling more comprehensive elemental analysis across various scientific and industrial applications.

Current technological trends in SEM-EDS light element detection focus on overcoming three primary challenges: detector window absorption, background interference, and matrix absorption effects. The development of windowless detectors represents a significant breakthrough, eliminating the absorption barrier that traditionally hindered light element detection. Simultaneously, advancements in signal processing algorithms have improved the discrimination between genuine elemental peaks and background noise, enhancing detection sensitivity.

The primary technical objectives in this field include achieving reliable quantitative analysis of elements such as carbon, nitrogen, oxygen, and fluorine with detection limits below 0.1 weight percent. Additionally, there is a growing emphasis on developing correction algorithms that can accurately account for absorption effects in complex matrices, particularly for in-situ analysis of heterogeneous materials.

From an industrial perspective, enhanced light element detection capabilities are increasingly critical across multiple sectors. In semiconductor manufacturing, precise carbon and oxygen analysis is essential for quality control. In battery technology, accurate quantification of lithium and oxygen distributions directly impacts performance optimization. Similarly, in advanced materials development, the ability to characterize light element distributions at nanoscale resolution provides crucial insights for material design and optimization.

The convergence of improved hardware designs, advanced signal processing techniques, and sophisticated correction algorithms represents the current frontier in SEM-EDS light element detection. This technological evolution aims to transform what was once a qualitative or semi-quantitative technique for light elements into a robust, quantitative analytical method capable of addressing increasingly complex material characterization challenges across scientific research and industrial applications.

The evolution of SEM-EDS technology has been marked by several key milestones, including the transition from Si(Li) detectors to Silicon Drift Detectors (SDDs), improvements in detector resolution, and the development of windowless or ultra-thin window detectors specifically designed to enhance light element detection capabilities. These advancements have progressively expanded the analytical capabilities of SEM-EDS systems, enabling more comprehensive elemental analysis across various scientific and industrial applications.

Current technological trends in SEM-EDS light element detection focus on overcoming three primary challenges: detector window absorption, background interference, and matrix absorption effects. The development of windowless detectors represents a significant breakthrough, eliminating the absorption barrier that traditionally hindered light element detection. Simultaneously, advancements in signal processing algorithms have improved the discrimination between genuine elemental peaks and background noise, enhancing detection sensitivity.

The primary technical objectives in this field include achieving reliable quantitative analysis of elements such as carbon, nitrogen, oxygen, and fluorine with detection limits below 0.1 weight percent. Additionally, there is a growing emphasis on developing correction algorithms that can accurately account for absorption effects in complex matrices, particularly for in-situ analysis of heterogeneous materials.

From an industrial perspective, enhanced light element detection capabilities are increasingly critical across multiple sectors. In semiconductor manufacturing, precise carbon and oxygen analysis is essential for quality control. In battery technology, accurate quantification of lithium and oxygen distributions directly impacts performance optimization. Similarly, in advanced materials development, the ability to characterize light element distributions at nanoscale resolution provides crucial insights for material design and optimization.

The convergence of improved hardware designs, advanced signal processing techniques, and sophisticated correction algorithms represents the current frontier in SEM-EDS light element detection. This technological evolution aims to transform what was once a qualitative or semi-quantitative technique for light elements into a robust, quantitative analytical method capable of addressing increasingly complex material characterization challenges across scientific research and industrial applications.

Market Demand Analysis for Light Element Detection Technologies

The global market for light element detection technologies has experienced significant growth in recent years, driven primarily by increasing demands in materials science, semiconductor manufacturing, and environmental monitoring sectors. The ability to accurately detect and analyze light elements such as carbon, nitrogen, oxygen, and fluorine has become crucial for quality control, research advancement, and regulatory compliance across multiple industries.

In the semiconductor industry, the market demand for precise light element detection has surged due to the continuous miniaturization of electronic components and the introduction of new materials in chip manufacturing. As semiconductor devices shrink below 5nm, even trace amounts of light elements can significantly impact performance characteristics, creating a $3.2 billion market segment specifically for advanced analytical instruments capable of detecting these elements.

Materials science research facilities represent another substantial market segment, with universities and corporate R&D centers investing heavily in technologies that can accurately characterize light elements in novel materials. This sector has shown a consistent annual growth rate of 7.8% over the past five years, reflecting the increasing importance of light element analysis in developing advanced materials for renewable energy, aerospace, and medical applications.

Environmental monitoring and regulatory compliance have emerged as significant drivers for light element detection technologies. With stricter global regulations on emissions and material composition, industries ranging from automotive to consumer electronics require more sensitive and accurate detection methods. This regulatory-driven demand has created a market estimated at $1.7 billion annually, with particularly strong growth in regions implementing stringent environmental standards.

The healthcare and pharmaceutical sectors have also contributed to market expansion, particularly in the analysis of biological samples where light elements form the backbone of organic compounds. The need for non-destructive, high-sensitivity analysis methods has led to increased adoption of advanced SEM-EDS systems with enhanced light element detection capabilities.

Geographically, North America and Europe currently dominate the market for high-end light element detection technologies, accounting for approximately 65% of global revenue. However, the Asia-Pacific region, particularly China, South Korea, and Taiwan, shows the fastest growth rate at 12.3% annually, driven by expanding semiconductor manufacturing and materials research facilities.

Market forecasts indicate that technologies addressing the specific challenges of light element detection, particularly windowless detector systems that eliminate absorption effects, will see accelerated adoption rates over the next five years. The total addressable market for these specialized detection technologies is projected to reach $5.8 billion by 2028, representing a significant opportunity for technology providers who can overcome the current limitations in sensitivity, accuracy, and reliability.

In the semiconductor industry, the market demand for precise light element detection has surged due to the continuous miniaturization of electronic components and the introduction of new materials in chip manufacturing. As semiconductor devices shrink below 5nm, even trace amounts of light elements can significantly impact performance characteristics, creating a $3.2 billion market segment specifically for advanced analytical instruments capable of detecting these elements.

Materials science research facilities represent another substantial market segment, with universities and corporate R&D centers investing heavily in technologies that can accurately characterize light elements in novel materials. This sector has shown a consistent annual growth rate of 7.8% over the past five years, reflecting the increasing importance of light element analysis in developing advanced materials for renewable energy, aerospace, and medical applications.

Environmental monitoring and regulatory compliance have emerged as significant drivers for light element detection technologies. With stricter global regulations on emissions and material composition, industries ranging from automotive to consumer electronics require more sensitive and accurate detection methods. This regulatory-driven demand has created a market estimated at $1.7 billion annually, with particularly strong growth in regions implementing stringent environmental standards.

The healthcare and pharmaceutical sectors have also contributed to market expansion, particularly in the analysis of biological samples where light elements form the backbone of organic compounds. The need for non-destructive, high-sensitivity analysis methods has led to increased adoption of advanced SEM-EDS systems with enhanced light element detection capabilities.

Geographically, North America and Europe currently dominate the market for high-end light element detection technologies, accounting for approximately 65% of global revenue. However, the Asia-Pacific region, particularly China, South Korea, and Taiwan, shows the fastest growth rate at 12.3% annually, driven by expanding semiconductor manufacturing and materials research facilities.

Market forecasts indicate that technologies addressing the specific challenges of light element detection, particularly windowless detector systems that eliminate absorption effects, will see accelerated adoption rates over the next five years. The total addressable market for these specialized detection technologies is projected to reach $5.8 billion by 2028, representing a significant opportunity for technology providers who can overcome the current limitations in sensitivity, accuracy, and reliability.

Current Challenges in Light Element Detection with SEM-EDS

Despite significant advancements in SEM-EDS technology, the detection and quantification of light elements (atomic number less than 11) continue to present substantial challenges for researchers and industry professionals. The fundamental issue stems from the low-energy X-rays emitted by light elements, which are easily absorbed by conventional detector windows, atmospheric components, and even the sample itself. This inherent limitation has created a persistent technological barrier in materials analysis.

Windowless detector systems have emerged as a potential solution, eliminating the beryllium window that traditionally absorbs low-energy X-rays. However, these systems introduce new complications, including increased detector vulnerability to contamination and the need for more sophisticated vacuum systems. The delicate balance between improved light element detection and detector longevity remains difficult to achieve in practical applications.

Background effects represent another significant challenge, particularly in complex matrices. The bremsstrahlung continuum can overwhelm the relatively weak signals from light elements, creating detection limits that are often inadequate for trace analysis. This is especially problematic in materials containing both heavy and light elements, where peak overlaps and background contributions can lead to significant quantification errors.

Absorption effects further complicate light element analysis. Self-absorption within the sample can dramatically reduce the intensity of detected X-rays from light elements, leading to systematic underestimation in quantitative analysis. This effect varies with sample composition, morphology, and surface condition, making standardless quantification particularly unreliable for light elements.

Matrix correction algorithms, while advanced for heavier elements, often perform poorly for light elements due to the complex physics involved in low-energy X-ray generation and detection. The ZAF (atomic number, absorption, fluorescence) corrections become increasingly uncertain as atomic number decreases, leading to significant analytical errors that can exceed 20% for elements like carbon, nitrogen, and oxygen.

The detection of ultra-light elements such as lithium, beryllium, and boron remains at the frontier of technical capability, with most commercial SEM-EDS systems unable to reliably detect these elements. This limitation has significant implications for industries such as battery technology, where lithium distribution analysis is crucial for performance optimization.

Calibration and standardization for light elements present additional challenges, as suitable standards are often difficult to prepare and maintain. The high reactivity of many light elements means that surface oxidation or contamination can rapidly alter standard compositions, introducing systematic errors in quantification routines.

Windowless detector systems have emerged as a potential solution, eliminating the beryllium window that traditionally absorbs low-energy X-rays. However, these systems introduce new complications, including increased detector vulnerability to contamination and the need for more sophisticated vacuum systems. The delicate balance between improved light element detection and detector longevity remains difficult to achieve in practical applications.

Background effects represent another significant challenge, particularly in complex matrices. The bremsstrahlung continuum can overwhelm the relatively weak signals from light elements, creating detection limits that are often inadequate for trace analysis. This is especially problematic in materials containing both heavy and light elements, where peak overlaps and background contributions can lead to significant quantification errors.

Absorption effects further complicate light element analysis. Self-absorption within the sample can dramatically reduce the intensity of detected X-rays from light elements, leading to systematic underestimation in quantitative analysis. This effect varies with sample composition, morphology, and surface condition, making standardless quantification particularly unreliable for light elements.

Matrix correction algorithms, while advanced for heavier elements, often perform poorly for light elements due to the complex physics involved in low-energy X-ray generation and detection. The ZAF (atomic number, absorption, fluorescence) corrections become increasingly uncertain as atomic number decreases, leading to significant analytical errors that can exceed 20% for elements like carbon, nitrogen, and oxygen.

The detection of ultra-light elements such as lithium, beryllium, and boron remains at the frontier of technical capability, with most commercial SEM-EDS systems unable to reliably detect these elements. This limitation has significant implications for industries such as battery technology, where lithium distribution analysis is crucial for performance optimization.

Calibration and standardization for light elements present additional challenges, as suitable standards are often difficult to prepare and maintain. The high reactivity of many light elements means that surface oxidation or contamination can rapidly alter standard compositions, introducing systematic errors in quantification routines.

Current Windowless Detector Solutions and Implementations

01 Windowless detector design for improved light element detection

Windowless detectors in SEM-EDS systems allow for enhanced detection of light elements by eliminating the absorption barrier typically present in conventional detectors. These designs optimize the detection of low-energy X-rays from elements like carbon, nitrogen, and oxygen that would otherwise be absorbed by detector windows. The windowless configuration minimizes signal loss and improves quantitative analysis accuracy for materials containing light elements.- Windowless detector design for improved light element detection: Windowless detectors in SEM-EDS systems allow for enhanced detection of light elements by eliminating the absorption barrier typically present in conventional detectors. This design modification enables the detection of low-energy X-rays that would otherwise be absorbed by detector windows, significantly improving sensitivity for elements with atomic numbers below 11. The windowless configuration reduces background noise and minimizes absorption effects, resulting in more accurate elemental analysis of materials containing light elements such as carbon, nitrogen, and oxygen.

- Background correction algorithms for SEM-EDS analysis: Advanced algorithms have been developed to correct for background effects in SEM-EDS analysis, particularly when using windowless detectors. These computational methods can distinguish between actual elemental peaks and background noise, improving the signal-to-noise ratio and enhancing the accuracy of quantitative analysis. The algorithms account for various sources of background radiation, including Bremsstrahlung radiation and detector artifacts, enabling more precise elemental identification and quantification even in complex sample matrices.

- Absorption correction techniques for accurate quantitative analysis: Absorption effects in SEM-EDS analysis can significantly impact quantitative results, particularly when analyzing heterogeneous samples. Various correction techniques have been developed to account for these effects, including matrix correction methods that consider the absorption of X-rays within the sample before they reach the detector. These techniques incorporate factors such as sample composition, density, and geometry to mathematically correct for absorption phenomena, resulting in more accurate elemental quantification. Advanced models also account for secondary fluorescence effects that can further complicate analysis.

- Integration of windowless detectors with automated analysis systems: Modern SEM-EDS systems incorporate windowless detectors into automated analysis workflows to enhance efficiency and reproducibility. These integrated systems combine hardware improvements with sophisticated software that can automatically identify regions of interest, optimize acquisition parameters, and apply appropriate background and absorption corrections. The automation reduces operator variability and enables high-throughput analysis while maintaining data quality. Some systems also incorporate machine learning algorithms to improve element identification and quantification in complex samples with significant background and absorption challenges.

- Calibration methods for windowless detector systems: Specialized calibration procedures have been developed for SEM-EDS systems with windowless detectors to address their unique characteristics and ensure accurate results. These methods include the use of certified reference materials with known compositions to establish detector response functions across the energy spectrum. Calibration protocols account for energy-dependent detection efficiency, particularly for light elements, and incorporate corrections for background and absorption effects. Regular calibration is essential to maintain system performance and ensure reliable quantitative analysis, especially when analyzing samples with complex matrices or when detecting trace elements.

02 Background correction algorithms for SEM-EDS analysis

Advanced algorithms have been developed to correct for background signals in SEM-EDS analysis, which is particularly important when using windowless detectors. These methods include mathematical modeling of the background spectrum, peak deconvolution techniques, and statistical approaches to separate true elemental signals from background noise. Proper background correction is essential for accurate quantitative analysis, especially when detecting trace elements or analyzing complex material compositions.Expand Specific Solutions03 Absorption effect compensation in windowless EDS systems

Absorption effects in windowless EDS systems can significantly impact quantitative analysis results. Various compensation techniques have been developed to account for these effects, including matrix correction methods, absorption factor calculations, and calibration standards. These approaches consider how X-rays from lighter elements are absorbed within the sample before reaching the detector, allowing for more accurate elemental composition determination in complex materials.Expand Specific Solutions04 Integration of windowless detectors with advanced SEM systems

Modern SEM systems incorporate windowless EDS detectors with advanced hardware and software integration. These integrated systems feature optimized detector positioning, improved signal processing, and real-time data analysis capabilities. The integration enables higher sensitivity for light element detection while maintaining the ability to analyze heavier elements, resulting in comprehensive elemental mapping and quantification across the periodic table.Expand Specific Solutions05 Calibration methods for windowless EDS to minimize absorption artifacts

Specialized calibration methods have been developed for windowless EDS systems to minimize absorption artifacts and improve quantitative accuracy. These include the use of reference standards with known compositions, automated calibration routines, and correction factors specific to windowless detector configurations. Regular calibration is essential to account for detector aging, contamination effects, and system drift that can otherwise lead to measurement errors, particularly for light elements where absorption effects are most pronounced.Expand Specific Solutions

Key Industry Players in SEM-EDS Detector Manufacturing

The SEM-EDS Light Elements market is currently in a growth phase, driven by increasing demand for advanced materials analysis across semiconductor, automotive, and research sectors. The market size is estimated to be expanding at a CAGR of 6-8%, with particular acceleration in windowless detector technologies that enhance light element detection capabilities. Technologically, the field is moderately mature but experiencing innovation waves, with companies like Hitachi High-Tech, EDAX LLC, and FEI Co. leading in detector development. Hamamatsu Photonics and Carl Zeiss SMT are advancing absorption correction algorithms, while research institutions like Electronics & Telecommunications Research Institute and National University of Singapore are pioneering background reduction techniques. The competitive landscape shows established players focusing on integration with existing microscopy systems, while newer entrants target specialized applications in semiconductor manufacturing and materials science.

Hitachi High-Tech America, Inc.

Technical Solution: Hitachi High-Tech has developed advanced windowless SEM-EDS detector systems that enable superior light element detection capabilities. Their technology eliminates the traditional beryllium window that typically absorbs low-energy X-rays from elements like carbon, nitrogen, and oxygen. The company's latest systems incorporate ultra-thin silicon nitride windows and specialized algorithms to compensate for absorption effects. Hitachi's detectors feature increased solid angle collection efficiency and improved energy resolution down to 123eV at Mn Kα, allowing for detection of elements as light as beryllium (Z=4). Their systems also implement sophisticated background correction algorithms that account for Bremsstrahlung radiation and system peaks, significantly improving signal-to-noise ratios for light element analysis. Hitachi's technology includes advanced pulse processing to handle high count rates while maintaining spectral integrity.

Strengths: Superior light element sensitivity with detection capabilities down to beryllium; excellent energy resolution; advanced background correction algorithms. Weaknesses: Higher cost compared to conventional EDS systems; requires more frequent calibration and maintenance; more complex operation requiring specialized training.

FEI Co.

Technical Solution: FEI (now part of Thermo Fisher Scientific) has pioneered Silicon Drift Detector (SDD) technology for windowless EDS systems. Their approach combines large-area SDDs with specialized electronics to achieve high count rates while maintaining excellent energy resolution for light elements. FEI's systems feature a proprietary detector design that minimizes the path length X-rays must travel, reducing absorption effects for light elements. Their ChemiSTEM technology integrates multiple SDDs around the sample to maximize collection efficiency, achieving solid angles greater than 1 steradian. FEI's systems incorporate sophisticated software algorithms that model and correct for absorption effects in the sample, detector, and column, particularly important for quantitative analysis of light elements. Their latest systems can achieve energy resolutions below 130eV for carbon while maintaining high throughput, enabling practical analysis of beam-sensitive materials containing light elements.

Strengths: Exceptional collection efficiency through multi-detector design; high count rates with minimal spectral degradation; advanced software for quantitative light element analysis. Weaknesses: Complex system integration requiring precise alignment; higher initial investment cost; challenging to retrofit to existing SEM systems.

Technical Analysis of Background and Absorption Effects

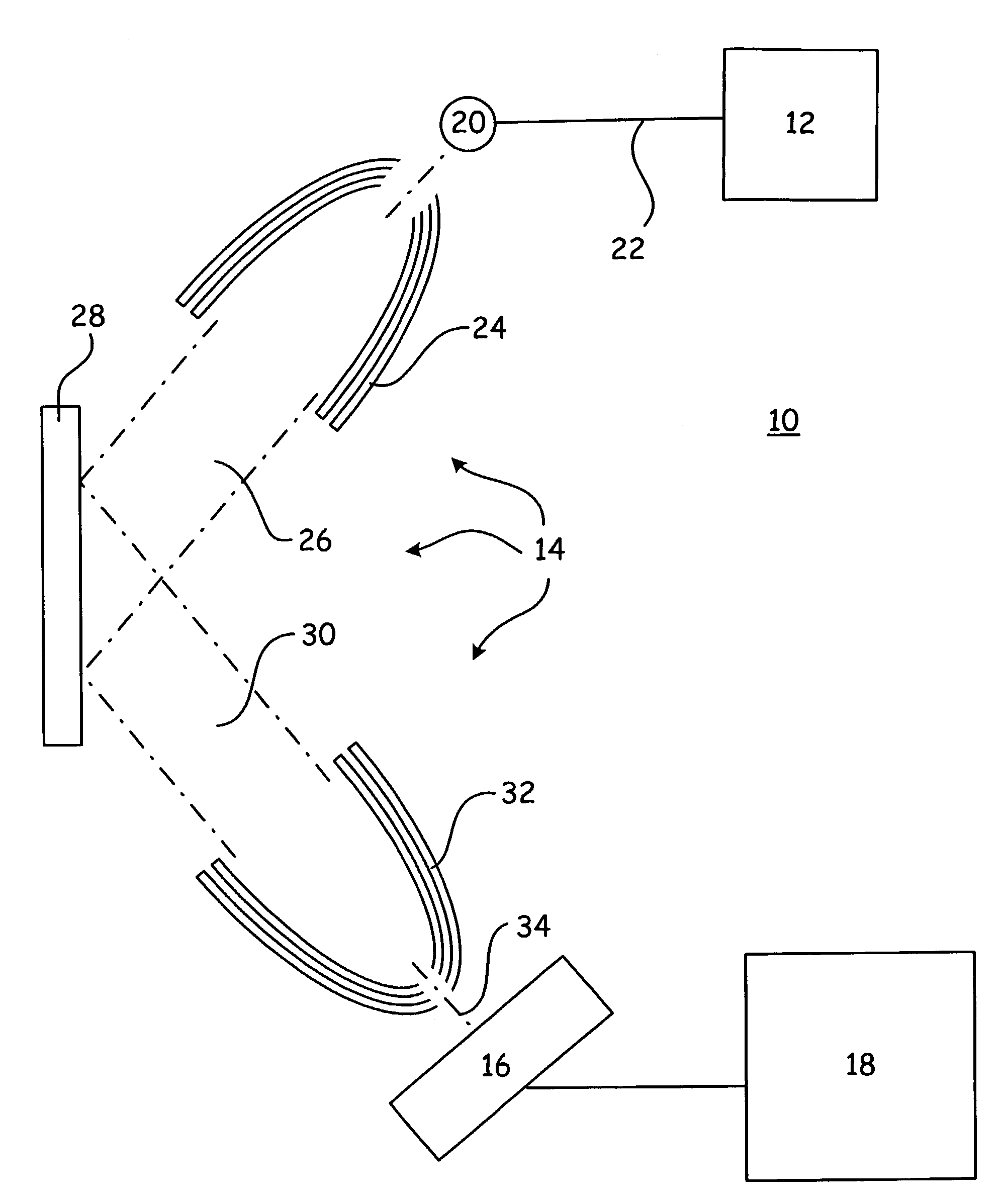

Light element measurement

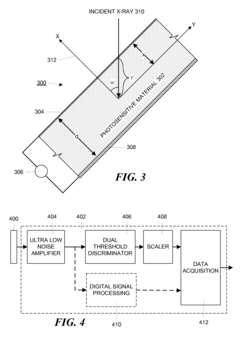

PatentInactiveUS7006596B1

Innovation

- A spectrometer system that includes an exciter, detector, and a filter system with a collimator and reflector to selectively block higher energy x-rays, allowing only light element x-rays to reach the detector, combining the advantages of energy dispersive and wavelength dispersive x-ray detection methods for improved accuracy and throughput.

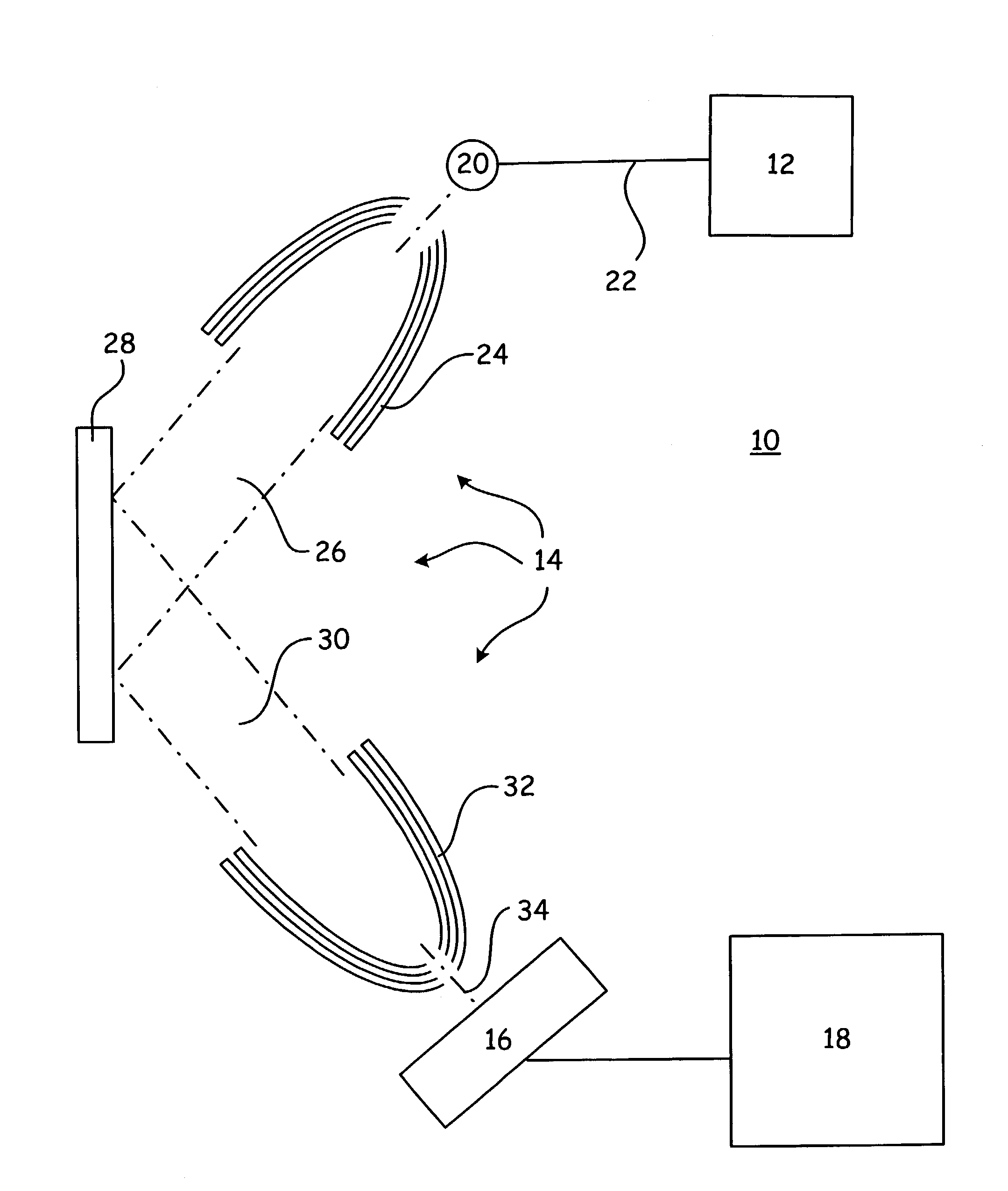

X-ray detection system for wavelength dispersive and energy dispersive spectroscopy and electron beam applications

PatentActiveUS7928400B1

Innovation

- A solid-state avalanche photodiode detector with a thin conductive entrance window and tilting mechanism, combined with advanced signal processing circuits, enhances the detection efficiency for both 'light' and 'heavy' elements by increasing absorption depth and count rates.

Calibration Methods for Accurate Light Element Quantification

Accurate quantification of light elements in SEM-EDS analysis requires sophisticated calibration methods to overcome the inherent challenges associated with their detection. Traditional calibration approaches using standard reference materials often fall short when applied to elements with atomic numbers below 11 due to their unique X-ray emission characteristics and susceptibility to absorption effects.

The fundamental calibration method for light element quantification involves the use of stoichiometric compounds with known compositions. These standards must be carefully selected to match the matrix of the unknown samples as closely as possible, minimizing matrix effects that disproportionately impact light element analysis. For instance, boron nitride (BN) serves as an excellent calibration standard for both boron and nitrogen quantification, while silicon carbide (SiC) provides reliable calibration for carbon.

ZAF correction algorithms, which account for atomic number (Z), absorption (A), and fluorescence (F) effects, require significant modifications when applied to light elements. The Pouchou and Pichoir (PAP) model has emerged as a superior alternative, offering more accurate corrections for the unique absorption characteristics of light elements. This model incorporates variable mass absorption coefficients that better represent the physical reality of X-ray generation and absorption for low-energy X-rays.

Peak deconvolution techniques play a crucial role in light element calibration, particularly when dealing with overlapping peaks. Advanced spectral processing algorithms can separate complex peak structures, allowing for more precise quantification. For example, the carbon K-alpha peak often overlaps with nitrogen K-alpha, requiring sophisticated deconvolution methods to achieve accurate measurements of both elements.

Windowless detector calibration demands special attention to detector response functions across the low-energy spectrum. This involves characterizing the detector efficiency at various energy levels and developing correction factors that account for the non-linear response to low-energy X-rays. Regular calibration using multiple standards of varying compositions helps establish reliable correction curves.

Background subtraction methodologies must be tailored specifically for light element analysis. The traditional methods often overestimate or underestimate the background contribution in the low-energy region of the spectrum. Advanced modeling approaches that incorporate physical principles of bremsstrahlung radiation generation provide more accurate background estimations, significantly improving quantification precision.

Interlaboratory comparison studies have demonstrated that implementing these specialized calibration methods can reduce quantification errors for light elements from typical levels of 20-30% to below 5% in optimal conditions. This improvement in accuracy opens new possibilities for applications requiring precise light element analysis, including advanced materials development, semiconductor manufacturing, and biological sample characterization.

The fundamental calibration method for light element quantification involves the use of stoichiometric compounds with known compositions. These standards must be carefully selected to match the matrix of the unknown samples as closely as possible, minimizing matrix effects that disproportionately impact light element analysis. For instance, boron nitride (BN) serves as an excellent calibration standard for both boron and nitrogen quantification, while silicon carbide (SiC) provides reliable calibration for carbon.

ZAF correction algorithms, which account for atomic number (Z), absorption (A), and fluorescence (F) effects, require significant modifications when applied to light elements. The Pouchou and Pichoir (PAP) model has emerged as a superior alternative, offering more accurate corrections for the unique absorption characteristics of light elements. This model incorporates variable mass absorption coefficients that better represent the physical reality of X-ray generation and absorption for low-energy X-rays.

Peak deconvolution techniques play a crucial role in light element calibration, particularly when dealing with overlapping peaks. Advanced spectral processing algorithms can separate complex peak structures, allowing for more precise quantification. For example, the carbon K-alpha peak often overlaps with nitrogen K-alpha, requiring sophisticated deconvolution methods to achieve accurate measurements of both elements.

Windowless detector calibration demands special attention to detector response functions across the low-energy spectrum. This involves characterizing the detector efficiency at various energy levels and developing correction factors that account for the non-linear response to low-energy X-rays. Regular calibration using multiple standards of varying compositions helps establish reliable correction curves.

Background subtraction methodologies must be tailored specifically for light element analysis. The traditional methods often overestimate or underestimate the background contribution in the low-energy region of the spectrum. Advanced modeling approaches that incorporate physical principles of bremsstrahlung radiation generation provide more accurate background estimations, significantly improving quantification precision.

Interlaboratory comparison studies have demonstrated that implementing these specialized calibration methods can reduce quantification errors for light elements from typical levels of 20-30% to below 5% in optimal conditions. This improvement in accuracy opens new possibilities for applications requiring precise light element analysis, including advanced materials development, semiconductor manufacturing, and biological sample characterization.

Environmental Considerations in Windowless Detector Operation

The operational environment of windowless detectors presents unique challenges and considerations that significantly impact their performance and reliability in SEM-EDS systems. Unlike conventional detectors with beryllium windows, windowless detectors are directly exposed to the SEM chamber environment, making them particularly sensitive to contamination and environmental fluctuations.

Vacuum quality becomes a critical factor in windowless detector operation. These systems typically require ultra-high vacuum conditions (10^-7 torr or better) to minimize interference from residual gas molecules. Even minor vacuum degradation can lead to increased background noise and compromised detection of light elements such as carbon, nitrogen, and oxygen. Regular vacuum system maintenance and monitoring are therefore essential components of operational protocols.

Contamination management represents another significant environmental consideration. Hydrocarbon contaminants from vacuum pump oils, specimen outgassing, or chamber materials can deposit on the detector surface, creating absorption layers that particularly affect light element detection. Modern systems increasingly incorporate oil-free vacuum pumps and cold traps to mitigate these contamination risks.

Temperature stability within the detector environment directly influences spectral resolution and peak positions. Thermal fluctuations can cause detector crystal expansion or contraction, leading to calibration drift and reduced analytical precision. Advanced windowless systems incorporate sophisticated temperature regulation mechanisms, including Peltier cooling and thermal isolation structures, to maintain stable operating conditions.

Electromagnetic interference (EMI) from nearby equipment or the microscope itself can introduce noise artifacts in windowless detector signals. This environmental factor necessitates careful system design with appropriate shielding and grounding schemes. In research facilities with multiple high-powered instruments, EMI mapping and mitigation strategies may be required to optimize detector performance.

Humidity control in the laboratory environment indirectly affects windowless detector operation. While the detector itself operates in vacuum, moisture can impact vacuum quality during sample exchanges or maintenance procedures. Facilities employing windowless detectors typically maintain controlled humidity environments and implement purging protocols to minimize moisture introduction during system venting.

Radiation protection considerations also apply to windowless detector environments, particularly in systems operating at high accelerating voltages. Without the attenuating effect of a beryllium window, operators must ensure appropriate shielding and safety protocols to protect sensitive electronic components from secondary radiation effects that could degrade detector performance over time.

Vacuum quality becomes a critical factor in windowless detector operation. These systems typically require ultra-high vacuum conditions (10^-7 torr or better) to minimize interference from residual gas molecules. Even minor vacuum degradation can lead to increased background noise and compromised detection of light elements such as carbon, nitrogen, and oxygen. Regular vacuum system maintenance and monitoring are therefore essential components of operational protocols.

Contamination management represents another significant environmental consideration. Hydrocarbon contaminants from vacuum pump oils, specimen outgassing, or chamber materials can deposit on the detector surface, creating absorption layers that particularly affect light element detection. Modern systems increasingly incorporate oil-free vacuum pumps and cold traps to mitigate these contamination risks.

Temperature stability within the detector environment directly influences spectral resolution and peak positions. Thermal fluctuations can cause detector crystal expansion or contraction, leading to calibration drift and reduced analytical precision. Advanced windowless systems incorporate sophisticated temperature regulation mechanisms, including Peltier cooling and thermal isolation structures, to maintain stable operating conditions.

Electromagnetic interference (EMI) from nearby equipment or the microscope itself can introduce noise artifacts in windowless detector signals. This environmental factor necessitates careful system design with appropriate shielding and grounding schemes. In research facilities with multiple high-powered instruments, EMI mapping and mitigation strategies may be required to optimize detector performance.

Humidity control in the laboratory environment indirectly affects windowless detector operation. While the detector itself operates in vacuum, moisture can impact vacuum quality during sample exchanges or maintenance procedures. Facilities employing windowless detectors typically maintain controlled humidity environments and implement purging protocols to minimize moisture introduction during system venting.

Radiation protection considerations also apply to windowless detector environments, particularly in systems operating at high accelerating voltages. Without the attenuating effect of a beryllium window, operators must ensure appropriate shielding and safety protocols to protect sensitive electronic components from secondary radiation effects that could degrade detector performance over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!