Throttle Body Optimization for Maglev Trains

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Maglev Train Propulsion Evolution and Objectives

Maglev train technology has undergone significant evolution since its inception in the mid-20th century. The development of magnetic levitation for transportation purposes began with the goal of achieving high-speed, frictionless travel. Early research focused on electromagnetic suspension (EMS) systems, which use electromagnets to lift the train above a guideway. This approach was pioneered by German engineers in the 1930s and further developed in the 1960s and 1970s.

As the technology progressed, researchers explored alternative levitation methods, leading to the development of electrodynamic suspension (EDS) systems. EDS utilizes superconducting magnets to create a strong magnetic field, allowing for higher speeds and greater stability. This breakthrough in the 1980s paved the way for more advanced maglev train designs.

The evolution of propulsion systems for maglev trains has been closely tied to advancements in linear motor technology. Early designs relied on linear induction motors (LIMs), which provided adequate acceleration but were limited in top speed. The introduction of linear synchronous motors (LSMs) in the 1990s marked a significant improvement, offering higher efficiency and better control at high speeds.

Throughout the 2000s and 2010s, research efforts focused on optimizing energy consumption and improving the overall efficiency of maglev systems. This led to the development of more sophisticated control systems and the integration of regenerative braking technologies. Additionally, advancements in materials science contributed to the creation of lighter, stronger guideway structures and more efficient superconducting magnets.

The current objectives in maglev train propulsion technology are multifaceted. One primary goal is to further increase operational speeds while maintaining safety and passenger comfort. This involves refining the aerodynamics of train designs and enhancing the stability of the levitation and guidance systems at ultra-high speeds.

Another key objective is to improve the energy efficiency of maglev systems. This includes optimizing the power consumption of levitation and propulsion systems, as well as developing more effective energy recovery mechanisms. Researchers are also exploring the integration of renewable energy sources to power maglev infrastructure, aiming to reduce the overall environmental impact of these transportation systems.

Enhancing the reliability and reducing the maintenance requirements of maglev systems is another critical objective. This involves developing more durable components, implementing advanced condition monitoring systems, and designing fail-safe mechanisms to ensure uninterrupted operation.

As maglev technology continues to evolve, there is a growing focus on cost reduction to make these systems more economically viable for widespread adoption. This includes streamlining manufacturing processes, standardizing components, and exploring new materials that offer improved performance at lower costs.

As the technology progressed, researchers explored alternative levitation methods, leading to the development of electrodynamic suspension (EDS) systems. EDS utilizes superconducting magnets to create a strong magnetic field, allowing for higher speeds and greater stability. This breakthrough in the 1980s paved the way for more advanced maglev train designs.

The evolution of propulsion systems for maglev trains has been closely tied to advancements in linear motor technology. Early designs relied on linear induction motors (LIMs), which provided adequate acceleration but were limited in top speed. The introduction of linear synchronous motors (LSMs) in the 1990s marked a significant improvement, offering higher efficiency and better control at high speeds.

Throughout the 2000s and 2010s, research efforts focused on optimizing energy consumption and improving the overall efficiency of maglev systems. This led to the development of more sophisticated control systems and the integration of regenerative braking technologies. Additionally, advancements in materials science contributed to the creation of lighter, stronger guideway structures and more efficient superconducting magnets.

The current objectives in maglev train propulsion technology are multifaceted. One primary goal is to further increase operational speeds while maintaining safety and passenger comfort. This involves refining the aerodynamics of train designs and enhancing the stability of the levitation and guidance systems at ultra-high speeds.

Another key objective is to improve the energy efficiency of maglev systems. This includes optimizing the power consumption of levitation and propulsion systems, as well as developing more effective energy recovery mechanisms. Researchers are also exploring the integration of renewable energy sources to power maglev infrastructure, aiming to reduce the overall environmental impact of these transportation systems.

Enhancing the reliability and reducing the maintenance requirements of maglev systems is another critical objective. This involves developing more durable components, implementing advanced condition monitoring systems, and designing fail-safe mechanisms to ensure uninterrupted operation.

As maglev technology continues to evolve, there is a growing focus on cost reduction to make these systems more economically viable for widespread adoption. This includes streamlining manufacturing processes, standardizing components, and exploring new materials that offer improved performance at lower costs.

Market Analysis for High-Speed Rail Technologies

The high-speed rail market has experienced significant growth in recent years, driven by increasing demand for efficient and sustainable transportation solutions. As countries worldwide seek to reduce carbon emissions and improve connectivity, high-speed rail technologies have emerged as a viable alternative to air and road travel for medium to long-distance journeys.

The global high-speed rail market is projected to expand at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2026. This growth is primarily attributed to government initiatives promoting rail infrastructure development, rising urbanization, and the need for faster intercity travel. China remains the largest market for high-speed rail, with an extensive network spanning over 38,000 kilometers. Other key markets include Japan, France, Germany, Spain, and Italy.

In the context of maglev train technologies, market demand is particularly strong in countries seeking to establish next-generation transportation systems. Japan's Chuo Shinkansen project, utilizing superconducting maglev technology, is expected to connect Tokyo and Nagoya by 2027, showcasing the potential for ultra-high-speed rail travel. China has also made significant investments in maglev technology, with plans to develop a network of maglev lines in the coming decades.

The market for throttle body optimization in maglev trains is closely tied to the overall development of maglev technology. As maglev systems rely on precise control of electromagnetic forces for propulsion and levitation, optimized throttle bodies play a crucial role in enhancing energy efficiency and performance. The demand for advanced throttle body solutions is expected to grow as more countries adopt maglev technology and seek to improve the operational efficiency of their high-speed rail systems.

Key market drivers for throttle body optimization in maglev trains include the need for increased energy efficiency, improved acceleration and deceleration capabilities, and enhanced overall system performance. As maglev trains operate at extremely high speeds, even small improvements in throttle body design can lead to significant gains in energy consumption and operational costs.

However, the market for maglev-specific throttle body technologies faces challenges, including high initial investment costs and the limited number of operational maglev systems worldwide. Despite these obstacles, ongoing research and development efforts are likely to drive innovation in this niche market segment, potentially leading to broader applications in conventional high-speed rail systems as well.

The global high-speed rail market is projected to expand at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2026. This growth is primarily attributed to government initiatives promoting rail infrastructure development, rising urbanization, and the need for faster intercity travel. China remains the largest market for high-speed rail, with an extensive network spanning over 38,000 kilometers. Other key markets include Japan, France, Germany, Spain, and Italy.

In the context of maglev train technologies, market demand is particularly strong in countries seeking to establish next-generation transportation systems. Japan's Chuo Shinkansen project, utilizing superconducting maglev technology, is expected to connect Tokyo and Nagoya by 2027, showcasing the potential for ultra-high-speed rail travel. China has also made significant investments in maglev technology, with plans to develop a network of maglev lines in the coming decades.

The market for throttle body optimization in maglev trains is closely tied to the overall development of maglev technology. As maglev systems rely on precise control of electromagnetic forces for propulsion and levitation, optimized throttle bodies play a crucial role in enhancing energy efficiency and performance. The demand for advanced throttle body solutions is expected to grow as more countries adopt maglev technology and seek to improve the operational efficiency of their high-speed rail systems.

Key market drivers for throttle body optimization in maglev trains include the need for increased energy efficiency, improved acceleration and deceleration capabilities, and enhanced overall system performance. As maglev trains operate at extremely high speeds, even small improvements in throttle body design can lead to significant gains in energy consumption and operational costs.

However, the market for maglev-specific throttle body technologies faces challenges, including high initial investment costs and the limited number of operational maglev systems worldwide. Despite these obstacles, ongoing research and development efforts are likely to drive innovation in this niche market segment, potentially leading to broader applications in conventional high-speed rail systems as well.

Throttle Body Challenges in Maglev Systems

The throttle body system in maglev trains faces unique challenges due to the high-speed and precision requirements of magnetic levitation technology. One of the primary issues is the need for rapid and accurate control of airflow to maintain optimal levitation and propulsion. Traditional throttle bodies designed for conventional trains or automobiles may not meet the stringent performance demands of maglev systems.

A significant challenge lies in the response time of the throttle body. Maglev trains operate at extremely high speeds, requiring near-instantaneous adjustments to airflow to maintain stability and efficiency. The throttle body must be capable of opening and closing with minimal latency to respond to sudden changes in track conditions, wind resistance, or passenger load.

Material selection for throttle bodies in maglev systems presents another hurdle. The components must withstand high temperatures and pressures while remaining lightweight to minimize the overall mass of the train. Additionally, the materials need to be resistant to electromagnetic interference, as the strong magnetic fields used in maglev propulsion can potentially affect the performance of electronic components within the throttle body.

Precision control is paramount in maglev throttle bodies. Even minor fluctuations in airflow can impact the train's levitation height and speed. Engineers must develop sophisticated control algorithms and sensors to ensure the throttle body maintains the exact airflow required for optimal performance across various operating conditions.

The integration of the throttle body with the maglev train's overall propulsion and levitation systems poses a complex challenge. The throttle body must work in harmony with other components, such as the linear motor and guidance system, to achieve seamless operation. This requires advanced communication protocols and synchronization mechanisms to ensure all systems respond cohesively to changing conditions.

Reliability and durability are critical factors in maglev throttle body design. Given the high-stakes nature of maglev transportation, the throttle body must operate flawlessly over extended periods with minimal maintenance. This necessitates robust engineering and extensive testing to validate the long-term performance and safety of the system.

Environmental considerations also play a role in throttle body challenges for maglev trains. The system must be designed to operate efficiently across a wide range of temperatures, humidity levels, and atmospheric pressures, as maglev routes may span diverse geographical regions. Furthermore, the throttle body should contribute to the overall energy efficiency of the maglev system, aligning with the technology's reputation for environmental sustainability.

A significant challenge lies in the response time of the throttle body. Maglev trains operate at extremely high speeds, requiring near-instantaneous adjustments to airflow to maintain stability and efficiency. The throttle body must be capable of opening and closing with minimal latency to respond to sudden changes in track conditions, wind resistance, or passenger load.

Material selection for throttle bodies in maglev systems presents another hurdle. The components must withstand high temperatures and pressures while remaining lightweight to minimize the overall mass of the train. Additionally, the materials need to be resistant to electromagnetic interference, as the strong magnetic fields used in maglev propulsion can potentially affect the performance of electronic components within the throttle body.

Precision control is paramount in maglev throttle bodies. Even minor fluctuations in airflow can impact the train's levitation height and speed. Engineers must develop sophisticated control algorithms and sensors to ensure the throttle body maintains the exact airflow required for optimal performance across various operating conditions.

The integration of the throttle body with the maglev train's overall propulsion and levitation systems poses a complex challenge. The throttle body must work in harmony with other components, such as the linear motor and guidance system, to achieve seamless operation. This requires advanced communication protocols and synchronization mechanisms to ensure all systems respond cohesively to changing conditions.

Reliability and durability are critical factors in maglev throttle body design. Given the high-stakes nature of maglev transportation, the throttle body must operate flawlessly over extended periods with minimal maintenance. This necessitates robust engineering and extensive testing to validate the long-term performance and safety of the system.

Environmental considerations also play a role in throttle body challenges for maglev trains. The system must be designed to operate efficiently across a wide range of temperatures, humidity levels, and atmospheric pressures, as maglev routes may span diverse geographical regions. Furthermore, the throttle body should contribute to the overall energy efficiency of the maglev system, aligning with the technology's reputation for environmental sustainability.

Current Throttle Body Solutions for Maglev Trains

01 Throttle body design and construction

Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Various designs focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.- Throttle body design and construction: Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Innovations in throttle body design focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.

- Electronic throttle control systems: Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on various engine parameters and driver input. This allows for improved fuel efficiency, smoother acceleration, and better integration with other engine management systems.

- Idle air control mechanisms: Throttle bodies may include integrated idle air control mechanisms to regulate engine idle speed. These systems bypass the main throttle plate to provide a controlled amount of air during idle conditions. Advancements in this area focus on improving idle stability, reducing emissions, and enhancing cold-start performance.

- Multi-valve throttle bodies: Some throttle body designs incorporate multiple valves or plates to provide more precise control over airflow across different engine operating conditions. These designs can offer improved throttle response, better low-end torque, and enhanced overall engine performance compared to traditional single-valve configurations.

- Throttle body cleaning and maintenance: Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting their performance. Innovations in this area include self-cleaning mechanisms, improved materials to resist deposit buildup, and designs that facilitate easier maintenance and cleaning procedures to ensure optimal throttle body operation throughout the engine's lifespan.

02 Electronic throttle control systems

Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on driver input and engine management requirements, improving responsiveness and fuel efficiency.Expand Specific Solutions03 Idle air control mechanisms

Throttle bodies may include idle air control mechanisms to regulate engine speed during idle conditions. These systems bypass the main throttle plate to provide a controlled amount of air, maintaining stable idle speed and smooth engine operation.Expand Specific Solutions04 Throttle body cleaning and maintenance

Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting performance. Various cleaning methods and maintenance procedures are developed to ensure optimal throttle body operation, including specialized cleaning solutions and tools for removing buildup without damaging sensitive components.Expand Specific Solutions05 Integration with fuel injection systems

Throttle bodies are often integrated with fuel injection systems to optimize air-fuel mixture. This integration can involve positioning fuel injectors near the throttle body or incorporating fuel delivery channels within the throttle body itself, improving atomization and distribution of fuel in the intake air stream.Expand Specific Solutions

Key Players in Maglev Train Industry

The throttle body optimization for maglev trains represents a niche yet rapidly evolving technological field within the broader maglev industry. The market is in its early growth stage, with significant potential for expansion as maglev technology gains traction globally. Key players like CRRC Qingdao Sifang, Hyperloop Technologies, and Beijing Enterprises Holdings Maglev Technology are driving innovation, while academic institutions such as Tongji University and Southwest Jiaotong University contribute to research and development. The technology's maturity is advancing, with companies like Pierburg GmbH and Safran Landing Systems bringing expertise from related industries to enhance throttle body design and performance for maglev applications.

CRRC Qingdao Sifang Co., Ltd.

Technical Solution: CRRC Qingdao Sifang has developed an advanced throttle body optimization system for maglev trains, focusing on improving energy efficiency and speed control. Their solution incorporates a high-precision electronic throttle control unit that utilizes adaptive algorithms to adjust throttle response based on real-time operating conditions[1]. The system integrates with the train's levitation and propulsion systems, allowing for seamless coordination between acceleration, deceleration, and cruising phases[3]. Additionally, they have implemented a regenerative braking system that captures kinetic energy during deceleration, further enhancing overall energy efficiency[5].

Strengths: Highly integrated system design, improved energy efficiency, and precise speed control. Weaknesses: Potentially higher initial costs and complexity in maintenance due to advanced electronic components.

Tongji University

Technical Solution: Tongji University's research team has developed an innovative throttle body optimization approach for maglev trains, focusing on aerodynamic efficiency and noise reduction. Their solution incorporates a variable geometry throttle body design that adapts to different speed ranges and environmental conditions[2]. The system utilizes advanced computational fluid dynamics (CFD) simulations to optimize airflow management, reducing drag and improving overall train performance[4]. Additionally, they have implemented active noise control technologies to minimize acoustic emissions at high speeds, enhancing passenger comfort and reducing environmental impact[6].

Strengths: Advanced aerodynamic optimization, reduced noise emissions, and improved overall efficiency. Weaknesses: Potential challenges in manufacturing complex variable geometry components and higher development costs.

Innovative Throttle Body Designs for Maglev Applications

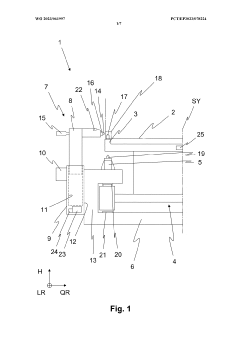

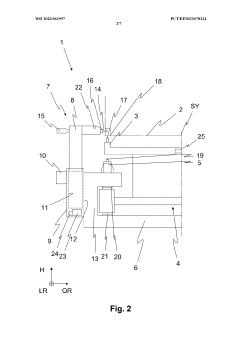

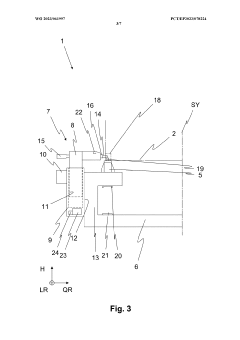

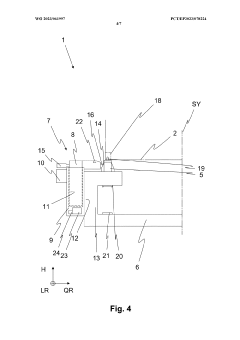

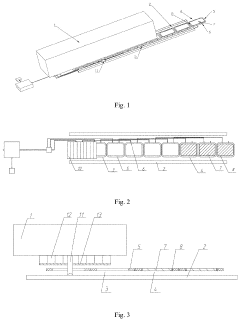

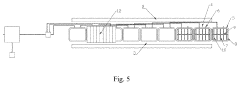

Maglev train with transverse positioning unit

PatentWO2023061997A1

Innovation

- A magnetic levitation train with a transverse positioning unit that includes guide elements and track narrowing features to mechanically align and hold the vehicle in place during loading and unloading, ensuring stable and efficient handling.

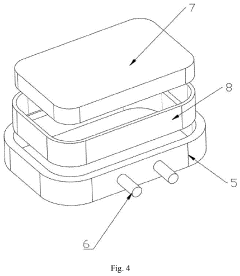

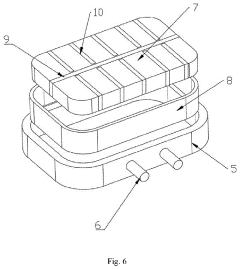

Levitation, propulsion and guidance integrated magnetic levitation system and improvement method of guidance and levitation

PatentActiveUS20220089196A1

Innovation

- An integrated magnetic levitation system where the driving device and levitation device are combined, using alternating coils with induction levitation plates and guidance magnetic strips to provide a unified levitation, propulsion, and guidance system, optimizing the use of magnetic fields and reducing equipment volume.

Environmental Impact of Maglev Propulsion Systems

The environmental impact of maglev propulsion systems is a critical consideration in the development and implementation of magnetic levitation train technology. These systems offer significant advantages in terms of energy efficiency and reduced emissions compared to traditional rail systems. Maglev trains utilize electromagnetic forces for propulsion and levitation, eliminating the need for wheels and physical contact with the track. This results in reduced friction and wear, leading to lower maintenance requirements and extended infrastructure lifespan.

One of the primary environmental benefits of maglev propulsion systems is their potential for energy efficiency. The absence of mechanical contact between the train and the track significantly reduces energy loss due to friction. This efficiency translates to lower energy consumption per passenger-kilometer compared to conventional high-speed rail systems. Additionally, maglev trains can achieve higher speeds with less energy input, further enhancing their overall efficiency.

The reduced energy consumption of maglev systems contributes to lower greenhouse gas emissions, particularly when powered by renewable energy sources. As countries increasingly shift towards cleaner energy grids, the environmental footprint of maglev trains becomes even more favorable. The potential for integration with renewable energy sources, such as solar or wind power, presents opportunities for creating nearly carbon-neutral transportation systems.

Noise pollution is another area where maglev propulsion systems demonstrate environmental advantages. The absence of wheel-rail contact and the use of electromagnetic levitation result in significantly reduced noise levels compared to traditional trains. This is particularly beneficial in urban areas and along densely populated corridors, where noise pollution from transportation can have substantial impacts on quality of life and local ecosystems.

Land use and habitat disruption are important considerations in assessing the environmental impact of maglev systems. While the construction of maglev infrastructure does require land allocation, the elevated nature of many maglev tracks can minimize ground-level disruption. This design approach can help preserve wildlife corridors and reduce habitat fragmentation compared to traditional ground-level rail systems.

However, it is important to note that the production and disposal of the specialized components used in maglev systems, such as superconducting magnets and advanced electronic systems, may have environmental implications. The lifecycle assessment of these components, including their manufacturing processes and end-of-life management, should be carefully considered to provide a comprehensive understanding of the overall environmental impact.

In conclusion, maglev propulsion systems offer significant environmental benefits in terms of energy efficiency, reduced emissions, and noise pollution. As technology advances and renewable energy integration improves, the potential for maglev trains to contribute to sustainable transportation solutions continues to grow. Ongoing research and development in this field should focus on further optimizing the environmental performance of maglev systems, addressing any potential drawbacks, and ensuring their long-term sustainability.

One of the primary environmental benefits of maglev propulsion systems is their potential for energy efficiency. The absence of mechanical contact between the train and the track significantly reduces energy loss due to friction. This efficiency translates to lower energy consumption per passenger-kilometer compared to conventional high-speed rail systems. Additionally, maglev trains can achieve higher speeds with less energy input, further enhancing their overall efficiency.

The reduced energy consumption of maglev systems contributes to lower greenhouse gas emissions, particularly when powered by renewable energy sources. As countries increasingly shift towards cleaner energy grids, the environmental footprint of maglev trains becomes even more favorable. The potential for integration with renewable energy sources, such as solar or wind power, presents opportunities for creating nearly carbon-neutral transportation systems.

Noise pollution is another area where maglev propulsion systems demonstrate environmental advantages. The absence of wheel-rail contact and the use of electromagnetic levitation result in significantly reduced noise levels compared to traditional trains. This is particularly beneficial in urban areas and along densely populated corridors, where noise pollution from transportation can have substantial impacts on quality of life and local ecosystems.

Land use and habitat disruption are important considerations in assessing the environmental impact of maglev systems. While the construction of maglev infrastructure does require land allocation, the elevated nature of many maglev tracks can minimize ground-level disruption. This design approach can help preserve wildlife corridors and reduce habitat fragmentation compared to traditional ground-level rail systems.

However, it is important to note that the production and disposal of the specialized components used in maglev systems, such as superconducting magnets and advanced electronic systems, may have environmental implications. The lifecycle assessment of these components, including their manufacturing processes and end-of-life management, should be carefully considered to provide a comprehensive understanding of the overall environmental impact.

In conclusion, maglev propulsion systems offer significant environmental benefits in terms of energy efficiency, reduced emissions, and noise pollution. As technology advances and renewable energy integration improves, the potential for maglev trains to contribute to sustainable transportation solutions continues to grow. Ongoing research and development in this field should focus on further optimizing the environmental performance of maglev systems, addressing any potential drawbacks, and ensuring their long-term sustainability.

Safety Standards for Maglev Train Technologies

Safety standards for maglev train technologies are paramount to ensure the secure operation and public acceptance of this advanced transportation system. These standards encompass a wide range of aspects, from electromagnetic field exposure limits to emergency evacuation procedures. The International Electrotechnical Commission (IEC) has established guidelines for electromagnetic compatibility and safety, which are crucial for maglev systems due to their reliance on powerful electromagnetic fields.

One of the primary safety concerns addressed by these standards is the structural integrity of the guideway and vehicle. Rigorous testing protocols are in place to evaluate the resilience of these components under various stress conditions, including extreme weather events and seismic activity. The standards also specify the required redundancy in critical systems to maintain safe operation in case of component failures.

Collision avoidance and derailment prevention are key focus areas within the safety standards. Advanced signaling systems and fail-safe control mechanisms are mandated to maintain safe distances between trains and prevent unauthorized track access. The standards also outline specifications for the design of the guideway to minimize the risk of derailment, even in the event of power failures or system malfunctions.

Passenger safety is another critical aspect covered by these standards. This includes requirements for fire-resistant materials, smoke detection and suppression systems, and emergency lighting. The standards also dictate the design of passenger compartments to minimize injury risks during normal operation and in the unlikely event of an accident.

Environmental safety considerations are also addressed, particularly regarding the potential impacts of strong magnetic fields on surrounding ecosystems and electronic devices. The standards set limits on electromagnetic emissions and require shielding measures to protect both passengers and the environment.

Operational safety standards cover aspects such as maximum operating speeds, acceleration and deceleration rates, and procedures for handling various emergency scenarios. These standards are continually evolving as new technologies emerge and more operational data becomes available from existing maglev systems.

Compliance with these safety standards is typically overseen by national transportation safety boards and international bodies. Regular inspections, maintenance protocols, and staff training requirements are integral parts of ensuring ongoing adherence to these standards throughout the lifecycle of maglev train systems.

One of the primary safety concerns addressed by these standards is the structural integrity of the guideway and vehicle. Rigorous testing protocols are in place to evaluate the resilience of these components under various stress conditions, including extreme weather events and seismic activity. The standards also specify the required redundancy in critical systems to maintain safe operation in case of component failures.

Collision avoidance and derailment prevention are key focus areas within the safety standards. Advanced signaling systems and fail-safe control mechanisms are mandated to maintain safe distances between trains and prevent unauthorized track access. The standards also outline specifications for the design of the guideway to minimize the risk of derailment, even in the event of power failures or system malfunctions.

Passenger safety is another critical aspect covered by these standards. This includes requirements for fire-resistant materials, smoke detection and suppression systems, and emergency lighting. The standards also dictate the design of passenger compartments to minimize injury risks during normal operation and in the unlikely event of an accident.

Environmental safety considerations are also addressed, particularly regarding the potential impacts of strong magnetic fields on surrounding ecosystems and electronic devices. The standards set limits on electromagnetic emissions and require shielding measures to protect both passengers and the environment.

Operational safety standards cover aspects such as maximum operating speeds, acceleration and deceleration rates, and procedures for handling various emergency scenarios. These standards are continually evolving as new technologies emerge and more operational data becomes available from existing maglev systems.

Compliance with these safety standards is typically overseen by national transportation safety boards and international bodies. Regular inspections, maintenance protocols, and staff training requirements are integral parts of ensuring ongoing adherence to these standards throughout the lifecycle of maglev train systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!