Acoustic monitoring for submersible pump diagnostics.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Acoustics: Background and Objectives

Acoustic monitoring for submersible pump diagnostics has emerged as a critical technology in the field of industrial maintenance and predictive analytics. This approach leverages the principles of sound wave propagation and analysis to assess the operational health and performance of submersible pumps, which are widely used in various industries, including oil and gas, water treatment, and mining.

The development of acoustic monitoring techniques for submersible pumps can be traced back to the early 1990s when researchers began exploring non-invasive methods for equipment diagnostics. Initially, these efforts were limited by the technological constraints of the time, particularly in terms of sensor sensitivity and data processing capabilities. However, as technology advanced, so did the potential for more sophisticated acoustic monitoring systems.

Over the past three decades, the field has witnessed significant progress, driven by advancements in sensor technology, signal processing algorithms, and machine learning techniques. Modern acoustic monitoring systems can detect a wide range of pump issues, including cavitation, bearing wear, impeller damage, and misalignment, often before they lead to catastrophic failure.

The primary objective of acoustic monitoring for submersible pump diagnostics is to enhance the reliability, efficiency, and longevity of these critical pieces of equipment. By providing real-time insights into pump performance and potential issues, this technology aims to reduce downtime, minimize maintenance costs, and optimize overall operational efficiency.

Key technical goals in this field include improving the accuracy of fault detection and classification, developing more robust sensors capable of withstanding harsh underwater environments, and creating advanced algorithms for noise filtering and pattern recognition in complex acoustic signatures. Additionally, there is a growing focus on integrating acoustic monitoring data with other sensor inputs to create comprehensive health monitoring systems for submersible pumps.

The evolution of this technology is closely tied to broader trends in Industry 4.0 and the Industrial Internet of Things (IIoT). As such, current research efforts are increasingly directed towards developing cloud-based analytics platforms, implementing edge computing solutions for real-time processing, and exploring the potential of artificial intelligence in predictive maintenance strategies.

Looking ahead, the field of acoustic monitoring for submersible pump diagnostics is poised for further innovation. Emerging areas of interest include the development of self-learning systems capable of adapting to changing pump conditions, the integration of acoustic monitoring with augmented reality for enhanced maintenance procedures, and the exploration of new materials and designs for more sensitive and durable acoustic sensors.

The development of acoustic monitoring techniques for submersible pumps can be traced back to the early 1990s when researchers began exploring non-invasive methods for equipment diagnostics. Initially, these efforts were limited by the technological constraints of the time, particularly in terms of sensor sensitivity and data processing capabilities. However, as technology advanced, so did the potential for more sophisticated acoustic monitoring systems.

Over the past three decades, the field has witnessed significant progress, driven by advancements in sensor technology, signal processing algorithms, and machine learning techniques. Modern acoustic monitoring systems can detect a wide range of pump issues, including cavitation, bearing wear, impeller damage, and misalignment, often before they lead to catastrophic failure.

The primary objective of acoustic monitoring for submersible pump diagnostics is to enhance the reliability, efficiency, and longevity of these critical pieces of equipment. By providing real-time insights into pump performance and potential issues, this technology aims to reduce downtime, minimize maintenance costs, and optimize overall operational efficiency.

Key technical goals in this field include improving the accuracy of fault detection and classification, developing more robust sensors capable of withstanding harsh underwater environments, and creating advanced algorithms for noise filtering and pattern recognition in complex acoustic signatures. Additionally, there is a growing focus on integrating acoustic monitoring data with other sensor inputs to create comprehensive health monitoring systems for submersible pumps.

The evolution of this technology is closely tied to broader trends in Industry 4.0 and the Industrial Internet of Things (IIoT). As such, current research efforts are increasingly directed towards developing cloud-based analytics platforms, implementing edge computing solutions for real-time processing, and exploring the potential of artificial intelligence in predictive maintenance strategies.

Looking ahead, the field of acoustic monitoring for submersible pump diagnostics is poised for further innovation. Emerging areas of interest include the development of self-learning systems capable of adapting to changing pump conditions, the integration of acoustic monitoring with augmented reality for enhanced maintenance procedures, and the exploration of new materials and designs for more sensitive and durable acoustic sensors.

Market Analysis for Pump Diagnostic Solutions

The market for pump diagnostic solutions, particularly those utilizing acoustic monitoring for submersible pumps, has been experiencing significant growth in recent years. This growth is driven by the increasing demand for efficient and reliable pump systems across various industries, including oil and gas, water and wastewater management, and mining.

The global submersible pump market was valued at approximately $11.68 billion in 2020 and is projected to reach $17.32 billion by 2028, growing at a CAGR of 5.1% during the forecast period. Within this market, the demand for advanced diagnostic solutions is rising rapidly as industries seek to minimize downtime, reduce maintenance costs, and improve overall operational efficiency.

Acoustic monitoring technology for submersible pump diagnostics offers several advantages over traditional monitoring methods. It provides real-time, non-invasive monitoring capabilities, allowing for early detection of potential issues such as cavitation, bearing wear, and impeller damage. This proactive approach to maintenance can significantly reduce the risk of catastrophic failures and extend the lifespan of pump systems.

The oil and gas industry remains the largest market segment for submersible pump diagnostic solutions, accounting for approximately 35% of the total market share. The water and wastewater management sector is the second-largest market, followed by the mining industry. These sectors are increasingly adopting acoustic monitoring technologies to enhance their pump maintenance strategies and optimize operational performance.

Geographically, North America and Europe are the leading markets for pump diagnostic solutions, owing to their advanced industrial infrastructure and stringent regulatory requirements. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in water and wastewater management projects.

Key market trends include the integration of artificial intelligence and machine learning algorithms with acoustic monitoring systems, enabling more accurate predictive maintenance capabilities. Additionally, there is a growing focus on developing cloud-based monitoring platforms that allow for remote diagnostics and data analysis, further enhancing the value proposition of these solutions.

The competitive landscape of the pump diagnostic solutions market is characterized by a mix of established industrial technology companies and innovative startups. Major players are investing heavily in research and development to enhance their product offerings and gain a competitive edge. Strategic partnerships and collaborations between pump manufacturers and diagnostic solution providers are also becoming increasingly common, as companies seek to offer comprehensive, integrated solutions to their customers.

The global submersible pump market was valued at approximately $11.68 billion in 2020 and is projected to reach $17.32 billion by 2028, growing at a CAGR of 5.1% during the forecast period. Within this market, the demand for advanced diagnostic solutions is rising rapidly as industries seek to minimize downtime, reduce maintenance costs, and improve overall operational efficiency.

Acoustic monitoring technology for submersible pump diagnostics offers several advantages over traditional monitoring methods. It provides real-time, non-invasive monitoring capabilities, allowing for early detection of potential issues such as cavitation, bearing wear, and impeller damage. This proactive approach to maintenance can significantly reduce the risk of catastrophic failures and extend the lifespan of pump systems.

The oil and gas industry remains the largest market segment for submersible pump diagnostic solutions, accounting for approximately 35% of the total market share. The water and wastewater management sector is the second-largest market, followed by the mining industry. These sectors are increasingly adopting acoustic monitoring technologies to enhance their pump maintenance strategies and optimize operational performance.

Geographically, North America and Europe are the leading markets for pump diagnostic solutions, owing to their advanced industrial infrastructure and stringent regulatory requirements. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in water and wastewater management projects.

Key market trends include the integration of artificial intelligence and machine learning algorithms with acoustic monitoring systems, enabling more accurate predictive maintenance capabilities. Additionally, there is a growing focus on developing cloud-based monitoring platforms that allow for remote diagnostics and data analysis, further enhancing the value proposition of these solutions.

The competitive landscape of the pump diagnostic solutions market is characterized by a mix of established industrial technology companies and innovative startups. Major players are investing heavily in research and development to enhance their product offerings and gain a competitive edge. Strategic partnerships and collaborations between pump manufacturers and diagnostic solution providers are also becoming increasingly common, as companies seek to offer comprehensive, integrated solutions to their customers.

Current Challenges in Underwater Acoustic Monitoring

Underwater acoustic monitoring for submersible pump diagnostics faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complex and dynamic nature of the underwater environment. Sound propagation in water is influenced by various factors such as temperature, pressure, salinity, and depth, which can vary greatly depending on the location and time. These variations can lead to signal distortion, attenuation, and multipath effects, making it difficult to accurately interpret acoustic data.

The presence of ambient noise in underwater environments poses another major challenge. Natural sources like waves, marine life, and weather conditions, as well as anthropogenic sources such as shipping traffic and industrial activities, contribute to a high level of background noise. This noise can mask or interfere with the acoustic signals emitted by submersible pumps, reducing the signal-to-noise ratio and complicating the detection and analysis of pump-specific sounds.

Hardware limitations also present significant hurdles in underwater acoustic monitoring. Developing robust, waterproof, and pressure-resistant sensors and data acquisition systems capable of operating reliably in harsh underwater conditions is technically challenging and costly. Additionally, power supply and data transmission issues arise when deploying long-term monitoring systems in remote underwater locations, necessitating innovative solutions for energy harvesting and efficient data communication.

Data processing and interpretation pose further challenges in this field. The vast amount of acoustic data collected requires sophisticated signal processing algorithms and machine learning techniques to extract meaningful information about pump health and performance. Developing accurate models that can distinguish between normal operational sounds and indicators of potential failures or degradation is a complex task, especially given the variability in pump designs and operating conditions.

The integration of acoustic monitoring systems with existing submersible pump infrastructure presents both technical and operational challenges. Retrofitting acoustic sensors to pumps already in service can be difficult and may require temporary shutdowns, impacting operational efficiency. Furthermore, ensuring compatibility between acoustic monitoring systems and existing control and monitoring platforms adds another layer of complexity to implementation.

Lastly, the lack of standardization in acoustic monitoring techniques for submersible pumps hinders widespread adoption. Different manufacturers and researchers may employ varying methodologies for data collection, analysis, and interpretation, making it challenging to compare results across different systems or establish industry-wide best practices. This fragmentation also complicates the development of universal diagnostic tools and predictive maintenance strategies based on acoustic data.

The presence of ambient noise in underwater environments poses another major challenge. Natural sources like waves, marine life, and weather conditions, as well as anthropogenic sources such as shipping traffic and industrial activities, contribute to a high level of background noise. This noise can mask or interfere with the acoustic signals emitted by submersible pumps, reducing the signal-to-noise ratio and complicating the detection and analysis of pump-specific sounds.

Hardware limitations also present significant hurdles in underwater acoustic monitoring. Developing robust, waterproof, and pressure-resistant sensors and data acquisition systems capable of operating reliably in harsh underwater conditions is technically challenging and costly. Additionally, power supply and data transmission issues arise when deploying long-term monitoring systems in remote underwater locations, necessitating innovative solutions for energy harvesting and efficient data communication.

Data processing and interpretation pose further challenges in this field. The vast amount of acoustic data collected requires sophisticated signal processing algorithms and machine learning techniques to extract meaningful information about pump health and performance. Developing accurate models that can distinguish between normal operational sounds and indicators of potential failures or degradation is a complex task, especially given the variability in pump designs and operating conditions.

The integration of acoustic monitoring systems with existing submersible pump infrastructure presents both technical and operational challenges. Retrofitting acoustic sensors to pumps already in service can be difficult and may require temporary shutdowns, impacting operational efficiency. Furthermore, ensuring compatibility between acoustic monitoring systems and existing control and monitoring platforms adds another layer of complexity to implementation.

Lastly, the lack of standardization in acoustic monitoring techniques for submersible pumps hinders widespread adoption. Different manufacturers and researchers may employ varying methodologies for data collection, analysis, and interpretation, making it challenging to compare results across different systems or establish industry-wide best practices. This fragmentation also complicates the development of universal diagnostic tools and predictive maintenance strategies based on acoustic data.

Existing Acoustic Monitoring Solutions for Pumps

01 Acoustic monitoring systems for submersible pumps

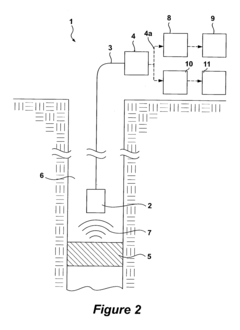

Acoustic monitoring systems are used to detect and analyze sounds produced by submersible pumps during operation. These systems can help identify potential issues, monitor performance, and predict maintenance needs. They typically involve sensors or microphones placed near the pump to capture acoustic signals, which are then processed and analyzed using specialized software.- Acoustic monitoring systems for submersible pumps: Acoustic monitoring systems are used to detect and analyze sounds produced by submersible pumps during operation. These systems can help identify potential issues, monitor performance, and predict maintenance needs. They typically involve sensors or microphones placed near the pump to capture acoustic data, which is then processed and analyzed using specialized software.

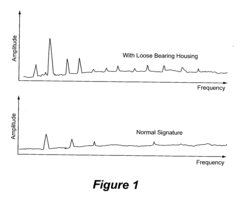

- Vibration analysis in submersible pump monitoring: Vibration analysis is a key component of acoustic monitoring for submersible pumps. By measuring and analyzing vibration patterns, operators can detect abnormalities in pump operation, such as cavitation, bearing wear, or impeller damage. Advanced signal processing techniques are often employed to extract meaningful information from vibration data and provide early warning of potential failures.

- Integration of acoustic monitoring with pump control systems: Acoustic monitoring can be integrated with pump control systems to enable real-time performance optimization and fault detection. This integration allows for automated adjustments to pump operation based on acoustic feedback, improving efficiency and reducing the risk of equipment damage. It may also include remote monitoring capabilities for off-site analysis and decision-making.

- Underwater acoustic communication for submersible pump monitoring: Underwater acoustic communication systems are used to transmit data from submersible pumps to surface monitoring stations. These systems overcome the challenges of wireless communication in aqueous environments, allowing for continuous monitoring of pump performance and condition without the need for physical connections. They may employ various modulation techniques and frequency ranges to optimize data transmission in different underwater conditions.

- Machine learning applications in submersible pump acoustic monitoring: Machine learning algorithms are increasingly being applied to acoustic monitoring of submersible pumps. These techniques can improve the accuracy of fault detection, predict maintenance needs, and optimize pump performance based on historical and real-time acoustic data. Neural networks and other AI models can be trained to recognize complex patterns in acoustic signatures that may indicate specific pump conditions or impending failures.

02 Vibration analysis in submersible pump monitoring

Vibration analysis is a key component of acoustic monitoring for submersible pumps. By measuring and analyzing vibration patterns, operators can detect abnormalities in pump operation, such as cavitation, bearing wear, or impeller damage. This technique allows for early detection of potential failures and helps optimize maintenance schedules.Expand Specific Solutions03 Integration of acoustic monitoring with pump control systems

Advanced submersible pump systems integrate acoustic monitoring data with pump control systems. This integration allows for real-time adjustments to pump operation based on acoustic feedback, optimizing performance and preventing damage. The combined system can automatically adjust pump speed, flow rate, or shut down the pump if critical acoustic thresholds are exceeded.Expand Specific Solutions04 Wireless acoustic monitoring for submersible pumps

Wireless technology is increasingly used in acoustic monitoring systems for submersible pumps, especially in remote or hard-to-access locations. These systems use wireless sensors to transmit acoustic data to a central monitoring station, allowing for continuous monitoring without the need for physical access to the pump site. This approach enhances the flexibility and scalability of monitoring solutions.Expand Specific Solutions05 Machine learning in submersible pump acoustic analysis

Machine learning algorithms are being applied to acoustic monitoring data from submersible pumps to improve fault detection and predictive maintenance. These algorithms can learn from historical data to identify patterns and anomalies that may indicate developing issues. This approach enhances the accuracy of fault diagnosis and allows for more proactive maintenance strategies.Expand Specific Solutions

Key Players in Acoustic Monitoring Industry

The acoustic monitoring market for submersible pump diagnostics is in a growth phase, driven by increasing demand for efficient pump maintenance in various industries. The market size is expanding, with a projected CAGR of 7-8% over the next five years. Technologically, the field is advancing rapidly, with key players like Schlumberger, Baker Hughes, and Weatherford leading innovation. These companies are developing sophisticated acoustic sensors and data analysis tools to enhance pump performance and reduce downtime. Emerging players such as Silixa and 4Subsea are also contributing to technological advancements, particularly in fiber optic-based monitoring solutions. The competitive landscape is characterized by a mix of established oilfield service giants and specialized monitoring technology providers, indicating a maturing but still dynamic market.

Schlumberger Technologies, Inc.

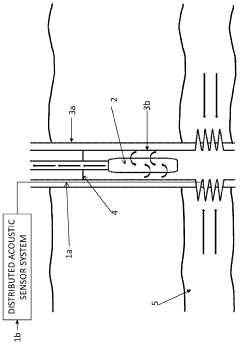

Technical Solution: Schlumberger has developed advanced acoustic monitoring systems for submersible pump diagnostics. Their technology utilizes an array of high-sensitivity acoustic sensors strategically placed along the pump assembly to detect and analyze various acoustic signatures. The system employs machine learning algorithms to process the acoustic data in real-time, identifying patterns indicative of pump performance issues, such as cavitation, bearing wear, or impeller damage[1]. Schlumberger's solution also incorporates fiber optic sensing technology, allowing for distributed acoustic sensing (DAS) along the entire length of the wellbore, providing a comprehensive view of pump operations and surrounding fluid dynamics[3]. This integrated approach enables early detection of potential failures and optimization of pump performance, significantly reducing downtime and maintenance costs.

Strengths: Comprehensive monitoring capability, real-time data analysis, and integration with existing oilfield infrastructure. Weaknesses: High initial implementation cost and potential complexity in data interpretation for less experienced operators.

Silixa Ltd.

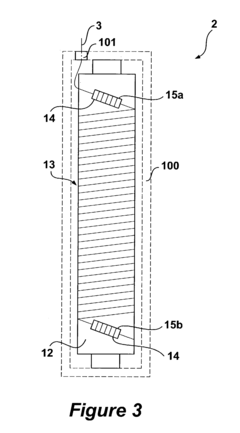

Technical Solution: Silixa has pioneered the use of Distributed Acoustic Sensing (DAS) technology for submersible pump diagnostics. Their iDAS (Intelligent Distributed Acoustic Sensor) system utilizes fiber optic cables as continuous linear sensors, capable of detecting acoustic events along the entire length of the cable with high spatial resolution[2]. For submersible pump applications, Silixa's technology can detect subtle changes in pump vibrations, flow regimes, and surrounding fluid dynamics. The system employs advanced signal processing algorithms to filter out noise and identify specific acoustic signatures associated with pump performance issues. Silixa's solution also integrates with their Carina® Sensing System, which offers improved sensitivity and a wider dynamic range compared to traditional DAS systems[4]. This allows for more accurate detection of low-amplitude acoustic events, crucial for early problem identification in submersible pumps.

Strengths: High spatial resolution, continuous monitoring along the entire wellbore, and improved sensitivity for early problem detection. Weaknesses: Requires installation of fiber optic cables, which may be challenging in existing wells without pre-installed fibers.

Innovative Acoustic Sensing Technologies

Submersible pump monitoring

PatentActiveGB2549663A

Innovation

- The use of optical fiber distributed acoustic sensors to measure acoustic waves generated by the submersible pump itself, allowing for non-invasive, continuous monitoring of fluid levels and flow rates, and enabling the detection of changes in operating frequencies to alert for potential faults.

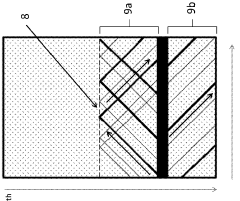

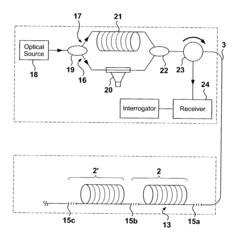

System and method for monitoring performance of downhole equipment using fiber optic based sensors

PatentInactiveUS20040141420A1

Innovation

- A system utilizing coiled fiber optic sensors, such as hydrophones and accelerometers, with fiber Bragg gratings to detect acoustic emissions from downhole equipment, converting these signals into frequency spectra for monitoring equipment health and enabling preventive maintenance.

Environmental Impact of Acoustic Monitoring

Acoustic monitoring for submersible pump diagnostics, while offering significant benefits in terms of predictive maintenance and operational efficiency, also has potential environmental impacts that need to be carefully considered. The primary environmental concern associated with this technology is the introduction of artificial underwater noise, which can affect marine ecosystems.

The acoustic signals used for pump diagnostics, although typically low in intensity, contribute to the overall underwater soundscape. In marine environments, this additional noise can potentially interfere with the communication and behavior of various aquatic species. Many marine animals, including fish, marine mammals, and invertebrates, rely on sound for navigation, finding food, and communicating with others of their species. The introduction of artificial noise, even at low levels, may disrupt these natural processes.

However, it is important to note that the environmental impact of acoustic monitoring for submersible pumps is generally considered minimal compared to other sources of underwater noise, such as shipping traffic or offshore construction activities. The acoustic signals used for pump diagnostics are usually localized and intermittent, which helps to mitigate their overall impact on marine ecosystems.

To further minimize potential environmental effects, several strategies can be employed. These include optimizing the frequency and duration of acoustic monitoring sessions to reduce unnecessary noise exposure, using directional acoustic sensors to focus the monitoring area, and implementing adaptive monitoring schedules that consider local marine life activity patterns.

Additionally, the environmental benefits of acoustic monitoring should be weighed against its potential impacts. By enabling early detection of pump malfunctions, this technology can prevent catastrophic failures that could lead to oil spills or other environmental hazards. This preventive aspect of acoustic monitoring contributes positively to environmental protection efforts in offshore and marine industrial operations.

Regulatory bodies and environmental agencies are increasingly recognizing the importance of managing underwater noise pollution. As a result, guidelines and standards for acoustic emissions in marine environments are being developed and implemented in various jurisdictions. Companies employing acoustic monitoring technologies for submersible pumps should stay informed about these regulations and ensure compliance to minimize their environmental footprint.

In conclusion, while acoustic monitoring for submersible pump diagnostics does introduce artificial noise into marine environments, its overall environmental impact is generally considered low. With proper management and mitigation strategies, the benefits of this technology in terms of operational efficiency and environmental risk reduction can outweigh its potential negative effects on marine ecosystems.

The acoustic signals used for pump diagnostics, although typically low in intensity, contribute to the overall underwater soundscape. In marine environments, this additional noise can potentially interfere with the communication and behavior of various aquatic species. Many marine animals, including fish, marine mammals, and invertebrates, rely on sound for navigation, finding food, and communicating with others of their species. The introduction of artificial noise, even at low levels, may disrupt these natural processes.

However, it is important to note that the environmental impact of acoustic monitoring for submersible pumps is generally considered minimal compared to other sources of underwater noise, such as shipping traffic or offshore construction activities. The acoustic signals used for pump diagnostics are usually localized and intermittent, which helps to mitigate their overall impact on marine ecosystems.

To further minimize potential environmental effects, several strategies can be employed. These include optimizing the frequency and duration of acoustic monitoring sessions to reduce unnecessary noise exposure, using directional acoustic sensors to focus the monitoring area, and implementing adaptive monitoring schedules that consider local marine life activity patterns.

Additionally, the environmental benefits of acoustic monitoring should be weighed against its potential impacts. By enabling early detection of pump malfunctions, this technology can prevent catastrophic failures that could lead to oil spills or other environmental hazards. This preventive aspect of acoustic monitoring contributes positively to environmental protection efforts in offshore and marine industrial operations.

Regulatory bodies and environmental agencies are increasingly recognizing the importance of managing underwater noise pollution. As a result, guidelines and standards for acoustic emissions in marine environments are being developed and implemented in various jurisdictions. Companies employing acoustic monitoring technologies for submersible pumps should stay informed about these regulations and ensure compliance to minimize their environmental footprint.

In conclusion, while acoustic monitoring for submersible pump diagnostics does introduce artificial noise into marine environments, its overall environmental impact is generally considered low. With proper management and mitigation strategies, the benefits of this technology in terms of operational efficiency and environmental risk reduction can outweigh its potential negative effects on marine ecosystems.

Data Analysis and AI in Pump Diagnostics

Data analysis and artificial intelligence (AI) are revolutionizing pump diagnostics, particularly in the field of acoustic monitoring for submersible pumps. Advanced data analysis techniques enable the extraction of valuable insights from complex acoustic signatures, while AI algorithms enhance the accuracy and efficiency of fault detection and prediction.

Machine learning models, such as support vector machines (SVMs) and neural networks, are increasingly employed to classify acoustic patterns associated with various pump conditions. These models can be trained on large datasets of historical pump performance and corresponding acoustic signatures, allowing them to recognize subtle changes in sound patterns that may indicate impending failures or suboptimal operation.

Deep learning architectures, including convolutional neural networks (CNNs) and recurrent neural networks (RNNs), have shown promising results in processing and analyzing time-series acoustic data from submersible pumps. CNNs excel at identifying spatial features in spectrograms, while RNNs are adept at capturing temporal dependencies in acoustic signals, making them particularly suitable for detecting anomalies in pump behavior over time.

Feature extraction techniques play a crucial role in preprocessing acoustic data for AI-driven analysis. Methods such as Mel-frequency cepstral coefficients (MFCCs) and wavelet transforms are commonly used to reduce the dimensionality of raw acoustic signals while preserving essential information. These techniques help in isolating relevant features that correlate with specific pump conditions or faults.

Real-time data processing and edge computing are emerging trends in pump diagnostics, enabling on-site analysis of acoustic data. This approach reduces latency in fault detection and allows for immediate corrective actions. Edge AI solutions, incorporating lightweight machine learning models, can be deployed directly on pump monitoring systems, providing continuous analysis without the need for constant cloud connectivity.

Predictive maintenance strategies are being enhanced through the integration of AI-driven acoustic monitoring. By analyzing historical data and real-time acoustic signatures, AI algorithms can forecast potential failures and recommend optimal maintenance schedules. This proactive approach significantly reduces downtime and extends the operational life of submersible pumps.

As the field advances, the integration of acoustic data with other sensor inputs, such as vibration, temperature, and pressure measurements, is becoming more prevalent. Multimodal AI models that can process and correlate data from various sources are being developed to provide a more comprehensive assessment of pump health and performance.

Machine learning models, such as support vector machines (SVMs) and neural networks, are increasingly employed to classify acoustic patterns associated with various pump conditions. These models can be trained on large datasets of historical pump performance and corresponding acoustic signatures, allowing them to recognize subtle changes in sound patterns that may indicate impending failures or suboptimal operation.

Deep learning architectures, including convolutional neural networks (CNNs) and recurrent neural networks (RNNs), have shown promising results in processing and analyzing time-series acoustic data from submersible pumps. CNNs excel at identifying spatial features in spectrograms, while RNNs are adept at capturing temporal dependencies in acoustic signals, making them particularly suitable for detecting anomalies in pump behavior over time.

Feature extraction techniques play a crucial role in preprocessing acoustic data for AI-driven analysis. Methods such as Mel-frequency cepstral coefficients (MFCCs) and wavelet transforms are commonly used to reduce the dimensionality of raw acoustic signals while preserving essential information. These techniques help in isolating relevant features that correlate with specific pump conditions or faults.

Real-time data processing and edge computing are emerging trends in pump diagnostics, enabling on-site analysis of acoustic data. This approach reduces latency in fault detection and allows for immediate corrective actions. Edge AI solutions, incorporating lightweight machine learning models, can be deployed directly on pump monitoring systems, providing continuous analysis without the need for constant cloud connectivity.

Predictive maintenance strategies are being enhanced through the integration of AI-driven acoustic monitoring. By analyzing historical data and real-time acoustic signatures, AI algorithms can forecast potential failures and recommend optimal maintenance schedules. This proactive approach significantly reduces downtime and extends the operational life of submersible pumps.

As the field advances, the integration of acoustic data with other sensor inputs, such as vibration, temperature, and pressure measurements, is becoming more prevalent. Multimodal AI models that can process and correlate data from various sources are being developed to provide a more comprehensive assessment of pump health and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!