Additive Manufacturing For Turbine Engine Components

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive Manufacturing Technology Background And Goals

## Directory: 技术背景与目标

Additive Manufacturing (AM) for turbine engine components has evolved significantly over the past few decades. Initially, AM was primarily used for prototyping and small-scale production. However, advancements in materials science and precision engineering have enabled its application in producing complex, high-performance components for turbine engines. The primary goal is to leverage AM to enhance the performance, efficiency, and durability of turbine engines while reducing production costs and lead times. This involves developing new materials and refining AM processes to meet the stringent requirements of the aerospace industry. The focus is on achieving superior mechanical properties, thermal resistance, and reliability in turbine components, which are critical for the demanding operational environments of modern aircraft and power generation systems.

Additive Manufacturing Market Demand Analysis

The demand for additive manufacturing (AM) in turbine engine components is driven by several key factors:

**Market Growth**: The aerospace and energy sectors are experiencing significant growth, increasing the demand for efficient and high-performance turbine engines. AM offers the ability to produce complex geometries and lightweight components, which are crucial for improving engine efficiency and reducing fuel consumption.

**Customization and Flexibility**: AM allows for the customization of turbine components, enabling manufacturers to tailor designs to specific performance requirements. This flexibility is particularly valuable in the aerospace industry, where bespoke solutions can lead to significant performance gains.

**Cost Efficiency**: Traditional manufacturing methods for turbine components are often expensive and time-consuming due to the complexity and precision required. AM can reduce production costs by minimizing material waste and shortening the production cycle, making it an attractive option for manufacturers.

**Supply Chain Optimization**: AM can streamline the supply chain by enabling on-demand production and reducing the need for extensive inventories. This capability is especially beneficial in the aerospace industry, where supply chain disruptions can have significant impacts.

**Technological Advancements**: Continuous advancements in AM technologies, such as improved materials and more precise printing techniques, are expanding the range of applications for turbine engine components. These innovations are enhancing the performance and reliability of AM-produced parts.

**Regulatory and Environmental Pressures**: Stricter environmental regulations and the push for greener technologies are driving the adoption of AM. The ability to produce lighter and more efficient components aligns with the industry's goals of reducing emissions and improving fuel efficiency. Overall, the market demand for AM in turbine engine components is poised for growth, driven by the need for advanced, cost-effective, and customizable manufacturing solutions.

**Market Growth**: The aerospace and energy sectors are experiencing significant growth, increasing the demand for efficient and high-performance turbine engines. AM offers the ability to produce complex geometries and lightweight components, which are crucial for improving engine efficiency and reducing fuel consumption.

**Customization and Flexibility**: AM allows for the customization of turbine components, enabling manufacturers to tailor designs to specific performance requirements. This flexibility is particularly valuable in the aerospace industry, where bespoke solutions can lead to significant performance gains.

**Cost Efficiency**: Traditional manufacturing methods for turbine components are often expensive and time-consuming due to the complexity and precision required. AM can reduce production costs by minimizing material waste and shortening the production cycle, making it an attractive option for manufacturers.

**Supply Chain Optimization**: AM can streamline the supply chain by enabling on-demand production and reducing the need for extensive inventories. This capability is especially beneficial in the aerospace industry, where supply chain disruptions can have significant impacts.

**Technological Advancements**: Continuous advancements in AM technologies, such as improved materials and more precise printing techniques, are expanding the range of applications for turbine engine components. These innovations are enhancing the performance and reliability of AM-produced parts.

**Regulatory and Environmental Pressures**: Stricter environmental regulations and the push for greener technologies are driving the adoption of AM. The ability to produce lighter and more efficient components aligns with the industry's goals of reducing emissions and improving fuel efficiency. Overall, the market demand for AM in turbine engine components is poised for growth, driven by the need for advanced, cost-effective, and customizable manufacturing solutions.

Additive Manufacturing Technology Status And Challenges

### Additive Manufacturing Technology Status And Challenges

**Current Status:**

- **Technological Maturity:** Additive manufacturing (AM) for turbine engine components has reached a significant level of maturity, with several successful implementations in both prototyping and production.

- **Material Development:** Advances in high-temperature alloys and ceramic materials have enhanced the performance and reliability of AM components in turbine engines.

- **Process Optimization:** Techniques such as selective laser melting (SLM) and electron beam melting (EBM) have been optimized for producing complex geometries with high precision.

**Challenges:**

- **Quality Control:** Ensuring consistent quality and performance of AM components remains a challenge due to variations in material properties and process parameters.

- **Cost Efficiency:** High production costs and the need for post-processing steps limit the widespread adoption of AM in turbine engine manufacturing.

- **Regulatory Compliance:** Meeting stringent aerospace industry standards and certifications for AM components is a complex and time-consuming process.

- **Scalability:** Scaling up production while maintaining quality and cost-effectiveness is a significant hurdle for the industry.

Additive Manufacturing Current Technical Solutions

01 Use of Additive Manufacturing for Turbine Blades

Additive manufacturing techniques produce turbine blades with complex geometries and optimized cooling channels, creating lightweight, high-strength components that withstand high temperatures and stresses.- Use of additive manufacturing for turbine blades: Additive manufacturing techniques produce turbine blades with complex geometries and internal cooling channels, creating lightweight, high-strength components that withstand high temperatures and stresses.

- Material selection for additive manufacturing: Selecting suitable materials like nickel-based superalloys and titanium alloys is crucial for additive manufacturing due to their excellent mechanical properties and high-temperature resistance.

- Post-processing techniques for additive manufactured components: Post-processing techniques like heat treatment and surface finishing enhance mechanical properties and surface quality, relieving residual stresses and improving fatigue life.

- Design optimization for additive manufacturing: Design optimization techniques, including topology optimization and lattice structures, reduce weight while maintaining strength and performance of turbine engine components.

- Quality control and inspection methods: Quality control and inspection methods, such as non-destructive testing (NDT) and in-situ monitoring, ensure the reliability and performance of additive manufactured components by detecting defects and ensuring consistency.

02 Material Selection for Additive Manufacturing

Selecting appropriate materials like superalloys and ceramics is crucial for additive manufacturing due to their high-temperature resistance and mechanical properties, ensuring durability and performance.Expand Specific Solutions03 Optimization of Manufacturing Processes

Optimizing additive manufacturing processes, such as laser sintering and electron beam melting, improves quality and performance by controlling parameters like temperature, speed, and layer thickness.Expand Specific Solutions04 Post-Processing Techniques

Post-processing techniques like heat treatment and surface finishing enhance properties, relieve residual stresses, improve surface quality, and ensure components meet specifications.Expand Specific Solutions05 Integration of Sensors and Monitoring Systems

Additive manufacturing allows integration of sensors and monitoring systems into components, enabling real-time performance monitoring and improving maintenance and operational efficiency.Expand Specific Solutions

Additive Manufacturing Main Player Analysis

The competitive landscape for Additive Manufacturing (AM) for Turbine Engine Components includes established aerospace and energy companies and specialized technology firms. The industry is growing, driven by the demand for lightweight, high-performance components. Leading companies like United Technologies Corp., Safran Aircraft Engines SAS, RTX Corp., Siemens Energy Global GmbH & Co. KG, and General Electric Company showcase high technical maturity in AM applications, producing complex geometries and reducing lead times.

United Technologies Corp.

Technical Solution: United Technologies Corp. uses advanced AM techniques for turbine engine components, focusing on high-performance materials and precision manufacturing to enhance engine efficiency and durability.

Strength: High-performance materials and precision. Weakness: High cost of implementation.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy Global GmbH & Co. KG uses AM to produce turbine blades and other critical components, emphasizing rapid prototyping and reduced lead times for faster innovation and customization.

Strength: Rapid prototyping and reduced lead times. Weakness: Limited material options.

Additive Manufacturing Key Technology Interpretation

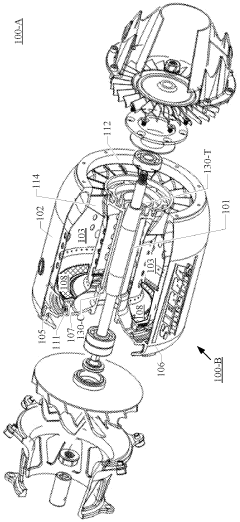

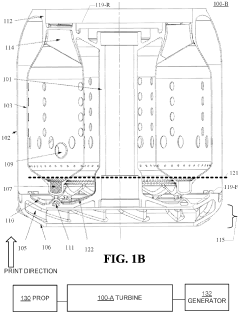

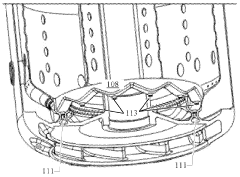

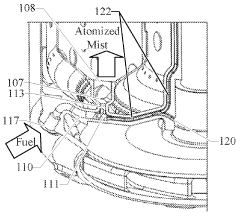

Additively manufactured gas turbine fuel injector ring and UNI-body turbine engine

PatentWO2024010565A1

Innovation

- The use of additive manufacturing (am) technology for the manufacturing of a unibodied micro turbine engine.

- The design of the unibodied micro turbine engine to take advantage of the benefits of geometries that are not possible via casting, or traditional subtractive machining operations.

- The consideration of the machine limitations found on existing laser powder bed am equipment, and the design of the unibodied micro turbine engine to work around these limitations.

Additive Manufacturing For Turbine Engine Components Material Analysis

Additive Manufacturing (AM) for turbine engine components offers significant advantages, including design flexibility, reduced material waste, and shorter production times. The primary materials used in AM for these components are high-performance alloys such as nickel-based superalloys, titanium alloys, and ceramic matrix composites. These materials are chosen for their ability to withstand extreme temperatures and stresses. However, challenges include ensuring material consistency, achieving desired mechanical properties, and addressing issues related to residual stresses and microstructural defects. Ongoing research focuses on optimizing material compositions and AM processes to enhance the performance and reliability of turbine engine components.

Additive Manufacturing For Turbine Engine Components Regulatory Impact

Additive Manufacturing (AM) for turbine engine components significantly impacts regulatory frameworks. AM introduces new challenges in certification, quality assurance, and standardization due to its unique production processes. Regulatory bodies must adapt to ensure safety and reliability, focusing on material properties, process consistency, and inspection methods. The evolving nature of AM technology necessitates continuous updates to regulations, fostering innovation while maintaining stringent safety standards. Collaboration between industry stakeholders and regulatory agencies is crucial to develop comprehensive guidelines that address the complexities of AM, ensuring its successful integration into turbine engine manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!