Reducing Wear In Turbine Engines: Properties And Applications

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

## Directory: 技术背景与目标

The primary goal of this research is to explore methods to reduce wear in turbine engines, a critical issue affecting engine efficiency, longevity, and maintenance costs. Turbine engines, widely used in aviation and power generation, face significant wear due to high temperatures, pressures, and rotational speeds. Historically, advancements in materials science, such as the development of superalloys and thermal barrier coatings, have played a crucial role in mitigating wear. However, as engine performance demands increase, new solutions are required. This research aims to identify innovative materials, coatings, and lubrication techniques that can further enhance wear resistance, thereby improving engine reliability and reducing operational costs. By understanding the evolution of wear reduction technologies and setting clear objectives, this study seeks to contribute to the next generation of turbine engine advancements.

Turbine Engine Market Demand Analysis

### Turbine Engine Market Demand Analysis

**Increasing Demand for Fuel Efficiency**

The aviation industry is increasingly focused on fuel efficiency due to rising fuel costs and environmental regulations. Turbine engines with reduced wear can significantly improve fuel efficiency, making them highly desirable. **Growing Commercial Aviation Sector**

The commercial aviation sector is expanding rapidly, driven by increased global travel and economic growth. This expansion necessitates more reliable and durable turbine engines, boosting demand for wear-reduction technologies. **Military Applications**

Military aircraft require high-performance engines that can withstand extreme conditions. Reducing wear in turbine engines enhances their reliability and longevity, which is critical for defense applications. **Maintenance Cost Reduction**

Airlines and operators are looking to reduce maintenance costs. Turbine engines with lower wear rates require less frequent maintenance, leading to significant cost savings and increased operational efficiency. **Technological Advancements**

Advances in materials science and engineering are enabling the development of more wear-resistant turbine engine components. These innovations are driving market demand as they promise longer engine life and better performance. **Environmental Regulations**

Stricter environmental regulations are pushing the industry towards more sustainable practices. Reducing wear in turbine engines contributes to lower emissions and compliance with environmental standards. **Emerging Markets**

Emerging markets, particularly in Asia and the Middle East, are investing heavily in aviation infrastructure. This investment is creating a substantial demand for advanced turbine engines with enhanced durability and performance.

The aviation industry is increasingly focused on fuel efficiency due to rising fuel costs and environmental regulations. Turbine engines with reduced wear can significantly improve fuel efficiency, making them highly desirable. **Growing Commercial Aviation Sector**

The commercial aviation sector is expanding rapidly, driven by increased global travel and economic growth. This expansion necessitates more reliable and durable turbine engines, boosting demand for wear-reduction technologies. **Military Applications**

Military aircraft require high-performance engines that can withstand extreme conditions. Reducing wear in turbine engines enhances their reliability and longevity, which is critical for defense applications. **Maintenance Cost Reduction**

Airlines and operators are looking to reduce maintenance costs. Turbine engines with lower wear rates require less frequent maintenance, leading to significant cost savings and increased operational efficiency. **Technological Advancements**

Advances in materials science and engineering are enabling the development of more wear-resistant turbine engine components. These innovations are driving market demand as they promise longer engine life and better performance. **Environmental Regulations**

Stricter environmental regulations are pushing the industry towards more sustainable practices. Reducing wear in turbine engines contributes to lower emissions and compliance with environmental standards. **Emerging Markets**

Emerging markets, particularly in Asia and the Middle East, are investing heavily in aviation infrastructure. This investment is creating a substantial demand for advanced turbine engines with enhanced durability and performance.

Turbine Engine Technology Status and Challenges

### Turbine Engine Technology Status and Challenges

**Current State of Technology**:

- Turbine engines are critical for aviation and power generation, with advancements focusing on efficiency and durability.

- Modern engines use advanced materials and coatings to withstand high temperatures and reduce wear.

**Challenges**:

- **Wear and Tear**: High operational temperatures and pressures lead to significant wear, impacting engine lifespan and performance.

- **Material Limitations**: Current materials, though advanced, still face limitations in extreme conditions, necessitating further innovation.

- **Cost and Maintenance**: High costs of advanced materials and frequent maintenance requirements pose economic challenges.

**Geographical Distribution**:

- **Global Leaders**: The US, Europe, and Asia are leading in turbine engine technology, with significant contributions from companies like GE, Rolls-Royce, and Pratt & Whitney.

- **Emerging Markets**: Countries like China and India are rapidly advancing, investing heavily in R&D to enhance their technological capabilities.

Turbine Engine Current Technical Solutions

01 Use of advanced coatings

Advanced coatings reduce wear and extend the lifespan of turbine engine components by providing protection against high temperatures, oxidation, and corrosion.- Use of advanced coatings: Advanced coatings protect turbine engine components from high temperatures, oxidation, and corrosion, reducing wear and extending lifespan.

- Incorporation of wear-resistant materials: Wear-resistant materials like ceramics and superalloys improve the performance and longevity of turbine engine components.

- Implementation of lubrication systems: Effective lubrication systems minimize friction and wear, ensuring adequate lubrication and extending the engine's operational life.

- Design optimization for wear reduction: Optimizing component design reduces wear by improving geometry and surface finish, minimizing stress concentrations, and enhancing load distribution.

- Use of advanced manufacturing techniques: Advanced manufacturing techniques like additive manufacturing and precision machining produce turbine components with superior wear resistance.

02 Application of lubricants

Specialized lubricants reduce friction and wear in turbine engines, improving efficiency and reducing maintenance costs.Expand Specific Solutions03 Use of wear-resistant materials

Wear-resistant materials enhance the performance and longevity of turbine engine components by withstanding harsh operating conditions.Expand Specific Solutions04 Implementation of cooling techniques

Advanced cooling techniques manage the temperature of critical components, preventing overheating and reducing thermal wear.Expand Specific Solutions05 Optimization of component design

Optimizing the design of turbine engine components reduces wear by improving aerodynamic efficiency, reducing stress, and enhancing structural integrity.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for reducing wear in turbine engines features industry leaders and specialized firms. Key players like Safran Aircraft Engines SAS, United Technologies Corp., Siemens Energy Global GmbH & Co. KG, and General Electric Company have advanced coatings and lubricants. Companies like The Lubrizol Corp. and Afton Chemical Corp. enhance lubricant formulations. Research institutions like Nanjing University of Aeronautics & Astronautics contribute to fundamental research, while Rolls-Royce Plc and Honeywell International Technologies Ltd. integrate innovations into applications. The market is driven by the need for efficiency and longevity in aerospace and energy sectors.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines SAS develops high-temperature resistant coatings to enhance engine durability and performance.

Strength: High-temperature resistance. Weakness: High cost of implementation.

United Technologies Corp.

Technical Solution: United Technologies Corp. uses ceramic matrix composites for superior wear resistance and higher temperature tolerance.

Strength: Superior wear resistance. Weakness: Complex manufacturing process.

Turbine Engine Key Technology Interpretation

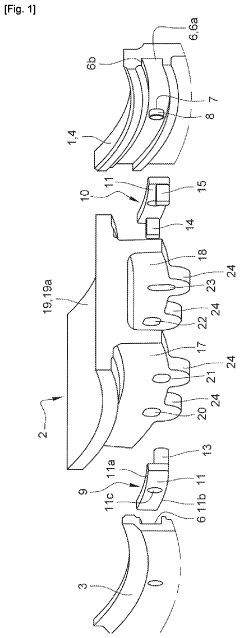

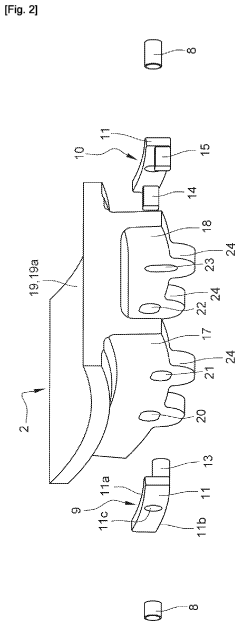

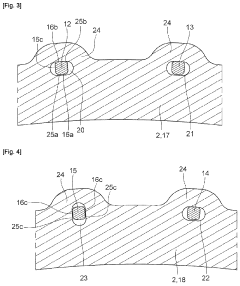

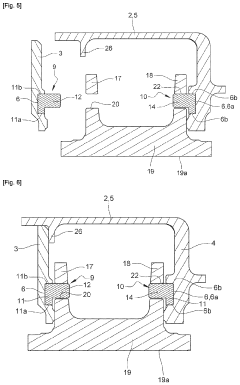

Assembly for a turbomachine turbine

PatentActiveUS20220154591A1

Innovation

- The use of large diameter cylindrical contact surfaces between the housing and the sectors, which maximize contact areas and reduce hertz pressures, resulting in improved durability and efficiency.

- The sectors are designed with circumferential positioning means that allow for radial and circumferential positioning of the sectors with respect to the housing. this feature ensures an isostatic mounting and precise radial positioning of the sectors.

Turbine Engine Wear Reduction Economic Analysis

The economic analysis of reducing wear in turbine engines focuses on the financial benefits and cost implications of implementing advanced wear-reduction technologies. By minimizing wear, maintenance costs and downtime are significantly reduced, leading to increased engine lifespan and operational efficiency. This translates to lower total cost of ownership and higher profitability for operators. Additionally, improved engine performance can result in fuel savings and reduced emissions, aligning with environmental regulations and sustainability goals. The investment in wear-reduction technologies, though initially high, is justified by the long-term economic gains and competitive advantage in the market.

Turbine Engine Wear Reduction Policy and Regulatory Impact

The policy and regulatory impact on reducing wear in turbine engines involves setting stringent standards for materials and manufacturing processes to enhance durability. Regulations may mandate the use of advanced coatings and alloys that resist wear and corrosion. Compliance with these policies ensures longer engine life, reduced maintenance costs, and improved safety. Additionally, regulatory bodies may incentivize research and development in wear-resistant technologies through grants and tax benefits. These measures collectively drive innovation, ensuring that turbine engines operate efficiently and reliably under various conditions, ultimately benefiting both manufacturers and end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!