Advanced Coating Technologies For Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Coating Technologies Background And Goals

## Directory: 技术背景与目标

Advanced coating technologies for turbine engines have evolved significantly over the past few decades, driven by the need for improved performance, durability, and efficiency in high-temperature environments. These coatings are essential for protecting turbine components from oxidation, corrosion, and thermal degradation, thereby extending their operational life and reducing maintenance costs. The primary goal is to develop coatings that can withstand higher temperatures and harsher conditions, enabling turbine engines to operate more efficiently and with greater reliability. Key trends include the development of thermal barrier coatings (TBCs), environmental barrier coatings (EBCs), and advanced metallic coatings, each offering unique benefits and challenges. The focus is on enhancing the thermal stability, adhesion, and overall performance of these coatings to meet the demanding requirements of modern turbine engines.

Advanced Coating Technologies Market Demand Analysis

- Market Demand Overview: The demand for advanced coating technologies in turbine engines is driven by the need for enhanced performance, durability, and efficiency. These coatings protect engine components from extreme temperatures, oxidation, and corrosion, extending their lifespan and reducing maintenance costs.

- Industry Growth Drivers: The aerospace and energy sectors are the primary markets for turbine engines, with increasing investments in these industries fueling the demand for advanced coatings. The push for more fuel-efficient and environmentally friendly engines also contributes to the growing need for innovative coating solutions.

- Market Size and Potential: The global market for advanced coating technologies in turbine engines is projected to grow significantly over the next decade. This growth is supported by the rising production of commercial aircraft, military jets, and power generation turbines.

- Technological Advancements: Continuous advancements in materials science and coating application techniques are expanding the capabilities of these technologies. Innovations such as thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) are critical in meeting the evolving demands of the market.

- Competitive Landscape: The market is highly competitive, with key players including major aerospace and industrial coating companies. These companies are investing heavily in research and development to stay ahead in the market and offer cutting-edge solutions.

- Regulatory and Environmental Factors: Stringent regulations on emissions and environmental impact are influencing the development and adoption of advanced coating technologies. Coatings that enhance fuel efficiency and reduce emissions are particularly in demand.

- Future Trends: The future of advanced coating technologies for turbine engines will likely see further integration of smart coatings, which can provide real-time data on engine conditions. Additionally, the development of more sustainable and eco-friendly coating materials will be a key focus area.

Advanced Coating Technologies Status And Challenges

### Advanced Coating Technologies Status And Challenges

**Current Status**:

- Advanced coating technologies for turbine engines have seen significant progress, focusing on enhancing thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs).

- Innovations include the development of new materials like yttria-stabilized zirconia (YSZ) and advanced deposition techniques such as electron beam physical vapor deposition (EB-PVD) and plasma spraying.

**Challenges**:

- **Thermal Stability**: Maintaining coating integrity at high temperatures remains a critical challenge, as coatings must withstand extreme thermal cycles without degradation.

- **Oxidation and Corrosion Resistance**: Coatings must provide robust protection against oxidation and corrosion caused by harsh operating environments.

- **Adhesion and Durability**: Ensuring strong adhesion between the coating and substrate is essential to prevent delamination and extend the lifespan of turbine components.

- **Manufacturing Complexity**: Advanced coatings often require sophisticated manufacturing processes, which can be costly and difficult to scale.

**Geographical Distribution**:

- Leading research and development activities are concentrated in regions with strong aerospace and power generation industries, such as North America, Europe, and parts of Asia.

Advanced Coating Technologies Current Technical Solutions

01 Use of Nanocoatings for Enhanced Durability

Nanocoatings enhance surface durability and resistance to wear, scratches, and corrosion.- Use of Nanocoatings for Enhanced Durability: Nanocoatings improve surface durability and resistance to wear, scratches, and corrosion.

- Application of Anti-Corrosion Coatings: Anti-corrosion coatings protect metal surfaces from rust and corrosion by forming a moisture barrier.

- Development of Self-Healing Coatings: Self-healing coatings repair minor damages autonomously using microcapsules filled with healing agents.

- Use of Hydrophobic Coatings for Water Resistance: Hydrophobic coatings repel water, making surfaces water-resistant, ideal for electronics and outdoor equipment.

- Incorporation of UV-Resistant Coatings: UV-resistant coatings protect surfaces from UV radiation, preventing degradation like fading and cracking.

02 Application of Anti-corrosion Coatings

Anti-corrosion coatings protect metal surfaces from oxidation and rust by forming a barrier.Expand Specific Solutions03 Development of Self-healing Coatings

Self-healing coatings automatically repair minor damages using microcapsules with healing agents.Expand Specific Solutions04 Use of Hydrophobic Coatings for Water Resistance

Hydrophobic coatings make surfaces water-resistant, protecting electronics and sensitive equipment.Expand Specific Solutions05 Incorporation of UV-resistant Coatings

UV-resistant coatings protect surfaces from UV radiation, preventing material degradation.Expand Specific Solutions

Advanced Coating Technologies Main Player Analysis

The competitive landscape for advanced coating technologies for turbine engines includes industry leaders and research institutions. Companies like United Technologies Corp., Honeywell International Technologies Ltd., Safran Aircraft Engines SAS, and General Electric Company lead with high technical maturity and market presence. Research institutions such as Beihang University and Delft University of Technology drive innovation. Collaboration between industry and academia is key for continuous improvement in turbine engine coatings.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced thermal barrier coatings (TBCs) for turbine engines, enhancing durability and efficiency.

Strength: High temperature resistance. Weakness: High cost of implementation.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell offers advanced coating technologies like ceramic matrix composites (CMCs) and environmental barrier coatings (EBCs) for turbine engines.

Strength: Improved engine performance. Weakness: Complex manufacturing process.

Advanced Coating Technologies Key Technology Interpretation

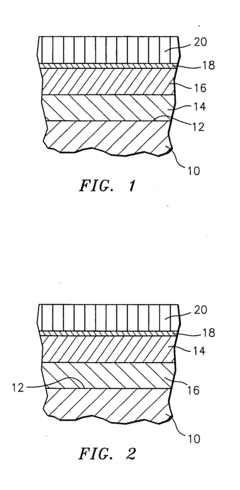

High strength NiPtAIHf Bondcoat

PatentInactiveEP1801257A2

Innovation

- The use of a nickel-platinum-aluminum-hafnium (Ni-Pt-Al-Hf) bondcoat provides superior high temperature resistance and corrosion resistance.

- The method of depositing layers of platinum and nickel-aluminum-hafnium onto the substrate and heat treating them results in a high strength bondcoat.

- The improved coating system enhances the durability and reliability of turbine engine components, leading to reduced maintenance costs and increased engine efficiency.

Advanced Coating Technologies Environmental Impact Analysis

The environmental impact of advanced coating technologies for turbine engines is multifaceted. These coatings, designed to enhance engine efficiency and durability, can reduce fuel consumption and emissions, contributing to lower greenhouse gas outputs. However, the production and application processes of these coatings involve the use of potentially hazardous materials and chemicals, which can pose environmental risks if not managed properly. Additionally, the lifecycle of these coatings, including their disposal, must be considered to ensure minimal environmental footprint. Overall, while advanced coatings offer significant environmental benefits in operation, their full lifecycle impact requires careful management and regulation.

Advanced Coating Technologies Regulatory And Compliance Issues

Regulatory and compliance issues for advanced coating technologies in turbine engines are critical for ensuring safety, performance, and environmental standards. These coatings must meet stringent regulations set by aviation authorities like the FAA and EASA, which mandate rigorous testing for durability, thermal resistance, and environmental impact. Compliance involves adhering to standards for material composition, application processes, and long-term performance under operational conditions. Additionally, manufacturers must navigate international regulations, which can vary significantly, requiring a comprehensive understanding of global compliance requirements to ensure market access and operational approval.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!