Advanced diagnostic tools for submersible pumps.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Diagnostics: Evolution and Objectives

Submersible pumps have been a cornerstone of various industries for decades, with their ability to operate efficiently in submerged environments. The evolution of diagnostic tools for these pumps has been driven by the increasing demand for reliability, efficiency, and reduced downtime in critical applications such as oil and gas extraction, wastewater management, and deep-sea exploration.

The journey of submersible pump diagnostics began with simple mechanical gauges and visual inspections. As technology advanced, more sophisticated methods emerged, including pressure and flow sensors, vibration analysis, and electrical parameter monitoring. These advancements allowed for basic fault detection and performance assessment, but often required pump shutdown or retrieval for thorough examination.

The advent of digital technologies in the late 20th century marked a significant turning point in submersible pump diagnostics. The integration of microprocessors and data logging capabilities enabled continuous monitoring and real-time data collection. This shift from reactive to proactive maintenance strategies helped operators anticipate potential failures and optimize pump performance.

In recent years, the focus has shifted towards developing advanced diagnostic tools that can provide comprehensive health assessments of submersible pumps without the need for physical access. These tools aim to leverage cutting-edge technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) connectivity to offer predictive maintenance capabilities and enhance overall system reliability.

The primary objectives of modern submersible pump diagnostic tools are multifaceted. Firstly, they seek to provide accurate, real-time insights into pump performance, including efficiency, power consumption, and wear patterns. Secondly, these tools aim to detect and diagnose faults at their earliest stages, allowing for timely interventions that can prevent catastrophic failures and extend pump lifespan.

Another crucial goal is to enable remote monitoring and diagnostics, reducing the need for costly and potentially dangerous manual inspections, especially in harsh or inaccessible environments. Advanced diagnostic tools also strive to integrate seamlessly with existing industrial control systems, facilitating data-driven decision-making and automated maintenance scheduling.

Looking ahead, the evolution of submersible pump diagnostics is expected to continue, with a focus on developing more intelligent, autonomous systems. Future objectives include the implementation of self-diagnosing and self-healing capabilities, as well as the integration of augmented reality for enhanced visualization and troubleshooting. As industries increasingly prioritize sustainability and energy efficiency, advanced diagnostic tools will play a pivotal role in optimizing submersible pump operations and minimizing environmental impact.

The journey of submersible pump diagnostics began with simple mechanical gauges and visual inspections. As technology advanced, more sophisticated methods emerged, including pressure and flow sensors, vibration analysis, and electrical parameter monitoring. These advancements allowed for basic fault detection and performance assessment, but often required pump shutdown or retrieval for thorough examination.

The advent of digital technologies in the late 20th century marked a significant turning point in submersible pump diagnostics. The integration of microprocessors and data logging capabilities enabled continuous monitoring and real-time data collection. This shift from reactive to proactive maintenance strategies helped operators anticipate potential failures and optimize pump performance.

In recent years, the focus has shifted towards developing advanced diagnostic tools that can provide comprehensive health assessments of submersible pumps without the need for physical access. These tools aim to leverage cutting-edge technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) connectivity to offer predictive maintenance capabilities and enhance overall system reliability.

The primary objectives of modern submersible pump diagnostic tools are multifaceted. Firstly, they seek to provide accurate, real-time insights into pump performance, including efficiency, power consumption, and wear patterns. Secondly, these tools aim to detect and diagnose faults at their earliest stages, allowing for timely interventions that can prevent catastrophic failures and extend pump lifespan.

Another crucial goal is to enable remote monitoring and diagnostics, reducing the need for costly and potentially dangerous manual inspections, especially in harsh or inaccessible environments. Advanced diagnostic tools also strive to integrate seamlessly with existing industrial control systems, facilitating data-driven decision-making and automated maintenance scheduling.

Looking ahead, the evolution of submersible pump diagnostics is expected to continue, with a focus on developing more intelligent, autonomous systems. Future objectives include the implementation of self-diagnosing and self-healing capabilities, as well as the integration of augmented reality for enhanced visualization and troubleshooting. As industries increasingly prioritize sustainability and energy efficiency, advanced diagnostic tools will play a pivotal role in optimizing submersible pump operations and minimizing environmental impact.

Market Analysis for Smart Pump Monitoring Solutions

The market for smart pump monitoring solutions is experiencing significant growth, driven by the increasing demand for efficient and reliable submersible pump operations across various industries. This market segment is characterized by a strong focus on advanced diagnostic tools that enable predictive maintenance, reduce downtime, and optimize pump performance.

The global smart pump market, which includes monitoring solutions, is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily fueled by the rising adoption of Industrial Internet of Things (IIoT) technologies and the increasing need for real-time monitoring and control of pump systems. The water and wastewater treatment sector is expected to be a major contributor to this market expansion, followed closely by the oil and gas industry.

In terms of regional distribution, North America currently holds the largest market share for smart pump monitoring solutions, owing to its advanced industrial infrastructure and early adoption of IoT technologies. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in water management and energy sectors.

The market demand for advanced diagnostic tools for submersible pumps is being shaped by several key factors. Firstly, there is a growing emphasis on energy efficiency and sustainability across industries, which is driving the need for intelligent pump systems that can optimize energy consumption. Secondly, the increasing complexity of industrial processes requires more sophisticated monitoring and control capabilities to ensure seamless operations.

Furthermore, the rising cost of equipment downtime and maintenance is pushing industries to adopt predictive maintenance strategies, which rely heavily on advanced diagnostic tools. These tools enable operators to detect potential issues before they lead to failures, thereby reducing unplanned downtime and extending the lifespan of pump systems.

Another significant trend influencing the market is the integration of artificial intelligence and machine learning algorithms into pump monitoring solutions. These technologies enable more accurate predictions of pump performance and potential failures, leading to more efficient maintenance schedules and improved overall system reliability.

The market is also seeing a shift towards cloud-based monitoring solutions, which offer greater flexibility, scalability, and accessibility. This trend is particularly beneficial for industries with geographically dispersed pump installations, as it allows for centralized monitoring and control of multiple sites from a single platform.

The global smart pump market, which includes monitoring solutions, is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily fueled by the rising adoption of Industrial Internet of Things (IIoT) technologies and the increasing need for real-time monitoring and control of pump systems. The water and wastewater treatment sector is expected to be a major contributor to this market expansion, followed closely by the oil and gas industry.

In terms of regional distribution, North America currently holds the largest market share for smart pump monitoring solutions, owing to its advanced industrial infrastructure and early adoption of IoT technologies. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in water management and energy sectors.

The market demand for advanced diagnostic tools for submersible pumps is being shaped by several key factors. Firstly, there is a growing emphasis on energy efficiency and sustainability across industries, which is driving the need for intelligent pump systems that can optimize energy consumption. Secondly, the increasing complexity of industrial processes requires more sophisticated monitoring and control capabilities to ensure seamless operations.

Furthermore, the rising cost of equipment downtime and maintenance is pushing industries to adopt predictive maintenance strategies, which rely heavily on advanced diagnostic tools. These tools enable operators to detect potential issues before they lead to failures, thereby reducing unplanned downtime and extending the lifespan of pump systems.

Another significant trend influencing the market is the integration of artificial intelligence and machine learning algorithms into pump monitoring solutions. These technologies enable more accurate predictions of pump performance and potential failures, leading to more efficient maintenance schedules and improved overall system reliability.

The market is also seeing a shift towards cloud-based monitoring solutions, which offer greater flexibility, scalability, and accessibility. This trend is particularly beneficial for industries with geographically dispersed pump installations, as it allows for centralized monitoring and control of multiple sites from a single platform.

Current Challenges in Underwater Pump Diagnostics

Submersible pumps operate in challenging underwater environments, presenting unique diagnostic challenges that require advanced tools and techniques. The current state of underwater pump diagnostics faces several significant hurdles that impede efficient maintenance and operation.

One of the primary challenges is the limited accessibility of submerged pumps. Traditional diagnostic methods often require pump retrieval, which is time-consuming, costly, and disruptive to operations. This constraint necessitates the development of non-invasive diagnostic tools capable of accurately assessing pump performance and health while the equipment remains underwater.

The harsh underwater environment poses another significant challenge. Corrosion, erosion, and the accumulation of debris can rapidly degrade pump components, making it difficult to distinguish between normal wear and critical failures. Advanced diagnostic tools must be capable of detecting subtle changes in pump performance that may indicate the onset of these issues before they lead to catastrophic failures.

Data acquisition in underwater settings presents its own set of challenges. The transmission of sensor data through water can be problematic due to signal attenuation and interference. This limitation often results in reduced data quality or quantity, hampering the effectiveness of diagnostic analyses. Developing robust data transmission methods or alternative sensing technologies is crucial for overcoming this obstacle.

The complexity of pump systems adds another layer of difficulty to diagnostics. Modern submersible pumps often incorporate multiple components and sophisticated control systems. Identifying the root cause of performance issues requires diagnostic tools capable of analyzing complex interactions between various pump elements, as well as their responses to changing operating conditions.

Energy efficiency and environmental concerns also play a role in shaping diagnostic challenges. There is an increasing need for tools that can accurately measure and optimize pump efficiency underwater, helping to reduce energy consumption and minimize environmental impact. However, developing such tools that function reliably in submerged conditions remains a significant technical challenge.

Predictive maintenance strategies, while highly desirable, are particularly challenging to implement for underwater pumps. The lack of continuous, high-quality data from submerged equipment makes it difficult to build accurate predictive models. Overcoming this challenge requires the development of advanced sensors and data analytics capabilities specifically tailored to underwater applications.

Lastly, the integration of diagnostic tools with existing pump control and monitoring systems presents both technical and operational challenges. Ensuring compatibility and seamless data exchange between new diagnostic technologies and legacy systems is crucial for widespread adoption and effective implementation of advanced diagnostic solutions in underwater pump applications.

One of the primary challenges is the limited accessibility of submerged pumps. Traditional diagnostic methods often require pump retrieval, which is time-consuming, costly, and disruptive to operations. This constraint necessitates the development of non-invasive diagnostic tools capable of accurately assessing pump performance and health while the equipment remains underwater.

The harsh underwater environment poses another significant challenge. Corrosion, erosion, and the accumulation of debris can rapidly degrade pump components, making it difficult to distinguish between normal wear and critical failures. Advanced diagnostic tools must be capable of detecting subtle changes in pump performance that may indicate the onset of these issues before they lead to catastrophic failures.

Data acquisition in underwater settings presents its own set of challenges. The transmission of sensor data through water can be problematic due to signal attenuation and interference. This limitation often results in reduced data quality or quantity, hampering the effectiveness of diagnostic analyses. Developing robust data transmission methods or alternative sensing technologies is crucial for overcoming this obstacle.

The complexity of pump systems adds another layer of difficulty to diagnostics. Modern submersible pumps often incorporate multiple components and sophisticated control systems. Identifying the root cause of performance issues requires diagnostic tools capable of analyzing complex interactions between various pump elements, as well as their responses to changing operating conditions.

Energy efficiency and environmental concerns also play a role in shaping diagnostic challenges. There is an increasing need for tools that can accurately measure and optimize pump efficiency underwater, helping to reduce energy consumption and minimize environmental impact. However, developing such tools that function reliably in submerged conditions remains a significant technical challenge.

Predictive maintenance strategies, while highly desirable, are particularly challenging to implement for underwater pumps. The lack of continuous, high-quality data from submerged equipment makes it difficult to build accurate predictive models. Overcoming this challenge requires the development of advanced sensors and data analytics capabilities specifically tailored to underwater applications.

Lastly, the integration of diagnostic tools with existing pump control and monitoring systems presents both technical and operational challenges. Ensuring compatibility and seamless data exchange between new diagnostic technologies and legacy systems is crucial for widespread adoption and effective implementation of advanced diagnostic solutions in underwater pump applications.

Existing Diagnostic Solutions for Submersible Pumps

01 Advanced diagnostic systems for vehicles

Modern vehicles are equipped with sophisticated diagnostic tools that can identify and analyze various issues. These systems use sensors and advanced algorithms to detect problems in real-time, providing detailed information about the vehicle's performance and potential malfunctions. This technology enables more accurate and efficient troubleshooting, reducing maintenance time and costs.- Advanced diagnostic systems for vehicles: Modern vehicles incorporate sophisticated diagnostic tools that can detect and analyze various system issues. These tools often use onboard computers and sensors to monitor vehicle performance, identify faults, and provide detailed diagnostic information to technicians or drivers. This capability enhances maintenance efficiency and helps prevent potential breakdowns.

- Machine learning and AI in diagnostics: Artificial intelligence and machine learning algorithms are increasingly being integrated into diagnostic tools. These technologies can analyze large datasets, recognize patterns, and make predictions about potential issues or failures. This advanced capability allows for more accurate and proactive diagnostics across various fields, including healthcare and industrial applications.

- Remote diagnostics and telemedicine: Remote diagnostic capabilities have significantly improved, allowing for real-time monitoring and analysis of systems or patients from a distance. This technology is particularly valuable in telemedicine, where healthcare professionals can assess patients remotely, and in industrial settings, where experts can diagnose equipment issues without being physically present.

- Enhanced imaging and scanning technologies: Advanced imaging and scanning technologies have revolutionized diagnostic capabilities in various fields. These tools provide high-resolution, detailed images or scans that can reveal subtle abnormalities or issues not visible to the naked eye. This improvement in visual diagnostics has led to more accurate and early detection of problems in medical, industrial, and scientific applications.

- Integrated diagnostic and repair systems: Modern diagnostic tools often integrate with repair systems, providing not only problem identification but also suggested solutions or repair procedures. This integration streamlines the diagnostic and repair process, reducing downtime and improving efficiency in various industries, from automotive to electronics manufacturing.

02 Remote diagnostic capabilities

Remote diagnostic tools allow technicians to assess and diagnose vehicle issues from a distance. These systems can transmit data over wireless networks, enabling real-time monitoring and analysis of vehicle performance. This capability is particularly useful for fleet management and can help prevent breakdowns by identifying potential issues before they become serious problems.Expand Specific Solutions03 Artificial intelligence in diagnostics

AI-powered diagnostic tools are revolutionizing the automotive industry. These systems can learn from vast amounts of data, recognizing patterns and predicting potential issues before they occur. AI algorithms can analyze complex sensor data, making more accurate diagnoses and suggesting appropriate solutions, thus improving the overall efficiency of vehicle maintenance.Expand Specific Solutions04 Enhanced user interfaces for diagnostic tools

Modern diagnostic tools feature improved user interfaces that make it easier for technicians to interpret and act on diagnostic information. These interfaces often include touchscreens, intuitive software, and visual representations of vehicle systems. By simplifying the presentation of complex data, these tools enable faster and more accurate diagnoses, even for less experienced technicians.Expand Specific Solutions05 Integration of diagnostic tools with maintenance systems

Diagnostic tools are increasingly being integrated with broader maintenance management systems. This integration allows for seamless communication between diagnostic processes and maintenance scheduling, parts ordering, and repair procedures. By connecting these systems, vehicle maintenance becomes more streamlined, reducing downtime and improving overall operational efficiency.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The advanced diagnostic tools for submersible pumps market is in a growth phase, driven by increasing demand for efficient pump maintenance in various industries. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, the field is advancing rapidly, with key players like Kubota Corp., WILO SE, and Grundfos Holding A/S leading innovation. These companies are developing sophisticated diagnostic systems incorporating IoT, AI, and predictive maintenance capabilities. Emerging players such as Hefei Evergrande Jianghai Pump Co. Ltd. and Wuhan Newfiber Optoelectronics Co., Ltd. are also contributing to technological advancements, particularly in sensor technology and data analytics for pump diagnostics.

Hunan Dadi Pump Co., Ltd.

Technical Solution: Hunan Dadi Pump Co., Ltd. has developed a range of diagnostic tools for their submersible pumps, focusing on practical and cost-effective solutions. Their system includes built-in sensors that monitor key parameters such as temperature, vibration, and current draw[1]. The company has implemented a cloud-based data analysis platform that allows for remote monitoring and basic predictive maintenance capabilities[2]. Hunan Dadi's diagnostic tools also feature user-friendly interfaces for on-site technicians, enabling quick troubleshooting and maintenance procedures[3]. While not as advanced as some competitors, their solutions offer a good balance of functionality and affordability, particularly suited for small to medium-sized operations[4].

Strengths: Cost-effective solutions, user-friendly interfaces for technicians, and good basic monitoring capabilities. Weaknesses: Less advanced predictive capabilities compared to industry leaders and limited integration with broader industrial IoT ecosystems.

ShinMaywa Industries, Ltd.

Technical Solution: ShinMaywa Industries has developed advanced diagnostic tools for submersible pumps, focusing on reliability and efficiency in water management applications. Their system incorporates smart sensors that monitor pump performance, energy consumption, and wear patterns[1]. ShinMaywa's diagnostic tools utilize edge computing technology to process data locally, reducing latency and improving response times for critical alerts[2]. The company has also implemented a cloud-based analytics platform that uses machine learning algorithms to predict maintenance needs and optimize pump operations across multiple installations[3]. ShinMaywa's diagnostic system includes advanced visualization tools, allowing operators to easily interpret complex pump data and make informed decisions[4].

Strengths: Strong focus on water management applications, efficient edge computing implementation, and advanced data visualization tools. Weaknesses: May have limited applicability outside of water management sector and potential for higher costs due to specialized features.

Innovative Sensor Technologies for Underwater Applications

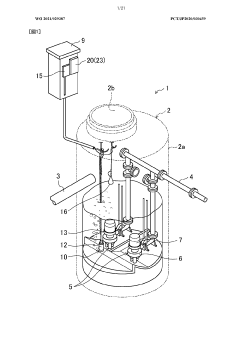

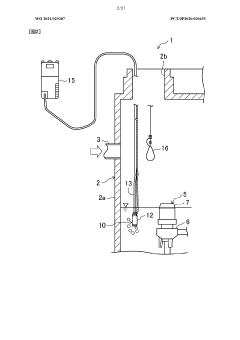

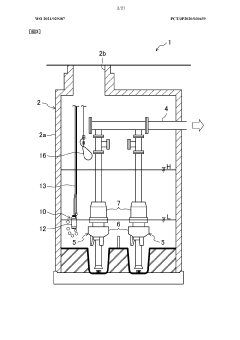

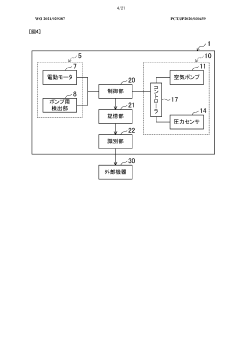

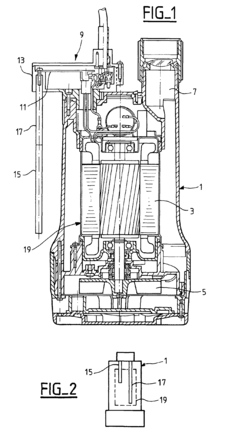

Underwater pump system, information processing device, and computer program

PatentWO2021029387A1

Innovation

- A submersible pump system that includes a current detection unit to analyze temporal changes in the drive current, calculating specific current parameters to determine the presence and type of abnormal operations such as airlock, dry running, or foreign object blockage, and integrates a water level detector to enhance the accuracy of failure identification.

Submersible pump with capacitive level detection

PatentInactiveEP1138951A1

Innovation

- The use of a capacitive level detection system where one armature is the metal casing of the pump motor, combined with electrically isolated rods coated with an insulating layer, enhances sensitivity and resistance to pollutants by leveraging the large surface area and dielectric permittivity differences between fluid and air.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of advanced diagnostic tools for submersible pumps are crucial aspects that require thorough examination. These tools play a significant role in enhancing the efficiency and longevity of submersible pumps, which in turn contributes to reduced energy consumption and resource utilization.

One of the primary environmental benefits of advanced diagnostic tools is their ability to detect potential issues early, preventing catastrophic failures that could lead to environmental contamination. By identifying problems such as leaks or wear before they escalate, these tools help minimize the risk of pump fluids or contaminants being released into surrounding ecosystems, particularly in sensitive underwater environments.

Furthermore, the implementation of advanced diagnostics can lead to optimized pump performance, resulting in reduced energy consumption. This energy efficiency translates to lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change. The extended lifespan of pumps achieved through proactive maintenance also reduces the frequency of replacements, thereby decreasing the environmental impact of manufacturing and disposing of pump equipment.

However, the development and deployment of these diagnostic tools also present environmental challenges. The production of sophisticated sensors and monitoring devices often involves the use of rare earth elements and other materials with complex supply chains and potential environmental impacts during extraction and processing. Manufacturers must consider sustainable sourcing practices and explore alternatives to minimize the ecological footprint of these components.

The disposal of obsolete diagnostic equipment also raises sustainability concerns. As technology rapidly advances, older diagnostic tools may become outdated, potentially contributing to electronic waste. To address this, manufacturers should prioritize modular designs that allow for easy upgrades and implement take-back programs to ensure proper recycling or refurbishment of outdated components.

In the context of submersible pumps used in water management systems, advanced diagnostic tools can contribute to water conservation efforts. By ensuring pumps operate at peak efficiency and detecting issues that could lead to water waste, these tools support sustainable water resource management, which is increasingly critical in the face of global water scarcity challenges.

Looking ahead, the integration of artificial intelligence and machine learning into diagnostic systems holds promise for further enhancing sustainability. These technologies can enable predictive maintenance strategies that optimize resource use and minimize downtime, leading to even greater environmental benefits in the long term.

One of the primary environmental benefits of advanced diagnostic tools is their ability to detect potential issues early, preventing catastrophic failures that could lead to environmental contamination. By identifying problems such as leaks or wear before they escalate, these tools help minimize the risk of pump fluids or contaminants being released into surrounding ecosystems, particularly in sensitive underwater environments.

Furthermore, the implementation of advanced diagnostics can lead to optimized pump performance, resulting in reduced energy consumption. This energy efficiency translates to lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change. The extended lifespan of pumps achieved through proactive maintenance also reduces the frequency of replacements, thereby decreasing the environmental impact of manufacturing and disposing of pump equipment.

However, the development and deployment of these diagnostic tools also present environmental challenges. The production of sophisticated sensors and monitoring devices often involves the use of rare earth elements and other materials with complex supply chains and potential environmental impacts during extraction and processing. Manufacturers must consider sustainable sourcing practices and explore alternatives to minimize the ecological footprint of these components.

The disposal of obsolete diagnostic equipment also raises sustainability concerns. As technology rapidly advances, older diagnostic tools may become outdated, potentially contributing to electronic waste. To address this, manufacturers should prioritize modular designs that allow for easy upgrades and implement take-back programs to ensure proper recycling or refurbishment of outdated components.

In the context of submersible pumps used in water management systems, advanced diagnostic tools can contribute to water conservation efforts. By ensuring pumps operate at peak efficiency and detecting issues that could lead to water waste, these tools support sustainable water resource management, which is increasingly critical in the face of global water scarcity challenges.

Looking ahead, the integration of artificial intelligence and machine learning into diagnostic systems holds promise for further enhancing sustainability. These technologies can enable predictive maintenance strategies that optimize resource use and minimize downtime, leading to even greater environmental benefits in the long term.

Data Analytics and AI in Pump Performance Optimization

Data analytics and artificial intelligence (AI) are revolutionizing the field of pump performance optimization, particularly for submersible pumps. These advanced technologies enable more accurate predictions, real-time monitoring, and proactive maintenance strategies, significantly enhancing the efficiency and reliability of pump operations.

Machine learning algorithms, a subset of AI, are being employed to analyze vast amounts of sensor data collected from submersible pumps. These algorithms can identify patterns and anomalies in pump performance that may be imperceptible to human operators. By processing historical and real-time data, AI systems can predict potential failures, optimize operating parameters, and suggest maintenance schedules.

Predictive maintenance, powered by AI and data analytics, is transforming the way submersible pumps are managed. By analyzing vibration patterns, temperature fluctuations, and other key performance indicators, these systems can detect early signs of wear or malfunction. This allows operators to address issues before they escalate into costly breakdowns, reducing downtime and extending the lifespan of pump equipment.

Digital twin technology is another innovative application of data analytics in pump optimization. By creating a virtual replica of a physical pump system, operators can simulate various operating conditions and scenarios. This enables them to test different strategies and optimize performance without risking actual equipment or production disruptions.

AI-driven control systems are being developed to automatically adjust pump parameters based on real-time data and predictive models. These systems can optimize energy consumption, flow rates, and pressure levels to match changing operational requirements and environmental conditions. This level of automation not only improves efficiency but also reduces the need for constant human intervention.

Edge computing is enhancing the capabilities of data analytics for submersible pumps in remote or challenging environments. By processing data closer to the source, edge devices can provide real-time insights and control even in areas with limited connectivity. This is particularly valuable for offshore or remote installations where traditional monitoring methods may be impractical.

The integration of Internet of Things (IoT) devices with AI and data analytics is creating more comprehensive monitoring networks for submersible pumps. These interconnected systems allow for a holistic view of pump performance across entire operations, facilitating better decision-making and resource allocation.

As these technologies continue to evolve, we can expect even more sophisticated diagnostic tools for submersible pumps. Future developments may include advanced neural networks capable of more complex pattern recognition, augmented reality interfaces for maintenance personnel, and AI systems that can autonomously manage entire pump networks with minimal human oversight.

Machine learning algorithms, a subset of AI, are being employed to analyze vast amounts of sensor data collected from submersible pumps. These algorithms can identify patterns and anomalies in pump performance that may be imperceptible to human operators. By processing historical and real-time data, AI systems can predict potential failures, optimize operating parameters, and suggest maintenance schedules.

Predictive maintenance, powered by AI and data analytics, is transforming the way submersible pumps are managed. By analyzing vibration patterns, temperature fluctuations, and other key performance indicators, these systems can detect early signs of wear or malfunction. This allows operators to address issues before they escalate into costly breakdowns, reducing downtime and extending the lifespan of pump equipment.

Digital twin technology is another innovative application of data analytics in pump optimization. By creating a virtual replica of a physical pump system, operators can simulate various operating conditions and scenarios. This enables them to test different strategies and optimize performance without risking actual equipment or production disruptions.

AI-driven control systems are being developed to automatically adjust pump parameters based on real-time data and predictive models. These systems can optimize energy consumption, flow rates, and pressure levels to match changing operational requirements and environmental conditions. This level of automation not only improves efficiency but also reduces the need for constant human intervention.

Edge computing is enhancing the capabilities of data analytics for submersible pumps in remote or challenging environments. By processing data closer to the source, edge devices can provide real-time insights and control even in areas with limited connectivity. This is particularly valuable for offshore or remote installations where traditional monitoring methods may be impractical.

The integration of Internet of Things (IoT) devices with AI and data analytics is creating more comprehensive monitoring networks for submersible pumps. These interconnected systems allow for a holistic view of pump performance across entire operations, facilitating better decision-making and resource allocation.

As these technologies continue to evolve, we can expect even more sophisticated diagnostic tools for submersible pumps. Future developments may include advanced neural networks capable of more complex pattern recognition, augmented reality interfaces for maintenance personnel, and AI systems that can autonomously manage entire pump networks with minimal human oversight.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!