Advanced flow simulation techniques for submersible pumps.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Flow Simulation Background

Submersible pumps have been a critical component in various industries, including oil and gas, water supply, and wastewater management, for decades. These pumps are designed to operate while fully submerged in the fluid they are pumping, making them ideal for applications where traditional surface-mounted pumps are impractical or inefficient. As the demand for more efficient and reliable submersible pumps has grown, so has the need for advanced flow simulation techniques to optimize their design and performance.

The evolution of flow simulation techniques for submersible pumps has been closely tied to the advancements in computational fluid dynamics (CFD) and computer processing power. In the early stages, engineers relied primarily on empirical data and simplified analytical models to predict pump behavior. However, these methods often fell short in accurately representing the complex flow patterns within the pump, leading to suboptimal designs and performance issues.

With the advent of CFD in the 1970s and its subsequent rapid development, engineers gained powerful tools to simulate and analyze fluid flow within submersible pumps. Early CFD simulations were limited to two-dimensional models and simplified geometries due to computational constraints. As computing power increased, three-dimensional simulations became feasible, allowing for more accurate representations of the pump's internal flow dynamics.

The 1990s and early 2000s saw significant improvements in CFD software and hardware capabilities, enabling more sophisticated simulations that could account for factors such as cavitation, multiphase flow, and turbulence. These advancements allowed engineers to better understand and predict pump performance under various operating conditions, leading to improved designs and increased efficiency.

In recent years, the focus of flow simulation techniques for submersible pumps has shifted towards integrating multiple physical phenomena and optimizing pump designs for specific applications. Advanced techniques now incorporate fluid-structure interaction, thermal analysis, and erosion prediction, providing a more comprehensive understanding of pump behavior in real-world scenarios.

The current state of flow simulation for submersible pumps involves the use of high-fidelity CFD models coupled with experimental validation and machine learning algorithms. These advanced techniques enable engineers to simulate complex flow phenomena, such as vortex formation, pressure pulsations, and transient behavior, with unprecedented accuracy. Additionally, the integration of optimization algorithms with CFD simulations has opened up new possibilities for automated design improvements and rapid prototyping.

As the field continues to evolve, researchers and engineers are exploring novel approaches to further enhance flow simulation techniques for submersible pumps. These include the development of multi-scale modeling methods to capture both large-scale flow structures and small-scale turbulence effects, as well as the incorporation of artificial intelligence and data-driven models to improve simulation accuracy and reduce computational costs.

The evolution of flow simulation techniques for submersible pumps has been closely tied to the advancements in computational fluid dynamics (CFD) and computer processing power. In the early stages, engineers relied primarily on empirical data and simplified analytical models to predict pump behavior. However, these methods often fell short in accurately representing the complex flow patterns within the pump, leading to suboptimal designs and performance issues.

With the advent of CFD in the 1970s and its subsequent rapid development, engineers gained powerful tools to simulate and analyze fluid flow within submersible pumps. Early CFD simulations were limited to two-dimensional models and simplified geometries due to computational constraints. As computing power increased, three-dimensional simulations became feasible, allowing for more accurate representations of the pump's internal flow dynamics.

The 1990s and early 2000s saw significant improvements in CFD software and hardware capabilities, enabling more sophisticated simulations that could account for factors such as cavitation, multiphase flow, and turbulence. These advancements allowed engineers to better understand and predict pump performance under various operating conditions, leading to improved designs and increased efficiency.

In recent years, the focus of flow simulation techniques for submersible pumps has shifted towards integrating multiple physical phenomena and optimizing pump designs for specific applications. Advanced techniques now incorporate fluid-structure interaction, thermal analysis, and erosion prediction, providing a more comprehensive understanding of pump behavior in real-world scenarios.

The current state of flow simulation for submersible pumps involves the use of high-fidelity CFD models coupled with experimental validation and machine learning algorithms. These advanced techniques enable engineers to simulate complex flow phenomena, such as vortex formation, pressure pulsations, and transient behavior, with unprecedented accuracy. Additionally, the integration of optimization algorithms with CFD simulations has opened up new possibilities for automated design improvements and rapid prototyping.

As the field continues to evolve, researchers and engineers are exploring novel approaches to further enhance flow simulation techniques for submersible pumps. These include the development of multi-scale modeling methods to capture both large-scale flow structures and small-scale turbulence effects, as well as the incorporation of artificial intelligence and data-driven models to improve simulation accuracy and reduce computational costs.

Market Demand Analysis

The market demand for advanced flow simulation techniques in submersible pumps has been steadily increasing due to the growing need for efficient and reliable pumping solutions across various industries. The oil and gas sector, in particular, has been a significant driver of this demand, as offshore and subsea operations require highly sophisticated pumping systems capable of operating in extreme conditions.

The global submersible pumps market is projected to experience substantial growth in the coming years, with a compound annual growth rate (CAGR) expected to exceed 6% between 2021 and 2026. This growth is primarily attributed to the rising demand for water and wastewater management solutions, increased urbanization, and the expansion of industrial activities in developing economies.

Advanced flow simulation techniques play a crucial role in optimizing the design and performance of submersible pumps. As industries strive for greater energy efficiency and reduced operational costs, there is a growing emphasis on developing pumps with improved hydraulic efficiency and extended service life. This has led to an increased focus on computational fluid dynamics (CFD) and other advanced simulation tools to analyze and predict pump behavior under various operating conditions.

The water and wastewater treatment industry has emerged as another significant market for advanced submersible pump technologies. With increasing environmental regulations and the need for sustainable water management practices, there is a rising demand for pumps that can handle complex fluid compositions and operate efficiently in challenging environments.

In the mining sector, the demand for submersible pumps with advanced flow simulation capabilities has been driven by the need to manage water in deep underground mines and handle abrasive slurries. The ability to accurately simulate and optimize pump performance in these harsh conditions is crucial for maintaining operational efficiency and minimizing downtime.

The agriculture sector is also contributing to the market demand for advanced submersible pump technologies. As precision agriculture practices become more widespread, there is a growing need for irrigation systems that can deliver water and nutrients more efficiently. Advanced flow simulation techniques are essential in developing pumps that can adapt to varying soil conditions and crop requirements.

Furthermore, the renewable energy sector, particularly geothermal power plants, has shown increasing interest in advanced submersible pump technologies. The ability to simulate and optimize pump performance in high-temperature and corrosive environments is critical for the efficient extraction of geothermal resources.

As industries continue to push the boundaries of pump performance and reliability, the demand for more sophisticated simulation tools and techniques is expected to grow. This includes the integration of artificial intelligence and machine learning algorithms to enhance predictive capabilities and enable real-time optimization of pump operations.

The global submersible pumps market is projected to experience substantial growth in the coming years, with a compound annual growth rate (CAGR) expected to exceed 6% between 2021 and 2026. This growth is primarily attributed to the rising demand for water and wastewater management solutions, increased urbanization, and the expansion of industrial activities in developing economies.

Advanced flow simulation techniques play a crucial role in optimizing the design and performance of submersible pumps. As industries strive for greater energy efficiency and reduced operational costs, there is a growing emphasis on developing pumps with improved hydraulic efficiency and extended service life. This has led to an increased focus on computational fluid dynamics (CFD) and other advanced simulation tools to analyze and predict pump behavior under various operating conditions.

The water and wastewater treatment industry has emerged as another significant market for advanced submersible pump technologies. With increasing environmental regulations and the need for sustainable water management practices, there is a rising demand for pumps that can handle complex fluid compositions and operate efficiently in challenging environments.

In the mining sector, the demand for submersible pumps with advanced flow simulation capabilities has been driven by the need to manage water in deep underground mines and handle abrasive slurries. The ability to accurately simulate and optimize pump performance in these harsh conditions is crucial for maintaining operational efficiency and minimizing downtime.

The agriculture sector is also contributing to the market demand for advanced submersible pump technologies. As precision agriculture practices become more widespread, there is a growing need for irrigation systems that can deliver water and nutrients more efficiently. Advanced flow simulation techniques are essential in developing pumps that can adapt to varying soil conditions and crop requirements.

Furthermore, the renewable energy sector, particularly geothermal power plants, has shown increasing interest in advanced submersible pump technologies. The ability to simulate and optimize pump performance in high-temperature and corrosive environments is critical for the efficient extraction of geothermal resources.

As industries continue to push the boundaries of pump performance and reliability, the demand for more sophisticated simulation tools and techniques is expected to grow. This includes the integration of artificial intelligence and machine learning algorithms to enhance predictive capabilities and enable real-time optimization of pump operations.

Current Challenges

The current challenges in advanced flow simulation techniques for submersible pumps are multifaceted and complex, requiring innovative solutions to overcome existing limitations. One of the primary obstacles is the accurate modeling of multiphase flows, particularly in scenarios involving gas-liquid mixtures or solid particles. The intricate interactions between different phases pose significant difficulties in predicting pump performance and efficiency under varying operating conditions.

Another critical challenge lies in the computational demands of high-fidelity simulations. As the complexity of pump geometries and flow conditions increases, so does the required computational power. This often leads to a trade-off between simulation accuracy and practical feasibility, especially for real-time applications or design optimization processes.

The representation of turbulence in submersible pump simulations remains a persistent challenge. Traditional turbulence models often struggle to capture the complex flow structures and energy dissipation mechanisms accurately, particularly in regions with strong curvature or rotation. This limitation can lead to discrepancies between simulated results and experimental data, affecting the reliability of performance predictions.

Cavitation modeling presents another significant hurdle in advanced flow simulations for submersible pumps. The rapid formation and collapse of vapor bubbles can cause severe damage to pump components and significantly impact performance. However, accurately predicting cavitation inception and its effects on flow characteristics requires sophisticated models that are computationally intensive and often lack universal applicability across different pump designs.

The integration of fluid-structure interaction (FSI) effects into flow simulations is an emerging challenge. As pump designs become more optimized and operate under increasingly demanding conditions, the coupling between fluid dynamics and structural deformations becomes more pronounced. Incorporating these interactions into simulation models adds another layer of complexity and computational burden.

Scale-resolving simulations, such as Large Eddy Simulation (LES) or Direct Numerical Simulation (DNS), offer promising avenues for improving prediction accuracy. However, their application to practical submersible pump designs is limited by the enormous computational resources required, especially for high Reynolds number flows typical in industrial applications.

Lastly, the validation of advanced simulation techniques against experimental data remains a significant challenge. The complex nature of flow within submersible pumps makes it difficult to obtain comprehensive experimental measurements, particularly in regions with limited optical access. This gap between simulation and experimental validation hinders the widespread adoption of advanced simulation techniques in industrial settings.

Another critical challenge lies in the computational demands of high-fidelity simulations. As the complexity of pump geometries and flow conditions increases, so does the required computational power. This often leads to a trade-off between simulation accuracy and practical feasibility, especially for real-time applications or design optimization processes.

The representation of turbulence in submersible pump simulations remains a persistent challenge. Traditional turbulence models often struggle to capture the complex flow structures and energy dissipation mechanisms accurately, particularly in regions with strong curvature or rotation. This limitation can lead to discrepancies between simulated results and experimental data, affecting the reliability of performance predictions.

Cavitation modeling presents another significant hurdle in advanced flow simulations for submersible pumps. The rapid formation and collapse of vapor bubbles can cause severe damage to pump components and significantly impact performance. However, accurately predicting cavitation inception and its effects on flow characteristics requires sophisticated models that are computationally intensive and often lack universal applicability across different pump designs.

The integration of fluid-structure interaction (FSI) effects into flow simulations is an emerging challenge. As pump designs become more optimized and operate under increasingly demanding conditions, the coupling between fluid dynamics and structural deformations becomes more pronounced. Incorporating these interactions into simulation models adds another layer of complexity and computational burden.

Scale-resolving simulations, such as Large Eddy Simulation (LES) or Direct Numerical Simulation (DNS), offer promising avenues for improving prediction accuracy. However, their application to practical submersible pump designs is limited by the enormous computational resources required, especially for high Reynolds number flows typical in industrial applications.

Lastly, the validation of advanced simulation techniques against experimental data remains a significant challenge. The complex nature of flow within submersible pumps makes it difficult to obtain comprehensive experimental measurements, particularly in regions with limited optical access. This gap between simulation and experimental validation hinders the widespread adoption of advanced simulation techniques in industrial settings.

Existing Simulation Solutions

01 Computational Fluid Dynamics (CFD) for Flow Simulation

CFD techniques are widely used for simulating fluid flow in various applications. These methods involve solving complex mathematical equations to model fluid behavior, including factors like velocity, pressure, and temperature. CFD allows for detailed analysis and visualization of flow patterns, making it valuable in engineering design and optimization processes.- Computational fluid dynamics (CFD) for flow simulation: CFD techniques are used to simulate and analyze fluid flow behavior in various systems. These methods involve solving complex mathematical equations to predict fluid dynamics, heat transfer, and related phenomena. CFD simulations help in understanding flow patterns, optimizing designs, and improving system performance across multiple industries.

- Reservoir flow simulation for oil and gas industry: Specialized flow simulation techniques are employed in the oil and gas industry to model reservoir behavior. These simulations help in predicting fluid movement, pressure changes, and production rates in hydrocarbon reservoirs. The techniques incorporate geological data, fluid properties, and well configurations to optimize extraction strategies and improve resource management.

- Flow simulation in manufacturing processes: Flow simulation techniques are applied in manufacturing to optimize production processes. These simulations model material flow, heat transfer, and fluid dynamics in various industrial applications such as injection molding, casting, and extrusion. By simulating these processes, manufacturers can improve product quality, reduce waste, and enhance overall efficiency.

- Multiphase flow simulation: Multiphase flow simulation techniques are used to model complex systems involving multiple fluid phases or components. These simulations are crucial in industries such as chemical processing, oil and gas, and nuclear engineering. They help in understanding the behavior of different phases, predicting flow regimes, and optimizing process parameters for improved performance and safety.

- Flow simulation for environmental and climate modeling: Flow simulation techniques are applied in environmental and climate modeling to predict weather patterns, ocean currents, and atmospheric phenomena. These simulations incorporate complex physical models and data from various sources to provide insights into climate change, pollution dispersion, and natural disaster prediction. The results aid in policy-making and environmental management strategies.

02 Seismic Data Processing for Flow Simulation

Seismic data processing techniques are employed to simulate fluid flow in geological formations. These methods involve analyzing seismic wave propagation to create models of subsurface structures and fluid dynamics. This approach is particularly useful in oil and gas exploration, reservoir characterization, and production optimization.Expand Specific Solutions03 Machine Learning Approaches in Flow Simulation

Machine learning algorithms are increasingly being applied to enhance flow simulation techniques. These methods can improve the accuracy and efficiency of simulations by learning from historical data and predicting flow behaviors. Machine learning approaches are particularly useful in handling complex, non-linear flow problems and reducing computational costs.Expand Specific Solutions04 Real-time Flow Simulation and Monitoring

Real-time flow simulation techniques involve continuous monitoring and updating of flow models based on live data. These methods allow for immediate analysis and decision-making in dynamic flow environments. Applications include process control in industrial settings, traffic flow management, and environmental monitoring systems.Expand Specific Solutions05 Multiphase Flow Simulation Techniques

Multiphase flow simulation techniques are used to model complex systems involving multiple fluid phases or components. These methods account for interactions between different phases and can simulate phenomena such as bubble formation, droplet dynamics, and phase transitions. They are crucial in applications like oil and gas production, chemical processing, and environmental studies.Expand Specific Solutions

Key Industry Players

The advanced flow simulation techniques for submersible pumps market is in a growth phase, driven by increasing demand for efficient oil and gas extraction. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, the field is rapidly evolving, with companies like Schlumberger, Baker Hughes, and Halliburton leading innovation. These industry giants are investing heavily in R&D to improve simulation accuracy and computational efficiency. Academic institutions such as Jiangsu University and China University of Geosciences are also contributing to advancements, bridging the gap between theoretical research and practical applications. The competitive landscape is characterized by a mix of established players and emerging specialized firms, indicating a maturing but still dynamic market.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced Computational Fluid Dynamics (CFD) techniques for submersible pump simulation. Their approach combines high-fidelity 3D CFD models with machine learning algorithms to optimize pump designs. They utilize a multi-phase flow simulation that accounts for gas, oil, and water interactions within the pump[1]. The company has also implemented a Digital Twin technology that allows real-time monitoring and predictive maintenance of submersible pumps in the field[3]. Schlumberger's simulation techniques incorporate erosion and cavitation models to predict pump wear and extend operational life[5]. Their latest advancements include coupling CFD with Finite Element Analysis (FEA) to simulate both fluid dynamics and structural responses simultaneously[7].

Strengths: Comprehensive multi-physics simulation capabilities, industry-leading Digital Twin technology, and extensive field data for model validation. Weaknesses: High computational requirements for complex simulations and potential over-reliance on proprietary software systems.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed a suite of advanced flow simulation techniques for submersible pumps, focusing on improving efficiency and reliability in challenging environments. Their approach integrates high-fidelity CFD models with artificial intelligence to predict pump performance under various operating conditions[2]. The company utilizes a proprietary vortex modeling technique to simulate complex flow patterns within the pump stages, enabling more accurate prediction of pump efficiency and potential failure points[4]. Baker Hughes has also implemented a novel gas handling simulation that accounts for the effects of gas bubbles on pump performance, crucial for operations in gas-rich reservoirs[6]. Their simulation platform incorporates real-time sensor data to continuously refine and update the flow models, ensuring accuracy over the pump's lifecycle[8].

Strengths: Robust gas handling simulation capabilities, AI-enhanced predictive modeling, and strong integration with real-time operational data. Weaknesses: Potential limitations in simulating extreme multiphase flow conditions and dependency on proprietary hardware for optimal performance.

Core Simulation Technologies

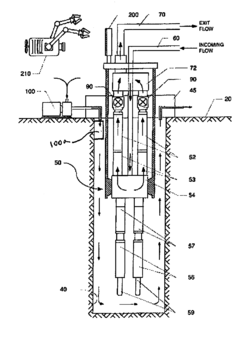

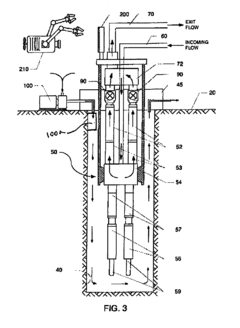

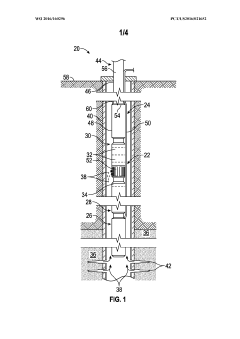

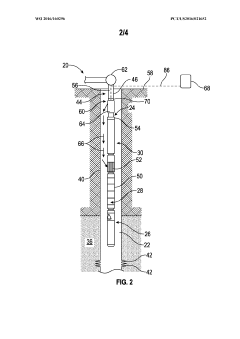

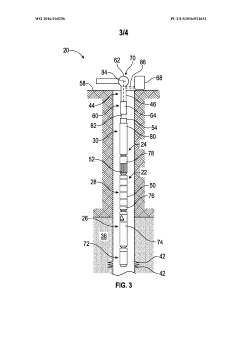

Submersible pumping system and method for boosting subsea production flow

PatentInactiveUS7914266B2

Innovation

- A submersible pumping system deployed in a dummy well with a conduit to isolate production fluid, using seawater for motor cooling and employing underwater vehicles for access and control, including remote operated vehicles (ROVs) or autonomous underwater vehicles (AUVs) for operation and monitoring.

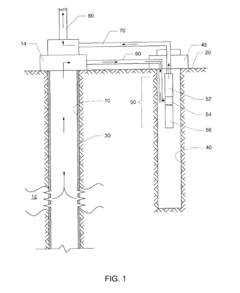

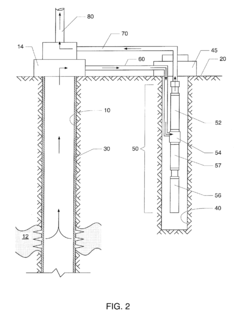

Submersible pumping system with dynamic flow bypass

PatentWO2016160296A1

Innovation

- A dynamic flow bypass system that diverts a portion of the fluid flow away from the primary path using a controllable valve or diverter device, allowing recirculation back to the intake or below the motor for cooling, preventing the system from operating at detrimental low-flow conditions and maintaining desired flow rates.

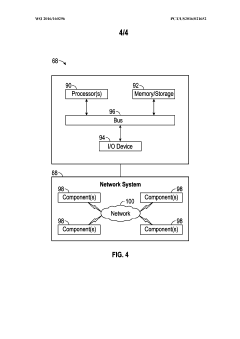

Computational Resources

Advanced flow simulation techniques for submersible pumps require substantial computational resources to achieve accurate and reliable results. The complexity of fluid dynamics in these systems demands high-performance computing capabilities to handle the intricate calculations involved in modeling turbulent flows, multiphase interactions, and complex geometries.

Modern simulation software packages utilize parallel processing to distribute the computational load across multiple cores or nodes. This parallelization significantly reduces simulation time and allows for more detailed and extensive analyses. High-performance computing clusters or cloud-based solutions are often employed to provide the necessary processing power for large-scale simulations.

Memory requirements for advanced flow simulations can be substantial, particularly when dealing with high-resolution meshes and transient analyses. Sufficient RAM is crucial to prevent excessive disk I/O operations that can bottleneck performance. Solid-state drives (SSDs) are increasingly used to accelerate data access and storage operations during simulations.

Graphics Processing Units (GPUs) have become invaluable in accelerating certain aspects of flow simulations. Many CFD software packages now offer GPU-accelerated solvers that can dramatically speed up computations, especially for visualization and post-processing tasks.

Data management and storage solutions are essential components of the computational infrastructure. Large-scale simulations generate vast amounts of data that need to be efficiently stored, accessed, and analyzed. High-speed networking is crucial for transferring data between storage systems and compute nodes, as well as for remote visualization and collaboration.

The choice of software and hardware must be carefully considered to optimize performance and cost-effectiveness. Commercial CFD packages often provide optimized solvers and user-friendly interfaces but can be expensive. Open-source alternatives offer flexibility and cost savings but may require more expertise to implement effectively.

As simulation techniques continue to advance, the demand for computational resources grows. Emerging technologies such as quantum computing and neuromorphic processors may offer new avenues for enhancing simulation capabilities in the future. However, current research and development efforts focus on optimizing existing hardware and software solutions to push the boundaries of what is possible in submersible pump flow simulations.

Modern simulation software packages utilize parallel processing to distribute the computational load across multiple cores or nodes. This parallelization significantly reduces simulation time and allows for more detailed and extensive analyses. High-performance computing clusters or cloud-based solutions are often employed to provide the necessary processing power for large-scale simulations.

Memory requirements for advanced flow simulations can be substantial, particularly when dealing with high-resolution meshes and transient analyses. Sufficient RAM is crucial to prevent excessive disk I/O operations that can bottleneck performance. Solid-state drives (SSDs) are increasingly used to accelerate data access and storage operations during simulations.

Graphics Processing Units (GPUs) have become invaluable in accelerating certain aspects of flow simulations. Many CFD software packages now offer GPU-accelerated solvers that can dramatically speed up computations, especially for visualization and post-processing tasks.

Data management and storage solutions are essential components of the computational infrastructure. Large-scale simulations generate vast amounts of data that need to be efficiently stored, accessed, and analyzed. High-speed networking is crucial for transferring data between storage systems and compute nodes, as well as for remote visualization and collaboration.

The choice of software and hardware must be carefully considered to optimize performance and cost-effectiveness. Commercial CFD packages often provide optimized solvers and user-friendly interfaces but can be expensive. Open-source alternatives offer flexibility and cost savings but may require more expertise to implement effectively.

As simulation techniques continue to advance, the demand for computational resources grows. Emerging technologies such as quantum computing and neuromorphic processors may offer new avenues for enhancing simulation capabilities in the future. However, current research and development efforts focus on optimizing existing hardware and software solutions to push the boundaries of what is possible in submersible pump flow simulations.

Environmental Impact Assessment

The environmental impact assessment of advanced flow simulation techniques for submersible pumps is a critical aspect of their development and implementation. These techniques, while primarily focused on improving pump performance and efficiency, also have significant implications for the surrounding ecosystem and natural resources.

One of the key environmental benefits of advanced flow simulation is the potential for reduced energy consumption. By optimizing fluid dynamics within the pump, these techniques can lead to more efficient operation, resulting in lower power requirements. This, in turn, contributes to reduced greenhouse gas emissions and a smaller carbon footprint for industrial processes utilizing submersible pumps.

Water conservation is another important environmental consideration. Advanced flow simulation can help identify areas of potential water loss or inefficiency within the pump system. By minimizing these losses, the overall water consumption of the pumping process can be reduced, contributing to more sustainable water management practices.

The impact on aquatic ecosystems is a crucial area of assessment. Submersible pumps often operate in sensitive marine or freshwater environments. Advanced flow simulation techniques can help predict and mitigate potential disturbances to local flora and fauna. By optimizing flow patterns, these techniques can minimize turbulence and sediment disturbance, reducing the impact on aquatic habitats and species.

Noise pollution is an often-overlooked environmental concern associated with submersible pumps. Advanced flow simulation can aid in designing pump systems that generate less noise and vibration. This is particularly important in marine environments, where excessive noise can disrupt the communication and behavior of aquatic species.

The use of materials in pump construction and operation is another area where environmental impact can be assessed. Flow simulation techniques can help optimize pump design, potentially reducing the amount of raw materials required. Additionally, by improving pump efficiency and longevity, these techniques can decrease the frequency of pump replacements, thereby reducing waste and resource consumption over time.

Chemical leaching and contamination risks can also be evaluated through advanced flow simulation. By accurately modeling fluid behavior within the pump and its immediate surroundings, potential points of chemical release or interaction with the environment can be identified and mitigated. This is particularly important in applications involving hazardous or sensitive materials.

Lastly, the environmental impact assessment should consider the lifecycle analysis of submersible pumps enhanced with advanced flow simulation techniques. This includes evaluating the environmental costs of research, development, and implementation of these technologies against their long-term environmental benefits. Such a comprehensive approach ensures that the overall environmental impact is thoroughly understood and optimized.

One of the key environmental benefits of advanced flow simulation is the potential for reduced energy consumption. By optimizing fluid dynamics within the pump, these techniques can lead to more efficient operation, resulting in lower power requirements. This, in turn, contributes to reduced greenhouse gas emissions and a smaller carbon footprint for industrial processes utilizing submersible pumps.

Water conservation is another important environmental consideration. Advanced flow simulation can help identify areas of potential water loss or inefficiency within the pump system. By minimizing these losses, the overall water consumption of the pumping process can be reduced, contributing to more sustainable water management practices.

The impact on aquatic ecosystems is a crucial area of assessment. Submersible pumps often operate in sensitive marine or freshwater environments. Advanced flow simulation techniques can help predict and mitigate potential disturbances to local flora and fauna. By optimizing flow patterns, these techniques can minimize turbulence and sediment disturbance, reducing the impact on aquatic habitats and species.

Noise pollution is an often-overlooked environmental concern associated with submersible pumps. Advanced flow simulation can aid in designing pump systems that generate less noise and vibration. This is particularly important in marine environments, where excessive noise can disrupt the communication and behavior of aquatic species.

The use of materials in pump construction and operation is another area where environmental impact can be assessed. Flow simulation techniques can help optimize pump design, potentially reducing the amount of raw materials required. Additionally, by improving pump efficiency and longevity, these techniques can decrease the frequency of pump replacements, thereby reducing waste and resource consumption over time.

Chemical leaching and contamination risks can also be evaluated through advanced flow simulation. By accurately modeling fluid behavior within the pump and its immediate surroundings, potential points of chemical release or interaction with the environment can be identified and mitigated. This is particularly important in applications involving hazardous or sensitive materials.

Lastly, the environmental impact assessment should consider the lifecycle analysis of submersible pumps enhanced with advanced flow simulation techniques. This includes evaluating the environmental costs of research, development, and implementation of these technologies against their long-term environmental benefits. Such a comprehensive approach ensures that the overall environmental impact is thoroughly understood and optimized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!