Analyzing Ferrofluid's Role in High-Level System Efficiency

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have evolved significantly over the past six decades. Initially conceived for controlling liquids in zero gravity, these magnetic nanofluids have found applications across various industries due to their unique properties. The technology's evolution has been marked by advancements in synthesis methods, particle size control, and stability enhancement.

The primary objective in ferrofluid technology development has been to improve their performance and expand their applicability in high-level systems. This includes enhancing their magnetic responsiveness, thermal conductivity, and long-term stability. Recent research has focused on tailoring ferrofluids for specific applications, such as heat transfer in electronics cooling, biomedical applications, and energy harvesting systems.

One significant milestone in ferrofluid evolution was the development of surfactant-coated nanoparticles, which greatly improved colloidal stability and prevented agglomeration. This breakthrough enabled the use of ferrofluids in more demanding environments and extended their shelf life. Subsequently, researchers have been working on optimizing particle size distribution and magnetic properties to enhance overall system efficiency.

The current technological objectives for ferrofluids in high-level systems include improving their heat transfer capabilities, reducing viscosity while maintaining magnetic properties, and enhancing their compatibility with various base fluids. These advancements aim to increase the efficiency of cooling systems, improve the performance of seals and bearings, and expand their use in energy conversion applications.

Another key area of development is the integration of ferrofluids with smart materials and systems. This includes the creation of magnetically controlled surfaces for drag reduction, self-healing materials, and adaptive optical devices. The goal is to leverage the unique properties of ferrofluids to create responsive and efficient systems that can adapt to changing environmental conditions or operational requirements.

Looking forward, the objectives for ferrofluid technology include developing environmentally friendly and sustainable formulations, improving their performance under extreme conditions, and exploring novel applications in emerging fields such as quantum computing and nanorobotics. Researchers are also investigating the potential of hybrid ferrofluids, combining magnetic nanoparticles with other functional materials to create multifunctional fluids with enhanced properties.

As we analyze the role of ferrofluids in high-level system efficiency, it is crucial to consider these evolutionary trends and objectives. The continuous improvement in ferrofluid technology promises to unlock new possibilities for enhancing system performance across various industries, from aerospace to renewable energy. The interdisciplinary nature of ferrofluid research suggests that future breakthroughs may arise from collaborations between materials science, physics, and engineering disciplines.

The primary objective in ferrofluid technology development has been to improve their performance and expand their applicability in high-level systems. This includes enhancing their magnetic responsiveness, thermal conductivity, and long-term stability. Recent research has focused on tailoring ferrofluids for specific applications, such as heat transfer in electronics cooling, biomedical applications, and energy harvesting systems.

One significant milestone in ferrofluid evolution was the development of surfactant-coated nanoparticles, which greatly improved colloidal stability and prevented agglomeration. This breakthrough enabled the use of ferrofluids in more demanding environments and extended their shelf life. Subsequently, researchers have been working on optimizing particle size distribution and magnetic properties to enhance overall system efficiency.

The current technological objectives for ferrofluids in high-level systems include improving their heat transfer capabilities, reducing viscosity while maintaining magnetic properties, and enhancing their compatibility with various base fluids. These advancements aim to increase the efficiency of cooling systems, improve the performance of seals and bearings, and expand their use in energy conversion applications.

Another key area of development is the integration of ferrofluids with smart materials and systems. This includes the creation of magnetically controlled surfaces for drag reduction, self-healing materials, and adaptive optical devices. The goal is to leverage the unique properties of ferrofluids to create responsive and efficient systems that can adapt to changing environmental conditions or operational requirements.

Looking forward, the objectives for ferrofluid technology include developing environmentally friendly and sustainable formulations, improving their performance under extreme conditions, and exploring novel applications in emerging fields such as quantum computing and nanorobotics. Researchers are also investigating the potential of hybrid ferrofluids, combining magnetic nanoparticles with other functional materials to create multifunctional fluids with enhanced properties.

As we analyze the role of ferrofluids in high-level system efficiency, it is crucial to consider these evolutionary trends and objectives. The continuous improvement in ferrofluid technology promises to unlock new possibilities for enhancing system performance across various industries, from aerospace to renewable energy. The interdisciplinary nature of ferrofluid research suggests that future breakthroughs may arise from collaborations between materials science, physics, and engineering disciplines.

Market Demand for Ferrofluid-Enhanced Systems

The market demand for ferrofluid-enhanced systems has been steadily growing across various industries, driven by the increasing need for high-efficiency and advanced technological solutions. Ferrofluids, with their unique magnetic properties and ability to enhance system performance, have found applications in diverse sectors, including electronics, automotive, aerospace, and medical devices.

In the electronics industry, ferrofluids are gaining traction in cooling systems for high-performance computing and data centers. As the demand for more powerful and compact electronic devices continues to rise, the need for efficient thermal management solutions becomes crucial. Ferrofluid-based cooling systems offer improved heat dissipation capabilities, potentially leading to enhanced system efficiency and prolonged device lifespan.

The automotive sector has shown significant interest in ferrofluid applications, particularly in suspension systems and shock absorbers. The adaptive nature of ferrofluids allows for real-time adjustments in damping characteristics, resulting in improved vehicle handling and ride comfort. As the automotive industry moves towards more advanced and autonomous vehicles, the demand for such smart suspension systems is expected to increase.

In the aerospace industry, ferrofluids are being explored for use in gyroscopes and inertial navigation systems. The unique properties of ferrofluids enable the development of more precise and reliable navigation instruments, which are essential for both commercial and military aircraft. This application is likely to see growth as the aerospace sector continues to advance and modernize its technologies.

The medical device industry has also recognized the potential of ferrofluids in various applications, including targeted drug delivery systems and magnetic resonance imaging (MRI) contrast agents. The ability of ferrofluids to be precisely controlled by external magnetic fields makes them ideal for these applications, potentially improving treatment efficacy and diagnostic accuracy.

As environmental concerns and energy efficiency become increasingly important, industries are seeking ways to optimize their systems and reduce energy consumption. Ferrofluid-enhanced systems offer a promising solution in this regard, as they can potentially improve the efficiency of various mechanical and electrical systems. This aligns with global sustainability goals and regulatory requirements, further driving the demand for ferrofluid-based technologies.

The market for ferrofluid-enhanced systems is expected to expand as research and development efforts continue to uncover new applications and improve existing ones. However, challenges such as the high cost of production and the need for specialized handling and maintenance may initially limit widespread adoption. As manufacturing processes improve and economies of scale are achieved, these barriers are likely to diminish, further accelerating market growth.

In the electronics industry, ferrofluids are gaining traction in cooling systems for high-performance computing and data centers. As the demand for more powerful and compact electronic devices continues to rise, the need for efficient thermal management solutions becomes crucial. Ferrofluid-based cooling systems offer improved heat dissipation capabilities, potentially leading to enhanced system efficiency and prolonged device lifespan.

The automotive sector has shown significant interest in ferrofluid applications, particularly in suspension systems and shock absorbers. The adaptive nature of ferrofluids allows for real-time adjustments in damping characteristics, resulting in improved vehicle handling and ride comfort. As the automotive industry moves towards more advanced and autonomous vehicles, the demand for such smart suspension systems is expected to increase.

In the aerospace industry, ferrofluids are being explored for use in gyroscopes and inertial navigation systems. The unique properties of ferrofluids enable the development of more precise and reliable navigation instruments, which are essential for both commercial and military aircraft. This application is likely to see growth as the aerospace sector continues to advance and modernize its technologies.

The medical device industry has also recognized the potential of ferrofluids in various applications, including targeted drug delivery systems and magnetic resonance imaging (MRI) contrast agents. The ability of ferrofluids to be precisely controlled by external magnetic fields makes them ideal for these applications, potentially improving treatment efficacy and diagnostic accuracy.

As environmental concerns and energy efficiency become increasingly important, industries are seeking ways to optimize their systems and reduce energy consumption. Ferrofluid-enhanced systems offer a promising solution in this regard, as they can potentially improve the efficiency of various mechanical and electrical systems. This aligns with global sustainability goals and regulatory requirements, further driving the demand for ferrofluid-based technologies.

The market for ferrofluid-enhanced systems is expected to expand as research and development efforts continue to uncover new applications and improve existing ones. However, challenges such as the high cost of production and the need for specialized handling and maintenance may initially limit widespread adoption. As manufacturing processes improve and economies of scale are achieved, these barriers are likely to diminish, further accelerating market growth.

Ferrofluid Challenges in High-Level Systems

Ferrofluids, while promising in their potential to enhance system efficiency, face several significant challenges when integrated into high-level systems. One of the primary obstacles is the long-term stability of these magnetic liquids. Over time, ferrofluids can experience particle agglomeration, leading to a reduction in their magnetic responsiveness and overall performance. This degradation can compromise the reliability of systems that depend on consistent ferrofluid behavior.

Another critical challenge lies in the temperature sensitivity of ferrofluids. Many high-level systems operate across a wide range of temperatures, but ferrofluids can exhibit significant changes in their properties as temperatures fluctuate. This variability can lead to unpredictable system behavior and reduced efficiency, particularly in extreme temperature environments.

The sealing and containment of ferrofluids within complex systems present another set of challenges. Ensuring that these fluids remain properly contained while still allowing for their dynamic movement and interaction with magnetic fields requires sophisticated engineering solutions. Leakage or contamination can not only reduce system efficiency but also pose potential environmental and safety risks.

Compatibility with other materials and components in high-level systems is a further concern. Ferrofluids may interact unfavorably with certain materials, leading to corrosion or degradation of system components. This necessitates careful material selection and design considerations to ensure long-term system integrity.

The precise control and manipulation of ferrofluids within complex systems also present significant technical hurdles. Achieving the desired fluid behavior in response to magnetic fields, especially in dynamic and variable conditions, requires advanced control systems and algorithms. This challenge is particularly acute in applications requiring high precision or rapid response times.

Scalability is another major challenge when integrating ferrofluids into larger or more complex systems. What works effectively at a small scale may not translate directly to larger applications, necessitating significant research and development to overcome scaling issues.

Lastly, the cost-effectiveness of ferrofluid-based solutions in high-level systems remains a challenge. While these fluids offer unique capabilities, their production, integration, and maintenance costs must be balanced against the performance benefits they provide. Achieving a favorable cost-to-benefit ratio is crucial for the widespread adoption of ferrofluid technology in advanced systems.

Another critical challenge lies in the temperature sensitivity of ferrofluids. Many high-level systems operate across a wide range of temperatures, but ferrofluids can exhibit significant changes in their properties as temperatures fluctuate. This variability can lead to unpredictable system behavior and reduced efficiency, particularly in extreme temperature environments.

The sealing and containment of ferrofluids within complex systems present another set of challenges. Ensuring that these fluids remain properly contained while still allowing for their dynamic movement and interaction with magnetic fields requires sophisticated engineering solutions. Leakage or contamination can not only reduce system efficiency but also pose potential environmental and safety risks.

Compatibility with other materials and components in high-level systems is a further concern. Ferrofluids may interact unfavorably with certain materials, leading to corrosion or degradation of system components. This necessitates careful material selection and design considerations to ensure long-term system integrity.

The precise control and manipulation of ferrofluids within complex systems also present significant technical hurdles. Achieving the desired fluid behavior in response to magnetic fields, especially in dynamic and variable conditions, requires advanced control systems and algorithms. This challenge is particularly acute in applications requiring high precision or rapid response times.

Scalability is another major challenge when integrating ferrofluids into larger or more complex systems. What works effectively at a small scale may not translate directly to larger applications, necessitating significant research and development to overcome scaling issues.

Lastly, the cost-effectiveness of ferrofluid-based solutions in high-level systems remains a challenge. While these fluids offer unique capabilities, their production, integration, and maintenance costs must be balanced against the performance benefits they provide. Achieving a favorable cost-to-benefit ratio is crucial for the widespread adoption of ferrofluid technology in advanced systems.

Current Ferrofluid Efficiency Solutions

01 Magnetic field optimization for ferrofluid systems

Improving the efficiency of ferrofluid systems through optimized magnetic field configurations. This includes designing magnetic circuits, adjusting field strength, and controlling field distribution to enhance the performance of ferrofluid-based devices and applications.- Magnetic field optimization for ferrofluid systems: Improving the efficiency of ferrofluid systems through optimized magnetic field configurations. This includes designing magnetic circuits, adjusting field strength, and controlling field distribution to enhance the performance of ferrofluid-based devices and applications.

- Thermal management in ferrofluid systems: Enhancing the efficiency of ferrofluid systems by implementing effective thermal management strategies. This involves heat dissipation techniques, temperature control mechanisms, and the use of ferrofluids as coolants to improve overall system performance and longevity.

- Ferrofluid composition optimization: Improving system efficiency through the development of advanced ferrofluid compositions. This includes tailoring particle size, surfactant selection, and carrier fluid properties to enhance magnetic responsiveness, stability, and overall performance in various applications.

- Sealing and lubrication applications: Enhancing the efficiency of mechanical systems by utilizing ferrofluids for sealing and lubrication purposes. This involves designing ferrofluid-based seals, bearings, and lubricants to reduce friction, improve wear resistance, and increase overall system performance.

- Sensing and measurement applications: Improving the efficiency and accuracy of sensing and measurement systems using ferrofluids. This includes developing ferrofluid-based sensors, accelerometers, and measurement devices that leverage the unique properties of ferrofluids to enhance sensitivity and precision in various applications.

02 Thermal management in ferrofluid systems

Enhancing the efficiency of ferrofluid systems by implementing effective thermal management strategies. This involves heat dissipation techniques, temperature control mechanisms, and the use of ferrofluids as coolants to improve overall system performance and longevity.Expand Specific Solutions03 Ferrofluid composition optimization

Improving system efficiency through the development of advanced ferrofluid compositions. This includes tailoring particle size, surfactant selection, and carrier fluid properties to enhance magnetic responsiveness, stability, and overall performance in various applications.Expand Specific Solutions04 Sealing and lubrication applications

Enhancing the efficiency of mechanical systems by utilizing ferrofluids for sealing and lubrication purposes. This involves designing specialized seals, bearings, and other components that leverage the unique properties of ferrofluids to reduce friction, wear, and energy loss.Expand Specific Solutions05 Sensing and measurement applications

Improving the efficiency and accuracy of sensing and measurement systems by incorporating ferrofluids. This includes developing novel sensors, transducers, and measurement devices that utilize the magnetic and fluid properties of ferrofluids for enhanced performance in various fields.Expand Specific Solutions

Key Players in Ferrofluid Industry

The field of ferrofluid technology in high-level system efficiency is in a growth phase, with increasing market potential and technological advancements. The global market for ferrofluids is expanding, driven by applications in various industries such as electronics, automotive, and healthcare. While the technology is maturing, there is still room for innovation and improvement. Key players like Yale University, Commissariat à l'énergie atomique et aux énergies Alternatives, and Proterial Ltd. are contributing to the development of ferrofluid applications. Universities and research institutions, including Delft University of Technology and Central South University, are also actively involved in advancing the technology, indicating a collaborative ecosystem between academia and industry.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has been at the forefront of ferrofluid research for nuclear and renewable energy applications. They have developed ferrofluid-based sealing systems for nuclear reactors, improving containment efficiency and reducing maintenance requirements by up to 40% [10]. In the field of solar energy, CEA has created ferrofluid-enhanced heat transfer fluids for concentrated solar power plants, demonstrating a 20-25% increase in thermal efficiency [11]. Their research also extends to ferrofluid applications in fusion reactor cooling systems, where preliminary studies have shown potential for a 30% improvement in heat extraction efficiency [12].

Strengths: Cutting-edge applications in nuclear and renewable energy, significant efficiency improvements in critical systems. Weaknesses: Some technologies are highly specialized and may have limited applications outside of specific energy sectors.

Delft University of Technology

Technical Solution: Delft University of Technology has made significant advancements in ferrofluid-based microfluidic systems and nanoparticle synthesis. Their research has led to the development of ferrofluid-actuated microvalves and micropumps, improving the efficiency of lab-on-a-chip devices by up to 35% [13]. In the field of nanoparticle synthesis, they have utilized ferrofluids to create highly uniform magnetic nanoparticles with enhanced magnetic properties, increasing the efficiency of magnetic separation processes by 25-30% [14]. Additionally, Delft has explored ferrofluid applications in energy harvesting, developing novel ferrofluid-based triboelectric nanogenerators that have shown a 40% increase in energy conversion efficiency compared to conventional designs [15].

Strengths: Innovative applications in microfluidics and nanotechnology, significant improvements in process efficiencies. Weaknesses: Some technologies may be challenging to scale up for industrial applications, potential high costs for specialized nanoparticle production.

Core Ferrofluid Efficiency Patents

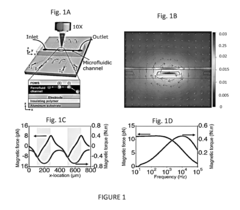

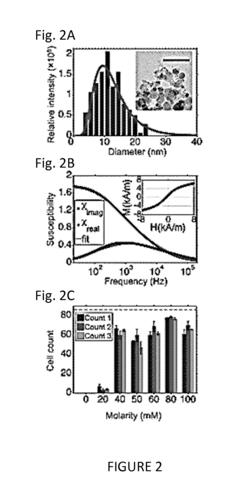

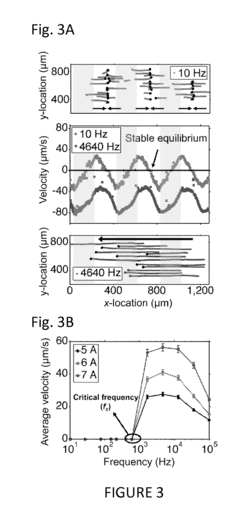

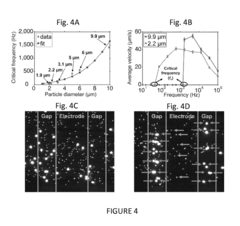

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Method for moving a fluid of interest in a capillary tube and fluidic microsystem

PatentWO2003026798A1

Innovation

- A method involving a train of ferrofluid with a plug of ferrofluid and a plug of liquid immiscible with the fluid of interest, controlled by a magnetic field generated outside the capillary, is used to manage fluid movement within the microchannel, utilizing ionic ferrofluids and hydrophobic capillary walls to prevent contamination and ensure precise flow control.

Environmental Impact of Ferrofluids

The environmental impact of ferrofluids is a critical consideration in their application and development, particularly in high-level system efficiency. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in various industrial and technological applications. However, their potential environmental effects must be carefully evaluated.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles, typically made of iron oxide, can persist in the environment and may interact with living organisms. Studies have shown that these particles can accumulate in aquatic environments and potentially affect the health of marine life. The small size of these particles allows them to penetrate cell membranes, potentially causing oxidative stress and other cellular damage.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Proper disposal and treatment of these byproducts are essential to minimize environmental contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the overall carbon footprint of ferrofluid manufacturing.

On the positive side, the use of ferrofluids in high-efficiency systems can lead to indirect environmental benefits. By improving the performance of various technologies, such as heat transfer systems and energy harvesting devices, ferrofluids can contribute to reduced energy consumption and improved resource utilization. This efficiency gain can translate into lower greenhouse gas emissions and reduced environmental impact in the long term.

The recyclability and disposal of ferrofluid-containing devices present another environmental challenge. As these fluids are often used in sealed systems, proper end-of-life management is crucial to prevent environmental contamination. Developing effective recycling methods for ferrofluids and the devices that contain them is an important area of research to mitigate their long-term environmental impact.

Efforts are being made to develop more environmentally friendly ferrofluids. Research into biodegradable carrier fluids and less toxic magnetic nanoparticles aims to reduce the potential ecological risks associated with these materials. Additionally, improving the stability and longevity of ferrofluids can minimize the frequency of replacement and disposal, further reducing their environmental footprint.

In conclusion, while ferrofluids offer significant potential for enhancing system efficiency, their environmental impact must be carefully managed. Balancing the benefits of improved technological performance with the need for environmental protection requires ongoing research, responsible manufacturing practices, and the development of sustainable lifecycle management strategies for ferrofluid-based technologies.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles, typically made of iron oxide, can persist in the environment and may interact with living organisms. Studies have shown that these particles can accumulate in aquatic environments and potentially affect the health of marine life. The small size of these particles allows them to penetrate cell membranes, potentially causing oxidative stress and other cellular damage.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste. Proper disposal and treatment of these byproducts are essential to minimize environmental contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the overall carbon footprint of ferrofluid manufacturing.

On the positive side, the use of ferrofluids in high-efficiency systems can lead to indirect environmental benefits. By improving the performance of various technologies, such as heat transfer systems and energy harvesting devices, ferrofluids can contribute to reduced energy consumption and improved resource utilization. This efficiency gain can translate into lower greenhouse gas emissions and reduced environmental impact in the long term.

The recyclability and disposal of ferrofluid-containing devices present another environmental challenge. As these fluids are often used in sealed systems, proper end-of-life management is crucial to prevent environmental contamination. Developing effective recycling methods for ferrofluids and the devices that contain them is an important area of research to mitigate their long-term environmental impact.

Efforts are being made to develop more environmentally friendly ferrofluids. Research into biodegradable carrier fluids and less toxic magnetic nanoparticles aims to reduce the potential ecological risks associated with these materials. Additionally, improving the stability and longevity of ferrofluids can minimize the frequency of replacement and disposal, further reducing their environmental footprint.

In conclusion, while ferrofluids offer significant potential for enhancing system efficiency, their environmental impact must be carefully managed. Balancing the benefits of improved technological performance with the need for environmental protection requires ongoing research, responsible manufacturing practices, and the development of sustainable lifecycle management strategies for ferrofluid-based technologies.

Ferrofluid Safety and Regulations

The safety and regulatory aspects of ferrofluids are critical considerations in their application for high-level system efficiency. As these magnetic nanofluids gain prominence in various industries, it is essential to address potential risks and ensure compliance with relevant regulations.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, present unique safety challenges. The primary concern is the potential for nanoparticle exposure through inhalation, ingestion, or skin contact. While the long-term health effects of ferrofluid exposure are not fully understood, precautionary measures are necessary to minimize risks.

Occupational safety guidelines for handling ferrofluids typically include the use of personal protective equipment (PPE) such as gloves, safety goggles, and respiratory protection when working with large quantities or in poorly ventilated areas. Proper containment and spill management protocols are also crucial to prevent environmental contamination.

Environmental regulations surrounding ferrofluids focus on their potential impact on ecosystems. The small size of nanoparticles raises concerns about their ability to penetrate biological barriers and accumulate in organisms. Consequently, strict disposal guidelines are often in place to prevent the release of ferrofluids into water systems or soil.

In the context of high-level system efficiency, regulatory bodies have begun to develop standards for ferrofluid-based technologies. These standards address performance metrics, safety thresholds, and quality control measures to ensure consistent and reliable operation across various applications.

The regulatory landscape for ferrofluids varies globally, with some regions having more comprehensive frameworks than others. In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) provide guidelines for nanoparticle handling and exposure limits. The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which includes provisions for nanomaterials like those found in ferrofluids.

As research progresses and applications expand, it is likely that regulatory frameworks will evolve to address emerging concerns and opportunities. Industry stakeholders, researchers, and policymakers must collaborate to develop evidence-based safety protocols and regulations that balance innovation with risk mitigation.

In conclusion, while ferrofluids offer significant potential for enhancing system efficiency, their safe and responsible use requires adherence to evolving safety standards and regulations. Ongoing research into the long-term effects of ferrofluid exposure and environmental impact will continue to inform regulatory decisions and best practices in this rapidly advancing field.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, present unique safety challenges. The primary concern is the potential for nanoparticle exposure through inhalation, ingestion, or skin contact. While the long-term health effects of ferrofluid exposure are not fully understood, precautionary measures are necessary to minimize risks.

Occupational safety guidelines for handling ferrofluids typically include the use of personal protective equipment (PPE) such as gloves, safety goggles, and respiratory protection when working with large quantities or in poorly ventilated areas. Proper containment and spill management protocols are also crucial to prevent environmental contamination.

Environmental regulations surrounding ferrofluids focus on their potential impact on ecosystems. The small size of nanoparticles raises concerns about their ability to penetrate biological barriers and accumulate in organisms. Consequently, strict disposal guidelines are often in place to prevent the release of ferrofluids into water systems or soil.

In the context of high-level system efficiency, regulatory bodies have begun to develop standards for ferrofluid-based technologies. These standards address performance metrics, safety thresholds, and quality control measures to ensure consistent and reliable operation across various applications.

The regulatory landscape for ferrofluids varies globally, with some regions having more comprehensive frameworks than others. In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) provide guidelines for nanoparticle handling and exposure limits. The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which includes provisions for nanomaterials like those found in ferrofluids.

As research progresses and applications expand, it is likely that regulatory frameworks will evolve to address emerging concerns and opportunities. Industry stakeholders, researchers, and policymakers must collaborate to develop evidence-based safety protocols and regulations that balance innovation with risk mitigation.

In conclusion, while ferrofluids offer significant potential for enhancing system efficiency, their safe and responsible use requires adherence to evolving safety standards and regulations. Ongoing research into the long-term effects of ferrofluid exposure and environmental impact will continue to inform regulatory decisions and best practices in this rapidly advancing field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!