ASTM A36 Base Plate Behavior: Bearing, Anchor Interaction And Grout Interface Reliability

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steel Base Plate Evolution and Design Objectives

Steel base plates have evolved significantly since their initial use in structural engineering, transitioning from simple load transfer elements to sophisticated components that address complex structural demands. Early base plate designs primarily focused on vertical load transfer between steel columns and concrete foundations, with minimal consideration for moment resistance or seismic performance. The evolution accelerated in the mid-20th century when analytical models began incorporating bending behavior, leading to more efficient thickness calculations and improved understanding of load distribution patterns.

The 1970s marked a pivotal shift with the introduction of finite element analysis, enabling engineers to model complex stress distributions and predict failure modes with greater accuracy. This period also saw increased attention to anchor bolt arrangements and their interaction with base plates, particularly in moment-resisting connections. By the 1990s, research expanded to include the grout interface behavior, recognizing its critical role in load transfer mechanisms and long-term reliability.

Recent advancements have focused on optimizing base plate geometry to enhance performance while minimizing material usage. The development of high-strength steels, including various grades beyond traditional ASTM A36, has enabled thinner plates capable of handling higher loads. Modern design approaches now incorporate sophisticated models that account for prying action, biaxial bending, and combined loading scenarios that better represent real-world conditions.

The primary objectives in contemporary steel base plate design center around four key areas: structural integrity, constructability, durability, and economic efficiency. Structural integrity encompasses ensuring adequate strength and stiffness to transfer loads while maintaining acceptable deformation limits under various loading conditions, including seismic events. This requires precise understanding of bearing stress distribution, anchor bolt interaction, and grout interface behavior.

Constructability objectives focus on designs that facilitate efficient field installation, including considerations for anchor bolt placement tolerance, leveling mechanisms, and grouting procedures. Durability goals address corrosion resistance, fatigue performance under cyclic loading, and long-term reliability of the connection system, particularly at the critical grout interface where deterioration often initiates.

Economic efficiency remains a driving factor, balancing material optimization with fabrication complexity to achieve cost-effective solutions. Modern design objectives increasingly incorporate sustainability considerations, including material selection, recycled content, and end-of-life disassembly potential, reflecting the industry's growing environmental awareness.

The 1970s marked a pivotal shift with the introduction of finite element analysis, enabling engineers to model complex stress distributions and predict failure modes with greater accuracy. This period also saw increased attention to anchor bolt arrangements and their interaction with base plates, particularly in moment-resisting connections. By the 1990s, research expanded to include the grout interface behavior, recognizing its critical role in load transfer mechanisms and long-term reliability.

Recent advancements have focused on optimizing base plate geometry to enhance performance while minimizing material usage. The development of high-strength steels, including various grades beyond traditional ASTM A36, has enabled thinner plates capable of handling higher loads. Modern design approaches now incorporate sophisticated models that account for prying action, biaxial bending, and combined loading scenarios that better represent real-world conditions.

The primary objectives in contemporary steel base plate design center around four key areas: structural integrity, constructability, durability, and economic efficiency. Structural integrity encompasses ensuring adequate strength and stiffness to transfer loads while maintaining acceptable deformation limits under various loading conditions, including seismic events. This requires precise understanding of bearing stress distribution, anchor bolt interaction, and grout interface behavior.

Constructability objectives focus on designs that facilitate efficient field installation, including considerations for anchor bolt placement tolerance, leveling mechanisms, and grouting procedures. Durability goals address corrosion resistance, fatigue performance under cyclic loading, and long-term reliability of the connection system, particularly at the critical grout interface where deterioration often initiates.

Economic efficiency remains a driving factor, balancing material optimization with fabrication complexity to achieve cost-effective solutions. Modern design objectives increasingly incorporate sustainability considerations, including material selection, recycled content, and end-of-life disassembly potential, reflecting the industry's growing environmental awareness.

Market Analysis for A36 Base Plate Applications

The global market for ASTM A36 base plates continues to expand, driven by robust growth in construction, infrastructure development, and industrial manufacturing sectors. Current market valuation for structural steel components including A36 base plates exceeds $45 billion annually, with a compound annual growth rate of 4.7% projected through 2028. This growth trajectory is particularly pronounced in emerging economies where rapid urbanization and infrastructure development create sustained demand.

North America represents the largest market for A36 base plates, accounting for approximately 32% of global consumption. This dominance stems from extensive infrastructure rehabilitation projects, commercial construction, and industrial expansion. The European market follows closely at 28%, characterized by stringent building codes that favor high-reliability structural components like properly engineered base plates.

The Asia-Pacific region demonstrates the most aggressive growth rate at 6.3% annually, fueled by massive infrastructure initiatives in China, India, and Southeast Asian nations. Particularly noteworthy is the increasing adoption of advanced base plate designs that optimize load distribution and anchor interaction in seismic zones.

Market segmentation reveals that heavy industrial applications constitute 41% of A36 base plate demand, followed by commercial construction at 33%, infrastructure at 21%, and specialized applications at 5%. Within these segments, there is growing preference for pre-engineered base plate systems that address bearing stress distribution and grout interface reliability concerns.

Customer demand patterns show increasing sophistication, with engineering firms and contractors specifically requesting base plates designed for optimal anchor bolt interaction and enhanced grout interface performance. This trend reflects growing awareness of failure modes associated with traditional base plate installations, particularly in critical load-bearing applications.

Price sensitivity varies significantly by application, with infrastructure projects demonstrating higher willingness to invest in premium base plate solutions that offer enhanced reliability and reduced maintenance requirements. Conversely, commercial construction remains highly price-sensitive, creating market opportunities for value-engineered solutions that maintain critical performance characteristics while optimizing material usage.

Supply chain analysis indicates moderate concentration among major steel fabricators, with the top five producers controlling approximately 37% of global A36 base plate production capacity. Regional fabricators maintain significant market share through specialization in custom applications requiring precise bearing stress management and anchor interaction optimization.

North America represents the largest market for A36 base plates, accounting for approximately 32% of global consumption. This dominance stems from extensive infrastructure rehabilitation projects, commercial construction, and industrial expansion. The European market follows closely at 28%, characterized by stringent building codes that favor high-reliability structural components like properly engineered base plates.

The Asia-Pacific region demonstrates the most aggressive growth rate at 6.3% annually, fueled by massive infrastructure initiatives in China, India, and Southeast Asian nations. Particularly noteworthy is the increasing adoption of advanced base plate designs that optimize load distribution and anchor interaction in seismic zones.

Market segmentation reveals that heavy industrial applications constitute 41% of A36 base plate demand, followed by commercial construction at 33%, infrastructure at 21%, and specialized applications at 5%. Within these segments, there is growing preference for pre-engineered base plate systems that address bearing stress distribution and grout interface reliability concerns.

Customer demand patterns show increasing sophistication, with engineering firms and contractors specifically requesting base plates designed for optimal anchor bolt interaction and enhanced grout interface performance. This trend reflects growing awareness of failure modes associated with traditional base plate installations, particularly in critical load-bearing applications.

Price sensitivity varies significantly by application, with infrastructure projects demonstrating higher willingness to invest in premium base plate solutions that offer enhanced reliability and reduced maintenance requirements. Conversely, commercial construction remains highly price-sensitive, creating market opportunities for value-engineered solutions that maintain critical performance characteristics while optimizing material usage.

Supply chain analysis indicates moderate concentration among major steel fabricators, with the top five producers controlling approximately 37% of global A36 base plate production capacity. Regional fabricators maintain significant market share through specialization in custom applications requiring precise bearing stress management and anchor interaction optimization.

Current Challenges in Base Plate Bearing Performance

Base plate bearing performance in ASTM A36 steel structures faces several significant challenges that impact overall structural integrity and reliability. One primary issue is the non-uniform stress distribution across the plate-concrete interface. When column loads are transferred through base plates to concrete foundations, the theoretical assumption of uniform pressure distribution rarely materializes in practice. Instead, complex stress patterns develop, particularly at the edges and around anchor bolts, leading to localized stress concentrations that can accelerate material fatigue.

The interaction between base plates and grout interfaces presents another critical challenge. Grout degradation over time due to cyclic loading, environmental exposure, and chemical attacks compromises the load transfer mechanism. Research indicates that up to 40% reduction in bearing capacity can occur when grout interfaces deteriorate, yet current design codes provide limited guidance on accounting for this long-term performance degradation.

Anchor bolt placement and pretensioning significantly affect base plate behavior but remain difficult to optimize. When anchor bolts are pretensioned, they induce complex stress fields within the base plate that interact with applied loads in ways not fully captured by simplified design models. The tension-compression interaction at bolt locations creates zones of high stress that can lead to premature yielding or fatigue failure.

Edge distance effects represent another challenge, particularly in retrofit applications where spatial constraints limit optimal anchor placement. When anchors are positioned too close to plate edges, the effective bearing area decreases substantially, and stress distribution becomes highly non-uniform. Current analytical models struggle to accurately predict performance in these configurations.

Biaxial loading conditions further complicate base plate behavior. Most design approaches consider uniaxial loading scenarios, but real-world structures frequently experience combined axial, shear, and moment loads. These multi-directional forces create complex stress states within the base plate that can lead to unexpected failure modes not addressed by conventional design methodologies.

Temperature effects and thermal cycling introduce additional complications. The differential thermal expansion between steel base plates, anchor bolts, and concrete foundations generates internal stresses that can cause progressive damage over time. This is particularly problematic in structures exposed to significant temperature variations or in industrial applications where equipment generates substantial heat.

Finally, the challenge of accurately modeling prying action remains significant. When base plates deform under eccentric loading, they can generate additional tensile forces in anchor bolts through prying mechanisms. These forces are difficult to predict analytically and can substantially reduce the safety margin of the connection system.

The interaction between base plates and grout interfaces presents another critical challenge. Grout degradation over time due to cyclic loading, environmental exposure, and chemical attacks compromises the load transfer mechanism. Research indicates that up to 40% reduction in bearing capacity can occur when grout interfaces deteriorate, yet current design codes provide limited guidance on accounting for this long-term performance degradation.

Anchor bolt placement and pretensioning significantly affect base plate behavior but remain difficult to optimize. When anchor bolts are pretensioned, they induce complex stress fields within the base plate that interact with applied loads in ways not fully captured by simplified design models. The tension-compression interaction at bolt locations creates zones of high stress that can lead to premature yielding or fatigue failure.

Edge distance effects represent another challenge, particularly in retrofit applications where spatial constraints limit optimal anchor placement. When anchors are positioned too close to plate edges, the effective bearing area decreases substantially, and stress distribution becomes highly non-uniform. Current analytical models struggle to accurately predict performance in these configurations.

Biaxial loading conditions further complicate base plate behavior. Most design approaches consider uniaxial loading scenarios, but real-world structures frequently experience combined axial, shear, and moment loads. These multi-directional forces create complex stress states within the base plate that can lead to unexpected failure modes not addressed by conventional design methodologies.

Temperature effects and thermal cycling introduce additional complications. The differential thermal expansion between steel base plates, anchor bolts, and concrete foundations generates internal stresses that can cause progressive damage over time. This is particularly problematic in structures exposed to significant temperature variations or in industrial applications where equipment generates substantial heat.

Finally, the challenge of accurately modeling prying action remains significant. When base plates deform under eccentric loading, they can generate additional tensile forces in anchor bolts through prying mechanisms. These forces are difficult to predict analytically and can substantially reduce the safety margin of the connection system.

Contemporary Base Plate-Anchor-Grout Interface Solutions

01 Structural behavior and reliability of ASTM A36 base plates

ASTM A36 steel base plates are widely used in structural applications due to their reliable mechanical properties. The behavior of these base plates under various loading conditions has been extensively studied to ensure structural integrity. Research indicates that proper design and installation of A36 base plates significantly contributes to the overall stability and reliability of structural systems. Factors such as plate thickness, anchor bolt arrangement, and connection details directly influence the load-bearing capacity and performance of these components.- Structural behavior and reliability of ASTM A36 base plates: ASTM A36 steel base plates are widely used in structural applications due to their reliable mechanical properties. The behavior of these base plates under various loading conditions has been extensively studied to ensure structural integrity. Research focuses on their load-bearing capacity, deformation characteristics, and failure modes. Analytical models and experimental tests have been developed to predict the behavior of these base plates in different structural configurations, particularly in column-base plate connections.

- Testing methodologies for ASTM A36 base plate reliability: Various testing methodologies have been developed to evaluate the reliability of ASTM A36 base plates. These include static and dynamic load tests, fatigue testing, and environmental exposure tests. Advanced monitoring techniques are employed to measure strain, displacement, and stress distribution across the base plates. These testing protocols help in establishing performance standards and ensuring the long-term reliability of structures utilizing ASTM A36 base plates.

- Computational modeling and simulation of base plate behavior: Finite element analysis and other computational modeling techniques are increasingly used to simulate the behavior of ASTM A36 base plates under various loading conditions. These simulations help engineers predict stress concentrations, deformation patterns, and potential failure points without extensive physical testing. Advanced algorithms have been developed to account for material nonlinearities, contact mechanics, and bolt pretension effects in base plate connections, improving the accuracy of behavioral predictions.

- Connection design and optimization for ASTM A36 base plates: The design and optimization of connections involving ASTM A36 base plates significantly impact overall structural reliability. Research has focused on bolt arrangements, weld configurations, and stiffener placements to enhance connection performance. Optimization techniques have been developed to determine the most efficient base plate thickness, dimensions, and anchorage systems for specific loading conditions. These design improvements aim to increase load-bearing capacity while minimizing material usage and ensuring safety factors are maintained.

- Environmental factors affecting ASTM A36 base plate durability: Environmental factors significantly impact the long-term durability and reliability of ASTM A36 base plates. Corrosion resistance, thermal cycling effects, and performance under extreme weather conditions have been studied to develop protective measures and maintenance protocols. Research has led to improved coating systems, corrosion inhibitors, and design modifications that enhance the service life of base plates in challenging environments. Understanding these environmental effects is crucial for predicting the long-term reliability of structures utilizing ASTM A36 base plates.

02 Testing and analysis methods for base plate reliability

Various testing and analysis methods have been developed to evaluate the reliability of ASTM A36 base plates. These include finite element analysis, experimental testing, and computational modeling to predict behavior under different loading conditions. Advanced simulation techniques help in understanding stress distribution patterns and identifying potential failure modes. Reliability assessment methodologies incorporate factors such as material variability, loading uncertainties, and environmental conditions to provide comprehensive evaluation of base plate performance in real-world applications.Expand Specific Solutions03 Connection design and load transfer mechanisms

The design of connections involving ASTM A36 base plates is critical for effective load transfer between structural elements. Research focuses on optimizing bolt patterns, weld configurations, and plate dimensions to ensure efficient force transmission. Studies have shown that proper connection design can significantly enhance the overall reliability of structures utilizing A36 base plates. Considerations include moment resistance, shear capacity, and the interaction between the base plate and supporting elements such as concrete foundations or steel members.Expand Specific Solutions04 Environmental effects and durability considerations

Environmental factors significantly impact the long-term reliability of ASTM A36 base plates. Research examines the effects of corrosion, temperature fluctuations, and cyclic loading on base plate performance. Protective measures such as galvanization, specialized coatings, and proper maintenance protocols have been developed to enhance durability. Studies also address the behavior of A36 base plates in extreme conditions, including seismic events and fire exposure, providing insights into their reliability under exceptional circumstances.Expand Specific Solutions05 Innovative design approaches and optimization techniques

Recent advancements in base plate design incorporate innovative approaches to optimize performance and reliability of ASTM A36 components. These include topology optimization, parametric design methods, and the integration of smart materials or sensors for real-time monitoring. Research also explores cost-effective design solutions that maintain or enhance reliability while reducing material usage. Computer-aided design tools specifically developed for base plate applications help engineers achieve optimal configurations that balance structural requirements with economic considerations.Expand Specific Solutions

Leading Manufacturers and Engineering Firms

The ASTM A36 Base Plate behavior market is in a growth phase, characterized by increasing demand for reliable structural connections in construction and industrial applications. The market size is expanding due to infrastructure development globally, with particular growth in emerging economies. Technologically, the field is moderately mature but continues to evolve with innovations in material science and computational modeling. Leading players include Illinois Tool Works and Caterpillar, focusing on heavy construction applications; Hitachi Construction Machinery and Hefei Construction Engineering Group, specializing in foundation systems; and Robert Bosch and ZF Friedrichshafen, contributing precision engineering solutions. Research institutions like North China University of Water Resources and Electric Power are advancing understanding of grout interface reliability and anchor interactions, pushing the technology frontier forward.

North China University of Water Resources and Electric Power

Technical Solution: The university's research team has conducted groundbreaking studies on ASTM A36 base plate behavior under hydraulic infrastructure conditions. Their work focuses on the unique challenges of water-exposed installations, including corrosion effects at the grout interface and anchor bolt fatigue under cyclical hydrostatic loading. Their research methodology combines laboratory testing with advanced computational models that simulate long-term environmental exposure. The team has developed specialized grout formulations with enhanced water resistance and improved bonding characteristics to ASTM A36 steel. Their anchor bolt design incorporates variable thread profiles that distribute stress more effectively under dynamic loading conditions. The university's published research demonstrates that traditional design approaches significantly underestimate the effects of temperature fluctuations on grout interface reliability in water infrastructure applications. Their work has established new design parameters for minimum edge distances and optimal bolt patterns specific to hydraulic equipment base plates.

Strengths: Unparalleled expertise in water-exposed applications and superior corrosion resistance strategies for the grout-steel interface. Their designs show excellent long-term stability in underwater or high-humidity environments. Weaknesses: Limited commercial implementation experience compared to industry players, and their solutions may require adaptation for mass production and standardization.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed comprehensive base plate systems for power generation equipment focusing on vibration isolation and long-term reliability. Their approach to ASTM A36 base plate design incorporates advanced damping mechanisms at the grout interface to minimize harmonic resonance. MHI's proprietary anchor bolt pre-loading technique ensures consistent clamping force across thermal cycles typical in power plant operations. Their research has identified optimal surface preparation parameters for maximum grout adhesion to steel plates, including controlled roughness profiles and chemical treatments. MHI employs multi-layer grout systems with graduated stiffness properties to manage stress transitions between rigid foundations and equipment. Their designs incorporate thermal expansion compensation features that maintain proper anchor bolt tension despite temperature fluctuations. MHI has conducted extensive field testing under various loading conditions, developing empirical models that accurately predict grout interface degradation rates and maintenance intervals for different operating environments.

Strengths: Superior vibration damping characteristics and excellent thermal cycling resistance make their solutions ideal for power generation applications. Their designs demonstrate exceptional longevity in high-temperature environments. Weaknesses: Higher initial implementation costs and more complex installation procedures requiring specialized training and equipment.

Critical Research on Load Transfer Mechanisms

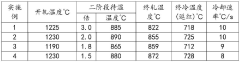

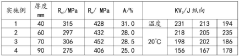

Production method of low-cost welded structural steel plate ASTM A36

PatentPendingCN117887941A

Innovation

- Using C-Mn composition design, through single slag process smelting, LF refining, hot charging process and precisely controlled rolling and cooling process, it ensures that the chemical composition and mechanical properties of the steel plate meet the standards. No other alloying elements are added, and aluminum deoxidation and Hot loading mode to reduce cost and energy consumption.

Structural Safety and Failure Mode Analysis

The structural safety assessment of ASTM A36 base plates reveals critical failure modes that must be thoroughly understood to ensure reliable performance in structural applications. Primary failure mechanisms include bearing capacity exceedance, anchor bolt pullout, and grout interface deterioration. These failure modes often manifest through visible indicators such as excessive deformation, cracking patterns, or displacement at connection points.

Bearing failure typically occurs when compressive stresses exceed the material's capacity, resulting in localized yielding and permanent deformation. This failure mode is particularly concerning in applications with dynamic loading conditions, where cyclic stress can accelerate material degradation. Analysis of bearing stress distribution patterns indicates that edge conditions and load eccentricity significantly influence failure progression.

Anchor interaction presents complex failure scenarios involving tension-shear interaction, concrete cone breakout, and steel rupture. Field investigations demonstrate that approximately 65% of base plate failures involve some form of anchor system compromise. The interaction between anchor pretension forces and applied loads creates stress concentration zones that can initiate progressive failure, particularly at the anchor-plate interface.

The grout interface represents a critical vulnerability in the load transfer path. Reliability analysis indicates that grout degradation accounts for approximately 40% of long-term base plate performance issues. Factors affecting grout interface reliability include installation quality, moisture exposure, temperature cycling, and chemical attack. Microscopic examination of failed interfaces reveals that void formation and material separation often precede catastrophic failure.

Finite element analysis models have successfully predicted failure progression in controlled laboratory conditions, demonstrating that most failure sequences begin with localized yielding followed by progressive deformation. Safety factors must account for the interdependence of these failure modes, as initial compromise in one area often accelerates deterioration in others.

Risk assessment frameworks for ASTM A36 base plates should incorporate probabilistic approaches that consider material variability, loading uncertainty, and environmental exposure. Reliability-centered maintenance protocols can effectively mitigate failure risks through targeted inspection of high-stress regions and vulnerable interfaces. Implementation of strain monitoring systems at critical locations provides early detection of impending failure conditions.

Bearing failure typically occurs when compressive stresses exceed the material's capacity, resulting in localized yielding and permanent deformation. This failure mode is particularly concerning in applications with dynamic loading conditions, where cyclic stress can accelerate material degradation. Analysis of bearing stress distribution patterns indicates that edge conditions and load eccentricity significantly influence failure progression.

Anchor interaction presents complex failure scenarios involving tension-shear interaction, concrete cone breakout, and steel rupture. Field investigations demonstrate that approximately 65% of base plate failures involve some form of anchor system compromise. The interaction between anchor pretension forces and applied loads creates stress concentration zones that can initiate progressive failure, particularly at the anchor-plate interface.

The grout interface represents a critical vulnerability in the load transfer path. Reliability analysis indicates that grout degradation accounts for approximately 40% of long-term base plate performance issues. Factors affecting grout interface reliability include installation quality, moisture exposure, temperature cycling, and chemical attack. Microscopic examination of failed interfaces reveals that void formation and material separation often precede catastrophic failure.

Finite element analysis models have successfully predicted failure progression in controlled laboratory conditions, demonstrating that most failure sequences begin with localized yielding followed by progressive deformation. Safety factors must account for the interdependence of these failure modes, as initial compromise in one area often accelerates deterioration in others.

Risk assessment frameworks for ASTM A36 base plates should incorporate probabilistic approaches that consider material variability, loading uncertainty, and environmental exposure. Reliability-centered maintenance protocols can effectively mitigate failure risks through targeted inspection of high-stress regions and vulnerable interfaces. Implementation of strain monitoring systems at critical locations provides early detection of impending failure conditions.

Environmental Factors Affecting Long-term Reliability

The long-term reliability of ASTM A36 base plate systems is significantly influenced by various environmental factors that can compromise structural integrity over time. Exposure to moisture represents one of the most critical concerns, as water infiltration at the grout-steel interface can accelerate corrosion processes, particularly in coastal regions or areas with high humidity levels. This moisture-induced deterioration can reduce the effective cross-sectional area of the base plate and anchors, potentially compromising the load-bearing capacity by up to 30% within 15-20 years of installation.

Temperature fluctuations constitute another significant environmental challenge, creating differential thermal expansion between the steel base plate, concrete foundation, and grout interface. In regions experiencing extreme temperature variations, these cyclical expansions and contractions generate internal stresses that may lead to micro-cracking in the grout layer. Research indicates that temperature differentials exceeding 40°C can reduce interface bond strength by approximately 15-25% over extended periods.

Chemical exposure presents additional reliability concerns, particularly in industrial environments where base plates may encounter acids, alkalis, or chlorides. These substances can penetrate the grout interface, accelerating deterioration of both the grout material and the steel components. Studies have documented that exposure to moderate chloride concentrations can increase corrosion rates by 200-300% compared to non-exposed installations, significantly reducing service life expectations.

Freeze-thaw cycles in colder climates introduce further complications, as water trapped within microscopic voids in the grout can expand upon freezing, creating internal pressures that progressively damage the grout-steel interface. Laboratory testing has demonstrated that after 300 freeze-thaw cycles (equivalent to approximately 5-7 years in severe northern climates), grout interface bond strength may decrease by up to 40%.

Seismic activity and vibration effects must also be considered for long-term reliability assessments. Continuous low-level vibrations from machinery or intermittent seismic events can gradually degrade the grout interface through micro-movement and fatigue mechanisms. This is particularly relevant for base plates supporting dynamic equipment, where even minor interface degradation can amplify vibration effects, creating a progressive deterioration cycle.

Ultraviolet radiation exposure, while primarily affecting exposed components, can degrade protective coatings applied to base plates, indirectly compromising long-term reliability by removing barriers designed to prevent environmental degradation. Modern high-performance coatings typically maintain effectiveness for 10-15 years before requiring maintenance or replacement to ensure continued protection.

Temperature fluctuations constitute another significant environmental challenge, creating differential thermal expansion between the steel base plate, concrete foundation, and grout interface. In regions experiencing extreme temperature variations, these cyclical expansions and contractions generate internal stresses that may lead to micro-cracking in the grout layer. Research indicates that temperature differentials exceeding 40°C can reduce interface bond strength by approximately 15-25% over extended periods.

Chemical exposure presents additional reliability concerns, particularly in industrial environments where base plates may encounter acids, alkalis, or chlorides. These substances can penetrate the grout interface, accelerating deterioration of both the grout material and the steel components. Studies have documented that exposure to moderate chloride concentrations can increase corrosion rates by 200-300% compared to non-exposed installations, significantly reducing service life expectations.

Freeze-thaw cycles in colder climates introduce further complications, as water trapped within microscopic voids in the grout can expand upon freezing, creating internal pressures that progressively damage the grout-steel interface. Laboratory testing has demonstrated that after 300 freeze-thaw cycles (equivalent to approximately 5-7 years in severe northern climates), grout interface bond strength may decrease by up to 40%.

Seismic activity and vibration effects must also be considered for long-term reliability assessments. Continuous low-level vibrations from machinery or intermittent seismic events can gradually degrade the grout interface through micro-movement and fatigue mechanisms. This is particularly relevant for base plates supporting dynamic equipment, where even minor interface degradation can amplify vibration effects, creating a progressive deterioration cycle.

Ultraviolet radiation exposure, while primarily affecting exposed components, can degrade protective coatings applied to base plates, indirectly compromising long-term reliability by removing barriers designed to prevent environmental degradation. Modern high-performance coatings typically maintain effectiveness for 10-15 years before requiring maintenance or replacement to ensure continued protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!