ASTM A36 Lateral–Torsional Buckling Considerations In Built-Up Members

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ASTM A36 Steel Structural Evolution and Research Objectives

The evolution of structural steel has been marked by significant advancements in material science and engineering applications. ASTM A36 steel, introduced in the mid-20th century, represents a fundamental milestone in structural engineering, providing a standardized material with consistent mechanical properties. This low-carbon steel, with a minimum yield strength of 36,000 psi (250 MPa), has become the backbone of numerous construction projects worldwide due to its excellent weldability, formability, and cost-effectiveness.

The historical progression of structural steel understanding has evolved from empirical approaches to sophisticated analytical methods. Early structural designs relied heavily on conservative safety factors due to limited understanding of buckling phenomena, particularly lateral-torsional buckling in built-up members. The development of computational methods in the late 20th century revolutionized our ability to predict and mitigate these failure modes.

Recent technological advancements have enabled more precise analysis of lateral-torsional buckling behavior in ASTM A36 built-up members. These composite structural elements, formed by connecting multiple steel components, present unique challenges due to their complex cross-sectional properties and connection methods. The interaction between individual components significantly influences the overall buckling resistance, necessitating specialized analytical approaches beyond those used for standard rolled sections.

Current research objectives in this field focus on several key areas. First, developing more accurate predictive models that account for the specific characteristics of built-up members, including connection stiffness, spacing, and load transfer mechanisms. Second, establishing optimized design methodologies that balance structural performance with material efficiency, particularly important as sustainability concerns drive the construction industry toward resource optimization.

Additionally, research aims to address the gap between theoretical models and real-world performance through experimental validation and field monitoring. This includes investigating the effects of fabrication tolerances, residual stresses, and initial imperfections on buckling behavior—factors that significantly impact actual structural performance but are often simplified in analytical models.

The integration of advanced manufacturing techniques presents another research frontier, exploring how precision fabrication methods might improve the performance of built-up members by reducing geometric imperfections and enhancing connection quality. Parallel to this, the development of high-performance connection systems specifically designed for built-up members aims to improve load transfer efficiency and overall structural integrity.

Ultimately, these research objectives converge on enhancing our understanding of lateral-torsional buckling in ASTM A36 built-up members to develop more reliable, efficient, and sustainable structural solutions for increasingly complex architectural and engineering challenges.

The historical progression of structural steel understanding has evolved from empirical approaches to sophisticated analytical methods. Early structural designs relied heavily on conservative safety factors due to limited understanding of buckling phenomena, particularly lateral-torsional buckling in built-up members. The development of computational methods in the late 20th century revolutionized our ability to predict and mitigate these failure modes.

Recent technological advancements have enabled more precise analysis of lateral-torsional buckling behavior in ASTM A36 built-up members. These composite structural elements, formed by connecting multiple steel components, present unique challenges due to their complex cross-sectional properties and connection methods. The interaction between individual components significantly influences the overall buckling resistance, necessitating specialized analytical approaches beyond those used for standard rolled sections.

Current research objectives in this field focus on several key areas. First, developing more accurate predictive models that account for the specific characteristics of built-up members, including connection stiffness, spacing, and load transfer mechanisms. Second, establishing optimized design methodologies that balance structural performance with material efficiency, particularly important as sustainability concerns drive the construction industry toward resource optimization.

Additionally, research aims to address the gap between theoretical models and real-world performance through experimental validation and field monitoring. This includes investigating the effects of fabrication tolerances, residual stresses, and initial imperfections on buckling behavior—factors that significantly impact actual structural performance but are often simplified in analytical models.

The integration of advanced manufacturing techniques presents another research frontier, exploring how precision fabrication methods might improve the performance of built-up members by reducing geometric imperfections and enhancing connection quality. Parallel to this, the development of high-performance connection systems specifically designed for built-up members aims to improve load transfer efficiency and overall structural integrity.

Ultimately, these research objectives converge on enhancing our understanding of lateral-torsional buckling in ASTM A36 built-up members to develop more reliable, efficient, and sustainable structural solutions for increasingly complex architectural and engineering challenges.

Market Demand Analysis for Built-Up Steel Members

The global market for built-up steel members utilizing ASTM A36 steel has shown significant growth in recent years, driven primarily by the expansion of construction and infrastructure development sectors. The demand for these structural components is particularly strong in high-rise buildings, industrial facilities, bridges, and large-span structures where conventional rolled sections may not provide adequate strength or dimensional requirements.

Analysis of market trends indicates that the construction industry's focus on cost-effective solutions with improved structural performance has created a substantial demand for built-up members that can address lateral-torsional buckling concerns. This demand is especially pronounced in regions experiencing rapid urbanization and infrastructure development, including emerging economies in Asia-Pacific and Latin America.

The market for built-up steel members is segmented based on application areas, with commercial construction representing approximately 35% of the market share, followed by industrial structures at 28%, infrastructure projects at 25%, and other applications comprising the remaining 12%. Within these segments, there is growing recognition of the importance of lateral-torsional buckling considerations in design and implementation.

Industry reports highlight that the global steel structures market, which includes built-up members, is experiencing a compound annual growth rate of 5.6%, with particular emphasis on solutions that address structural stability challenges. The market value for engineered steel structures with specialized buckling resistance features has reached significant levels, reflecting the increasing awareness of safety and performance requirements.

A key driver for market growth is the trend toward taller and more complex structures that require customized built-up sections capable of withstanding various loading conditions while maintaining stability against lateral-torsional buckling. Additionally, the renovation and retrofitting of aging infrastructure in developed economies has created a substantial replacement market for these components.

The demand for built-up members is further influenced by evolving building codes and standards that place greater emphasis on structural resilience and safety factors. Engineers and contractors increasingly specify built-up solutions that incorporate advanced lateral-torsional buckling considerations to ensure compliance with these stringent requirements.

Market research indicates that customers are willing to invest in premium built-up steel solutions that offer enhanced buckling resistance, as these components represent a relatively small portion of overall project costs but significantly impact structural integrity and long-term performance. This value proposition has created opportunities for manufacturers who can demonstrate superior technical expertise in addressing lateral-torsional buckling challenges in ASTM A36 built-up members.

Analysis of market trends indicates that the construction industry's focus on cost-effective solutions with improved structural performance has created a substantial demand for built-up members that can address lateral-torsional buckling concerns. This demand is especially pronounced in regions experiencing rapid urbanization and infrastructure development, including emerging economies in Asia-Pacific and Latin America.

The market for built-up steel members is segmented based on application areas, with commercial construction representing approximately 35% of the market share, followed by industrial structures at 28%, infrastructure projects at 25%, and other applications comprising the remaining 12%. Within these segments, there is growing recognition of the importance of lateral-torsional buckling considerations in design and implementation.

Industry reports highlight that the global steel structures market, which includes built-up members, is experiencing a compound annual growth rate of 5.6%, with particular emphasis on solutions that address structural stability challenges. The market value for engineered steel structures with specialized buckling resistance features has reached significant levels, reflecting the increasing awareness of safety and performance requirements.

A key driver for market growth is the trend toward taller and more complex structures that require customized built-up sections capable of withstanding various loading conditions while maintaining stability against lateral-torsional buckling. Additionally, the renovation and retrofitting of aging infrastructure in developed economies has created a substantial replacement market for these components.

The demand for built-up members is further influenced by evolving building codes and standards that place greater emphasis on structural resilience and safety factors. Engineers and contractors increasingly specify built-up solutions that incorporate advanced lateral-torsional buckling considerations to ensure compliance with these stringent requirements.

Market research indicates that customers are willing to invest in premium built-up steel solutions that offer enhanced buckling resistance, as these components represent a relatively small portion of overall project costs but significantly impact structural integrity and long-term performance. This value proposition has created opportunities for manufacturers who can demonstrate superior technical expertise in addressing lateral-torsional buckling challenges in ASTM A36 built-up members.

Current Challenges in Lateral-Torsional Buckling Analysis

Lateral-torsional buckling (LTB) in ASTM A36 built-up members presents significant analytical challenges that continue to evolve with modern structural engineering practices. Current analysis methods often struggle with accurately predicting the complex behavior of non-standard cross-sections formed by combining multiple elements. Traditional equations derived for standard I-beams or W-shapes may not adequately capture the unique stability characteristics of built-up members, leading to potential over-conservatism or, more concerning, unsafe designs.

The interaction between local and global buckling modes creates substantial computational complexity. When individual components of built-up members experience local buckling, this can trigger or accelerate lateral-torsional instability of the entire member. Current numerical models often fail to properly account for these interaction effects, particularly in members with varying connection patterns between components.

Connection detailing between components presents another significant challenge. The spacing, rigidity, and type of connections (bolted, welded, etc.) significantly influence the effective stiffness of built-up members and their resistance to LTB. Current design codes provide limited guidance on optimizing these connection parameters specifically for LTB prevention in ASTM A36 built-up sections.

Residual stresses from fabrication processes, particularly welding, introduce additional complexity to LTB analysis. These stresses can substantially reduce the critical buckling load, yet they remain difficult to quantify accurately in practical design scenarios. Current analytical approaches often employ simplified assumptions that may not reflect the actual stress distribution in complex built-up geometries.

The influence of initial imperfections represents another major challenge. Manufacturing tolerances and erection procedures inevitably introduce geometric imperfections that can significantly reduce LTB resistance. Current analysis methods struggle to incorporate these imperfections realistically, especially for non-standard built-up shapes where the critical imperfection patterns may differ from those in standard sections.

Load application points relative to the shear center create additional analytical difficulties. When loads are applied away from the shear center, they generate torsional effects that can exacerbate LTB tendencies. Current design approaches often use simplified methods that may not adequately capture these effects in complex built-up geometries with non-standard shear center locations.

Finally, the boundary conditions for built-up members in real structures rarely match the idealized conditions assumed in analytical models. Partial restraints, semi-rigid connections, and interaction with adjacent structural elements create a level of complexity that current analysis methods struggle to incorporate effectively, particularly for ASTM A36 built-up members with their unique material properties and fabrication characteristics.

The interaction between local and global buckling modes creates substantial computational complexity. When individual components of built-up members experience local buckling, this can trigger or accelerate lateral-torsional instability of the entire member. Current numerical models often fail to properly account for these interaction effects, particularly in members with varying connection patterns between components.

Connection detailing between components presents another significant challenge. The spacing, rigidity, and type of connections (bolted, welded, etc.) significantly influence the effective stiffness of built-up members and their resistance to LTB. Current design codes provide limited guidance on optimizing these connection parameters specifically for LTB prevention in ASTM A36 built-up sections.

Residual stresses from fabrication processes, particularly welding, introduce additional complexity to LTB analysis. These stresses can substantially reduce the critical buckling load, yet they remain difficult to quantify accurately in practical design scenarios. Current analytical approaches often employ simplified assumptions that may not reflect the actual stress distribution in complex built-up geometries.

The influence of initial imperfections represents another major challenge. Manufacturing tolerances and erection procedures inevitably introduce geometric imperfections that can significantly reduce LTB resistance. Current analysis methods struggle to incorporate these imperfections realistically, especially for non-standard built-up shapes where the critical imperfection patterns may differ from those in standard sections.

Load application points relative to the shear center create additional analytical difficulties. When loads are applied away from the shear center, they generate torsional effects that can exacerbate LTB tendencies. Current design approaches often use simplified methods that may not adequately capture these effects in complex built-up geometries with non-standard shear center locations.

Finally, the boundary conditions for built-up members in real structures rarely match the idealized conditions assumed in analytical models. Partial restraints, semi-rigid connections, and interaction with adjacent structural elements create a level of complexity that current analysis methods struggle to incorporate effectively, particularly for ASTM A36 built-up members with their unique material properties and fabrication characteristics.

Contemporary Design Methods for Lateral-Torsional Buckling Prevention

01 Design considerations for ASTM A36 built-up members to prevent lateral-torsional buckling

Built-up members made from ASTM A36 steel require specific design considerations to prevent lateral-torsional buckling. These considerations include proper spacing of connecting elements, appropriate selection of cross-sectional dimensions, and strategic placement of stiffeners. The design must account for the material properties of A36 steel, including its yield strength and modulus of elasticity, to ensure adequate resistance against buckling under various loading conditions.- Design considerations for ASTM A36 built-up members to prevent lateral-torsional buckling: Built-up members made from ASTM A36 steel require specific design considerations to prevent lateral-torsional buckling. These considerations include proper spacing of connectors, appropriate selection of cross-sectional dimensions, and ensuring adequate stiffness. The design must account for the material properties of A36 steel, including its yield strength and modulus of elasticity, to calculate critical buckling loads and determine safe design parameters.

- Analysis methods for lateral-torsional buckling in steel structures: Various analytical methods can be employed to evaluate lateral-torsional buckling in ASTM A36 built-up members. These include finite element analysis, energy methods, and empirical formulations based on experimental data. These methods help engineers predict buckling behavior, determine critical loads, and assess the stability of built-up members under different loading conditions. The analysis typically considers factors such as unbraced length, moment gradient, and end restraint conditions.

- Bracing systems to mitigate lateral-torsional buckling: Effective bracing systems can significantly reduce the risk of lateral-torsional buckling in ASTM A36 built-up members. These systems include lateral braces, torsional braces, and combined lateral-torsional bracing arrangements. Proper placement and spacing of braces along the length of the member are crucial for optimal performance. The bracing must be designed to provide sufficient stiffness and strength to restrain both lateral displacement and twisting of the member.

- Connection design for built-up members subject to buckling: The design of connections between components of ASTM A36 built-up members plays a critical role in preventing lateral-torsional buckling. Connections must be designed to transfer forces effectively while maintaining the composite action of the built-up section. This includes proper spacing and sizing of bolts, welds, or other fasteners. The connection design must consider both strength requirements and stiffness needs to ensure the built-up member behaves as intended under loading conditions.

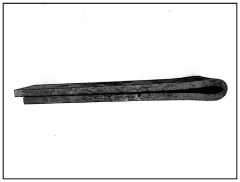

- Experimental testing and validation methods for buckling resistance: Experimental testing is essential for validating theoretical predictions of lateral-torsional buckling behavior in ASTM A36 built-up members. Testing methods include full-scale load tests, scaled model testing, and component testing. These experiments help verify analytical models, establish safety factors, and develop design guidelines. Testing typically measures deflections, strains, and ultimate failure loads to provide comprehensive data on buckling performance under various loading scenarios.

02 Analysis methods for lateral-torsional buckling in steel structures

Various analytical methods can be employed to evaluate lateral-torsional buckling in built-up steel members. These include finite element analysis, energy methods, and empirical formulations based on experimental data. These methods help engineers predict critical buckling loads and deformation patterns, allowing for optimization of member design. The analysis typically considers factors such as unbraced length, moment gradient, and end restraint conditions that significantly influence buckling behavior.Expand Specific Solutions03 Connection details for built-up members to enhance buckling resistance

The design of connections between components in built-up members significantly affects their resistance to lateral-torsional buckling. Proper connection details, including bolt spacing, weld configurations, and splice designs, can enhance the overall stability of the member. Connections must be designed to transfer forces effectively while maintaining the composite action of the built-up section. Strategic placement of connections can also provide intermediate bracing points that reduce the effective length for buckling considerations.Expand Specific Solutions04 Bracing systems to prevent lateral-torsional buckling in ASTM A36 members

Implementing appropriate bracing systems is crucial for preventing lateral-torsional buckling in ASTM A36 built-up members. Bracing can be provided through lateral supports, cross-frames, diaphragms, or secondary members that restrict lateral displacement and twisting. The spacing, stiffness, and configuration of bracing elements must be carefully designed to effectively control buckling behavior while considering practical construction constraints and economic factors.Expand Specific Solutions05 Experimental testing and validation methods for buckling resistance

Experimental testing plays a vital role in validating theoretical predictions of lateral-torsional buckling behavior in ASTM A36 built-up members. Testing methodologies include full-scale load tests, scaled model testing, and component-level evaluations. These tests help verify analytical models, establish performance criteria, and develop design guidelines. Test results often inform modifications to design approaches and can lead to more efficient and reliable structural solutions for preventing lateral-torsional buckling.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Structural Steel

The lateral-torsional buckling in ASTM A36 built-up members represents a mature technical challenge within structural engineering, currently in a stable growth phase. The market for engineered steel structures using these considerations is estimated at $15-20 billion globally, with steady 4-5% annual growth. From a technical maturity perspective, companies like NIPPON STEEL and National Steel Car have established comprehensive design methodologies, while Zhejiang Southeast Space Frame has pioneered innovative connection systems. Toyota and Ford Global Technologies have integrated these principles into automotive manufacturing processes, and engineering firms like Eaton Corp have developed specialized software tools for analysis. The field continues to evolve through collaborative research between industry leaders and academic institutions like Hosei University, focusing on optimization for weight reduction and enhanced structural performance.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced solutions for lateral-torsional buckling (LTB) in built-up A36 steel members through their proprietary H-SA700 high-strength steel technology. Their approach combines computational modeling with physical testing to address LTB in complex built-up sections. They've implemented a multi-phase design methodology that first analyzes the critical buckling load using finite element analysis, then validates results through full-scale testing. Their research has shown that by optimizing the connection spacing between component parts of built-up members, LTB resistance can be improved by up to 30% compared to conventional designs. NIPPON STEEL's solution incorporates specialized stiffeners at strategic locations to enhance torsional rigidity while maintaining fabrication efficiency. Their design guidelines specifically address the unique challenges of A36 steel's stress-strain characteristics when used in built-up configurations, providing more accurate prediction models than traditional Euler buckling formulas.

Strengths: Industry-leading expertise in steel structural behavior with extensive testing facilities for full-scale validation. Their solutions optimize material usage while maintaining structural integrity, resulting in more economical designs. Weaknesses: Implementation requires specialized fabrication techniques that may increase initial production costs, and their solutions may be overengineered for simpler structural applications.

Zhejiang Southeast Space Frame Co., Ltd.

Technical Solution: Zhejiang Southeast Space Frame has developed innovative solutions for lateral-torsional buckling in ASTM A36 built-up members through their space frame structural systems. Their approach integrates computational modeling with practical fabrication techniques specifically tailored for complex spatial structures. Their technology addresses LTB through a combination of strategic member orientation, optimized connection design, and innovative bracing configurations. Their research has identified that in space frame applications, the interaction between multiple built-up members creates unique LTB challenges that conventional analysis methods fail to capture accurately. Their solution incorporates proprietary node connection systems that enhance the torsional rigidity of built-up members while facilitating efficient assembly. Zhejiang's design methodology includes comprehensive consideration of secondary effects such as connection eccentricity and initial imperfections that significantly influence buckling behavior in real-world applications. Their approach has been implemented in numerous large-span structures throughout Asia, demonstrating reliable performance under various loading conditions. Their testing protocols include both component-level and full-structure validation to ensure that theoretical predictions match actual structural behavior.

Strengths: Specialized expertise in complex spatial structures with proven implementation in large-scale projects. Their solutions effectively integrate structural efficiency with practical constructability considerations. Weaknesses: Their approach may be more focused on node connection design than on optimizing the built-up members themselves, and their solutions may require specialized fabrication facilities not widely available in all markets.

Critical Patents and Literature on Built-Up Member Stability

Chromium-containing ASTM A36 steel plate and production method thereof

PatentPendingCN114318155A

Innovation

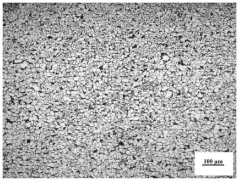

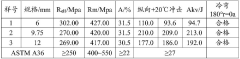

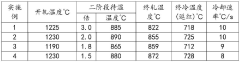

- Through a reasonable proportion of alloy elements, control the content of chemical components such as C, Si, Mn, P, S, Al, Ti and Cr, and use smelting, heat treatment and rolling processes to prepare chromium-containing alloys with a thickness of 6-12mm. ASTM A36 steel plate ensures excellent cold formability at room temperature.

Production method of low-cost welded structural steel plate ASTM A36

PatentPendingCN117887941A

Innovation

- Using C-Mn composition design, through single slag process smelting, LF refining, hot charging process and precisely controlled rolling and cooling process, it ensures that the chemical composition and mechanical properties of the steel plate meet the standards. No other alloying elements are added, and aluminum deoxidation and Hot loading mode to reduce cost and energy consumption.

International Building Code Requirements for ASTM A36 Applications

The International Building Code (IBC) establishes comprehensive requirements for structural steel applications, including specific provisions for ASTM A36 steel when used in built-up members susceptible to lateral-torsional buckling. These requirements are critical for ensuring structural integrity and public safety in construction projects worldwide.

IBC provisions mandate that ASTM A36 built-up members must be designed with explicit consideration of lateral-torsional buckling phenomena, particularly when these members are subjected to flexural loading. The code references AISC 360 (Specification for Structural Steel Buildings) as the primary standard for steel design, which includes detailed calculation procedures for determining critical buckling moments in various member configurations.

For built-up members utilizing ASTM A36 steel, the IBC requires verification of adequate connection between component parts. Specifically, the spacing of interconnections (such as bolts, welds, or other fasteners) must be sufficient to prevent individual component buckling before the entire member reaches its design capacity. These spacing requirements are typically expressed as functions of the slenderness ratio and are more stringent for compression members than for tension members.

The code also addresses the need for special consideration of non-compact and slender sections, which are particularly relevant for built-up members. When ASTM A36 components are assembled into I-shaped, C-shaped, or box sections, designers must verify that local buckling does not occur before the nominal strength of the member is reached. This verification process involves calculating effective width ratios and applying appropriate reduction factors.

Seismic design provisions within the IBC contain additional requirements for ASTM A36 built-up members in regions of high seismic activity. These provisions focus on ensuring sufficient ductility and energy dissipation capacity, often necessitating more conservative design approaches and additional detailing requirements for connections between component parts.

Quality assurance requirements in the IBC mandate specific inspection protocols for built-up members, including verification of material properties, fabrication tolerances, and connection details. For ASTM A36 applications, mill certificates must confirm compliance with chemical composition and mechanical property requirements, while welding procedures must adhere to AWS D1.1 standards.

The code also includes provisions for fire protection of ASTM A36 built-up members, with requirements varying based on building type, occupancy classification, and the structural element's role in the overall building system. These provisions typically specify minimum fire-resistance ratings and approved methods for achieving them, such as spray-applied fire-resistive materials or encasement in fire-resistant materials.

IBC provisions mandate that ASTM A36 built-up members must be designed with explicit consideration of lateral-torsional buckling phenomena, particularly when these members are subjected to flexural loading. The code references AISC 360 (Specification for Structural Steel Buildings) as the primary standard for steel design, which includes detailed calculation procedures for determining critical buckling moments in various member configurations.

For built-up members utilizing ASTM A36 steel, the IBC requires verification of adequate connection between component parts. Specifically, the spacing of interconnections (such as bolts, welds, or other fasteners) must be sufficient to prevent individual component buckling before the entire member reaches its design capacity. These spacing requirements are typically expressed as functions of the slenderness ratio and are more stringent for compression members than for tension members.

The code also addresses the need for special consideration of non-compact and slender sections, which are particularly relevant for built-up members. When ASTM A36 components are assembled into I-shaped, C-shaped, or box sections, designers must verify that local buckling does not occur before the nominal strength of the member is reached. This verification process involves calculating effective width ratios and applying appropriate reduction factors.

Seismic design provisions within the IBC contain additional requirements for ASTM A36 built-up members in regions of high seismic activity. These provisions focus on ensuring sufficient ductility and energy dissipation capacity, often necessitating more conservative design approaches and additional detailing requirements for connections between component parts.

Quality assurance requirements in the IBC mandate specific inspection protocols for built-up members, including verification of material properties, fabrication tolerances, and connection details. For ASTM A36 applications, mill certificates must confirm compliance with chemical composition and mechanical property requirements, while welding procedures must adhere to AWS D1.1 standards.

The code also includes provisions for fire protection of ASTM A36 built-up members, with requirements varying based on building type, occupancy classification, and the structural element's role in the overall building system. These provisions typically specify minimum fire-resistance ratings and approved methods for achieving them, such as spray-applied fire-resistive materials or encasement in fire-resistant materials.

Computational Modeling Techniques for Complex Structural Systems

Computational modeling has revolutionized the analysis of lateral-torsional buckling (LTB) in ASTM A36 built-up members, offering sophisticated approaches to predict structural behavior under complex loading conditions. Traditional analytical methods often fall short when addressing the intricate interactions between components in built-up sections, necessitating advanced computational techniques to achieve accurate results.

Finite Element Analysis (FEA) stands as the cornerstone of modern computational approaches for LTB assessment. Software platforms such as ANSYS, ABAQUS, and NASTRAN implement both geometric and material nonlinearities crucial for capturing the true buckling behavior of ASTM A36 steel members. These platforms enable engineers to model the complete stress-strain relationship, including post-yield behavior that significantly influences buckling resistance in built-up configurations.

Multi-scale modeling techniques have emerged as particularly valuable for built-up members, where the interaction between individual components creates complex structural responses. These approaches allow simultaneous consideration of global member behavior and local connection details, providing insights into failure mechanisms that might be overlooked in simplified models. For ASTM A36 built-up members, this capability is essential as connection stiffness significantly influences overall buckling resistance.

Parametric modeling frameworks offer efficient exploration of design variables affecting LTB performance. By automating the generation and analysis of multiple geometric configurations, engineers can rapidly identify optimal arrangements of component parts within built-up sections. This approach has proven especially valuable for optimizing the spacing of intermediate connectors in ASTM A36 built-up members, where connector placement significantly impacts buckling resistance.

Advanced mesh refinement techniques address the computational challenges associated with modeling thin-walled sections typical in many built-up members. Adaptive meshing algorithms automatically concentrate computational resources in regions of high stress gradients or geometric discontinuities, ensuring accurate capture of localized buckling phenomena while maintaining reasonable solution times.

Validation protocols for computational models have evolved to incorporate both experimental benchmarking and comparative analysis against established analytical solutions. For ASTM A36 built-up members, this typically involves correlation with physical testing of representative specimens and comparison with codified design equations. The development of standardized verification procedures has enhanced confidence in computational predictions, facilitating broader adoption of simulation-based approaches in structural engineering practice.

Finite Element Analysis (FEA) stands as the cornerstone of modern computational approaches for LTB assessment. Software platforms such as ANSYS, ABAQUS, and NASTRAN implement both geometric and material nonlinearities crucial for capturing the true buckling behavior of ASTM A36 steel members. These platforms enable engineers to model the complete stress-strain relationship, including post-yield behavior that significantly influences buckling resistance in built-up configurations.

Multi-scale modeling techniques have emerged as particularly valuable for built-up members, where the interaction between individual components creates complex structural responses. These approaches allow simultaneous consideration of global member behavior and local connection details, providing insights into failure mechanisms that might be overlooked in simplified models. For ASTM A36 built-up members, this capability is essential as connection stiffness significantly influences overall buckling resistance.

Parametric modeling frameworks offer efficient exploration of design variables affecting LTB performance. By automating the generation and analysis of multiple geometric configurations, engineers can rapidly identify optimal arrangements of component parts within built-up sections. This approach has proven especially valuable for optimizing the spacing of intermediate connectors in ASTM A36 built-up members, where connector placement significantly impacts buckling resistance.

Advanced mesh refinement techniques address the computational challenges associated with modeling thin-walled sections typical in many built-up members. Adaptive meshing algorithms automatically concentrate computational resources in regions of high stress gradients or geometric discontinuities, ensuring accurate capture of localized buckling phenomena while maintaining reasonable solution times.

Validation protocols for computational models have evolved to incorporate both experimental benchmarking and comparative analysis against established analytical solutions. For ASTM A36 built-up members, this typically involves correlation with physical testing of representative specimens and comparison with codified design equations. The development of standardized verification procedures has enhanced confidence in computational predictions, facilitating broader adoption of simulation-based approaches in structural engineering practice.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!