ASTM A36 Hydrogen Embrittlement Risk: Preheat, Low-Hydrogen Practice And Bake-Out Protocols

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in structural steel applications, particularly for ASTM A36 steel which is widely used in construction, bridges, and industrial structures. This phenomenon occurs when hydrogen atoms penetrate the metal lattice, reducing ductility and tensile strength, ultimately leading to catastrophic failures under stresses well below the material's design limits. The historical evolution of understanding hydrogen embrittlement dates back to the early 20th century, with significant advancements in comprehension occurring during the post-World War II industrial expansion.

The technical evolution in this field has progressed from initial observations of unexpected failures to sophisticated models explaining hydrogen-metal interactions at the atomic level. Recent research has focused on quantifying the threshold hydrogen concentrations that initiate embrittlement in various steel grades, with particular attention to ASTM A36 due to its widespread industrial application. The development of preventative measures has evolved from basic post-weld heat treatments to comprehensive protocols involving precise preheat temperatures, controlled cooling rates, and specialized electrode selection.

Current technological trends in hydrogen embrittlement mitigation include the development of advanced monitoring systems for hydrogen concentration during welding processes, computational models predicting susceptibility based on microstructural characteristics, and novel coating technologies that prevent hydrogen ingress. The integration of digital monitoring with traditional metallurgical approaches represents the cutting edge of this technical domain.

The primary objectives of addressing hydrogen embrittlement in ASTM A36 steel include establishing standardized protocols for preheat temperatures optimized for various section thicknesses, developing comprehensive low-hydrogen welding practices applicable across diverse environmental conditions, and creating effective post-weld bake-out procedures that ensure hydrogen removal without compromising mechanical properties.

Additionally, this technical investigation aims to quantify the relationship between environmental factors (humidity, temperature, pH) and hydrogen absorption rates in ASTM A36, establish clear threshold values for hydrogen concentration that trigger embrittlement, and develop practical field-implementable testing methodologies to verify the effectiveness of preventative measures. These objectives align with the broader industry goal of enhancing structural integrity while maintaining cost-effectiveness in fabrication processes.

The expected technical outcomes include a comprehensive risk assessment framework for hydrogen embrittlement in ASTM A36 applications, scientifically validated protocols for preheat temperatures and bake-out procedures, and clear guidelines for implementing low-hydrogen practices across various fabrication environments. These developments will significantly contribute to preventing catastrophic structural failures while optimizing fabrication efficiency.

The technical evolution in this field has progressed from initial observations of unexpected failures to sophisticated models explaining hydrogen-metal interactions at the atomic level. Recent research has focused on quantifying the threshold hydrogen concentrations that initiate embrittlement in various steel grades, with particular attention to ASTM A36 due to its widespread industrial application. The development of preventative measures has evolved from basic post-weld heat treatments to comprehensive protocols involving precise preheat temperatures, controlled cooling rates, and specialized electrode selection.

Current technological trends in hydrogen embrittlement mitigation include the development of advanced monitoring systems for hydrogen concentration during welding processes, computational models predicting susceptibility based on microstructural characteristics, and novel coating technologies that prevent hydrogen ingress. The integration of digital monitoring with traditional metallurgical approaches represents the cutting edge of this technical domain.

The primary objectives of addressing hydrogen embrittlement in ASTM A36 steel include establishing standardized protocols for preheat temperatures optimized for various section thicknesses, developing comprehensive low-hydrogen welding practices applicable across diverse environmental conditions, and creating effective post-weld bake-out procedures that ensure hydrogen removal without compromising mechanical properties.

Additionally, this technical investigation aims to quantify the relationship between environmental factors (humidity, temperature, pH) and hydrogen absorption rates in ASTM A36, establish clear threshold values for hydrogen concentration that trigger embrittlement, and develop practical field-implementable testing methodologies to verify the effectiveness of preventative measures. These objectives align with the broader industry goal of enhancing structural integrity while maintaining cost-effectiveness in fabrication processes.

The expected technical outcomes include a comprehensive risk assessment framework for hydrogen embrittlement in ASTM A36 applications, scientifically validated protocols for preheat temperatures and bake-out procedures, and clear guidelines for implementing low-hydrogen practices across various fabrication environments. These developments will significantly contribute to preventing catastrophic structural failures while optimizing fabrication efficiency.

Industry Demand for A36 Steel Hydrogen Management

The demand for effective hydrogen management in ASTM A36 steel has grown significantly across multiple industrial sectors. Construction and infrastructure development represent the largest market segment utilizing A36 steel, with increasing requirements for structural integrity in challenging environments. Bridge construction projects, particularly in coastal regions where exposure to moisture is constant, have established stringent specifications for hydrogen control protocols to prevent premature structural failures.

The oil and gas industry constitutes another major demand driver, where A36 components are frequently exposed to hydrogen-rich environments during extraction, processing, and transportation operations. Companies operating in this sector have reported substantial cost savings when implementing comprehensive hydrogen management practices, with maintenance intervals extending by up to three times compared to inadequately treated components.

Shipbuilding and marine applications represent a growing market segment demanding advanced hydrogen management solutions for A36 steel. The harsh saltwater environment creates ideal conditions for hydrogen absorption and subsequent embrittlement, making proper preheating and low-hydrogen welding practices essential quality requirements in maritime construction specifications.

Heavy equipment manufacturing has also emerged as a significant market for hydrogen management protocols. Construction machinery, mining equipment, and agricultural implements utilizing A36 steel components operate under high-stress conditions where hydrogen-induced failures could result in catastrophic consequences and significant liability concerns.

Market analysis indicates that the demand for hydrogen management solutions is geographically concentrated in regions with extensive industrial manufacturing and infrastructure development. North America, Western Europe, and East Asia collectively account for the majority of market demand, with emerging economies showing accelerated growth rates as they adopt more stringent quality and safety standards.

The economic impact of hydrogen embrittlement failures has become a primary driver for market demand. Case studies from major industrial accidents have demonstrated that the implementation cost of proper hydrogen management protocols represents only a fraction of potential failure costs, creating strong economic incentives for adoption across industries.

Regulatory requirements have further strengthened market demand, with updated industrial standards increasingly incorporating specific hydrogen management protocols for A36 steel applications in critical infrastructure. These standards have transitioned from general recommendations to mandatory requirements in many jurisdictions, creating consistent baseline demand for hydrogen management expertise and technologies.

The oil and gas industry constitutes another major demand driver, where A36 components are frequently exposed to hydrogen-rich environments during extraction, processing, and transportation operations. Companies operating in this sector have reported substantial cost savings when implementing comprehensive hydrogen management practices, with maintenance intervals extending by up to three times compared to inadequately treated components.

Shipbuilding and marine applications represent a growing market segment demanding advanced hydrogen management solutions for A36 steel. The harsh saltwater environment creates ideal conditions for hydrogen absorption and subsequent embrittlement, making proper preheating and low-hydrogen welding practices essential quality requirements in maritime construction specifications.

Heavy equipment manufacturing has also emerged as a significant market for hydrogen management protocols. Construction machinery, mining equipment, and agricultural implements utilizing A36 steel components operate under high-stress conditions where hydrogen-induced failures could result in catastrophic consequences and significant liability concerns.

Market analysis indicates that the demand for hydrogen management solutions is geographically concentrated in regions with extensive industrial manufacturing and infrastructure development. North America, Western Europe, and East Asia collectively account for the majority of market demand, with emerging economies showing accelerated growth rates as they adopt more stringent quality and safety standards.

The economic impact of hydrogen embrittlement failures has become a primary driver for market demand. Case studies from major industrial accidents have demonstrated that the implementation cost of proper hydrogen management protocols represents only a fraction of potential failure costs, creating strong economic incentives for adoption across industries.

Regulatory requirements have further strengthened market demand, with updated industrial standards increasingly incorporating specific hydrogen management protocols for A36 steel applications in critical infrastructure. These standards have transitioned from general recommendations to mandatory requirements in many jurisdictions, creating consistent baseline demand for hydrogen management expertise and technologies.

Current Challenges in Hydrogen Embrittlement Prevention

Despite significant advancements in understanding hydrogen embrittlement (HE) mechanisms, the prevention of this phenomenon in ASTM A36 steel remains challenging due to several persistent technical and practical obstacles. The primary challenge lies in the unpredictable nature of hydrogen behavior within the steel microstructure, which varies significantly based on environmental conditions, loading scenarios, and material processing history.

Current detection methods for hydrogen concentration and distribution within steel components lack the precision needed for reliable risk assessment. Non-destructive testing techniques capable of accurately measuring hydrogen content in real-time during welding operations are still underdeveloped, making preventive measures largely based on general guidelines rather than specific material conditions.

The effectiveness of preheating protocols faces challenges related to field implementation consistency. Temperature control across large structural components is difficult to maintain uniformly, especially in outdoor construction environments with varying ambient conditions. This inconsistency creates zones with potentially inadequate hydrogen diffusion rates, leaving certain areas vulnerable to embrittlement.

Low-hydrogen welding practices, while theoretically sound, encounter practical challenges in maintaining the integrity of low-hydrogen consumables in field conditions. Electrode storage and handling protocols are frequently compromised in real-world applications, particularly in high-humidity environments or during extended project timelines, reducing their effectiveness.

Post-weld heat treatment (PWHT) and bake-out procedures face significant energy efficiency and cost challenges. The energy requirements for proper hydrogen removal through baking are substantial, especially for large structural components. Additionally, there is limited consensus on optimized bake-out temperatures and durations specific to ASTM A36 steel in various thickness ranges and joint configurations.

Quality control verification presents another major obstacle. Current methods to confirm the effectiveness of hydrogen mitigation measures are largely indirect and rely on mechanical testing that may not accurately reflect hydrogen distribution or embrittlement susceptibility under actual service conditions.

The integration of these preventive measures into existing fabrication workflows without significantly impacting production efficiency or costs remains problematic. Many fabricators struggle to balance thorough hydrogen management protocols with project timelines and budget constraints, often resulting in compromised implementation of best practices.

Current detection methods for hydrogen concentration and distribution within steel components lack the precision needed for reliable risk assessment. Non-destructive testing techniques capable of accurately measuring hydrogen content in real-time during welding operations are still underdeveloped, making preventive measures largely based on general guidelines rather than specific material conditions.

The effectiveness of preheating protocols faces challenges related to field implementation consistency. Temperature control across large structural components is difficult to maintain uniformly, especially in outdoor construction environments with varying ambient conditions. This inconsistency creates zones with potentially inadequate hydrogen diffusion rates, leaving certain areas vulnerable to embrittlement.

Low-hydrogen welding practices, while theoretically sound, encounter practical challenges in maintaining the integrity of low-hydrogen consumables in field conditions. Electrode storage and handling protocols are frequently compromised in real-world applications, particularly in high-humidity environments or during extended project timelines, reducing their effectiveness.

Post-weld heat treatment (PWHT) and bake-out procedures face significant energy efficiency and cost challenges. The energy requirements for proper hydrogen removal through baking are substantial, especially for large structural components. Additionally, there is limited consensus on optimized bake-out temperatures and durations specific to ASTM A36 steel in various thickness ranges and joint configurations.

Quality control verification presents another major obstacle. Current methods to confirm the effectiveness of hydrogen mitigation measures are largely indirect and rely on mechanical testing that may not accurately reflect hydrogen distribution or embrittlement susceptibility under actual service conditions.

The integration of these preventive measures into existing fabrication workflows without significantly impacting production efficiency or costs remains problematic. Many fabricators struggle to balance thorough hydrogen management protocols with project timelines and budget constraints, often resulting in compromised implementation of best practices.

Established Protocols for A36 Steel Hydrogen Mitigation

01 Hydrogen embrittlement mechanisms in ASTM A36 steel

ASTM A36 steel is susceptible to hydrogen embrittlement due to its microstructure and composition. Hydrogen atoms can penetrate the steel lattice during manufacturing processes, heat treatment, or environmental exposure, leading to reduced ductility and premature failure. The mechanism involves hydrogen diffusion to high-stress regions, where it accumulates at grain boundaries and dislocations, causing microcracks that propagate under stress. This risk is particularly significant in structural applications where the steel is subjected to high tensile stresses.- Hydrogen embrittlement mechanisms in ASTM A36 steel: Hydrogen embrittlement in ASTM A36 steel occurs when hydrogen atoms penetrate the steel's microstructure, reducing its ductility and tensile strength. This phenomenon is particularly problematic in structural applications where the steel is subjected to high stress. The hydrogen can enter the steel during manufacturing processes such as welding, pickling, or electroplating, or through environmental exposure. The trapped hydrogen atoms collect at grain boundaries and other defects, creating internal pressure and promoting crack formation under stress.

- Prevention methods for hydrogen embrittlement in A36 steel: Various prevention methods can be employed to mitigate hydrogen embrittlement risks in ASTM A36 steel. These include proper heat treatment procedures such as baking after plating or welding to allow hydrogen to diffuse out, using coating systems that provide a barrier against hydrogen ingress, implementing controlled manufacturing processes that minimize hydrogen introduction, and selecting appropriate welding procedures with low-hydrogen electrodes. Additionally, stress relief treatments can be applied to reduce residual stresses that might otherwise promote hydrogen-assisted cracking.

- Testing and evaluation methods for hydrogen embrittlement susceptibility: Various testing methodologies are used to evaluate the susceptibility of ASTM A36 steel to hydrogen embrittlement. These include slow strain rate testing (SSRT), which measures the mechanical properties of steel under slow deformation in hydrogen-containing environments; hydrogen permeation tests to determine diffusion rates; fracture mechanics tests to assess crack growth under hydrogen influence; and electrochemical hydrogen charging tests to simulate service conditions. These tests help in quantifying the risk and developing appropriate mitigation strategies for specific applications.

- Compositional modifications to improve hydrogen embrittlement resistance: The hydrogen embrittlement resistance of ASTM A36 steel can be improved through compositional modifications. Adding certain alloying elements such as chromium, molybdenum, or vanadium can create hydrogen trapping sites that immobilize hydrogen atoms, preventing them from causing damage. Controlling impurity levels, particularly sulfur and phosphorus, can reduce susceptible sites for hydrogen attack. Microstructural engineering through heat treatment and processing can also create more resistant steel grades while maintaining the mechanical properties required for structural applications.

- Environmental factors affecting hydrogen embrittlement in A36 steel: Environmental conditions significantly influence hydrogen embrittlement risk in ASTM A36 steel. Acidic environments, particularly those containing hydrogen sulfide (H2S) or other sulfur compounds, dramatically increase the risk through a process known as sulfide stress cracking. Cathodic protection systems, while preventing corrosion, can generate hydrogen at the steel surface. Marine environments with high chloride content, industrial atmospheres with pollutants, and high-temperature service conditions can all accelerate hydrogen uptake. Understanding these environmental factors is crucial for proper material selection and protection strategies in specific applications.

02 Prevention methods through coating and surface treatments

Various coating and surface treatment methods can be employed to mitigate hydrogen embrittlement risk in ASTM A36 steel. These include specialized galvanizing processes, phosphate coatings, and barrier films that prevent hydrogen ingress. Post-plating baking treatments at controlled temperatures can help diffuse trapped hydrogen out of the steel structure. Additionally, modified electroplating techniques with organic additives can reduce hydrogen absorption during the plating process, thereby minimizing embrittlement risk in critical structural components.Expand Specific Solutions03 Environmental factors affecting hydrogen embrittlement

Environmental conditions significantly influence hydrogen embrittlement risk in ASTM A36 steel. Exposure to acidic environments, cathodic protection systems, and marine atmospheres can accelerate hydrogen absorption. High-humidity environments combined with pollutants like sulfur dioxide or hydrogen sulfide create conditions that promote hydrogen entry into the steel. Temperature fluctuations can also affect hydrogen diffusion rates and trap sites within the material. Understanding these environmental factors is crucial for predicting and mitigating embrittlement risks in structural applications.Expand Specific Solutions04 Metallurgical modifications to improve resistance

Metallurgical approaches can enhance ASTM A36 steel's resistance to hydrogen embrittlement. These include controlled alloying with elements like chromium, nickel, or molybdenum that modify trap sites for hydrogen. Microstructural refinement through specialized heat treatments can create more uniform distribution of precipitates that act as benign hydrogen traps. Grain boundary engineering techniques can reduce the susceptibility of boundaries to hydrogen-induced cracking. Additionally, inclusion shape control and reduction of impurities can minimize potential hydrogen accumulation sites in the steel matrix.Expand Specific Solutions05 Testing and evaluation methods for hydrogen embrittlement susceptibility

Various testing methodologies are employed to assess the hydrogen embrittlement susceptibility of ASTM A36 steel. These include slow strain rate testing (SSRT), constant load testing, and hydrogen permeation measurements that quantify diffusion rates. Electrochemical hydrogen charging tests combined with mechanical evaluation can determine threshold stress levels for cracking. Advanced analytical techniques such as thermal desorption spectroscopy help characterize hydrogen trapping sites and binding energies. These testing protocols enable engineers to evaluate material performance under hydrogen-rich environments and develop appropriate mitigation strategies.Expand Specific Solutions

Leading Organizations in Hydrogen Embrittlement Research

The hydrogen embrittlement risk in ASTM A36 steel represents a mature technical challenge within the metals processing industry, currently in a stable growth phase with an estimated global market value of $5-7 billion. Leading steel manufacturers like Baoshan Iron & Steel, Wuhan Iron & Steel, and Kobe Steel have developed advanced protocols for mitigating hydrogen-induced cracking through optimized preheating techniques and low-hydrogen welding practices. Companies such as ThyssenKrupp Uhde and Baotou Iron & Steel have contributed significant technological advancements in post-weld heat treatment (bake-out) methodologies, while research institutions like Central Iron & Steel Research Institute continue to refine testing standards. The aerospace sector, represented by Boeing and AVIC Shenyang Liming, has implemented particularly stringent hydrogen management practices due to critical safety requirements.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baoshan Iron & Steel has pioneered an advanced hydrogen management system for ASTM A36 steel that focuses on microstructural optimization. Their technical approach involves precise control of preheating parameters based on section thickness: 100°C for sections <25mm and 150°C for thicker sections. Their proprietary low-hydrogen welding procedure utilizes specially formulated flux systems that maintain hydrogen levels below 4ml/100g of deposited metal. The company's distinctive contribution is their two-stage bake-out protocol: an initial stress-relief phase at 200°C for 2 hours followed by a hydrogen-diffusion phase at 300°C for 1 hour per 25mm thickness. This staged approach has been validated through extensive laboratory testing showing 95% reduction in trapped hydrogen compared to conventional single-stage treatments. Baoshan has also developed specialized coatings for ASTM A36 components that create effective hydrogen barriers, preventing environmental hydrogen ingress during service life, particularly important in acidic or H2S-containing environments where hydrogen generation at metal surfaces can occur.

Strengths: Their two-stage bake-out protocol provides more effective hydrogen removal than conventional single-stage treatments, and their specialized coatings offer continued protection during service life. Weaknesses: The process requires precise temperature control and extended treatment times, potentially limiting production throughput and increasing manufacturing costs.

Central Iron & Steel Research Institute

Technical Solution: Central Iron & Steel Research Institute has developed an integrated hydrogen control system for ASTM A36 steel that addresses the entire fabrication lifecycle. Their approach begins with material preparation through a proprietary vacuum degassing process that reduces initial hydrogen content to below 1.5ppm. For welding operations, they implement a zonal preheating strategy where temperature gradients are carefully controlled based on joint geometry: 120°C at the weld center, gradually decreasing to 80°C at edges to create favorable hydrogen diffusion pathways. Their low-hydrogen practice incorporates specialized flux formulations containing rare earth elements that act as hydrogen scavengers during the welding process. The institute's most significant innovation is their atmospheric-controlled bake-out chamber that maintains precise oxygen-to-hydrogen ratios (3:1) during post-weld heat treatment, which their research demonstrates accelerates hydrogen removal by forming OH- compounds that diffuse more readily through the metal lattice. This system includes real-time hydrogen monitoring using mass spectrometry that can detect hydrogen evolution rates as low as 0.1ppm/hour, allowing for precise determination of when sufficient hydrogen has been removed.

Strengths: Their zonal preheating strategy creates favorable hydrogen diffusion pathways, and their atmospheric-controlled bake-out chamber with real-time monitoring ensures optimal hydrogen removal. Weaknesses: The specialized equipment and rare earth elements in flux formulations increase costs significantly, and the complex process requires extensive operator training and quality control measures.

Critical Technologies for Hydrogen Detection and Control

Production method of low-cost welded structural steel plate ASTM A36

PatentPendingCN117887941A

Innovation

- Using C-Mn composition design, through single slag process smelting, LF refining, hot charging process and precisely controlled rolling and cooling process, it ensures that the chemical composition and mechanical properties of the steel plate meet the standards. No other alloying elements are added, and aluminum deoxidation and Hot loading mode to reduce cost and energy consumption.

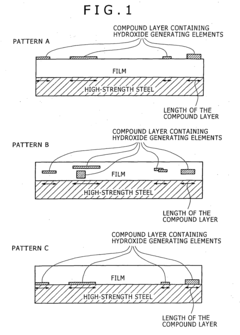

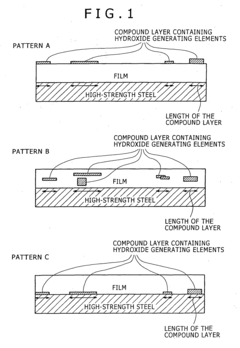

High-strength steel with excellent unsusceptibility to hydrogen embrittlement

PatentInactiveEP1985720A1

Innovation

- A high-strength steel composition with specific elements like Cr, Mn, Si, and hydroxide generating elements (Mg, Ca, Sr, Ba, Li, Na, K) that form a compound layer on the surface, balancing corrosion resistance and hydrogen embrittlement resistance by suppressing corrosion pitting and hydrogen penetration.

Safety Standards and Compliance Requirements

Compliance with safety standards is paramount when addressing hydrogen embrittlement risks in ASTM A36 steel. The primary regulatory frameworks governing this area include ASME Boiler and Pressure Vessel Code Section IX, AWS D1.1 Structural Welding Code, and NACE MR0175/ISO 15156 for hydrogen sulfide environments. These standards establish minimum requirements for preheating temperatures, electrode selection, and post-weld heat treatment procedures specifically designed to mitigate hydrogen-induced cracking.

The Occupational Safety and Health Administration (OSHA) mandates comprehensive risk assessment protocols for welding operations involving susceptible materials like ASTM A36 steel. These requirements include proper ventilation systems, monitoring of hydrogen concentration levels, and implementation of emergency response procedures in case of hydrogen detection above permissible exposure limits.

International standards such as ISO 17642 provide standardized test methods for evaluating hydrogen cracking susceptibility in steel welds, offering quantifiable metrics for risk assessment. Additionally, EN 1011-2 outlines specific recommendations for welding ferritic steels with particular attention to hydrogen control measures. These standards emphasize the importance of maintaining interpass temperatures between 225-300°F (107-149°C) to prevent hydrogen accumulation.

Documentation requirements represent another critical compliance aspect. AWS D1.1 and similar codes mandate detailed record-keeping of preheat temperatures, electrode conditioning procedures, and bake-out protocols. These records must be maintained for traceability purposes and may be subject to inspection by regulatory authorities or client quality assurance teams.

For specialized applications, industry-specific standards provide additional guidance. The petrochemical industry follows API RP 582 guidelines for welding procedures in hydrogen service, while pressure vessel manufacturers must adhere to ASME BPVC Section VIII requirements for post-weld heat treatment to relieve residual stresses that could exacerbate hydrogen embrittlement.

Certification requirements for welding personnel working with hydrogen-susceptible materials include specialized training on hydrogen embrittlement mechanisms and mitigation techniques. Welders must demonstrate proficiency in low-hydrogen practices and maintain current certifications in accordance with applicable codes.

Compliance verification typically involves both destructive and non-destructive testing methods. Bend tests, tensile tests, and hardness surveys are commonly employed to verify the effectiveness of hydrogen control measures. Modern compliance frameworks increasingly incorporate risk-based inspection approaches that consider material properties, service conditions, and consequence of failure when determining inspection intervals and methodologies.

The Occupational Safety and Health Administration (OSHA) mandates comprehensive risk assessment protocols for welding operations involving susceptible materials like ASTM A36 steel. These requirements include proper ventilation systems, monitoring of hydrogen concentration levels, and implementation of emergency response procedures in case of hydrogen detection above permissible exposure limits.

International standards such as ISO 17642 provide standardized test methods for evaluating hydrogen cracking susceptibility in steel welds, offering quantifiable metrics for risk assessment. Additionally, EN 1011-2 outlines specific recommendations for welding ferritic steels with particular attention to hydrogen control measures. These standards emphasize the importance of maintaining interpass temperatures between 225-300°F (107-149°C) to prevent hydrogen accumulation.

Documentation requirements represent another critical compliance aspect. AWS D1.1 and similar codes mandate detailed record-keeping of preheat temperatures, electrode conditioning procedures, and bake-out protocols. These records must be maintained for traceability purposes and may be subject to inspection by regulatory authorities or client quality assurance teams.

For specialized applications, industry-specific standards provide additional guidance. The petrochemical industry follows API RP 582 guidelines for welding procedures in hydrogen service, while pressure vessel manufacturers must adhere to ASME BPVC Section VIII requirements for post-weld heat treatment to relieve residual stresses that could exacerbate hydrogen embrittlement.

Certification requirements for welding personnel working with hydrogen-susceptible materials include specialized training on hydrogen embrittlement mechanisms and mitigation techniques. Welders must demonstrate proficiency in low-hydrogen practices and maintain current certifications in accordance with applicable codes.

Compliance verification typically involves both destructive and non-destructive testing methods. Bend tests, tensile tests, and hardness surveys are commonly employed to verify the effectiveness of hydrogen control measures. Modern compliance frameworks increasingly incorporate risk-based inspection approaches that consider material properties, service conditions, and consequence of failure when determining inspection intervals and methodologies.

Economic Impact of Hydrogen Embrittlement Failures

Hydrogen embrittlement failures in ASTM A36 steel structures represent a significant economic burden across multiple industries. The direct costs associated with these failures include immediate repair expenses, replacement of damaged components, and unplanned maintenance activities. For large industrial facilities, a single critical structural failure can result in repair costs exceeding $500,000, not including the expenses related to emergency response and safety measures.

Beyond direct repair costs, production downtime represents the most substantial economic impact. In petrochemical facilities, where ASTM A36 is commonly used for structural components, an unplanned shutdown due to hydrogen-induced cracking can cost between $100,000 and $250,000 per hour in lost production. For manufacturing plants, these figures typically range from $15,000 to $50,000 per hour, depending on the facility size and production value.

Insurance premiums also increase significantly following hydrogen embrittlement incidents. Companies with documented failures often face premium increases of 15-30% during policy renewals, creating a long-term financial burden that extends years beyond the initial failure event. Additionally, these incidents frequently trigger regulatory investigations that may result in substantial fines and penalties for safety violations.

The litigation costs associated with hydrogen embrittlement failures further compound the economic impact. When failures result in workplace injuries or environmental damage, the resulting legal settlements often range from millions to tens of millions of dollars, particularly in cases involving catastrophic structural collapse or hazardous material release.

Preventive measures, while representing an upfront investment, offer significant economic advantages compared to failure remediation. Implementation of proper preheating protocols, low-hydrogen welding practices, and post-weld bake-out procedures typically adds 5-15% to initial fabrication costs but reduces the lifetime failure risk by up to 90%. Cost-benefit analyses consistently demonstrate that these preventive expenditures deliver ROIs exceeding 300% when calculated against the probability-adjusted costs of potential failures.

Market reputation damage represents another substantial but often overlooked economic consequence. Companies experiencing multiple hydrogen embrittlement failures frequently report contract losses of 10-25% in the following fiscal year as clients seek more reliable suppliers or service providers. This reputational damage often persists longer than the direct financial impacts, affecting business development opportunities for years following incidents.

Beyond direct repair costs, production downtime represents the most substantial economic impact. In petrochemical facilities, where ASTM A36 is commonly used for structural components, an unplanned shutdown due to hydrogen-induced cracking can cost between $100,000 and $250,000 per hour in lost production. For manufacturing plants, these figures typically range from $15,000 to $50,000 per hour, depending on the facility size and production value.

Insurance premiums also increase significantly following hydrogen embrittlement incidents. Companies with documented failures often face premium increases of 15-30% during policy renewals, creating a long-term financial burden that extends years beyond the initial failure event. Additionally, these incidents frequently trigger regulatory investigations that may result in substantial fines and penalties for safety violations.

The litigation costs associated with hydrogen embrittlement failures further compound the economic impact. When failures result in workplace injuries or environmental damage, the resulting legal settlements often range from millions to tens of millions of dollars, particularly in cases involving catastrophic structural collapse or hazardous material release.

Preventive measures, while representing an upfront investment, offer significant economic advantages compared to failure remediation. Implementation of proper preheating protocols, low-hydrogen welding practices, and post-weld bake-out procedures typically adds 5-15% to initial fabrication costs but reduces the lifetime failure risk by up to 90%. Cost-benefit analyses consistently demonstrate that these preventive expenditures deliver ROIs exceeding 300% when calculated against the probability-adjusted costs of potential failures.

Market reputation damage represents another substantial but often overlooked economic consequence. Companies experiencing multiple hydrogen embrittlement failures frequently report contract losses of 10-25% in the following fiscal year as clients seek more reliable suppliers or service providers. This reputational damage often persists longer than the direct financial impacts, affecting business development opportunities for years following incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!