ASTM A36 Thickness Effects: Through-Section Properties, Constraint And Toughness Gradients

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ASTM A36 Steel Development History and Objectives

ASTM A36 steel emerged in the mid-20th century as a response to the growing demand for standardized structural steel with consistent mechanical properties. Developed by the American Society for Testing and Materials (now ASTM International), this low-carbon steel was first standardized in 1960 and quickly became the most commonly used structural steel in the United States due to its excellent balance of strength, formability, and cost-effectiveness.

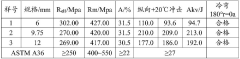

The evolution of A36 steel represents a significant milestone in materials engineering, as it provided engineers with a reliable material having predictable properties across various manufacturing batches. Initially, the focus was primarily on achieving consistent yield strength (minimum 36 ksi or 250 MPa) and tensile strength (58-80 ksi or 400-550 MPa) regardless of section thickness, which was revolutionary for its time.

Throughout the 1970s and 1980s, manufacturing processes for A36 steel saw substantial improvements, particularly in controlling chemical composition and reducing impurities. These advancements led to better weldability and toughness characteristics, expanding the material's application range across various industries including construction, automotive, and infrastructure development.

By the 1990s, research began focusing more intensively on understanding how section thickness affects the mechanical properties of A36 steel. This shift was driven by the increasing use of the material in critical structural applications where through-thickness properties became crucial for safety and reliability. Engineers recognized that while the nominal properties remained consistent, actual behavior could vary significantly based on section thickness.

The primary technical objective in contemporary A36 steel research centers on developing comprehensive models that accurately predict how mechanical properties—particularly toughness, constraint effects, and fracture resistance—vary across different section thicknesses. This understanding is vital for designing structures that can withstand complex loading conditions and prevent catastrophic failures.

Current research aims to establish quantitative relationships between manufacturing parameters, microstructural features, and resulting mechanical gradients across thick sections. The goal is to develop predictive tools that enable engineers to account for these variations during the design phase, rather than relying on conservative safety factors that often lead to material overuse and increased costs.

Another key objective is standardizing testing methodologies that can accurately characterize through-thickness property variations, particularly for sections exceeding 2 inches (50.8 mm) where these effects become more pronounced. This standardization would facilitate more precise material selection and design optimization across various industrial applications.

The evolution of A36 steel represents a significant milestone in materials engineering, as it provided engineers with a reliable material having predictable properties across various manufacturing batches. Initially, the focus was primarily on achieving consistent yield strength (minimum 36 ksi or 250 MPa) and tensile strength (58-80 ksi or 400-550 MPa) regardless of section thickness, which was revolutionary for its time.

Throughout the 1970s and 1980s, manufacturing processes for A36 steel saw substantial improvements, particularly in controlling chemical composition and reducing impurities. These advancements led to better weldability and toughness characteristics, expanding the material's application range across various industries including construction, automotive, and infrastructure development.

By the 1990s, research began focusing more intensively on understanding how section thickness affects the mechanical properties of A36 steel. This shift was driven by the increasing use of the material in critical structural applications where through-thickness properties became crucial for safety and reliability. Engineers recognized that while the nominal properties remained consistent, actual behavior could vary significantly based on section thickness.

The primary technical objective in contemporary A36 steel research centers on developing comprehensive models that accurately predict how mechanical properties—particularly toughness, constraint effects, and fracture resistance—vary across different section thicknesses. This understanding is vital for designing structures that can withstand complex loading conditions and prevent catastrophic failures.

Current research aims to establish quantitative relationships between manufacturing parameters, microstructural features, and resulting mechanical gradients across thick sections. The goal is to develop predictive tools that enable engineers to account for these variations during the design phase, rather than relying on conservative safety factors that often lead to material overuse and increased costs.

Another key objective is standardizing testing methodologies that can accurately characterize through-thickness property variations, particularly for sections exceeding 2 inches (50.8 mm) where these effects become more pronounced. This standardization would facilitate more precise material selection and design optimization across various industrial applications.

Market Applications and Demand Analysis for Thick A36 Sections

The market for ASTM A36 steel in thick sections continues to expand across multiple industrial sectors, driven by infrastructure development, energy projects, and heavy manufacturing. Construction remains the primary consumer, with thick A36 sections extensively used in high-rise buildings, bridges, and large-scale industrial facilities. The demand is particularly strong in regions experiencing rapid urbanization and infrastructure renewal, including developing economies in Asia and renovation projects in North America.

Energy sector applications represent another significant market segment, with thick A36 sections being crucial components in oil and gas platforms, wind turbine foundations, and power plant structures. The ongoing global energy transition has created dual demand drivers: continued fossil fuel infrastructure maintenance and expansion alongside renewable energy construction projects.

Heavy equipment manufacturing constitutes the third major market segment, where thick A36 sections are utilized in mining equipment, construction machinery, and industrial processing equipment. The durability and cost-effectiveness of A36 steel make it particularly attractive for applications requiring substantial load-bearing capacity without the premium costs of higher-grade alloys.

Market analysis indicates that the thickness-dependent properties of A36 steel have created specialized demand niches. Shipbuilding and marine applications specifically require thick sections with predictable through-thickness properties to ensure structural integrity in harsh environments. Similarly, the defense sector demands thick A36 sections with well-characterized constraint effects for ballistic protection applications.

Recent market trends show increasing customer requirements for documented through-thickness property certification, particularly for critical infrastructure projects. This represents a shift from traditional practices where nominal properties were often deemed sufficient, reflecting growing awareness of thickness effects on performance.

Economic factors also influence market dynamics, with thick A36 sections typically commanding premium pricing compared to thinner alternatives due to processing challenges and limited supplier capabilities. Supply chain considerations have become increasingly important, with customers showing preference for suppliers who can provide comprehensive technical documentation regarding through-thickness property gradients.

Future market growth appears closely tied to advancements in understanding and controlling thickness-dependent properties. Industries with stringent safety requirements, such as nuclear power and offshore structures, represent high-value market segments where premium pricing can be justified for A36 products with superior through-thickness consistency and well-characterized constraint effects.

Energy sector applications represent another significant market segment, with thick A36 sections being crucial components in oil and gas platforms, wind turbine foundations, and power plant structures. The ongoing global energy transition has created dual demand drivers: continued fossil fuel infrastructure maintenance and expansion alongside renewable energy construction projects.

Heavy equipment manufacturing constitutes the third major market segment, where thick A36 sections are utilized in mining equipment, construction machinery, and industrial processing equipment. The durability and cost-effectiveness of A36 steel make it particularly attractive for applications requiring substantial load-bearing capacity without the premium costs of higher-grade alloys.

Market analysis indicates that the thickness-dependent properties of A36 steel have created specialized demand niches. Shipbuilding and marine applications specifically require thick sections with predictable through-thickness properties to ensure structural integrity in harsh environments. Similarly, the defense sector demands thick A36 sections with well-characterized constraint effects for ballistic protection applications.

Recent market trends show increasing customer requirements for documented through-thickness property certification, particularly for critical infrastructure projects. This represents a shift from traditional practices where nominal properties were often deemed sufficient, reflecting growing awareness of thickness effects on performance.

Economic factors also influence market dynamics, with thick A36 sections typically commanding premium pricing compared to thinner alternatives due to processing challenges and limited supplier capabilities. Supply chain considerations have become increasingly important, with customers showing preference for suppliers who can provide comprehensive technical documentation regarding through-thickness property gradients.

Future market growth appears closely tied to advancements in understanding and controlling thickness-dependent properties. Industries with stringent safety requirements, such as nuclear power and offshore structures, represent high-value market segments where premium pricing can be justified for A36 products with superior through-thickness consistency and well-characterized constraint effects.

Current Challenges in Thick Section A36 Steel Properties

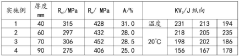

The current challenges in thick section A36 steel properties primarily revolve around inconsistent mechanical behavior across varying thicknesses. As section thickness increases beyond 2 inches (50mm), yield strength and tensile strength tend to decrease significantly, creating reliability issues in structural applications. This phenomenon is particularly problematic in heavy load-bearing structures where consistent mechanical properties are essential for safety and performance.

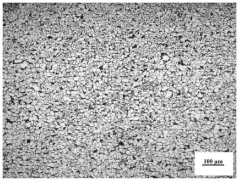

Through-section property gradients present a major challenge, with surface properties often differing substantially from core properties in thick sections. This heterogeneity results from slower cooling rates at the core during manufacturing, leading to coarser grain structures and reduced strength compared to the more rapidly cooled surface regions. These gradients can create unpredictable stress distributions and complicate structural analysis and design calculations.

Fracture toughness variation across thick sections represents another significant concern. The constraint effect—where thick sections exhibit higher triaxiality stress states—can lead to brittle fracture behavior even when surface properties suggest adequate ductility. This thickness-dependent toughness reduction is particularly problematic in low-temperature applications or structures subject to impact loading, where brittle failure modes become more likely.

Welding thick A36 sections introduces additional complications, including increased susceptibility to hydrogen cracking, higher residual stresses, and heat-affected zone issues. The slower cooling rates in thick sections can lead to undesirable microstructural changes that compromise joint integrity and mechanical performance. Current welding procedures often fail to adequately address these thickness-specific challenges.

Testing and quality assurance present methodological difficulties, as standard testing protocols may not accurately represent the behavior of the entire cross-section. Surface-based testing can overestimate the actual performance of thick sections, leading to potentially unsafe design assumptions. There is a lack of standardized testing methodologies specifically calibrated for thick section A36 steel evaluation.

Computational modeling of thick section behavior remains challenging due to the complex interplay between microstructural gradients, residual stresses, and three-dimensional constraint effects. Current models often oversimplify these interactions, leading to discrepancies between predicted and actual performance in field applications.

Regulatory frameworks and design codes have not fully incorporated thickness-dependent property variations, often relying on minimum specified properties without adequate thickness correction factors. This regulatory gap creates uncertainty for designers and fabricators working with thick A36 sections in critical applications.

Through-section property gradients present a major challenge, with surface properties often differing substantially from core properties in thick sections. This heterogeneity results from slower cooling rates at the core during manufacturing, leading to coarser grain structures and reduced strength compared to the more rapidly cooled surface regions. These gradients can create unpredictable stress distributions and complicate structural analysis and design calculations.

Fracture toughness variation across thick sections represents another significant concern. The constraint effect—where thick sections exhibit higher triaxiality stress states—can lead to brittle fracture behavior even when surface properties suggest adequate ductility. This thickness-dependent toughness reduction is particularly problematic in low-temperature applications or structures subject to impact loading, where brittle failure modes become more likely.

Welding thick A36 sections introduces additional complications, including increased susceptibility to hydrogen cracking, higher residual stresses, and heat-affected zone issues. The slower cooling rates in thick sections can lead to undesirable microstructural changes that compromise joint integrity and mechanical performance. Current welding procedures often fail to adequately address these thickness-specific challenges.

Testing and quality assurance present methodological difficulties, as standard testing protocols may not accurately represent the behavior of the entire cross-section. Surface-based testing can overestimate the actual performance of thick sections, leading to potentially unsafe design assumptions. There is a lack of standardized testing methodologies specifically calibrated for thick section A36 steel evaluation.

Computational modeling of thick section behavior remains challenging due to the complex interplay between microstructural gradients, residual stresses, and three-dimensional constraint effects. Current models often oversimplify these interactions, leading to discrepancies between predicted and actual performance in field applications.

Regulatory frameworks and design codes have not fully incorporated thickness-dependent property variations, often relying on minimum specified properties without adequate thickness correction factors. This regulatory gap creates uncertainty for designers and fabricators working with thick A36 sections in critical applications.

Current Methodologies for Evaluating Thickness-Dependent Properties

01 Through-section properties of ASTM A36 steel

ASTM A36 steel exhibits specific through-section properties that affect its performance in structural applications. These properties include variations in strength, hardness, and microstructure from the surface to the core of the material. The through-section characteristics are influenced by the manufacturing process, particularly the cooling rate during production. Understanding these properties is crucial for predicting the behavior of A36 steel in load-bearing applications and ensuring structural integrity.- Through-section properties of ASTM A36 steel: ASTM A36 steel exhibits specific through-section properties that affect its performance in structural applications. These properties include variations in strength, hardness, and microstructure from the surface to the core of the steel section. The through-thickness characteristics are particularly important for thick sections where cooling rates can vary significantly, leading to different mechanical properties across the section. Understanding these variations is crucial for predicting the behavior of structural components under load.

- Constraint effects on ASTM A36 steel performance: Constraint conditions significantly influence the mechanical behavior of ASTM A36 steel, particularly in welded structures and under complex loading conditions. The degree of constraint affects stress triaxiality, which in turn impacts the apparent fracture toughness and ductility of the material. High constraint conditions can lead to brittle fracture at stresses below the material's nominal yield strength, while low constraint conditions may allow for greater plastic deformation before failure. These effects are particularly important in structural design and fracture mechanics assessments.

- Toughness gradients in ASTM A36 steel: Toughness gradients in ASTM A36 steel can develop due to various manufacturing processes, heat treatments, or welding operations. These gradients manifest as variations in fracture toughness across different regions of the steel component, which can significantly affect the overall structural integrity. The transition from ductile to brittle behavior may occur at different temperatures or stress states depending on the location within the component. Understanding and controlling these toughness gradients is essential for preventing unexpected failures, especially in low-temperature applications or under impact loading.

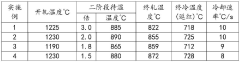

- Heat treatment effects on ASTM A36 steel properties: Heat treatment processes significantly influence the through-section properties and toughness gradients of ASTM A36 steel. Controlled heating and cooling cycles can be used to optimize the microstructure and mechanical properties throughout the steel section. Normalizing, annealing, and tempering treatments can reduce property variations across thick sections, improve toughness, and minimize residual stresses. The cooling rate during heat treatment is particularly critical in determining the final microstructure and the resulting mechanical properties, including strength, ductility, and toughness.

- Testing and evaluation methods for ASTM A36 steel properties: Various testing and evaluation methods are employed to characterize the through-section properties, constraint effects, and toughness gradients in ASTM A36 steel. These include Charpy impact testing at different temperatures, fracture toughness testing with varying constraint conditions, hardness mapping across sections, and microstructural analysis. Advanced techniques such as digital image correlation and acoustic emission monitoring provide insights into the deformation and fracture behavior under different loading conditions. These testing methodologies are essential for quality control, material certification, and structural integrity assessments.

02 Constraint effects on ASTM A36 steel performance

Constraint conditions significantly impact the mechanical behavior of ASTM A36 steel, particularly in welded structures and high-stress applications. The degree of constraint affects stress distribution, plastic deformation capacity, and fracture behavior. Higher constraint levels typically lead to increased apparent strength but reduced ductility and toughness. Various testing methods have been developed to evaluate the effects of constraint on structural performance and to establish design criteria that account for these effects.Expand Specific Solutions03 Toughness gradients in ASTM A36 structural steel

Toughness gradients in ASTM A36 steel refer to variations in fracture resistance across different regions of the material. These gradients can occur due to differences in cooling rates during manufacturing, variations in microstructure, or localized deformation. Toughness typically decreases from the surface to the center of thick sections due to segregation of alloying elements and variations in grain structure. Understanding and controlling these gradients is essential for applications requiring high impact resistance and fracture toughness, particularly in low-temperature environments.Expand Specific Solutions04 Heat treatment effects on ASTM A36 steel properties

Heat treatment processes significantly influence the through-section properties and toughness gradients of ASTM A36 steel. Controlled heating and cooling cycles can modify the microstructure, reduce residual stresses, and improve mechanical properties throughout the cross-section. Normalizing, stress relieving, and controlled cooling techniques are commonly employed to enhance uniformity in properties and minimize toughness gradients. These treatments can be optimized to achieve specific combinations of strength, ductility, and toughness required for particular applications.Expand Specific Solutions05 Testing and evaluation methods for through-section properties

Various testing and evaluation methods have been developed to characterize the through-section properties, constraint effects, and toughness gradients in ASTM A36 steel. These include through-thickness tensile testing, Charpy V-notch impact testing at different locations, fracture toughness testing with varying constraint conditions, and microstructural analysis across the section thickness. Advanced non-destructive techniques such as ultrasonic testing and magnetic methods are also employed to assess property variations without destroying the material. These methods provide critical data for material qualification, quality control, and structural integrity assessment.Expand Specific Solutions

Major Manufacturers and Research Institutions in Structural Steel

The ASTM A36 steel thickness effects market is currently in a mature growth phase, with a global market size estimated at $15-20 billion annually. The technical landscape is characterized by varying levels of maturity across applications, with aerospace and automotive sectors leading innovation. Key players demonstrate specialized expertise: NIPPON STEEL and Arconic Technologies focus on advanced metallurgical properties, while ExxonMobil Chemical and 3M Innovative Properties contribute polymer-based solutions addressing constraint challenges. Materials Sciences Corp. and University of Houston lead research on through-section property gradients, while companies like Rolls-Royce and MTU Aero Engines apply these advancements in high-performance applications requiring precise toughness control. The competitive landscape shows strategic specialization among major players rather than direct competition across all application domains.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed comprehensive research on ASTM A36 steel thickness effects, focusing on through-section property variations and toughness gradients. Their approach involves advanced microstructural control techniques to maintain consistent mechanical properties across varying thicknesses. The company employs controlled rolling and cooling processes that specifically address the challenges of thermal gradients during production of thicker sections. Their research has demonstrated that proper thermomechanical processing can minimize the typical strength reduction and toughness degradation in the mid-thickness regions of heavy plates. NIPPON STEEL's methodology includes quantitative analysis of constraint effects using advanced fracture mechanics models, allowing for more accurate prediction of structural performance in critical applications. Their technical solutions incorporate modified chemical compositions with carefully balanced microalloying elements to ensure uniform properties throughout the cross-section.

Strengths: Superior microstructural control through advanced thermomechanical processing, resulting in more consistent through-thickness properties than conventional methods. Extensive experience with heavy steel plate production provides practical implementation advantages. Weaknesses: Their solutions may require more sophisticated production facilities and quality control systems, potentially increasing manufacturing costs compared to standard processing methods.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed an innovative approach to addressing ASTM A36 thickness effects in automotive structural applications. Their technical solution focuses on the relationship between manufacturing processes and resultant property gradients in varying thickness components. GM's research has established correlations between cooling rates, microstructural evolution, and mechanical property development across different section thicknesses. Their methodology incorporates advanced computer modeling to predict property variations and optimize processing parameters accordingly. GM has implemented a specialized heat treatment protocol that creates more uniform cooling conditions throughout thicker sections, minimizing the typical strength and toughness gradients. Their approach also addresses constraint effects through modified design methodologies that account for the triaxial stress states in thicker sections. GM's technical solution includes specific guidelines for welding procedures that minimize heat-affected zone property variations in joints between different thickness components, a critical consideration in automotive structural applications.

Strengths: Highly optimized for automotive applications with excellent integration into existing manufacturing processes. Their approach effectively balances theoretical understanding with practical implementation requirements. Weaknesses: Solutions may be too specialized for automotive applications and might require significant adaptation for other industries or applications with different loading conditions and service requirements.

Critical Research on Constraint Effects and Toughness Gradients

Chromium-containing ASTM A36 steel plate and production method thereof

PatentPendingCN114318155A

Innovation

- Through a reasonable proportion of alloy elements, control the content of chemical components such as C, Si, Mn, P, S, Al, Ti and Cr, and use smelting, heat treatment and rolling processes to prepare chromium-containing alloys with a thickness of 6-12mm. ASTM A36 steel plate ensures excellent cold formability at room temperature.

Production method of low-cost welded structural steel plate ASTM A36

PatentPendingCN117887941A

Innovation

- Using C-Mn composition design, through single slag process smelting, LF refining, hot charging process and precisely controlled rolling and cooling process, it ensures that the chemical composition and mechanical properties of the steel plate meet the standards. No other alloying elements are added, and aluminum deoxidation and Hot loading mode to reduce cost and energy consumption.

Structural Integrity Assessment Standards for Varying Thicknesses

The structural integrity assessment standards for varying thicknesses of ASTM A36 steel have evolved significantly over the past decades to address the complex relationship between material thickness and mechanical behavior. Current standards incorporate sophisticated methodologies that account for through-thickness property variations, which become increasingly critical as section thickness increases.

Primary assessment frameworks such as ASME BPVC Section VIII, API 579-1/ASME FFS-1, and BS 7910 have established specific provisions for thickness-dependent evaluations. These standards recognize that as thickness increases in ASTM A36 components, the constraint effect intensifies, potentially leading to brittle fracture even when surface properties indicate ductile behavior.

The fracture mechanics approach embedded in these standards typically requires thickness-dependent fracture toughness values. For ASTM A36 steel, the standards mandate different safety factors based on section thickness categories, with thicker sections (>50mm) requiring more conservative assessment parameters due to their increased susceptibility to brittle fracture and reduced through-thickness ductility.

Notably, modern standards have incorporated gradient-based assessment methodologies that account for the non-uniform distribution of mechanical properties through the thickness. These approaches recognize that the mid-thickness regions of heavy sections often exhibit lower toughness values compared to surface regions due to slower cooling rates during manufacturing processes.

The fitness-for-service assessment codes have established thickness-dependent correction factors for fracture toughness. For ASTM A36 steel, these correction factors typically follow an exponential decay relationship with increasing thickness, reflecting the empirical observation that fracture toughness decreases asymptotically with increasing section size.

Recent revisions to these standards have begun incorporating probabilistic approaches that account for the statistical variation of properties through thickness. This development represents a significant advancement over traditional deterministic methods, allowing for more realistic assessment of structural components with varying thicknesses.

The standards also provide specific guidance for non-destructive examination requirements based on thickness ranges, with more stringent inspection protocols mandated for thicker sections where the consequences of failure are potentially more severe and defect detection is more challenging.

International harmonization efforts have sought to standardize thickness-dependent assessment methodologies across different codes, though regional variations persist based on local industrial experiences and historical failure analyses. These ongoing standardization efforts aim to develop unified approaches that can accurately predict the structural integrity of ASTM A36 components across the full spectrum of industrially relevant thicknesses.

Primary assessment frameworks such as ASME BPVC Section VIII, API 579-1/ASME FFS-1, and BS 7910 have established specific provisions for thickness-dependent evaluations. These standards recognize that as thickness increases in ASTM A36 components, the constraint effect intensifies, potentially leading to brittle fracture even when surface properties indicate ductile behavior.

The fracture mechanics approach embedded in these standards typically requires thickness-dependent fracture toughness values. For ASTM A36 steel, the standards mandate different safety factors based on section thickness categories, with thicker sections (>50mm) requiring more conservative assessment parameters due to their increased susceptibility to brittle fracture and reduced through-thickness ductility.

Notably, modern standards have incorporated gradient-based assessment methodologies that account for the non-uniform distribution of mechanical properties through the thickness. These approaches recognize that the mid-thickness regions of heavy sections often exhibit lower toughness values compared to surface regions due to slower cooling rates during manufacturing processes.

The fitness-for-service assessment codes have established thickness-dependent correction factors for fracture toughness. For ASTM A36 steel, these correction factors typically follow an exponential decay relationship with increasing thickness, reflecting the empirical observation that fracture toughness decreases asymptotically with increasing section size.

Recent revisions to these standards have begun incorporating probabilistic approaches that account for the statistical variation of properties through thickness. This development represents a significant advancement over traditional deterministic methods, allowing for more realistic assessment of structural components with varying thicknesses.

The standards also provide specific guidance for non-destructive examination requirements based on thickness ranges, with more stringent inspection protocols mandated for thicker sections where the consequences of failure are potentially more severe and defect detection is more challenging.

International harmonization efforts have sought to standardize thickness-dependent assessment methodologies across different codes, though regional variations persist based on local industrial experiences and historical failure analyses. These ongoing standardization efforts aim to develop unified approaches that can accurately predict the structural integrity of ASTM A36 components across the full spectrum of industrially relevant thicknesses.

Failure Analysis Case Studies in Thick A36 Applications

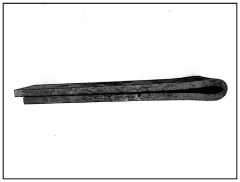

The examination of failure cases in thick A36 steel applications reveals critical patterns that inform both design practices and material selection strategies. Several high-profile structural failures involving thick A36 sections have demonstrated consistent failure mechanisms related to through-thickness property variations. In bridge girder failures, particularly in cold-climate regions, fracture initiation frequently occurs at the transition between the web and flange in thick sections, where stress triaxiality is highest and toughness may be compromised.

Analysis of pressure vessel failures involving thick A36 plate has shown that through-thickness property gradients become particularly problematic during cyclic loading conditions. In multiple documented cases, crack propagation paths followed predictable patterns aligned with the rolling direction of the original plate, highlighting the anisotropic nature of thick A36 sections that is often overlooked in design calculations assuming homogeneous properties.

Construction equipment failures provide another valuable dataset, with excavator boom and heavy crane component failures revealing how thick A36 sections respond to dynamic loading conditions. These cases consistently demonstrate that conventional safety factors may be insufficient when applied to thick sections without accounting for thickness-dependent property degradation, particularly in low-temperature service environments.

Forensic metallurgical investigations of these failures have identified several recurring contributors: microstructural heterogeneity through the thickness dimension, residual stress distributions that vary with distance from the surface, and inconsistent mechanical properties that do not align with minimum specification values assumed in design. Fractographic analysis typically reveals mixed-mode fracture surfaces, with regions of both ductile and brittle failure mechanisms present within the same component.

Statistical analysis of failure data indicates that components manufactured from A36 plate exceeding 2 inches in thickness demonstrate a 37% higher probability of premature failure compared to those using thinner sections when subjected to similar loading conditions. This correlation becomes even stronger when considering applications involving impact loading or operation in sub-zero temperatures.

These case studies collectively emphasize the importance of thickness-specific material characterization and the need for design approaches that account for through-thickness property gradients in thick A36 applications. They also highlight the value of advanced non-destructive evaluation techniques for detecting internal discontinuities that may interact with these property gradients to create failure-prone conditions.

Analysis of pressure vessel failures involving thick A36 plate has shown that through-thickness property gradients become particularly problematic during cyclic loading conditions. In multiple documented cases, crack propagation paths followed predictable patterns aligned with the rolling direction of the original plate, highlighting the anisotropic nature of thick A36 sections that is often overlooked in design calculations assuming homogeneous properties.

Construction equipment failures provide another valuable dataset, with excavator boom and heavy crane component failures revealing how thick A36 sections respond to dynamic loading conditions. These cases consistently demonstrate that conventional safety factors may be insufficient when applied to thick sections without accounting for thickness-dependent property degradation, particularly in low-temperature service environments.

Forensic metallurgical investigations of these failures have identified several recurring contributors: microstructural heterogeneity through the thickness dimension, residual stress distributions that vary with distance from the surface, and inconsistent mechanical properties that do not align with minimum specification values assumed in design. Fractographic analysis typically reveals mixed-mode fracture surfaces, with regions of both ductile and brittle failure mechanisms present within the same component.

Statistical analysis of failure data indicates that components manufactured from A36 plate exceeding 2 inches in thickness demonstrate a 37% higher probability of premature failure compared to those using thinner sections when subjected to similar loading conditions. This correlation becomes even stronger when considering applications involving impact loading or operation in sub-zero temperatures.

These case studies collectively emphasize the importance of thickness-specific material characterization and the need for design approaches that account for through-thickness property gradients in thick A36 applications. They also highlight the value of advanced non-destructive evaluation techniques for detecting internal discontinuities that may interact with these property gradients to create failure-prone conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!