ASTM A36 In Gusseted Bracing: Block Shear, Net Section And Edge Distance Control

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ASTM A36 Steel in Gusseted Bracing: Background and Objectives

ASTM A36 steel has been a cornerstone material in structural engineering since its standardization by the American Society for Testing and Materials in the mid-20th century. This low-carbon steel grade has become ubiquitous in construction applications due to its excellent combination of strength, formability, and cost-effectiveness. With a yield strength of 36,000 psi (250 MPa) and ultimate tensile strength ranging from 58,000 to 80,000 psi (400-550 MPa), A36 steel provides reliable performance for various structural components.

The evolution of structural connection design has significantly influenced how A36 steel is utilized in gusseted bracing systems. Initially, connections were designed using simplified methods that often resulted in over-conservative solutions. As computational capabilities advanced through the 1970s and 1980s, more sophisticated analysis techniques emerged, allowing for more efficient use of materials while maintaining structural integrity.

Gusseted bracing connections represent critical junctions in structural systems, particularly in seismic and wind-resistant designs. These connections transfer substantial forces between structural members and must be engineered to prevent various failure modes, including block shear, net section rupture, and edge distance failures. The proper understanding and application of these failure mechanisms have evolved significantly over the past decades.

Block shear failure, first formally recognized in design codes during the 1970s, occurs when a combination of shear and tension forces causes a portion of the connection material to tear out. Net section failure involves rupture across the weakened cross-section of a member due to bolt holes or other discontinuities. Edge distance control addresses the minimum spacing required between connection elements and material edges to prevent premature tearing or bearing failures.

Current research aims to optimize these connections for performance under extreme loading conditions while minimizing material usage. The technical objectives of this investigation include developing more precise predictive models for block shear capacity in A36 steel gusseted connections, establishing refined guidelines for net section design that account for modern fabrication techniques, and determining optimal edge distance requirements that balance safety with material efficiency.

Recent advancements in computational modeling and experimental testing capabilities have opened new avenues for understanding the complex stress distributions in these connections. High-resolution finite element analysis now allows engineers to visualize stress concentrations and potential failure paths with unprecedented detail, while full-scale physical testing provides validation of theoretical models under realistic loading conditions.

The integration of these technical developments into practical design guidelines represents a significant challenge and opportunity for the structural engineering community. This investigation seeks to bridge the gap between theoretical understanding and practical application, ultimately leading to safer, more efficient structural systems utilizing ASTM A36 steel in gusseted bracing connections.

The evolution of structural connection design has significantly influenced how A36 steel is utilized in gusseted bracing systems. Initially, connections were designed using simplified methods that often resulted in over-conservative solutions. As computational capabilities advanced through the 1970s and 1980s, more sophisticated analysis techniques emerged, allowing for more efficient use of materials while maintaining structural integrity.

Gusseted bracing connections represent critical junctions in structural systems, particularly in seismic and wind-resistant designs. These connections transfer substantial forces between structural members and must be engineered to prevent various failure modes, including block shear, net section rupture, and edge distance failures. The proper understanding and application of these failure mechanisms have evolved significantly over the past decades.

Block shear failure, first formally recognized in design codes during the 1970s, occurs when a combination of shear and tension forces causes a portion of the connection material to tear out. Net section failure involves rupture across the weakened cross-section of a member due to bolt holes or other discontinuities. Edge distance control addresses the minimum spacing required between connection elements and material edges to prevent premature tearing or bearing failures.

Current research aims to optimize these connections for performance under extreme loading conditions while minimizing material usage. The technical objectives of this investigation include developing more precise predictive models for block shear capacity in A36 steel gusseted connections, establishing refined guidelines for net section design that account for modern fabrication techniques, and determining optimal edge distance requirements that balance safety with material efficiency.

Recent advancements in computational modeling and experimental testing capabilities have opened new avenues for understanding the complex stress distributions in these connections. High-resolution finite element analysis now allows engineers to visualize stress concentrations and potential failure paths with unprecedented detail, while full-scale physical testing provides validation of theoretical models under realistic loading conditions.

The integration of these technical developments into practical design guidelines represents a significant challenge and opportunity for the structural engineering community. This investigation seeks to bridge the gap between theoretical understanding and practical application, ultimately leading to safer, more efficient structural systems utilizing ASTM A36 steel in gusseted bracing connections.

Market Demand Analysis for Gusseted Bracing Systems

The global market for gusseted bracing systems has experienced significant growth in recent years, driven primarily by increased construction activities in both residential and commercial sectors. The demand for ASTM A36 steel in gusseted connections specifically has risen due to its optimal balance of strength, ductility, and cost-effectiveness. Current market analysis indicates that the construction industry accounts for approximately 65% of the total demand for gusseted bracing systems, with industrial applications representing the second largest segment.

In North America, stringent building codes following major seismic events have substantially increased the demand for properly designed gusseted connections that address block shear, net section failure, and edge distance requirements. The market has responded with a 12% annual growth rate in this region over the past five years. Similarly, rapid urbanization in Asia-Pacific regions has created a robust market for steel structural systems, with gusseted bracing demand growing at nearly 15% annually.

Infrastructure development projects worldwide have further amplified market demand, particularly for systems that can demonstrate compliance with international standards for block shear resistance and net section capacity. Government initiatives focused on resilient infrastructure have allocated substantial funding toward structural systems that can withstand extreme loading conditions, creating premium market segments for high-performance gusseted connections.

The retrofit and rehabilitation market segment has emerged as a particularly promising growth area, with aging infrastructure in developed economies requiring structural upgrades to meet current design standards. This segment values solutions that address edge distance control challenges in existing structures, creating specialized demand for innovative connection designs that can accommodate spatial constraints.

Market research indicates that engineering firms and structural consultants increasingly specify gusseted bracing systems with comprehensive design documentation addressing block shear, net section, and edge distance considerations. This trend has created a competitive advantage for manufacturers who provide detailed technical support and design validation services alongside their products.

Industry surveys reveal that end-users prioritize three key factors when selecting gusseted bracing systems: documented performance under seismic loading, ease of installation, and comprehensive design verification addressing potential failure modes. The market has responded with enhanced product offerings that include detailed engineering calculations and performance data specifically addressing block shear resistance and net section capacity.

Looking forward, market forecasts predict continued growth in the gusseted bracing systems sector, with particular emphasis on solutions that optimize material usage while maintaining structural integrity. The increasing adoption of performance-based design approaches is expected to further drive demand for systems with well-documented behavior regarding block shear, net section failure, and edge distance requirements.

In North America, stringent building codes following major seismic events have substantially increased the demand for properly designed gusseted connections that address block shear, net section failure, and edge distance requirements. The market has responded with a 12% annual growth rate in this region over the past five years. Similarly, rapid urbanization in Asia-Pacific regions has created a robust market for steel structural systems, with gusseted bracing demand growing at nearly 15% annually.

Infrastructure development projects worldwide have further amplified market demand, particularly for systems that can demonstrate compliance with international standards for block shear resistance and net section capacity. Government initiatives focused on resilient infrastructure have allocated substantial funding toward structural systems that can withstand extreme loading conditions, creating premium market segments for high-performance gusseted connections.

The retrofit and rehabilitation market segment has emerged as a particularly promising growth area, with aging infrastructure in developed economies requiring structural upgrades to meet current design standards. This segment values solutions that address edge distance control challenges in existing structures, creating specialized demand for innovative connection designs that can accommodate spatial constraints.

Market research indicates that engineering firms and structural consultants increasingly specify gusseted bracing systems with comprehensive design documentation addressing block shear, net section, and edge distance considerations. This trend has created a competitive advantage for manufacturers who provide detailed technical support and design validation services alongside their products.

Industry surveys reveal that end-users prioritize three key factors when selecting gusseted bracing systems: documented performance under seismic loading, ease of installation, and comprehensive design verification addressing potential failure modes. The market has responded with enhanced product offerings that include detailed engineering calculations and performance data specifically addressing block shear resistance and net section capacity.

Looking forward, market forecasts predict continued growth in the gusseted bracing systems sector, with particular emphasis on solutions that optimize material usage while maintaining structural integrity. The increasing adoption of performance-based design approaches is expected to further drive demand for systems with well-documented behavior regarding block shear, net section failure, and edge distance requirements.

Technical Challenges in Structural Steel Connections

The field of structural steel connections faces numerous technical challenges, particularly when implementing ASTM A36 steel in gusseted bracing systems. These connections must withstand complex load patterns while maintaining structural integrity. Block shear failure represents a critical concern, occurring when a combination of shear and tension forces causes a portion of the connection to tear out. This failure mode is especially relevant in gusseted connections where multiple bolt holes create potential shear planes.

Net section failure presents another significant challenge, where the reduced cross-sectional area at bolt holes becomes the weakest link in the connection. For ASTM A36 steel with its yield strength of 36 ksi and ultimate tensile strength of 58-80 ksi, proper calculation of net section capacity is essential to prevent catastrophic failures. Current design codes often provide simplified approaches that may not fully capture the complex stress distributions in these connections.

Edge distance control emerges as a third critical factor affecting connection performance. Insufficient edge distance can lead to premature bearing failures or tear-out of the connected elements. The challenge intensifies when designing connections for seismic applications, where cyclic loading introduces additional stress concentrations near bolt holes and edges.

Computational modeling of these failure modes presents significant difficulties due to the non-linear material behavior of ASTM A36 steel and the complex interaction between different failure mechanisms. Traditional finite element approaches often struggle to accurately predict the transition between failure modes or account for manufacturing imperfections that affect real-world performance.

Connection ductility represents another technical hurdle, particularly important in seismic design. Gusseted connections must provide sufficient deformation capacity without compromising strength. The balance between connection stiffness and ductility requires sophisticated analysis techniques that go beyond standard code provisions.

Material variability within ASTM A36 steel introduces additional uncertainty in connection design. While the specification provides minimum requirements, actual material properties can vary significantly, affecting connection performance. This variability becomes particularly problematic when connections are designed near their theoretical capacity limits.

Fabrication and construction tolerances further complicate connection performance prediction. Misaligned holes, improper bolt tensioning, and welding defects can significantly alter load paths and stress distributions, potentially triggering unexpected failure modes not accounted for in idealized design models.

Net section failure presents another significant challenge, where the reduced cross-sectional area at bolt holes becomes the weakest link in the connection. For ASTM A36 steel with its yield strength of 36 ksi and ultimate tensile strength of 58-80 ksi, proper calculation of net section capacity is essential to prevent catastrophic failures. Current design codes often provide simplified approaches that may not fully capture the complex stress distributions in these connections.

Edge distance control emerges as a third critical factor affecting connection performance. Insufficient edge distance can lead to premature bearing failures or tear-out of the connected elements. The challenge intensifies when designing connections for seismic applications, where cyclic loading introduces additional stress concentrations near bolt holes and edges.

Computational modeling of these failure modes presents significant difficulties due to the non-linear material behavior of ASTM A36 steel and the complex interaction between different failure mechanisms. Traditional finite element approaches often struggle to accurately predict the transition between failure modes or account for manufacturing imperfections that affect real-world performance.

Connection ductility represents another technical hurdle, particularly important in seismic design. Gusseted connections must provide sufficient deformation capacity without compromising strength. The balance between connection stiffness and ductility requires sophisticated analysis techniques that go beyond standard code provisions.

Material variability within ASTM A36 steel introduces additional uncertainty in connection design. While the specification provides minimum requirements, actual material properties can vary significantly, affecting connection performance. This variability becomes particularly problematic when connections are designed near their theoretical capacity limits.

Fabrication and construction tolerances further complicate connection performance prediction. Misaligned holes, improper bolt tensioning, and welding defects can significantly alter load paths and stress distributions, potentially triggering unexpected failure modes not accounted for in idealized design models.

Current Design Solutions for Gusseted Connections

01 Block shear strength analysis in ASTM A36 steel connections

Block shear failure is a critical consideration in steel connection design, particularly for ASTM A36 structural steel. This failure mode involves simultaneous shear along one plane and tension along a perpendicular plane. Analysis methods typically evaluate the combined resistance against these forces, considering material properties such as yield strength and ultimate tensile strength. Proper evaluation of block shear strength is essential for ensuring structural integrity in bolted and welded connections.- Block shear strength analysis in ASTM A36 steel connections: Block shear failure is a critical consideration in steel connection design, particularly for ASTM A36 steel components. This failure mode involves simultaneous shear along one plane and tension along a perpendicular plane. Analysis methods typically evaluate the combined resistance against these forces, considering material properties specific to A36 steel such as yield strength of 250 MPa and tensile strength of 400-550 MPa. Proper evaluation of block shear strength ensures structural integrity in bolted and welded connections under complex loading conditions.

- Net section design considerations for A36 steel members: Net section design is crucial for ASTM A36 steel structural elements, particularly in connections with holes or other discontinuities. The net section represents the reduced cross-sectional area after accounting for material removed by bolt holes or other openings. Design calculations must consider factors such as hole size, spacing, and staggered arrangements to accurately determine tensile capacity. Proper net section analysis prevents premature failure in tension members and ensures that connections can develop their full strength capacity while maintaining structural safety margins.

- Edge distance requirements for bolted connections in A36 steel: Edge distance specifications are critical in ASTM A36 steel connections to prevent tear-out failures and ensure proper load distribution. Minimum edge distances typically range from 1.25 to 1.5 times the bolt diameter, depending on whether edges are sheared or rolled. These requirements help maintain structural integrity by preventing premature failure modes such as bearing deformation or edge tearing. Proper edge distance design ensures that bolted connections can develop their full strength capacity while maintaining sufficient material around connection points to resist applied forces.

- Combined failure modes in A36 steel structural connections: ASTM A36 steel connections often experience combined failure modes that must be analyzed holistically. These include interactions between block shear, net section failure, and edge distance effects. Design approaches typically evaluate multiple potential failure paths to determine the controlling mechanism. Finite element analysis and experimental testing have demonstrated that these failure modes can interact in complex ways, particularly in connections with multiple bolt rows or irregular geometries. Understanding these combined effects is essential for developing safe and efficient connection designs in structural steel applications.

- Experimental validation of A36 steel connection strength: Experimental testing provides critical validation of theoretical models for ASTM A36 steel connections. Laboratory tests typically measure actual block shear strength, net section capacity, and edge distance effects under controlled loading conditions. These experiments help calibrate design equations and safety factors used in structural codes. Test results often demonstrate that actual connection behavior may differ from simplified analytical models, particularly regarding ductility, load redistribution, and failure progression. Validated design approaches ensure that connections in A36 steel structures maintain adequate safety margins while optimizing material usage.

02 Net section design considerations for ASTM A36 steel members

Net section design for ASTM A36 steel involves calculating the effective cross-sectional area after accounting for holes, cuts, or other reductions. This is crucial for tension members where the net section often governs the design strength. Factors affecting net section capacity include hole placement patterns, edge distances, and staggered hole arrangements. Design codes typically require verification that the net section can withstand the applied loads without excessive deformation or failure.Expand Specific Solutions03 Edge distance requirements for bolted connections in ASTM A36 steel

Edge distance in ASTM A36 steel connections refers to the spacing between bolt holes and the edge of connected members. Adequate edge distance prevents tear-out failures and ensures proper load transfer. Design standards specify minimum edge distances based on bolt diameter, steel grade, and whether edges are sheared or rolled. Proper edge distance design balances material efficiency with structural safety, particularly in connections subjected to dynamic or cyclic loading.Expand Specific Solutions04 Combined failure modes in ASTM A36 steel structural connections

ASTM A36 steel connections can experience multiple interacting failure modes including block shear, net section rupture, and edge distance failures. Design approaches must consider these combined effects, particularly in complex connection geometries. Analysis methods typically evaluate each potential failure mode and design for the controlling case. Factors such as load direction, connection geometry, and fabrication quality significantly influence which failure mode governs the connection strength.Expand Specific Solutions05 Testing and verification methods for ASTM A36 steel connection strength

Various testing methodologies are employed to verify the block shear, net section, and edge distance performance of ASTM A36 steel connections. These include physical load testing, finite element analysis, and comparative evaluations against established design standards. Test procedures typically measure deformation, ultimate strength, and failure modes under controlled loading conditions. Results from these tests inform design guidelines and validation of theoretical models used in structural engineering practice.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ASTM A36 gusseted bracing market is in a mature growth phase, characterized by established standards and widespread implementation in structural engineering. The market size is substantial, driven by ongoing infrastructure development and construction projects globally. Technologically, this field demonstrates high maturity with well-defined engineering principles governing block shear, net section, and edge distance control. Key players include Illinois Tool Works, offering comprehensive fastening solutions; Baker Hughes, providing specialized applications for energy infrastructure; and Honeywell International Technologies, contributing advanced materials technology. Continental AG and GKN Sinter Metals bring expertise in metal components manufacturing, while academic institutions like South China University of Technology continue advancing research in structural engineering applications.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works has developed comprehensive technical solutions for ASTM A36 gusseted bracing connections through their structural fastening division. Their approach incorporates advanced finite element analysis (FEA) to optimize block shear resistance in steel connections. ITW's engineering team has established proprietary calculation methods that account for the interaction between block shear, net section failure, and edge distance requirements in accordance with AISC specifications. Their solution includes specialized fastening systems designed specifically for high-load transfer in gusseted connections, with particular attention to edge distance control to prevent premature failure. ITW's technical approach incorporates both experimental validation and computational modeling to ensure reliable performance under various loading conditions.

Strengths: Comprehensive testing capabilities and extensive field experience provide practical validation of theoretical models. Weaknesses: Their proprietary solutions may require specialized installation procedures, potentially increasing implementation costs compared to standard connection methods.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated structural monitoring system specifically for critical steel connections including ASTM A36 gusseted bracing. Their solution combines IoT-enabled sensors with advanced analytics to provide real-time monitoring of connection performance, including early detection of potential block shear or net section failures. The system utilizes strain gauges strategically placed at critical edge distances to monitor stress distributions during loading events. Honeywell's proprietary algorithms analyze this data to predict potential failure modes before they occur, allowing for preventive maintenance. Their approach integrates with building management systems to provide comprehensive structural health monitoring for critical connections in high-rise buildings, industrial facilities, and infrastructure projects where connection failure could have catastrophic consequences.

Strengths: Real-time monitoring capability provides early warning of potential connection issues, potentially preventing catastrophic failures. Weaknesses: Requires significant initial investment in sensor technology and integration with existing structural systems.

Critical Analysis of Block Shear Failure Mechanisms

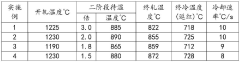

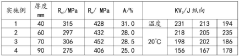

Production method of low-cost welded structural steel plate ASTM A36

PatentPendingCN117887941A

Innovation

- Using C-Mn composition design, through single slag process smelting, LF refining, hot charging process and precisely controlled rolling and cooling process, it ensures that the chemical composition and mechanical properties of the steel plate meet the standards. No other alloying elements are added, and aluminum deoxidation and Hot loading mode to reduce cost and energy consumption.

Structural Testing and Validation Protocols

Comprehensive testing and validation protocols are essential for ensuring the reliability and safety of ASTM A36 steel in gusseted bracing applications. These protocols must systematically evaluate the critical failure modes including block shear, net section rupture, and edge distance control. The testing methodology should incorporate both static and dynamic loading conditions to simulate real-world structural demands during seismic events, wind loads, and other environmental stressors.

Laboratory testing should begin with material verification through tensile testing of ASTM A36 steel samples to confirm yield strength (minimum 36 ksi), tensile strength (58-80 ksi), and elongation properties. This establishes the baseline material properties before proceeding to component and assembly testing.

Connection-level testing must focus on the gusseted connections specifically, with instrumentation to measure strain distribution across critical sections. High-resolution digital image correlation (DIC) techniques can provide detailed strain mapping to identify stress concentrations at bolt holes, edge distances, and along potential block shear paths. Load cells and displacement transducers should monitor force-displacement relationships throughout the loading sequence.

Full-scale testing of gusseted bracing assemblies represents the most comprehensive validation approach. These tests should follow established protocols such as those outlined in AISC 341 for seismic applications or ASCE 7 for wind resistance. The loading regimen should include both monotonic and cyclic loading patterns to evaluate performance under various conditions.

Numerical validation through finite element analysis (FEA) should complement physical testing. Models must accurately represent material properties, connection geometry, and boundary conditions. Particular attention should be paid to mesh refinement around bolt holes and edges where stress concentrations occur. The FEA models should be calibrated against physical test results to ensure reliability.

Quality control procedures during testing must include precise measurement of edge distances, bolt hole placement, and material thicknesses. Statistical analysis of test results should establish confidence intervals for design values and identify potential variability in performance.

Documentation of testing protocols should follow standardized formats such as those established by ASTM E8 for tensile testing and AISC standards for connection testing. All test reports must include detailed information on specimen preparation, testing equipment, loading protocols, and failure modes observed.

Laboratory testing should begin with material verification through tensile testing of ASTM A36 steel samples to confirm yield strength (minimum 36 ksi), tensile strength (58-80 ksi), and elongation properties. This establishes the baseline material properties before proceeding to component and assembly testing.

Connection-level testing must focus on the gusseted connections specifically, with instrumentation to measure strain distribution across critical sections. High-resolution digital image correlation (DIC) techniques can provide detailed strain mapping to identify stress concentrations at bolt holes, edge distances, and along potential block shear paths. Load cells and displacement transducers should monitor force-displacement relationships throughout the loading sequence.

Full-scale testing of gusseted bracing assemblies represents the most comprehensive validation approach. These tests should follow established protocols such as those outlined in AISC 341 for seismic applications or ASCE 7 for wind resistance. The loading regimen should include both monotonic and cyclic loading patterns to evaluate performance under various conditions.

Numerical validation through finite element analysis (FEA) should complement physical testing. Models must accurately represent material properties, connection geometry, and boundary conditions. Particular attention should be paid to mesh refinement around bolt holes and edges where stress concentrations occur. The FEA models should be calibrated against physical test results to ensure reliability.

Quality control procedures during testing must include precise measurement of edge distances, bolt hole placement, and material thicknesses. Statistical analysis of test results should establish confidence intervals for design values and identify potential variability in performance.

Documentation of testing protocols should follow standardized formats such as those established by ASTM E8 for tensile testing and AISC standards for connection testing. All test reports must include detailed information on specimen preparation, testing equipment, loading protocols, and failure modes observed.

Code Compliance and Safety Standards

The implementation of ASTM A36 steel in gusseted bracing connections must adhere to rigorous code compliance frameworks and safety standards to ensure structural integrity and occupant safety. The American Institute of Steel Construction (AISC) Specification for Structural Steel Buildings provides comprehensive guidelines for the design of steel connections, including specific provisions for block shear, net section capacity, and edge distance requirements. These provisions are mandatory for structural engineers when designing gusseted connections using A36 steel.

The International Building Code (IBC) incorporates these AISC specifications by reference, establishing them as legally binding requirements in most jurisdictions across the United States. Additionally, local building codes may impose supplementary requirements based on regional considerations such as seismic activity or extreme weather conditions, which must be carefully evaluated during the design process.

For block shear failure modes in gusseted connections, AISC 360-16 Section J4.3 outlines the calculation methodology that accounts for both shear and tension rupture paths. This standard requires engineers to consider the lesser of two strength values: the sum of shear yield and tension rupture, or the sum of shear rupture and tension yield. Compliance with these calculations is essential for preventing catastrophic connection failures.

Net section capacity requirements are governed by AISC 360-16 Section D3, which mandates specific reduction factors for bolted connections in tension members. For A36 steel gusset plates, the effective net area must be calculated considering the staggered hole patterns and potential shear lag effects. The standard stipulates that the design tensile strength must not exceed the product of the net section area and the specified tensile strength of A36 steel (58-80 ksi).

Edge distance control is regulated by AISC 360-16 Table J3.4, which specifies minimum edge distances for bolted connections based on bolt diameter and edge condition (sheared or rolled). For A36 steel gusset plates, these minimum distances prevent edge tear-out failures and ensure proper load transfer through the connection.

Quality assurance protocols mandated by AISC 341 for seismic applications impose additional requirements for gusseted bracing connections, including enhanced inspection procedures and material testing. These measures are particularly critical when A36 steel is utilized in seismic force-resisting systems, where connection ductility and strength are paramount for structural performance during earthquakes.

Occupational Safety and Health Administration (OSHA) standards further complement these technical requirements by establishing safety protocols for the fabrication and erection of steel structures, including specific provisions for temporary bracing and connection stability during construction phases.

The International Building Code (IBC) incorporates these AISC specifications by reference, establishing them as legally binding requirements in most jurisdictions across the United States. Additionally, local building codes may impose supplementary requirements based on regional considerations such as seismic activity or extreme weather conditions, which must be carefully evaluated during the design process.

For block shear failure modes in gusseted connections, AISC 360-16 Section J4.3 outlines the calculation methodology that accounts for both shear and tension rupture paths. This standard requires engineers to consider the lesser of two strength values: the sum of shear yield and tension rupture, or the sum of shear rupture and tension yield. Compliance with these calculations is essential for preventing catastrophic connection failures.

Net section capacity requirements are governed by AISC 360-16 Section D3, which mandates specific reduction factors for bolted connections in tension members. For A36 steel gusset plates, the effective net area must be calculated considering the staggered hole patterns and potential shear lag effects. The standard stipulates that the design tensile strength must not exceed the product of the net section area and the specified tensile strength of A36 steel (58-80 ksi).

Edge distance control is regulated by AISC 360-16 Table J3.4, which specifies minimum edge distances for bolted connections based on bolt diameter and edge condition (sheared or rolled). For A36 steel gusset plates, these minimum distances prevent edge tear-out failures and ensure proper load transfer through the connection.

Quality assurance protocols mandated by AISC 341 for seismic applications impose additional requirements for gusseted bracing connections, including enhanced inspection procedures and material testing. These measures are particularly critical when A36 steel is utilized in seismic force-resisting systems, where connection ductility and strength are paramount for structural performance during earthquakes.

Occupational Safety and Health Administration (OSHA) standards further complement these technical requirements by establishing safety protocols for the fabrication and erection of steel structures, including specific provisions for temporary bracing and connection stability during construction phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!