Challenges in Recycling Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Recycling Background

Battery Management Systems (BMS) have become an integral part of modern energy storage solutions, particularly in electric vehicles and renewable energy systems. As the global demand for batteries continues to surge, the need for efficient recycling of BMS components has become increasingly critical. The recycling of BMS presents unique challenges due to the complex nature of these systems, which typically consist of electronic components, sensors, and control units integrated with the battery pack.

The background of BMS recycling is rooted in the broader context of electronic waste management and the circular economy. As the world transitions towards cleaner energy sources and electrification of transportation, the volume of batteries and associated management systems reaching end-of-life is expected to grow exponentially. This trend has prompted governments, industries, and researchers to focus on developing sustainable recycling solutions for BMS.

Historically, the recycling of electronic components has primarily focused on recovering precious metals and other valuable materials. However, the recycling of BMS requires a more holistic approach due to the specialized nature of these systems and their close integration with battery cells. The evolution of BMS technology, from simple voltage monitoring to sophisticated thermal management and cell balancing systems, has further complicated the recycling process.

The importance of BMS recycling is underscored by several factors. Firstly, the materials used in BMS, including rare earth elements and precious metals, are often sourced from limited reserves and environmentally sensitive regions. Recycling these components can help reduce the demand for raw materials and mitigate the environmental impact of mining activities. Secondly, improper disposal of BMS can lead to environmental contamination due to the presence of hazardous substances in electronic components.

Moreover, the recycling of BMS aligns with global sustainability goals and circular economy principles. By recovering and reusing materials from spent BMS, the industry can reduce waste, conserve resources, and lower the overall carbon footprint of battery production. This approach also presents economic opportunities, as the recovered materials can be reintroduced into the supply chain, potentially reducing production costs and enhancing resource security.

The regulatory landscape surrounding BMS recycling is evolving, with many countries implementing extended producer responsibility (EPR) programs and setting targets for battery recycling rates. These regulations often encompass the entire battery system, including the BMS, pushing manufacturers to consider end-of-life management in their product design and business models.

As the field of BMS recycling continues to develop, researchers and industry players are exploring innovative technologies and processes to address the unique challenges posed by these systems. These efforts include the development of automated disassembly techniques, advanced sorting methods, and novel material recovery processes tailored to the specific components found in BMS.

The background of BMS recycling is rooted in the broader context of electronic waste management and the circular economy. As the world transitions towards cleaner energy sources and electrification of transportation, the volume of batteries and associated management systems reaching end-of-life is expected to grow exponentially. This trend has prompted governments, industries, and researchers to focus on developing sustainable recycling solutions for BMS.

Historically, the recycling of electronic components has primarily focused on recovering precious metals and other valuable materials. However, the recycling of BMS requires a more holistic approach due to the specialized nature of these systems and their close integration with battery cells. The evolution of BMS technology, from simple voltage monitoring to sophisticated thermal management and cell balancing systems, has further complicated the recycling process.

The importance of BMS recycling is underscored by several factors. Firstly, the materials used in BMS, including rare earth elements and precious metals, are often sourced from limited reserves and environmentally sensitive regions. Recycling these components can help reduce the demand for raw materials and mitigate the environmental impact of mining activities. Secondly, improper disposal of BMS can lead to environmental contamination due to the presence of hazardous substances in electronic components.

Moreover, the recycling of BMS aligns with global sustainability goals and circular economy principles. By recovering and reusing materials from spent BMS, the industry can reduce waste, conserve resources, and lower the overall carbon footprint of battery production. This approach also presents economic opportunities, as the recovered materials can be reintroduced into the supply chain, potentially reducing production costs and enhancing resource security.

The regulatory landscape surrounding BMS recycling is evolving, with many countries implementing extended producer responsibility (EPR) programs and setting targets for battery recycling rates. These regulations often encompass the entire battery system, including the BMS, pushing manufacturers to consider end-of-life management in their product design and business models.

As the field of BMS recycling continues to develop, researchers and industry players are exploring innovative technologies and processes to address the unique challenges posed by these systems. These efforts include the development of automated disassembly techniques, advanced sorting methods, and novel material recovery processes tailored to the specific components found in BMS.

Market Analysis

The market for recycling Battery Management Systems (BMS) is experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. As the global shift towards sustainable energy solutions accelerates, the demand for efficient and environmentally friendly battery recycling processes has become more pressing.

The EV market, in particular, is a major contributor to the growing need for BMS recycling. With the global EV sales projected to reach 26.8 million units by 2030, the volume of end-of-life batteries requiring recycling is set to surge. This trend is further amplified by the expanding energy storage sector, where large-scale battery systems are being deployed for grid stabilization and renewable energy integration.

The recycling of BMS presents both challenges and opportunities for market players. On one hand, the complexity of BMS components, including sensors, control units, and communication modules, makes the recycling process more intricate compared to traditional battery recycling. This complexity has led to a gap in the market for specialized recycling solutions tailored to BMS.

On the other hand, the valuable materials contained within BMS, such as rare earth elements and precious metals, offer a compelling economic incentive for recycling. The recovery of these materials not only reduces the environmental impact but also presents a potential revenue stream for recycling companies.

Geographically, the market for BMS recycling is most developed in regions with strong EV adoption and stringent environmental regulations. Europe, with its ambitious climate goals and circular economy initiatives, is at the forefront of BMS recycling efforts. Countries like Germany, France, and the Netherlands are investing heavily in recycling infrastructure and technologies.

In Asia, China leads the market due to its dominant position in EV production and battery manufacturing. The country's policies promoting a closed-loop battery economy have spurred significant investments in recycling capabilities. North America is also seeing growing interest in BMS recycling, driven by increasing EV sales and supportive government policies.

The market landscape is characterized by a mix of established waste management companies expanding into BMS recycling and specialized startups focusing exclusively on battery and BMS recycling technologies. Collaborations between automakers, battery manufacturers, and recycling companies are becoming more common, aiming to create efficient and scalable recycling solutions.

As the market matures, we can expect to see increased standardization of BMS designs to facilitate easier recycling, as well as the development of more advanced recycling technologies capable of handling the diverse range of BMS components. The integration of artificial intelligence and robotics in the recycling process is likely to improve efficiency and reduce costs, further driving market growth.

The EV market, in particular, is a major contributor to the growing need for BMS recycling. With the global EV sales projected to reach 26.8 million units by 2030, the volume of end-of-life batteries requiring recycling is set to surge. This trend is further amplified by the expanding energy storage sector, where large-scale battery systems are being deployed for grid stabilization and renewable energy integration.

The recycling of BMS presents both challenges and opportunities for market players. On one hand, the complexity of BMS components, including sensors, control units, and communication modules, makes the recycling process more intricate compared to traditional battery recycling. This complexity has led to a gap in the market for specialized recycling solutions tailored to BMS.

On the other hand, the valuable materials contained within BMS, such as rare earth elements and precious metals, offer a compelling economic incentive for recycling. The recovery of these materials not only reduces the environmental impact but also presents a potential revenue stream for recycling companies.

Geographically, the market for BMS recycling is most developed in regions with strong EV adoption and stringent environmental regulations. Europe, with its ambitious climate goals and circular economy initiatives, is at the forefront of BMS recycling efforts. Countries like Germany, France, and the Netherlands are investing heavily in recycling infrastructure and technologies.

In Asia, China leads the market due to its dominant position in EV production and battery manufacturing. The country's policies promoting a closed-loop battery economy have spurred significant investments in recycling capabilities. North America is also seeing growing interest in BMS recycling, driven by increasing EV sales and supportive government policies.

The market landscape is characterized by a mix of established waste management companies expanding into BMS recycling and specialized startups focusing exclusively on battery and BMS recycling technologies. Collaborations between automakers, battery manufacturers, and recycling companies are becoming more common, aiming to create efficient and scalable recycling solutions.

As the market matures, we can expect to see increased standardization of BMS designs to facilitate easier recycling, as well as the development of more advanced recycling technologies capable of handling the diverse range of BMS components. The integration of artificial intelligence and robotics in the recycling process is likely to improve efficiency and reduce costs, further driving market growth.

Technical Challenges

The recycling of Battery Management Systems (BMS) presents several significant technical challenges that hinder the widespread adoption of efficient recycling processes. One of the primary obstacles is the complex integration of BMS components within battery packs, making disassembly and separation a labor-intensive and time-consuming task. The intricate connections between sensors, control units, and battery cells often require specialized tools and expertise to safely dismantle without damaging critical components.

Another major challenge lies in the diversity of BMS designs across different manufacturers and battery types. This lack of standardization complicates the development of universal recycling processes, as each system may require a unique approach for efficient material recovery. The proprietary nature of BMS technologies further exacerbates this issue, as limited access to technical specifications can impede the development of effective recycling strategies.

The presence of hazardous materials within BMS components poses additional technical hurdles. Many BMS units contain flame retardants, adhesives, and other potentially toxic substances that require careful handling and specialized treatment during the recycling process. Ensuring worker safety and environmental protection while effectively recovering valuable materials demands advanced technological solutions and strict protocols.

Data security and privacy concerns also present significant challenges in BMS recycling. These systems often store sensitive information about battery usage patterns and vehicle performance. Developing secure methods to erase or protect this data before recycling is crucial to maintain user privacy and prevent potential misuse of information.

The rapid evolution of BMS technology further complicates recycling efforts. As new features and components are integrated into these systems, recycling processes must continuously adapt to handle emerging materials and designs. This constant evolution requires ongoing research and development to keep recycling technologies up-to-date and effective.

Achieving high-purity material recovery from BMS components is another technical challenge. The intricate mix of materials used in circuit boards, connectors, and sensors necessitates advanced separation techniques to isolate valuable elements like rare earth metals and precious metals. Developing cost-effective methods for high-purity recovery is essential for making BMS recycling economically viable.

Lastly, the challenge of scale and automation in BMS recycling processes remains significant. As the volume of end-of-life electric vehicle batteries increases, developing automated systems capable of efficiently handling large quantities of diverse BMS units becomes crucial. Balancing the need for thorough disassembly and material separation with the demands of high-throughput processing presents ongoing technical challenges for the recycling industry.

Another major challenge lies in the diversity of BMS designs across different manufacturers and battery types. This lack of standardization complicates the development of universal recycling processes, as each system may require a unique approach for efficient material recovery. The proprietary nature of BMS technologies further exacerbates this issue, as limited access to technical specifications can impede the development of effective recycling strategies.

The presence of hazardous materials within BMS components poses additional technical hurdles. Many BMS units contain flame retardants, adhesives, and other potentially toxic substances that require careful handling and specialized treatment during the recycling process. Ensuring worker safety and environmental protection while effectively recovering valuable materials demands advanced technological solutions and strict protocols.

Data security and privacy concerns also present significant challenges in BMS recycling. These systems often store sensitive information about battery usage patterns and vehicle performance. Developing secure methods to erase or protect this data before recycling is crucial to maintain user privacy and prevent potential misuse of information.

The rapid evolution of BMS technology further complicates recycling efforts. As new features and components are integrated into these systems, recycling processes must continuously adapt to handle emerging materials and designs. This constant evolution requires ongoing research and development to keep recycling technologies up-to-date and effective.

Achieving high-purity material recovery from BMS components is another technical challenge. The intricate mix of materials used in circuit boards, connectors, and sensors necessitates advanced separation techniques to isolate valuable elements like rare earth metals and precious metals. Developing cost-effective methods for high-purity recovery is essential for making BMS recycling economically viable.

Lastly, the challenge of scale and automation in BMS recycling processes remains significant. As the volume of end-of-life electric vehicle batteries increases, developing automated systems capable of efficiently handling large quantities of diverse BMS units becomes crucial. Balancing the need for thorough disassembly and material separation with the demands of high-throughput processing presents ongoing technical challenges for the recycling industry.

Current Recycling Methods

01 Battery monitoring and control systems

These systems monitor battery parameters such as voltage, current, and temperature to optimize performance and ensure safe operation. They employ advanced algorithms to estimate battery state of charge, state of health, and remaining useful life, enabling efficient energy management and prolonging battery lifespan.- Battery monitoring and control systems: These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.

- Thermal management in battery systems: Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.

- Cell balancing techniques: Cell balancing ensures that all cells in a battery pack maintain similar voltage levels, preventing overcharging or undercharging of individual cells. This can be achieved through passive or active balancing methods, improving overall battery pack performance and longevity.

- State of charge and state of health estimation: Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are crucial for optimizing battery usage, predicting remaining range in electric vehicles, and scheduling maintenance or replacement of battery packs.

- Battery management for electric vehicles: Specialized battery management systems for electric vehicles focus on optimizing range, fast charging capabilities, and integration with vehicle systems. These systems may include features like regenerative braking energy recovery, power distribution management, and driver interface for battery status information.

02 Thermal management in battery systems

Thermal management solutions are crucial for maintaining optimal battery temperature, preventing overheating, and ensuring consistent performance. These systems may include active cooling mechanisms, heat dissipation techniques, and temperature-based charging control to enhance battery efficiency and longevity.Expand Specific Solutions03 Battery balancing techniques

Battery balancing methods are employed to equalize the charge levels across multiple cells or modules in a battery pack. This ensures uniform charge distribution, prevents overcharging of individual cells, and maximizes overall battery capacity and lifespan.Expand Specific Solutions04 Intelligent charging strategies

Advanced charging algorithms and strategies are implemented to optimize charging processes, reduce charging time, and minimize battery degradation. These may include adaptive charging rates, pulse charging techniques, and charging profiles based on battery chemistry and usage patterns.Expand Specific Solutions05 Integration with energy management systems

Battery management systems are integrated with broader energy management systems to optimize energy distribution, support grid stability, and enable smart charging in electric vehicles. This integration allows for demand response, peak shaving, and efficient utilization of renewable energy sources in conjunction with battery storage.Expand Specific Solutions

Industry Players

The recycling of Battery Management Systems (BMS) presents a complex competitive landscape in an emerging industry. The market is in its early growth stage, with increasing demand driven by the rising adoption of electric vehicles and renewable energy storage systems. While the market size is expanding rapidly, it remains relatively small compared to mature industries. Technologically, BMS recycling is still evolving, with companies like Honda Motor Co., Ltd., Guangdong Bangpu Recycling Technology Co., Ltd., and Astemo Ltd. leading innovation efforts. These firms are developing advanced recycling processes and technologies to improve efficiency and reduce environmental impact, indicating a moderate level of technological maturity with significant room for further advancements and market growth.

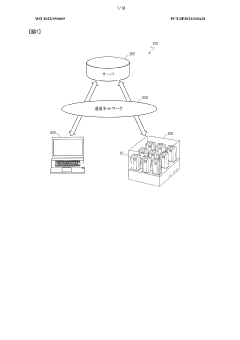

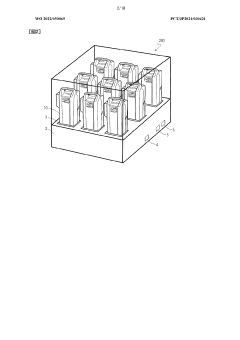

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has implemented a large-scale, nationwide approach to recycling battery management systems from electric vehicles and grid storage systems. Their strategy involves establishing a network of regional recycling centers equipped with standardized processing lines[1]. The company employs a combination of mechanical crushing, magnetic separation, and hydrometallurgical processes to recover materials from BMS components[3]. State Grid has developed a unique high-temperature plasma treatment for hazardous materials within BMS, ensuring safe disposal[5]. They have also implemented a grid-wide smart collection system that uses IoT sensors to optimize the logistics of BMS collection and transportation to recycling facilities[7]. Additionally, State Grid is pioneering the use of recycled BMS materials in grid infrastructure, creating a circular economy within their operations[9].

Strengths: Nationwide infrastructure for efficient collection and processing; Advanced plasma treatment for hazardous materials; Integration of recycled materials into grid infrastructure. Weaknesses: Standardized approach may be less effective for non-standard BMS designs; High energy consumption for plasma treatment.

Northvolt Systems AB

Technical Solution: Northvolt has pioneered a closed-loop recycling system for battery management systems, focusing on recovering critical materials. Their process begins with a precise disassembly technique that preserves the integrity of BMS components[2]. They employ hydrometallurgical processes to extract and purify valuable metals such as lithium, cobalt, and nickel from BMS circuits[4]. Northvolt's approach includes an innovative energy recovery system that harnesses heat generated during the recycling process to power their facilities, reducing overall energy consumption[6]. The company has also developed a machine learning algorithm to optimize the recycling process based on the specific composition of each BMS batch[8].

Strengths: Closed-loop system maximizes material recovery; Energy-efficient process; Adaptive ML algorithm improves efficiency. Weaknesses: Process may be less effective for older or non-standard BMS designs; High operational costs.

Key Innovations

Battery management system for recycling waste battery

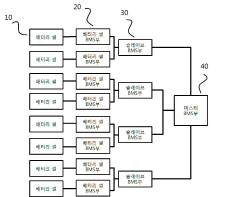

PatentPendingKR1020210111060A

Innovation

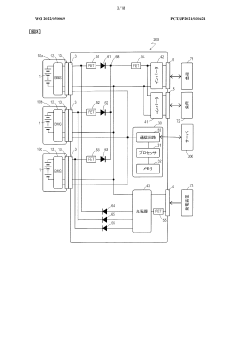

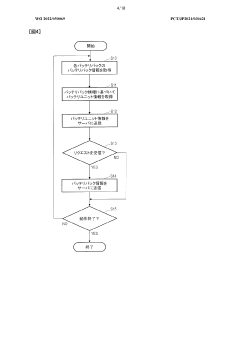

- A battery management system (BMS) is implemented to control and stabilize the voltage and current output from waste batteries by connecting battery cells, modules, and packs in series and parallel, using BMS units to measure and control voltage and current across multiple levels, ensuring uniform application and management.

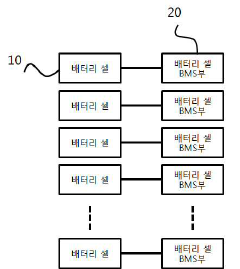

Battery management system

PatentWO2022050069A1

Innovation

- A battery management system that aggregates information from multiple battery packs into a single unit, reducing data communication needs and allowing users to evaluate the battery unit without detailing each pack's status, thereby expanding usage options and reducing data transmission.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of battery management system (BMS) recycling. As the global push for sustainability intensifies, governments worldwide are implementing stricter regulations to address the environmental impact of battery disposal and promote recycling initiatives.

The European Union has been at the forefront of battery recycling regulations with its Battery Directive. This comprehensive framework sets targets for battery collection and recycling rates, placing responsibility on producers to finance the collection, treatment, and recycling of waste batteries. The directive also mandates the removal of batteries from electronic devices before disposal, facilitating more efficient recycling processes.

In the United States, regulations vary by state, with California leading the way through its Battery Recycling Act. This legislation requires retailers to implement battery take-back programs and mandates proper disposal methods for batteries. Other states are following suit, implementing similar regulations to address the growing concern of battery waste.

China, a major player in battery production and consumption, has also introduced regulations to tackle battery recycling challenges. The country's New Energy Vehicle (NEV) battery recycling policy places responsibility on vehicle manufacturers to establish recycling networks and ensure proper disposal of end-of-life batteries.

These regulations have significant implications for BMS recycling. As BMS components often contain valuable materials such as copper, aluminum, and rare earth elements, proper recycling is essential for resource conservation and environmental protection. However, the complexity of BMS designs poses challenges for recyclers in complying with these regulations.

One key aspect of environmental regulations is the requirement for proper handling and disposal of hazardous materials within BMS. Many batteries contain toxic substances like lead, cadmium, or lithium, which require specialized treatment during the recycling process. Recyclers must invest in advanced technologies and processes to safely extract and neutralize these materials, adding to the complexity and cost of BMS recycling.

Furthermore, regulations often mandate the traceability of battery components throughout their lifecycle. This requirement necessitates the implementation of robust tracking systems within the BMS, adding another layer of complexity to the recycling process. Recyclers must be able to identify and separate different battery types and their associated BMS components to ensure compliance with specific recycling requirements for each material.

As environmental regulations continue to evolve, the challenges in recycling BMS are likely to intensify. However, these regulations also drive innovation in recycling technologies and processes, pushing the industry towards more sustainable practices. The development of standardized BMS designs that facilitate easier disassembly and recycling may become a priority for manufacturers seeking to comply with increasingly stringent environmental regulations.

The European Union has been at the forefront of battery recycling regulations with its Battery Directive. This comprehensive framework sets targets for battery collection and recycling rates, placing responsibility on producers to finance the collection, treatment, and recycling of waste batteries. The directive also mandates the removal of batteries from electronic devices before disposal, facilitating more efficient recycling processes.

In the United States, regulations vary by state, with California leading the way through its Battery Recycling Act. This legislation requires retailers to implement battery take-back programs and mandates proper disposal methods for batteries. Other states are following suit, implementing similar regulations to address the growing concern of battery waste.

China, a major player in battery production and consumption, has also introduced regulations to tackle battery recycling challenges. The country's New Energy Vehicle (NEV) battery recycling policy places responsibility on vehicle manufacturers to establish recycling networks and ensure proper disposal of end-of-life batteries.

These regulations have significant implications for BMS recycling. As BMS components often contain valuable materials such as copper, aluminum, and rare earth elements, proper recycling is essential for resource conservation and environmental protection. However, the complexity of BMS designs poses challenges for recyclers in complying with these regulations.

One key aspect of environmental regulations is the requirement for proper handling and disposal of hazardous materials within BMS. Many batteries contain toxic substances like lead, cadmium, or lithium, which require specialized treatment during the recycling process. Recyclers must invest in advanced technologies and processes to safely extract and neutralize these materials, adding to the complexity and cost of BMS recycling.

Furthermore, regulations often mandate the traceability of battery components throughout their lifecycle. This requirement necessitates the implementation of robust tracking systems within the BMS, adding another layer of complexity to the recycling process. Recyclers must be able to identify and separate different battery types and their associated BMS components to ensure compliance with specific recycling requirements for each material.

As environmental regulations continue to evolve, the challenges in recycling BMS are likely to intensify. However, these regulations also drive innovation in recycling technologies and processes, pushing the industry towards more sustainable practices. The development of standardized BMS designs that facilitate easier disassembly and recycling may become a priority for manufacturers seeking to comply with increasingly stringent environmental regulations.

Economic Feasibility

The economic feasibility of recycling Battery Management Systems (BMS) is a critical aspect that influences the overall sustainability and viability of battery recycling initiatives. The cost-effectiveness of BMS recycling is primarily determined by the balance between the expenses incurred in the recycling process and the value of recovered materials. Currently, the recycling of BMS faces several economic challenges that impact its feasibility.

One of the main economic hurdles is the high cost of disassembly and material separation. BMS components are often tightly integrated into battery packs, making their extraction a labor-intensive and time-consuming process. This increases the overall recycling costs, potentially outweighing the value of recoverable materials. Additionally, the complexity of BMS designs varies across manufacturers, requiring specialized equipment and processes for efficient recycling, further adding to the capital investment needed.

The market value of recovered materials from BMS is another crucial factor. While BMS contain valuable components such as copper, aluminum, and various electronic parts, the quantities of these materials in individual units are relatively small. This can make the economics of large-scale recycling challenging, as the revenue generated from recovered materials may not always justify the recycling costs. The fluctuating prices of raw materials in the global market also introduce uncertainty into the economic equation of BMS recycling.

Regulatory frameworks and incentives play a significant role in the economic feasibility of BMS recycling. In regions where strict environmental regulations mandate the recycling of electronic components, the economic burden on recyclers may be offset by government subsidies or producer responsibility schemes. However, in areas lacking such supportive policies, the financial viability of BMS recycling operations can be severely compromised.

Technological advancements in recycling processes have the potential to improve the economic feasibility of BMS recycling. Innovations in automated disassembly techniques and more efficient material recovery methods could significantly reduce processing costs. Moreover, the development of standardized BMS designs across the industry could lead to economies of scale in recycling operations, making the process more cost-effective.

The scale of operations is another critical factor influencing economic feasibility. Large-scale recycling facilities can benefit from economies of scale, spreading fixed costs over a larger volume of processed materials. However, the current fragmented nature of the BMS market, with various designs and chemistries, poses challenges to achieving such scale efficiencies.

In conclusion, while the recycling of Battery Management Systems presents economic challenges, ongoing technological advancements, potential regulatory support, and the increasing volume of end-of-life batteries entering the waste stream may improve its feasibility in the future. A holistic approach considering design for recyclability, policy support, and technological innovation is crucial for enhancing the economic viability of BMS recycling.

One of the main economic hurdles is the high cost of disassembly and material separation. BMS components are often tightly integrated into battery packs, making their extraction a labor-intensive and time-consuming process. This increases the overall recycling costs, potentially outweighing the value of recoverable materials. Additionally, the complexity of BMS designs varies across manufacturers, requiring specialized equipment and processes for efficient recycling, further adding to the capital investment needed.

The market value of recovered materials from BMS is another crucial factor. While BMS contain valuable components such as copper, aluminum, and various electronic parts, the quantities of these materials in individual units are relatively small. This can make the economics of large-scale recycling challenging, as the revenue generated from recovered materials may not always justify the recycling costs. The fluctuating prices of raw materials in the global market also introduce uncertainty into the economic equation of BMS recycling.

Regulatory frameworks and incentives play a significant role in the economic feasibility of BMS recycling. In regions where strict environmental regulations mandate the recycling of electronic components, the economic burden on recyclers may be offset by government subsidies or producer responsibility schemes. However, in areas lacking such supportive policies, the financial viability of BMS recycling operations can be severely compromised.

Technological advancements in recycling processes have the potential to improve the economic feasibility of BMS recycling. Innovations in automated disassembly techniques and more efficient material recovery methods could significantly reduce processing costs. Moreover, the development of standardized BMS designs across the industry could lead to economies of scale in recycling operations, making the process more cost-effective.

The scale of operations is another critical factor influencing economic feasibility. Large-scale recycling facilities can benefit from economies of scale, spreading fixed costs over a larger volume of processed materials. However, the current fragmented nature of the BMS market, with various designs and chemistries, poses challenges to achieving such scale efficiencies.

In conclusion, while the recycling of Battery Management Systems presents economic challenges, ongoing technological advancements, potential regulatory support, and the increasing volume of end-of-life batteries entering the waste stream may improve its feasibility in the future. A holistic approach considering design for recyclability, policy support, and technological innovation is crucial for enhancing the economic viability of BMS recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!