Sensor Fusion in Battery Management System Fault Diagnosis

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Fault Diagnosis Background and Objectives

Battery Management Systems (BMS) have become increasingly crucial in the rapidly evolving landscape of electric vehicles and energy storage systems. As the complexity and demands on these systems grow, so does the need for accurate and reliable fault diagnosis. The background of BMS fault diagnosis is rooted in the critical role these systems play in ensuring the safety, performance, and longevity of battery packs.

Historically, BMS fault diagnosis relied primarily on individual sensor readings and simple threshold-based algorithms. However, as battery technologies advanced and applications became more demanding, the limitations of these traditional approaches became apparent. False alarms, missed faults, and inability to detect complex failure modes led to the exploration of more sophisticated diagnostic techniques.

The evolution of BMS fault diagnosis has been driven by several factors. First, the increasing energy density and power capabilities of modern batteries have raised the stakes for accurate fault detection, as undetected issues can lead to catastrophic failures. Second, the automotive industry's push towards electrification has demanded higher reliability and longer lifespans from battery systems, necessitating more robust diagnostic capabilities. Third, advancements in sensor technologies and computational power have opened up new possibilities for data collection and analysis.

The primary objective of research on sensor fusion in BMS fault diagnosis is to overcome the limitations of single-sensor approaches and leverage the complementary strengths of multiple sensor types. By combining data from various sources such as voltage, current, temperature, and impedance measurements, sensor fusion aims to provide a more comprehensive and accurate picture of the battery's state and potential faults.

Key goals of this research include improving the accuracy of fault detection, reducing false positive rates, enabling early detection of incipient faults, and enhancing the ability to diagnose complex, multi-factor failure modes. Additionally, researchers aim to develop diagnostic algorithms that are robust to sensor noise, drift, and failures, ensuring reliable operation even in challenging environments.

Another important objective is to create diagnostic systems that can adapt to different battery chemistries, form factors, and applications. This flexibility is crucial as the battery industry continues to innovate and diversify. Furthermore, there is a strong focus on developing diagnostic techniques that are computationally efficient and can be implemented in real-time on embedded systems with limited resources.

The research also seeks to integrate sensor fusion-based fault diagnosis with other advanced BMS functions such as state estimation, thermal management, and charge control. This holistic approach aims to create synergies that enhance overall system performance and reliability. Ultimately, the goal is to contribute to the development of next-generation BMS that can support the increasing demands of electric mobility and renewable energy storage, ensuring safer, more efficient, and more durable battery systems.

Historically, BMS fault diagnosis relied primarily on individual sensor readings and simple threshold-based algorithms. However, as battery technologies advanced and applications became more demanding, the limitations of these traditional approaches became apparent. False alarms, missed faults, and inability to detect complex failure modes led to the exploration of more sophisticated diagnostic techniques.

The evolution of BMS fault diagnosis has been driven by several factors. First, the increasing energy density and power capabilities of modern batteries have raised the stakes for accurate fault detection, as undetected issues can lead to catastrophic failures. Second, the automotive industry's push towards electrification has demanded higher reliability and longer lifespans from battery systems, necessitating more robust diagnostic capabilities. Third, advancements in sensor technologies and computational power have opened up new possibilities for data collection and analysis.

The primary objective of research on sensor fusion in BMS fault diagnosis is to overcome the limitations of single-sensor approaches and leverage the complementary strengths of multiple sensor types. By combining data from various sources such as voltage, current, temperature, and impedance measurements, sensor fusion aims to provide a more comprehensive and accurate picture of the battery's state and potential faults.

Key goals of this research include improving the accuracy of fault detection, reducing false positive rates, enabling early detection of incipient faults, and enhancing the ability to diagnose complex, multi-factor failure modes. Additionally, researchers aim to develop diagnostic algorithms that are robust to sensor noise, drift, and failures, ensuring reliable operation even in challenging environments.

Another important objective is to create diagnostic systems that can adapt to different battery chemistries, form factors, and applications. This flexibility is crucial as the battery industry continues to innovate and diversify. Furthermore, there is a strong focus on developing diagnostic techniques that are computationally efficient and can be implemented in real-time on embedded systems with limited resources.

The research also seeks to integrate sensor fusion-based fault diagnosis with other advanced BMS functions such as state estimation, thermal management, and charge control. This holistic approach aims to create synergies that enhance overall system performance and reliability. Ultimately, the goal is to contribute to the development of next-generation BMS that can support the increasing demands of electric mobility and renewable energy storage, ensuring safer, more efficient, and more durable battery systems.

Market Demand for Advanced BMS Solutions

The demand for advanced Battery Management System (BMS) solutions has been steadily increasing in recent years, driven by the rapid growth of electric vehicles (EVs) and renewable energy storage systems. As the automotive industry shifts towards electrification, the need for more sophisticated and reliable BMS technologies has become paramount. This surge in demand is not only limited to the automotive sector but extends to various industries where energy storage plays a crucial role.

In the EV market, consumers are increasingly demanding vehicles with longer range, faster charging capabilities, and improved safety features. These requirements directly translate to a need for more advanced BMS solutions that can accurately monitor and manage battery health, performance, and safety. The ability to precisely diagnose faults and predict potential issues has become a key differentiator for EV manufacturers, driving investment in sensor fusion technologies within BMS.

The renewable energy sector is another major driver of demand for advanced BMS solutions. As grid-scale energy storage systems become more prevalent, the need for robust and efficient battery management becomes critical. These large-scale installations require BMS that can handle complex sensor data from multiple sources to ensure optimal performance, longevity, and safety of the battery systems.

The industrial and consumer electronics markets are also contributing to the growing demand for advanced BMS solutions. With the proliferation of portable devices and the increasing adoption of lithium-ion batteries in various applications, there is a rising need for more sophisticated battery management technologies that can enhance device performance and user safety.

Furthermore, regulatory pressures and safety concerns are pushing manufacturers to adopt more advanced BMS solutions. Stringent safety standards and environmental regulations are driving the need for BMS that can provide more accurate fault diagnosis and predictive maintenance capabilities. This trend is particularly evident in the automotive industry, where battery safety is of utmost importance.

The market is also seeing a shift towards more integrated BMS solutions that can seamlessly interface with other vehicle systems or energy management platforms. This integration allows for better overall system performance and efficiency, further driving the demand for advanced BMS technologies that can handle complex sensor fusion and data analysis tasks.

As the Internet of Things (IoT) and artificial intelligence continue to evolve, there is an increasing demand for BMS solutions that can leverage these technologies. The ability to collect, analyze, and act upon vast amounts of sensor data in real-time is becoming a key requirement for next-generation BMS, opening up new opportunities for innovation in sensor fusion and fault diagnosis techniques.

In the EV market, consumers are increasingly demanding vehicles with longer range, faster charging capabilities, and improved safety features. These requirements directly translate to a need for more advanced BMS solutions that can accurately monitor and manage battery health, performance, and safety. The ability to precisely diagnose faults and predict potential issues has become a key differentiator for EV manufacturers, driving investment in sensor fusion technologies within BMS.

The renewable energy sector is another major driver of demand for advanced BMS solutions. As grid-scale energy storage systems become more prevalent, the need for robust and efficient battery management becomes critical. These large-scale installations require BMS that can handle complex sensor data from multiple sources to ensure optimal performance, longevity, and safety of the battery systems.

The industrial and consumer electronics markets are also contributing to the growing demand for advanced BMS solutions. With the proliferation of portable devices and the increasing adoption of lithium-ion batteries in various applications, there is a rising need for more sophisticated battery management technologies that can enhance device performance and user safety.

Furthermore, regulatory pressures and safety concerns are pushing manufacturers to adopt more advanced BMS solutions. Stringent safety standards and environmental regulations are driving the need for BMS that can provide more accurate fault diagnosis and predictive maintenance capabilities. This trend is particularly evident in the automotive industry, where battery safety is of utmost importance.

The market is also seeing a shift towards more integrated BMS solutions that can seamlessly interface with other vehicle systems or energy management platforms. This integration allows for better overall system performance and efficiency, further driving the demand for advanced BMS technologies that can handle complex sensor fusion and data analysis tasks.

As the Internet of Things (IoT) and artificial intelligence continue to evolve, there is an increasing demand for BMS solutions that can leverage these technologies. The ability to collect, analyze, and act upon vast amounts of sensor data in real-time is becoming a key requirement for next-generation BMS, opening up new opportunities for innovation in sensor fusion and fault diagnosis techniques.

Current Challenges in BMS Fault Diagnosis

Battery Management System (BMS) fault diagnosis faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of modern battery systems, which incorporate numerous sensors and components, making it difficult to isolate and identify specific faults accurately. This complexity is further compounded by the interdependencies between various subsystems within the BMS, leading to potential cascading effects when a fault occurs.

Another major challenge is the dynamic nature of battery behavior, which can vary significantly based on factors such as temperature, state of charge, and usage patterns. This variability makes it challenging to establish consistent baseline parameters for fault detection, often resulting in false positives or missed faults. The need for real-time monitoring and diagnosis adds another layer of complexity, as the BMS must process and analyze large volumes of data quickly to detect and respond to faults before they escalate.

The reliability and accuracy of sensor data pose additional challenges. Sensor degradation over time, environmental interference, and manufacturing variations can all contribute to inaccurate readings, potentially leading to misdiagnosis of faults or overlooking critical issues. Furthermore, the integration of multiple sensor types, each with its own characteristics and potential failure modes, complicates the fault diagnosis process.

Cost considerations also present a significant hurdle in BMS fault diagnosis. While more advanced sensor technologies and sophisticated diagnostic algorithms can improve fault detection accuracy, they often come with higher implementation costs. Striking a balance between diagnostic capability and economic viability remains a persistent challenge for BMS designers and manufacturers.

Standardization, or lack thereof, in BMS fault diagnosis methodologies and reporting formats across different manufacturers and battery types further complicates the landscape. This lack of uniformity makes it difficult to compare and validate diagnostic results across different systems or to develop universal diagnostic tools.

Lastly, the evolving nature of battery technology itself presents an ongoing challenge. As new battery chemistries and designs emerge, BMS fault diagnosis techniques must adapt quickly to address novel failure modes and performance characteristics. This constant evolution requires continuous research and development efforts to keep pace with the changing technology landscape.

Another major challenge is the dynamic nature of battery behavior, which can vary significantly based on factors such as temperature, state of charge, and usage patterns. This variability makes it challenging to establish consistent baseline parameters for fault detection, often resulting in false positives or missed faults. The need for real-time monitoring and diagnosis adds another layer of complexity, as the BMS must process and analyze large volumes of data quickly to detect and respond to faults before they escalate.

The reliability and accuracy of sensor data pose additional challenges. Sensor degradation over time, environmental interference, and manufacturing variations can all contribute to inaccurate readings, potentially leading to misdiagnosis of faults or overlooking critical issues. Furthermore, the integration of multiple sensor types, each with its own characteristics and potential failure modes, complicates the fault diagnosis process.

Cost considerations also present a significant hurdle in BMS fault diagnosis. While more advanced sensor technologies and sophisticated diagnostic algorithms can improve fault detection accuracy, they often come with higher implementation costs. Striking a balance between diagnostic capability and economic viability remains a persistent challenge for BMS designers and manufacturers.

Standardization, or lack thereof, in BMS fault diagnosis methodologies and reporting formats across different manufacturers and battery types further complicates the landscape. This lack of uniformity makes it difficult to compare and validate diagnostic results across different systems or to develop universal diagnostic tools.

Lastly, the evolving nature of battery technology itself presents an ongoing challenge. As new battery chemistries and designs emerge, BMS fault diagnosis techniques must adapt quickly to address novel failure modes and performance characteristics. This constant evolution requires continuous research and development efforts to keep pace with the changing technology landscape.

Existing Sensor Fusion Techniques in BMS

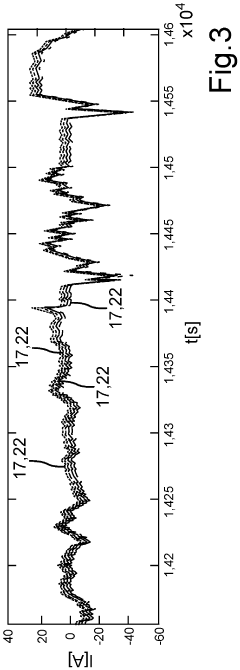

01 Fault detection using voltage and current measurements

Battery Management Systems can detect faults by analyzing voltage and current measurements from the battery cells. This method involves comparing the measured values with predefined thresholds or expected ranges to identify abnormalities. Advanced algorithms can be used to process these measurements and detect various types of faults, including short circuits, open circuits, and capacity degradation.- Fault detection using voltage and current measurements: Battery Management Systems can detect faults by analyzing voltage and current measurements from battery cells. This method involves comparing measured values with predefined thresholds or expected ranges to identify abnormalities. Advanced algorithms can be used to process these measurements and detect various types of faults, including short circuits, open circuits, and capacity degradation.

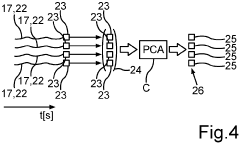

- State estimation techniques for fault diagnosis: State estimation techniques, such as Kalman filtering and observers, are employed in Battery Management Systems to estimate internal states of the battery that cannot be directly measured. These estimated states are then used to diagnose faults by comparing them with expected values or patterns. This approach allows for early detection of faults and can provide insights into the battery's health and performance.

- Machine learning and data-driven fault diagnosis: Machine learning algorithms and data-driven approaches are increasingly used in Battery Management Systems for fault diagnosis. These methods involve training models on historical data to recognize patterns associated with different fault types. Techniques such as neural networks, support vector machines, and decision trees can be employed to classify faults and predict potential failures based on real-time battery data.

- Thermal management and fault detection: Thermal management is crucial in Battery Management Systems, and temperature-related fault detection is an important aspect of fault diagnosis. This involves monitoring temperature distributions across battery cells and packs, detecting thermal runaway conditions, and identifying cooling system failures. Advanced thermal models and sensors are used to ensure accurate temperature measurements and timely fault detection.

- Communication and network-based fault diagnosis: Modern Battery Management Systems often incorporate communication networks and distributed architectures. Fault diagnosis in these systems involves monitoring communication links, detecting network failures, and identifying discrepancies in data from multiple sources. This approach allows for more robust fault detection and can help isolate faults in complex battery systems with multiple modules or packs.

02 State estimation techniques for fault diagnosis

State estimation techniques, such as Kalman filtering and observers, are employed in Battery Management Systems to estimate internal states of the battery that cannot be directly measured. These estimated states, including State of Charge (SOC) and State of Health (SOH), are then used to detect and diagnose faults. Deviations between estimated and expected states can indicate potential faults in the battery system.Expand Specific Solutions03 Machine learning and data-driven approaches

Machine learning algorithms and data-driven approaches are increasingly used in Battery Management Systems for fault diagnosis. These methods can learn from historical data to identify patterns associated with different fault types. Techniques such as neural networks, support vector machines, and decision trees can be employed to classify faults and predict potential failures based on real-time battery data.Expand Specific Solutions04 Thermal management and fault detection

Thermal management is crucial in Battery Management Systems, and temperature-related fault detection is an important aspect of fault diagnosis. This involves monitoring temperature distributions across the battery pack, detecting thermal runaway conditions, and identifying cooling system failures. Advanced thermal models and sensors are used to ensure accurate temperature-based fault diagnosis.Expand Specific Solutions05 Communication and network-based fault diagnosis

Modern Battery Management Systems often incorporate communication networks for data exchange between various components. Fault diagnosis can be performed by analyzing communication patterns, detecting network failures, and identifying discrepancies in data transmitted between different modules. This approach allows for system-level fault detection and can help isolate faults in specific components or subsystems.Expand Specific Solutions

Key Players in BMS and Sensor Fusion Industry

The sensor fusion technology in Battery Management System (BMS) fault diagnosis is in a growth phase, with increasing market size driven by the expanding electric vehicle industry. The global BMS market is projected to reach significant value in the coming years, indicating substantial opportunities. Technologically, the field is advancing rapidly, with major players like LG Energy Solution, Samsung SDI, and Contemporary Amperex Technology leading innovation. These companies, along with automotive giants such as Hyundai Motor, BYD, and Bosch, are investing heavily in R&D to improve BMS accuracy and reliability. The technology's maturity is progressing, with a focus on integrating multiple sensor types and advanced algorithms for more precise fault detection and prediction in battery systems.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a sensor fusion system for BMS fault diagnosis that focuses on balancing accuracy and computational efficiency. Their approach utilizes a combination of model-based and data-driven techniques, integrating information from voltage, current, and thermal sensors[7]. The system employs a hierarchical fault diagnosis structure, with local processing units handling immediate fault detection and a central unit performing more complex analysis and system-wide optimization[9]. LG's solution also incorporates adaptive sampling rates for different sensor types, optimizing data collection based on the battery's operating conditions and reducing overall system power consumption[11].

Strengths: Balanced approach between accuracy and efficiency, hierarchical fault diagnosis structure for scalability. Weaknesses: May have limitations in detecting subtle or emerging fault types compared to more complex systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has implemented a multi-modal sensor fusion approach in their BMS fault diagnosis system. Their technology combines electrochemical impedance spectroscopy (EIS) data with traditional voltage and current measurements to provide a more detailed analysis of battery health[2]. The system uses advanced signal processing techniques to extract features from the fused sensor data, which are then fed into a hybrid model combining physics-based and data-driven approaches for fault diagnosis[4]. Samsung's solution also incorporates cloud-based data analytics for long-term trend analysis and predictive maintenance, allowing for proactive fault prevention in large-scale battery deployments[6].

Strengths: High-fidelity battery health analysis, predictive maintenance capabilities, and scalability for large deployments. Weaknesses: Reliance on cloud connectivity for advanced features may limit applicability in some scenarios.

Core Innovations in BMS Fault Diagnosis

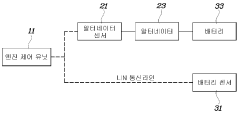

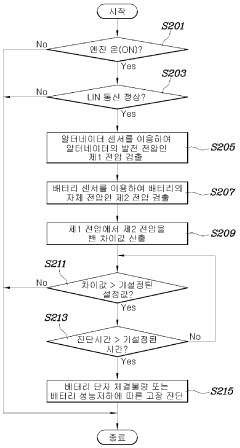

Fault diagnosis apparatus for battery system

PatentInactiveKR1020160110700A

Innovation

- A battery system fault diagnosis device that utilizes an alternator sensor and battery sensor to detect and calculate voltage differences, employing LIN communication to distinguish between alternator and battery voltages, and an engine control unit to diagnose battery terminal connections and performance degradation based on these differences.

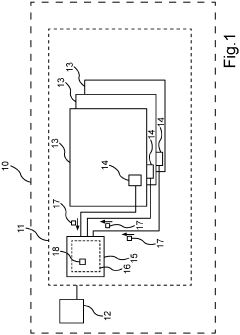

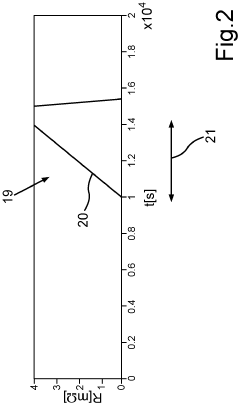

Method for detecting a fault in a battery system and battery system and motor vehicle

PatentPendingDE102019212909A1

Innovation

- A method utilizing component-specific monitoring units and a computing device that calculates statistical measures based on correlation data to detect deviations from expected behavior patterns in monitoring signals, enabling early detection of faults by analyzing the correlation between different battery components.

Safety Standards and Regulations for BMS

Safety standards and regulations play a crucial role in ensuring the reliability and performance of Battery Management Systems (BMS) in the context of sensor fusion for fault diagnosis. These standards are designed to address potential risks associated with battery systems and provide guidelines for manufacturers and operators to maintain safe and efficient operations.

One of the primary safety standards for BMS is the ISO 26262 standard, which focuses on functional safety for road vehicles. This standard outlines requirements for the development and implementation of safety-critical systems, including BMS. It emphasizes the importance of systematic risk assessment and mitigation strategies throughout the product lifecycle.

The UL 1642 standard, developed by Underwriters Laboratories, specifically addresses the safety of lithium batteries. This standard provides guidelines for testing and evaluating the safety of lithium batteries used in various applications, including those monitored by BMS. Compliance with UL 1642 ensures that batteries meet stringent safety requirements and can withstand potential abuse conditions.

In the automotive industry, the SAE J2464 standard is widely recognized for electric and hybrid vehicle rechargeable energy storage systems. This standard outlines safety and abuse testing procedures for battery systems, including requirements for BMS performance and fault detection capabilities.

The IEC 62133 standard, developed by the International Electrotechnical Commission, focuses on the safety requirements for portable sealed secondary cells and batteries. This standard includes specifications for protection against abnormal operation and fault conditions, which are directly relevant to BMS fault diagnosis and sensor fusion applications.

For grid energy storage applications, the UL 9540 standard provides safety requirements for energy storage systems and equipment. This standard addresses the integration of BMS in large-scale energy storage systems and outlines requirements for monitoring, control, and fault detection.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union Agency for the Space Programme (EUSPA) also provide guidelines and regulations for BMS safety in automotive and aerospace applications, respectively. These regulations often incorporate elements from the aforementioned standards and may include additional requirements specific to their respective industries.

Compliance with these safety standards and regulations is essential for BMS manufacturers and integrators. It ensures that sensor fusion techniques employed in fault diagnosis meet the necessary safety criteria and contribute to the overall reliability of battery systems across various applications.

One of the primary safety standards for BMS is the ISO 26262 standard, which focuses on functional safety for road vehicles. This standard outlines requirements for the development and implementation of safety-critical systems, including BMS. It emphasizes the importance of systematic risk assessment and mitigation strategies throughout the product lifecycle.

The UL 1642 standard, developed by Underwriters Laboratories, specifically addresses the safety of lithium batteries. This standard provides guidelines for testing and evaluating the safety of lithium batteries used in various applications, including those monitored by BMS. Compliance with UL 1642 ensures that batteries meet stringent safety requirements and can withstand potential abuse conditions.

In the automotive industry, the SAE J2464 standard is widely recognized for electric and hybrid vehicle rechargeable energy storage systems. This standard outlines safety and abuse testing procedures for battery systems, including requirements for BMS performance and fault detection capabilities.

The IEC 62133 standard, developed by the International Electrotechnical Commission, focuses on the safety requirements for portable sealed secondary cells and batteries. This standard includes specifications for protection against abnormal operation and fault conditions, which are directly relevant to BMS fault diagnosis and sensor fusion applications.

For grid energy storage applications, the UL 9540 standard provides safety requirements for energy storage systems and equipment. This standard addresses the integration of BMS in large-scale energy storage systems and outlines requirements for monitoring, control, and fault detection.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union Agency for the Space Programme (EUSPA) also provide guidelines and regulations for BMS safety in automotive and aerospace applications, respectively. These regulations often incorporate elements from the aforementioned standards and may include additional requirements specific to their respective industries.

Compliance with these safety standards and regulations is essential for BMS manufacturers and integrators. It ensures that sensor fusion techniques employed in fault diagnosis meet the necessary safety criteria and contribute to the overall reliability of battery systems across various applications.

Cost-Benefit Analysis of Sensor Fusion in BMS

The implementation of sensor fusion in Battery Management Systems (BMS) for fault diagnosis presents a complex cost-benefit scenario that requires careful analysis. On the cost side, integrating multiple sensors and developing sophisticated fusion algorithms can significantly increase the initial investment in BMS hardware and software. This includes expenses for additional sensors, more powerful processors to handle complex data integration, and the development of advanced algorithms.

However, these costs must be weighed against the potential benefits. Sensor fusion can dramatically improve the accuracy and reliability of fault diagnosis in BMS, leading to several long-term advantages. Firstly, enhanced fault detection capabilities can prevent catastrophic battery failures, thereby extending the overall lifespan of battery systems and reducing replacement costs. This is particularly crucial in high-value applications such as electric vehicles and grid-scale energy storage.

Moreover, improved diagnostic precision can optimize battery performance and efficiency. By accurately identifying and addressing minor issues before they escalate, sensor fusion enables proactive maintenance strategies. This approach can minimize downtime, reduce maintenance costs, and enhance overall system reliability. In industries where battery performance is critical, such as aerospace or telecommunications, these benefits can translate into substantial operational cost savings.

From a safety perspective, the enhanced fault detection provided by sensor fusion can significantly reduce the risk of thermal runaway and other dangerous battery failures. This not only protects valuable assets but also mitigates potential liability costs associated with battery-related accidents or recalls. In sectors with stringent safety regulations, such as automotive or aviation, this improved safety profile can facilitate regulatory compliance and market acceptance.

Additionally, the rich data generated through sensor fusion can provide valuable insights for battery design and optimization. This information can feed back into research and development processes, potentially leading to innovations in battery technology and management strategies. Over time, these advancements could result in more efficient and cost-effective battery systems, offsetting the initial investment in sensor fusion technology.

While the upfront costs of implementing sensor fusion in BMS are considerable, the long-term benefits in terms of extended battery life, improved safety, reduced maintenance costs, and potential for innovation often justify the investment. The exact cost-benefit ratio will vary depending on the specific application and scale of implementation, but for many high-performance and safety-critical applications, the advantages of sensor fusion in BMS fault diagnosis are likely to outweigh the costs over the system's lifecycle.

However, these costs must be weighed against the potential benefits. Sensor fusion can dramatically improve the accuracy and reliability of fault diagnosis in BMS, leading to several long-term advantages. Firstly, enhanced fault detection capabilities can prevent catastrophic battery failures, thereby extending the overall lifespan of battery systems and reducing replacement costs. This is particularly crucial in high-value applications such as electric vehicles and grid-scale energy storage.

Moreover, improved diagnostic precision can optimize battery performance and efficiency. By accurately identifying and addressing minor issues before they escalate, sensor fusion enables proactive maintenance strategies. This approach can minimize downtime, reduce maintenance costs, and enhance overall system reliability. In industries where battery performance is critical, such as aerospace or telecommunications, these benefits can translate into substantial operational cost savings.

From a safety perspective, the enhanced fault detection provided by sensor fusion can significantly reduce the risk of thermal runaway and other dangerous battery failures. This not only protects valuable assets but also mitigates potential liability costs associated with battery-related accidents or recalls. In sectors with stringent safety regulations, such as automotive or aviation, this improved safety profile can facilitate regulatory compliance and market acceptance.

Additionally, the rich data generated through sensor fusion can provide valuable insights for battery design and optimization. This information can feed back into research and development processes, potentially leading to innovations in battery technology and management strategies. Over time, these advancements could result in more efficient and cost-effective battery systems, offsetting the initial investment in sensor fusion technology.

While the upfront costs of implementing sensor fusion in BMS are considerable, the long-term benefits in terms of extended battery life, improved safety, reduced maintenance costs, and potential for innovation often justify the investment. The exact cost-benefit ratio will vary depending on the specific application and scale of implementation, but for many high-performance and safety-critical applications, the advantages of sensor fusion in BMS fault diagnosis are likely to outweigh the costs over the system's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!