The Interaction Between Batteries and Battery Management Systems in Embedded Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery-BMS Interaction Background and Objectives

The interaction between batteries and Battery Management Systems (BMS) in embedded systems has become a critical area of focus in recent years, driven by the increasing demand for portable and efficient electronic devices. This technological domain has evolved significantly since the introduction of rechargeable batteries in the 1980s, with lithium-ion batteries emerging as the dominant power source for most modern embedded systems.

The primary objective of studying this interaction is to optimize energy efficiency, extend battery life, and enhance overall system performance. As embedded systems become more complex and power-hungry, the need for sophisticated battery management has grown exponentially. The goal is to develop intelligent systems that can accurately monitor, control, and protect the battery while maximizing its potential.

The evolution of this technology has been marked by several key milestones. Initially, basic voltage monitoring and simple charge control were the primary functions of BMS. However, as battery chemistry advanced and applications diversified, BMS capabilities expanded to include advanced features such as state-of-charge estimation, thermal management, and cell balancing.

Current trends in this field are focused on developing more accurate and predictive BMS algorithms, integrating artificial intelligence and machine learning techniques to improve battery performance and longevity. There is also a growing emphasis on miniaturization and integration of BMS components directly into battery packs, enabling more compact and efficient embedded system designs.

The interaction between batteries and BMS is particularly crucial in applications such as electric vehicles, renewable energy storage systems, and portable medical devices. In these domains, the reliability and efficiency of power management can have significant implications for safety, performance, and user experience.

Looking ahead, the technological trajectory points towards the development of more adaptive and intelligent BMS that can dynamically adjust to varying load conditions and battery degradation over time. There is also a push towards standardization in BMS protocols and interfaces to improve interoperability across different embedded system platforms.

As we delve deeper into this technology, it's essential to consider the challenges that lie ahead. These include improving the accuracy of battery state estimation, developing more robust safety mechanisms, and addressing the environmental impact of battery production and disposal. The interaction between batteries and BMS in embedded systems represents a dynamic and evolving field with significant potential for innovation and impact across multiple industries.

The primary objective of studying this interaction is to optimize energy efficiency, extend battery life, and enhance overall system performance. As embedded systems become more complex and power-hungry, the need for sophisticated battery management has grown exponentially. The goal is to develop intelligent systems that can accurately monitor, control, and protect the battery while maximizing its potential.

The evolution of this technology has been marked by several key milestones. Initially, basic voltage monitoring and simple charge control were the primary functions of BMS. However, as battery chemistry advanced and applications diversified, BMS capabilities expanded to include advanced features such as state-of-charge estimation, thermal management, and cell balancing.

Current trends in this field are focused on developing more accurate and predictive BMS algorithms, integrating artificial intelligence and machine learning techniques to improve battery performance and longevity. There is also a growing emphasis on miniaturization and integration of BMS components directly into battery packs, enabling more compact and efficient embedded system designs.

The interaction between batteries and BMS is particularly crucial in applications such as electric vehicles, renewable energy storage systems, and portable medical devices. In these domains, the reliability and efficiency of power management can have significant implications for safety, performance, and user experience.

Looking ahead, the technological trajectory points towards the development of more adaptive and intelligent BMS that can dynamically adjust to varying load conditions and battery degradation over time. There is also a push towards standardization in BMS protocols and interfaces to improve interoperability across different embedded system platforms.

As we delve deeper into this technology, it's essential to consider the challenges that lie ahead. These include improving the accuracy of battery state estimation, developing more robust safety mechanisms, and addressing the environmental impact of battery production and disposal. The interaction between batteries and BMS in embedded systems represents a dynamic and evolving field with significant potential for innovation and impact across multiple industries.

Market Demand for Efficient Energy Management

The market demand for efficient energy management in embedded systems, particularly concerning the interaction between batteries and battery management systems (BMS), has been growing exponentially in recent years. This surge is driven by the increasing proliferation of portable electronic devices, electric vehicles, and renewable energy storage systems. As these technologies become more prevalent in our daily lives, the need for optimized power consumption and extended battery life has become paramount.

In the consumer electronics sector, smartphones, laptops, and wearable devices are at the forefront of this demand. Users expect longer battery life without compromising on device performance or size. This has led to a significant market push for advanced BMS solutions that can maximize energy efficiency and prolong battery lifespan. The automotive industry, especially with the rise of electric vehicles, has become another major driver for efficient energy management. Electric vehicle manufacturers are constantly seeking ways to improve range and charging times, making the interaction between batteries and BMS a critical factor in their product development.

The industrial and IoT sectors are also contributing to this market demand. With the increasing deployment of sensor networks and edge computing devices in various applications such as smart cities, agriculture, and manufacturing, there is a growing need for power-efficient embedded systems that can operate for extended periods without frequent battery replacements or recharging.

Furthermore, the renewable energy sector, particularly in solar and wind power applications, requires sophisticated energy storage solutions. This has created a substantial market for large-scale battery systems with advanced BMS capabilities to ensure optimal performance and longevity of these expensive assets.

The healthcare industry is another significant contributor to this market demand, with the rise of implantable medical devices and portable diagnostic equipment. These applications require ultra-low power consumption and highly reliable battery management to ensure patient safety and device longevity.

As a result of these diverse market needs, there has been a surge in research and development activities focused on improving the interaction between batteries and BMS in embedded systems. Companies are investing heavily in developing more efficient power management integrated circuits (PMICs), advanced battery chemistries, and sophisticated algorithms for battery state estimation and health monitoring.

The market is also seeing a trend towards more integrated solutions, where BMS functionalities are being incorporated directly into battery packs or embedded system designs. This integration is driven by the need for more compact and cost-effective solutions, especially in space-constrained applications.

In the consumer electronics sector, smartphones, laptops, and wearable devices are at the forefront of this demand. Users expect longer battery life without compromising on device performance or size. This has led to a significant market push for advanced BMS solutions that can maximize energy efficiency and prolong battery lifespan. The automotive industry, especially with the rise of electric vehicles, has become another major driver for efficient energy management. Electric vehicle manufacturers are constantly seeking ways to improve range and charging times, making the interaction between batteries and BMS a critical factor in their product development.

The industrial and IoT sectors are also contributing to this market demand. With the increasing deployment of sensor networks and edge computing devices in various applications such as smart cities, agriculture, and manufacturing, there is a growing need for power-efficient embedded systems that can operate for extended periods without frequent battery replacements or recharging.

Furthermore, the renewable energy sector, particularly in solar and wind power applications, requires sophisticated energy storage solutions. This has created a substantial market for large-scale battery systems with advanced BMS capabilities to ensure optimal performance and longevity of these expensive assets.

The healthcare industry is another significant contributor to this market demand, with the rise of implantable medical devices and portable diagnostic equipment. These applications require ultra-low power consumption and highly reliable battery management to ensure patient safety and device longevity.

As a result of these diverse market needs, there has been a surge in research and development activities focused on improving the interaction between batteries and BMS in embedded systems. Companies are investing heavily in developing more efficient power management integrated circuits (PMICs), advanced battery chemistries, and sophisticated algorithms for battery state estimation and health monitoring.

The market is also seeing a trend towards more integrated solutions, where BMS functionalities are being incorporated directly into battery packs or embedded system designs. This integration is driven by the need for more compact and cost-effective solutions, especially in space-constrained applications.

Current Challenges in Battery-BMS Integration

The integration of batteries and Battery Management Systems (BMS) in embedded systems presents several significant challenges that hinder optimal performance and reliability. One of the primary issues is the complexity of accurately monitoring and managing diverse battery chemistries and configurations. Different battery types, such as lithium-ion, lead-acid, and nickel-metal hydride, require specific management strategies, making it difficult to develop a universal BMS solution.

Another challenge lies in the precise measurement of battery parameters, including state of charge (SOC), state of health (SOH), and remaining useful life (RUL). These measurements are critical for efficient battery utilization and system performance, but they are often subject to inaccuracies due to factors like temperature variations, aging effects, and varying discharge rates. The development of robust algorithms to accurately estimate these parameters remains an ongoing challenge in the field.

Power consumption of the BMS itself is a significant concern, especially in low-power embedded systems. The BMS must continuously monitor and manage the battery while minimizing its own energy draw to avoid draining the battery unnecessarily. Balancing the need for frequent and accurate measurements with power efficiency is a delicate trade-off that designers must carefully consider.

Thermal management presents another critical challenge in battery-BMS integration. Batteries generate heat during charging and discharging, which can affect their performance and lifespan. The BMS must effectively monitor and manage temperature to prevent overheating and ensure safe operation. This becomes particularly challenging in compact embedded systems where space for cooling solutions is limited.

Communication between the BMS and other system components is also a significant hurdle. Ensuring reliable, real-time data exchange between the BMS, power management ICs, and the main system controller is crucial for optimal performance. However, implementing robust communication protocols that can handle potential electromagnetic interference and maintain data integrity in diverse operating conditions remains challenging.

Scalability and flexibility of BMS solutions pose additional difficulties. As embedded systems evolve and battery technologies advance, BMS designs must be adaptable to accommodate varying battery configurations, capacities, and chemistries. Developing modular and scalable BMS architectures that can be easily customized for different applications without compromising performance or reliability is an ongoing challenge for engineers.

Lastly, ensuring the safety and reliability of the battery-BMS system in various environmental conditions and use cases is paramount. This includes implementing fail-safe mechanisms, redundancy features, and robust error detection and handling capabilities. Balancing these safety requirements with system cost and complexity adds another layer of challenge to the integration process.

Another challenge lies in the precise measurement of battery parameters, including state of charge (SOC), state of health (SOH), and remaining useful life (RUL). These measurements are critical for efficient battery utilization and system performance, but they are often subject to inaccuracies due to factors like temperature variations, aging effects, and varying discharge rates. The development of robust algorithms to accurately estimate these parameters remains an ongoing challenge in the field.

Power consumption of the BMS itself is a significant concern, especially in low-power embedded systems. The BMS must continuously monitor and manage the battery while minimizing its own energy draw to avoid draining the battery unnecessarily. Balancing the need for frequent and accurate measurements with power efficiency is a delicate trade-off that designers must carefully consider.

Thermal management presents another critical challenge in battery-BMS integration. Batteries generate heat during charging and discharging, which can affect their performance and lifespan. The BMS must effectively monitor and manage temperature to prevent overheating and ensure safe operation. This becomes particularly challenging in compact embedded systems where space for cooling solutions is limited.

Communication between the BMS and other system components is also a significant hurdle. Ensuring reliable, real-time data exchange between the BMS, power management ICs, and the main system controller is crucial for optimal performance. However, implementing robust communication protocols that can handle potential electromagnetic interference and maintain data integrity in diverse operating conditions remains challenging.

Scalability and flexibility of BMS solutions pose additional difficulties. As embedded systems evolve and battery technologies advance, BMS designs must be adaptable to accommodate varying battery configurations, capacities, and chemistries. Developing modular and scalable BMS architectures that can be easily customized for different applications without compromising performance or reliability is an ongoing challenge for engineers.

Lastly, ensuring the safety and reliability of the battery-BMS system in various environmental conditions and use cases is paramount. This includes implementing fail-safe mechanisms, redundancy features, and robust error detection and handling capabilities. Balancing these safety requirements with system cost and complexity adds another layer of challenge to the integration process.

Existing Battery-BMS Communication Protocols

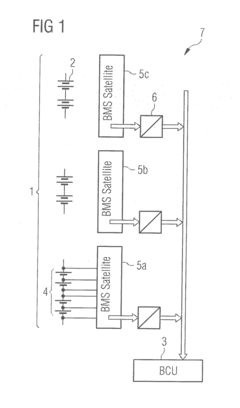

01 Battery Management Systems (BMS) for Electric Vehicles

Advanced BMS designed specifically for electric vehicles, focusing on optimizing battery performance, monitoring state of charge, and ensuring safe operation. These systems often include features for thermal management, cell balancing, and predictive maintenance to extend battery life and improve overall vehicle efficiency.- Battery Management Systems (BMS) for Electric Vehicles: Advanced BMS designs for electric vehicles focus on optimizing battery performance, safety, and longevity. These systems monitor and control various parameters such as temperature, voltage, and state of charge across multiple cells. They also implement sophisticated algorithms for battery balancing and power distribution, enhancing overall efficiency and range of electric vehicles.

- Lithium-ion Battery Technologies: Innovations in lithium-ion battery technologies aim to improve energy density, charging speed, and cycle life. These advancements include novel electrode materials, electrolyte formulations, and cell designs. Research focuses on enhancing the stability of high-capacity cathodes and developing silicon-based anodes for increased energy storage capabilities.

- Thermal Management in Battery Systems: Effective thermal management is crucial for battery performance and safety. Advanced cooling systems, including liquid cooling and phase-change materials, are being developed to maintain optimal operating temperatures. These solutions address heat generation during charging and discharging, preventing thermal runaway and extending battery life.

- Smart Charging and Grid Integration: Intelligent charging systems are being developed to optimize battery charging processes and integrate with smart grids. These systems incorporate predictive algorithms to determine optimal charging times, rates, and power sources. They also enable vehicle-to-grid (V2G) capabilities, allowing batteries to serve as energy storage units for grid stabilization.

- Battery Recycling and Sustainability: Advancements in battery recycling technologies focus on recovering valuable materials from spent batteries and reducing environmental impact. New processes are being developed to efficiently extract and purify materials like lithium, cobalt, and nickel. These innovations aim to create a more sustainable lifecycle for batteries and reduce dependence on raw material mining.

02 Lithium-ion Battery Technology Advancements

Innovations in lithium-ion battery technology, including new electrode materials, electrolyte compositions, and cell designs. These advancements aim to increase energy density, improve charging speeds, and enhance the overall lifespan of batteries for various applications, from consumer electronics to large-scale energy storage systems.Expand Specific Solutions03 Smart Grid Integration and Energy Storage Solutions

Development of battery systems and management technologies for smart grid integration and renewable energy storage. These solutions focus on grid stabilization, peak shaving, and efficient energy distribution, incorporating advanced control algorithms and communication protocols for seamless integration with existing power infrastructure.Expand Specific Solutions04 Wireless Charging and Power Management

Innovative approaches to wireless charging technologies and power management systems for batteries. This includes developments in inductive and resonant charging methods, as well as intelligent power distribution systems that optimize charging efficiency and battery longevity across various devices and applications.Expand Specific Solutions05 Safety and Thermal Management in Battery Systems

Advanced safety features and thermal management solutions for battery systems, addressing concerns such as overheating, thermal runaway, and fire prevention. These innovations include novel cooling systems, intelligent temperature monitoring, and fail-safe mechanisms to ensure the safe operation of batteries in diverse environments and applications.Expand Specific Solutions

Key Players in Battery and BMS Industry

The interaction between batteries and battery management systems in embedded systems is a rapidly evolving field, currently in a growth phase. The market size is expanding significantly, driven by the increasing adoption of electric vehicles and renewable energy storage solutions. Technologically, the field is advancing quickly but still has room for maturation. Companies like Samsung SDI, LG Energy Solution, and Infineon Technologies are at the forefront, developing sophisticated battery management systems. Emerging players such as Titan Advanced Energy Solutions are introducing innovative technologies like ultrasound-based battery monitoring. The competitive landscape is diverse, with traditional electronics giants, specialized battery manufacturers, and startups all vying for market share and technological leadership.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced Battery Management Systems (BMS) for embedded systems, focusing on lithium-ion batteries. Their BMS utilizes a multi-cell balancing technique to optimize battery performance and lifespan. The system employs a sophisticated algorithm that monitors individual cell voltages, temperatures, and state of charge in real-time[1]. This allows for precise control of charging and discharging processes, enhancing overall battery efficiency. Samsung's BMS also incorporates predictive analytics to forecast battery health and potential failures, enabling proactive maintenance[3]. The company has integrated wireless communication capabilities into their BMS, facilitating remote monitoring and diagnostics in various embedded applications[5].

Strengths: Advanced cell balancing technology, predictive analytics for battery health, and wireless monitoring capabilities. Weaknesses: Potential complexity in implementation for smaller embedded systems and higher initial costs.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive Battery Management System for embedded applications, focusing on automotive and industrial sectors. Their BMS utilizes a distributed architecture, with intelligent sensors placed on each cell for precise monitoring[2]. The system employs advanced algorithms for state estimation, including State of Charge (SoC), State of Health (SoH), and State of Function (SoF) calculations[4]. Bosch's BMS incorporates active cell balancing techniques, which can transfer energy between cells, significantly improving overall battery efficiency and lifespan[6]. The system also features adaptive thermal management, adjusting cooling strategies based on battery conditions and usage patterns. Bosch has integrated their BMS with vehicle control systems, enabling optimized energy management across the entire embedded system[8].

Strengths: Distributed architecture for precise monitoring, advanced state estimation algorithms, and integration with vehicle systems. Weaknesses: May be over-engineered for simpler embedded applications, potentially higher cost for small-scale implementations.

Innovations in Battery-BMS Interaction

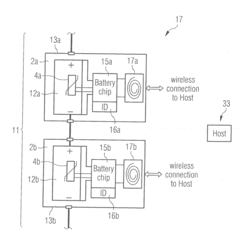

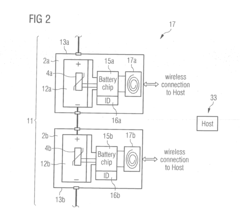

Battery, Battery Management System, and Method to Control a Battery

PatentInactiveUS20140035357A1

Innovation

- The proposed solution integrates a battery control chip within each battery cell, enabling individual voltage and temperature measurement, wireless communication with a central control unit, and active/passive balancing, eliminating the need for multiple BMS Satellites and reducing cable complexity.

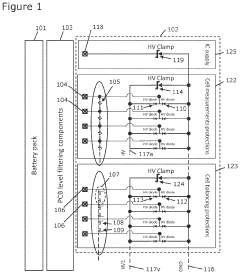

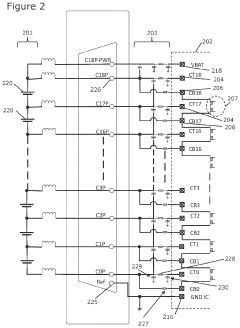

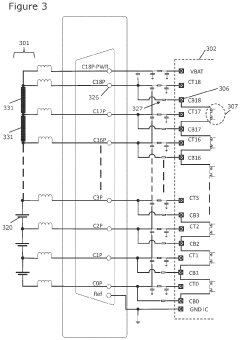

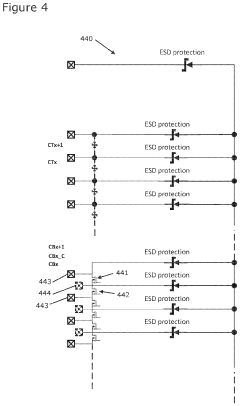

Battery management system intergrated circuit

PatentPendingUS20230307724A1

Innovation

- The BMS IC incorporates bi-directional ESD protection elements and dual polarity switches connected between cell-measuring and balancing pins, along with diodes and clamps for centralized ESD protection, allowing for safe monitoring and reduced component requirements, including minimal discrete components between pins and the battery pack.

Safety Standards for Battery-BMS Systems

Safety standards for battery-BMS systems in embedded applications are crucial for ensuring the reliable and secure operation of these critical components. These standards encompass a wide range of requirements, from design and manufacturing to testing and certification processes.

One of the primary safety standards governing battery-BMS systems is IEC 62133, which outlines safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard addresses various aspects, including electrical, mechanical, and environmental safety considerations.

UL 1642 is another important standard that focuses on lithium batteries used in embedded systems. It provides guidelines for the construction, performance, and safety of lithium batteries, including requirements for protection against short circuits, overcharging, and thermal runaway.

The automotive industry has its own set of standards for battery-BMS systems, such as ISO 26262, which addresses functional safety in road vehicles. This standard is particularly relevant for electric and hybrid vehicles, where battery-BMS interactions are critical for vehicle performance and safety.

For aerospace applications, standards like DO-311 and DO-160 provide guidelines for the design, testing, and certification of lithium batteries and their management systems in airborne environments. These standards address unique challenges faced in aviation, such as extreme temperature variations and pressure changes.

In addition to these specific standards, general safety regulations like IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems are also applicable to battery-BMS interactions in embedded systems.

Compliance with these safety standards typically involves rigorous testing procedures, including abuse testing, environmental testing, and electromagnetic compatibility (EMC) testing. These tests ensure that battery-BMS systems can withstand various operational stresses and maintain safe performance under diverse conditions.

As technology evolves, safety standards are continuously updated to address new challenges and emerging risks. For instance, recent updates to standards have focused on cybersecurity aspects of battery-BMS systems, recognizing the increasing connectivity and potential vulnerabilities in modern embedded systems.

One of the primary safety standards governing battery-BMS systems is IEC 62133, which outlines safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard addresses various aspects, including electrical, mechanical, and environmental safety considerations.

UL 1642 is another important standard that focuses on lithium batteries used in embedded systems. It provides guidelines for the construction, performance, and safety of lithium batteries, including requirements for protection against short circuits, overcharging, and thermal runaway.

The automotive industry has its own set of standards for battery-BMS systems, such as ISO 26262, which addresses functional safety in road vehicles. This standard is particularly relevant for electric and hybrid vehicles, where battery-BMS interactions are critical for vehicle performance and safety.

For aerospace applications, standards like DO-311 and DO-160 provide guidelines for the design, testing, and certification of lithium batteries and their management systems in airborne environments. These standards address unique challenges faced in aviation, such as extreme temperature variations and pressure changes.

In addition to these specific standards, general safety regulations like IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems are also applicable to battery-BMS interactions in embedded systems.

Compliance with these safety standards typically involves rigorous testing procedures, including abuse testing, environmental testing, and electromagnetic compatibility (EMC) testing. These tests ensure that battery-BMS systems can withstand various operational stresses and maintain safe performance under diverse conditions.

As technology evolves, safety standards are continuously updated to address new challenges and emerging risks. For instance, recent updates to standards have focused on cybersecurity aspects of battery-BMS systems, recognizing the increasing connectivity and potential vulnerabilities in modern embedded systems.

Environmental Impact of Battery Technologies

The environmental impact of battery technologies in embedded systems is a critical consideration as the demand for portable and energy-efficient devices continues to grow. The interaction between batteries and battery management systems (BMS) plays a significant role in determining the overall environmental footprint of these technologies.

Battery production processes often involve the extraction and processing of raw materials, which can have substantial environmental consequences. The mining of lithium, cobalt, and other metals used in battery manufacturing can lead to habitat destruction, water pollution, and greenhouse gas emissions. Additionally, the energy-intensive nature of battery production contributes to carbon dioxide emissions and resource depletion.

The lifespan of batteries in embedded systems is a crucial factor in their environmental impact. Efficient battery management systems can extend battery life by optimizing charging and discharging cycles, reducing the frequency of battery replacements. This, in turn, decreases the demand for new batteries and mitigates the environmental burden associated with their production and disposal.

Proper disposal and recycling of batteries are essential for minimizing their environmental impact. Many batteries contain toxic materials that can harm ecosystems if not handled correctly. Advanced BMS can help identify when batteries are nearing the end of their useful life, facilitating timely and appropriate recycling. Recycling processes can recover valuable materials, reducing the need for raw material extraction and lowering the overall environmental footprint.

The energy efficiency of batteries and BMS in embedded systems also affects their environmental impact. More efficient systems require less frequent charging, reducing energy consumption and associated emissions. Furthermore, improved power management can lead to smaller battery sizes, decreasing the material requirements and environmental impact of production.

Innovations in battery chemistry and BMS design are continually working to address environmental concerns. For example, the development of solid-state batteries promises improved energy density and reduced reliance on rare earth metals. Similarly, advancements in BMS algorithms and hardware are enhancing the overall efficiency and lifespan of battery systems.

As embedded systems become more prevalent in various industries, including automotive, consumer electronics, and industrial applications, the cumulative environmental impact of battery technologies becomes increasingly significant. Therefore, ongoing research and development efforts are focused on creating more sustainable battery solutions and optimizing the interaction between batteries and BMS to minimize environmental harm while maximizing performance and longevity.

Battery production processes often involve the extraction and processing of raw materials, which can have substantial environmental consequences. The mining of lithium, cobalt, and other metals used in battery manufacturing can lead to habitat destruction, water pollution, and greenhouse gas emissions. Additionally, the energy-intensive nature of battery production contributes to carbon dioxide emissions and resource depletion.

The lifespan of batteries in embedded systems is a crucial factor in their environmental impact. Efficient battery management systems can extend battery life by optimizing charging and discharging cycles, reducing the frequency of battery replacements. This, in turn, decreases the demand for new batteries and mitigates the environmental burden associated with their production and disposal.

Proper disposal and recycling of batteries are essential for minimizing their environmental impact. Many batteries contain toxic materials that can harm ecosystems if not handled correctly. Advanced BMS can help identify when batteries are nearing the end of their useful life, facilitating timely and appropriate recycling. Recycling processes can recover valuable materials, reducing the need for raw material extraction and lowering the overall environmental footprint.

The energy efficiency of batteries and BMS in embedded systems also affects their environmental impact. More efficient systems require less frequent charging, reducing energy consumption and associated emissions. Furthermore, improved power management can lead to smaller battery sizes, decreasing the material requirements and environmental impact of production.

Innovations in battery chemistry and BMS design are continually working to address environmental concerns. For example, the development of solid-state batteries promises improved energy density and reduced reliance on rare earth metals. Similarly, advancements in BMS algorithms and hardware are enhancing the overall efficiency and lifespan of battery systems.

As embedded systems become more prevalent in various industries, including automotive, consumer electronics, and industrial applications, the cumulative environmental impact of battery technologies becomes increasingly significant. Therefore, ongoing research and development efforts are focused on creating more sustainable battery solutions and optimizing the interaction between batteries and BMS to minimize environmental harm while maximizing performance and longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!