Comparative Study of Battery Management Systems for Consumer Electronics

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Evolution and Objectives

Battery Management Systems (BMS) have undergone significant evolution since their inception, driven by the rapid advancement of consumer electronics and the increasing demand for more efficient and reliable power management solutions. The journey of BMS began in the early 1990s with simple voltage monitoring and basic protection circuits. These rudimentary systems were primarily designed to prevent overcharging and deep discharging of batteries in portable devices.

As consumer electronics became more sophisticated and power-hungry, the role of BMS expanded. By the early 2000s, BMS had evolved to include more advanced features such as temperature monitoring, state-of-charge estimation, and cell balancing. This evolution was crucial in supporting the widespread adoption of lithium-ion batteries, which offered higher energy density but required more precise management to ensure safety and longevity.

The mid-2000s saw a paradigm shift in BMS technology with the integration of microcontrollers and advanced algorithms. This allowed for more accurate battery state estimation, predictive maintenance, and adaptive charging strategies. The introduction of smart batteries with embedded BMS further revolutionized power management in consumer electronics, enabling devices to communicate directly with chargers and host systems for optimized performance.

In recent years, the objectives of BMS have expanded beyond basic functionality to address emerging challenges in consumer electronics. These include extending battery life, improving charging speeds, enhancing safety features, and supporting new battery chemistries. Modern BMS aims to maximize energy efficiency, provide real-time diagnostics, and enable seamless integration with device operating systems for a more holistic approach to power management.

Looking forward, the evolution of BMS is closely tied to advancements in artificial intelligence and machine learning. Future systems are expected to leverage these technologies for more accurate prediction of battery behavior, personalized power management strategies, and self-learning capabilities that adapt to user habits and environmental conditions. The ultimate goal is to create intelligent BMS that can optimize battery performance throughout its lifecycle, potentially revolutionizing the user experience in consumer electronics.

As we progress, the objectives of BMS in consumer electronics are becoming increasingly ambitious. These include achieving ultra-fast charging without compromising battery health, enabling bidirectional power flow for device-to-device charging, and supporting the integration of multiple energy sources. Additionally, there is a growing focus on sustainability, with BMS playing a crucial role in extending battery lifespan and facilitating second-life applications for used batteries.

As consumer electronics became more sophisticated and power-hungry, the role of BMS expanded. By the early 2000s, BMS had evolved to include more advanced features such as temperature monitoring, state-of-charge estimation, and cell balancing. This evolution was crucial in supporting the widespread adoption of lithium-ion batteries, which offered higher energy density but required more precise management to ensure safety and longevity.

The mid-2000s saw a paradigm shift in BMS technology with the integration of microcontrollers and advanced algorithms. This allowed for more accurate battery state estimation, predictive maintenance, and adaptive charging strategies. The introduction of smart batteries with embedded BMS further revolutionized power management in consumer electronics, enabling devices to communicate directly with chargers and host systems for optimized performance.

In recent years, the objectives of BMS have expanded beyond basic functionality to address emerging challenges in consumer electronics. These include extending battery life, improving charging speeds, enhancing safety features, and supporting new battery chemistries. Modern BMS aims to maximize energy efficiency, provide real-time diagnostics, and enable seamless integration with device operating systems for a more holistic approach to power management.

Looking forward, the evolution of BMS is closely tied to advancements in artificial intelligence and machine learning. Future systems are expected to leverage these technologies for more accurate prediction of battery behavior, personalized power management strategies, and self-learning capabilities that adapt to user habits and environmental conditions. The ultimate goal is to create intelligent BMS that can optimize battery performance throughout its lifecycle, potentially revolutionizing the user experience in consumer electronics.

As we progress, the objectives of BMS in consumer electronics are becoming increasingly ambitious. These include achieving ultra-fast charging without compromising battery health, enabling bidirectional power flow for device-to-device charging, and supporting the integration of multiple energy sources. Additionally, there is a growing focus on sustainability, with BMS playing a crucial role in extending battery lifespan and facilitating second-life applications for used batteries.

Consumer Electronics BMS Market Analysis

The consumer electronics Battery Management System (BMS) market has experienced significant growth in recent years, driven by the increasing demand for portable electronic devices and the growing emphasis on battery performance and safety. This market segment encompasses a wide range of products, including smartphones, laptops, tablets, wearables, and other portable consumer electronics.

Market size estimates indicate that the global consumer electronics BMS market is poised for substantial expansion. The market is expected to grow at a compound annual growth rate (CAGR) of over 15% during the forecast period from 2021 to 2026. This growth is attributed to several factors, including the rising adoption of lithium-ion batteries in consumer electronics, the need for improved battery life and performance, and the increasing focus on energy efficiency and sustainability.

Key market drivers include the proliferation of smart devices, the growing trend of Internet of Things (IoT) integration in consumer electronics, and the increasing consumer demand for longer battery life and faster charging capabilities. Additionally, the rising awareness of battery safety issues and the implementation of stringent regulations regarding battery management have further propelled the market growth.

The consumer electronics BMS market is characterized by intense competition among key players, including established electronics manufacturers and specialized BMS solution providers. Major companies in this space are investing heavily in research and development to enhance their product offerings and gain a competitive edge. Some of the prominent players in the market include Texas Instruments, Analog Devices, Maxim Integrated, and STMicroelectronics.

Regional analysis reveals that Asia-Pacific dominates the consumer electronics BMS market, owing to the presence of major electronics manufacturing hubs in countries like China, South Korea, and Japan. North America and Europe follow closely, driven by technological advancements and the high adoption rate of smart devices in these regions.

The market is witnessing several trends that are shaping its future trajectory. These include the development of advanced BMS solutions with artificial intelligence and machine learning capabilities, the integration of wireless charging technologies, and the focus on miniaturization to accommodate smaller form factors in consumer devices.

Challenges in the market include the need for continuous innovation to keep pace with rapidly evolving battery technologies, the pressure to reduce costs while maintaining high performance, and the increasing complexity of battery management in multi-cell configurations. Despite these challenges, the consumer electronics BMS market presents significant opportunities for growth and innovation, driven by the ever-increasing demand for smarter, more efficient, and longer-lasting electronic devices.

Market size estimates indicate that the global consumer electronics BMS market is poised for substantial expansion. The market is expected to grow at a compound annual growth rate (CAGR) of over 15% during the forecast period from 2021 to 2026. This growth is attributed to several factors, including the rising adoption of lithium-ion batteries in consumer electronics, the need for improved battery life and performance, and the increasing focus on energy efficiency and sustainability.

Key market drivers include the proliferation of smart devices, the growing trend of Internet of Things (IoT) integration in consumer electronics, and the increasing consumer demand for longer battery life and faster charging capabilities. Additionally, the rising awareness of battery safety issues and the implementation of stringent regulations regarding battery management have further propelled the market growth.

The consumer electronics BMS market is characterized by intense competition among key players, including established electronics manufacturers and specialized BMS solution providers. Major companies in this space are investing heavily in research and development to enhance their product offerings and gain a competitive edge. Some of the prominent players in the market include Texas Instruments, Analog Devices, Maxim Integrated, and STMicroelectronics.

Regional analysis reveals that Asia-Pacific dominates the consumer electronics BMS market, owing to the presence of major electronics manufacturing hubs in countries like China, South Korea, and Japan. North America and Europe follow closely, driven by technological advancements and the high adoption rate of smart devices in these regions.

The market is witnessing several trends that are shaping its future trajectory. These include the development of advanced BMS solutions with artificial intelligence and machine learning capabilities, the integration of wireless charging technologies, and the focus on miniaturization to accommodate smaller form factors in consumer devices.

Challenges in the market include the need for continuous innovation to keep pace with rapidly evolving battery technologies, the pressure to reduce costs while maintaining high performance, and the increasing complexity of battery management in multi-cell configurations. Despite these challenges, the consumer electronics BMS market presents significant opportunities for growth and innovation, driven by the ever-increasing demand for smarter, more efficient, and longer-lasting electronic devices.

BMS Technology Landscape

Battery Management Systems (BMS) have become an integral component in the landscape of consumer electronics, playing a crucial role in optimizing battery performance, ensuring safety, and extending the lifespan of devices. The BMS technology landscape is characterized by a diverse array of solutions, each tailored to meet the specific requirements of different consumer electronic products.

At the core of BMS technology are sophisticated algorithms and hardware configurations designed to monitor and control various battery parameters. These systems typically incorporate voltage and current sensing, temperature monitoring, and state-of-charge (SOC) estimation. Advanced BMS solutions also feature state-of-health (SOH) tracking, which provides valuable insights into battery degradation over time.

The evolution of BMS technology has been driven by the increasing demands of consumer electronics for longer battery life, faster charging capabilities, and enhanced safety features. This has led to the development of more intelligent and adaptive BMS architectures that can dynamically adjust battery management strategies based on usage patterns and environmental conditions.

One significant trend in the BMS landscape is the integration of artificial intelligence and machine learning algorithms. These advanced techniques enable more accurate predictions of battery behavior, optimize charging cycles, and provide personalized power management strategies for individual users. This shift towards AI-driven BMS represents a paradigm change in how battery systems are managed in consumer devices.

Another key aspect of the BMS technology landscape is the focus on miniaturization and power efficiency. As consumer electronics continue to shrink in size while demanding more power, BMS solutions have had to evolve to occupy less physical space and consume minimal energy themselves. This has led to the development of highly integrated BMS chips that combine multiple functions into a single package.

Wireless charging technologies have also influenced the BMS landscape, necessitating the development of specialized management systems capable of handling the unique challenges posed by inductive charging methods. These systems must account for variations in charging efficiency and manage potential thermal issues associated with wireless power transfer.

The BMS technology landscape is further shaped by the emergence of new battery chemistries and form factors. As manufacturers explore alternatives to traditional lithium-ion batteries, such as solid-state batteries or flexible batteries, BMS solutions must adapt to manage these novel energy storage technologies effectively.

Standardization efforts within the industry are also impacting the BMS landscape. Initiatives aimed at creating common protocols and interfaces for battery management systems are gaining traction, potentially leading to greater interoperability and simplified integration across different device ecosystems.

At the core of BMS technology are sophisticated algorithms and hardware configurations designed to monitor and control various battery parameters. These systems typically incorporate voltage and current sensing, temperature monitoring, and state-of-charge (SOC) estimation. Advanced BMS solutions also feature state-of-health (SOH) tracking, which provides valuable insights into battery degradation over time.

The evolution of BMS technology has been driven by the increasing demands of consumer electronics for longer battery life, faster charging capabilities, and enhanced safety features. This has led to the development of more intelligent and adaptive BMS architectures that can dynamically adjust battery management strategies based on usage patterns and environmental conditions.

One significant trend in the BMS landscape is the integration of artificial intelligence and machine learning algorithms. These advanced techniques enable more accurate predictions of battery behavior, optimize charging cycles, and provide personalized power management strategies for individual users. This shift towards AI-driven BMS represents a paradigm change in how battery systems are managed in consumer devices.

Another key aspect of the BMS technology landscape is the focus on miniaturization and power efficiency. As consumer electronics continue to shrink in size while demanding more power, BMS solutions have had to evolve to occupy less physical space and consume minimal energy themselves. This has led to the development of highly integrated BMS chips that combine multiple functions into a single package.

Wireless charging technologies have also influenced the BMS landscape, necessitating the development of specialized management systems capable of handling the unique challenges posed by inductive charging methods. These systems must account for variations in charging efficiency and manage potential thermal issues associated with wireless power transfer.

The BMS technology landscape is further shaped by the emergence of new battery chemistries and form factors. As manufacturers explore alternatives to traditional lithium-ion batteries, such as solid-state batteries or flexible batteries, BMS solutions must adapt to manage these novel energy storage technologies effectively.

Standardization efforts within the industry are also impacting the BMS landscape. Initiatives aimed at creating common protocols and interfaces for battery management systems are gaining traction, potentially leading to greater interoperability and simplified integration across different device ecosystems.

Current BMS Architectures

01 Battery monitoring and control systems

These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.- Battery monitoring and control systems: These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.

- Thermal management in battery systems: Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.

- Cell balancing techniques: Cell balancing ensures that all cells in a battery pack maintain similar voltage levels, preventing overcharging or undercharging of individual cells. This can be achieved through passive or active balancing methods, improving overall battery pack performance and longevity.

- State of charge and state of health estimation: Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are crucial for effective battery management, helping to optimize charging strategies and predict maintenance needs.

- Integration with energy management systems: Battery management systems are increasingly integrated with broader energy management systems, particularly in applications like electric vehicles and renewable energy storage. This integration allows for optimized energy flow, improved efficiency, and better coordination with other power systems.

02 Thermal management in battery systems

Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.Expand Specific Solutions03 Cell balancing techniques

Cell balancing ensures uniform charge distribution across multiple cells in a battery pack. This extends battery life, improves overall performance, and prevents individual cells from overcharging or over-discharging. Various methods, including passive and active balancing, are used to equalize cell voltages.Expand Specific Solutions04 State of charge and state of health estimation

Advanced algorithms are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are crucial for optimizing battery usage, predicting remaining range in electric vehicles, and scheduling maintenance. Machine learning and data-driven approaches are increasingly being used to improve accuracy.Expand Specific Solutions05 Integration with power management systems

Battery management systems are often integrated with broader power management systems, especially in applications like electric vehicles and renewable energy storage. This integration allows for optimized energy distribution, efficient charging strategies, and coordination with other vehicle or grid systems to maximize overall efficiency and performance.Expand Specific Solutions

Key BMS Manufacturers

The battery management systems (BMS) market for consumer electronics is in a growth phase, driven by increasing demand for portable devices and electric vehicles. The market size is expanding rapidly, with major players like Samsung SDI, LG Energy Solution, and Robert Bosch GmbH leading the competition. These companies are investing heavily in R&D to improve BMS technology, focusing on enhancing battery life, safety, and efficiency. The technology is maturing, with advancements in areas such as intelligent power management and thermal control. Emerging players like A123 Systems and BYD are also making significant contributions, particularly in the development of high-performance lithium-ion batteries and integrated BMS solutions for various applications.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced Battery Management System (BMS) for consumer electronics that utilizes artificial intelligence and machine learning algorithms to optimize battery performance and longevity. Their system employs real-time monitoring of cell voltage, current, and temperature, coupled with predictive analytics to forecast battery health and prevent potential failures. The BMS incorporates adaptive charging protocols that adjust based on usage patterns and environmental conditions, significantly extending battery life cycles[1]. Additionally, Samsung's BMS features a proprietary balancing algorithm that ensures uniform charge distribution across cells, minimizing capacity loss over time[2]. The system also includes a sophisticated thermal management solution, using active cooling techniques to maintain optimal operating temperatures even under high-load conditions[3].

Strengths: Advanced AI integration for predictive maintenance, adaptive charging for extended battery life, and superior thermal management. Weaknesses: Potentially higher cost due to advanced features, may require more processing power in devices.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has engineered a comprehensive Battery Management System tailored for consumer electronics, focusing on safety and efficiency. Their BMS employs a multi-layered protection scheme, incorporating both hardware and software safeguards to prevent overcharging, over-discharging, and thermal runaway[4]. The system utilizes a sophisticated State of Charge (SoC) and State of Health (SoH) estimation algorithm, which leverages machine learning to provide highly accurate readings throughout the battery's lifecycle[5]. LG's BMS also features dynamic power management, automatically adjusting power output based on device demands and battery conditions to optimize performance and longevity. Furthermore, the system includes a wireless communication module for remote diagnostics and over-the-air updates, allowing for continuous improvement of battery management strategies[6].

Strengths: Robust safety features, accurate SoC and SoH estimation, and remote update capability. Weaknesses: Potential complexity in implementation, may require more frequent software updates.

BMS Innovation Patents

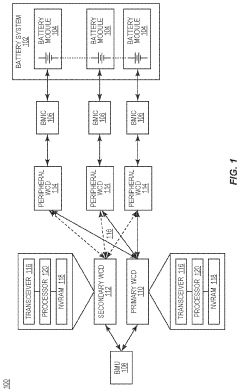

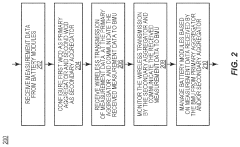

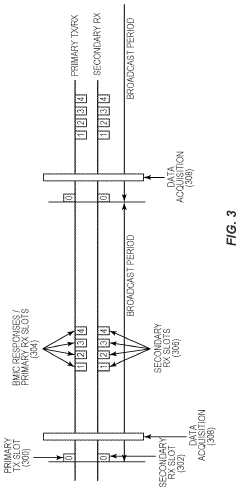

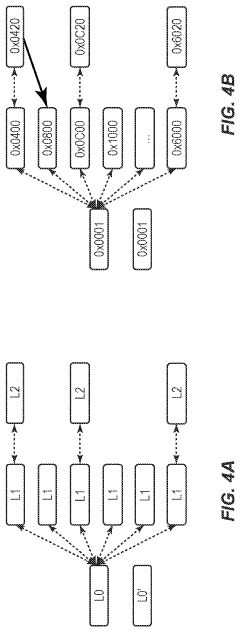

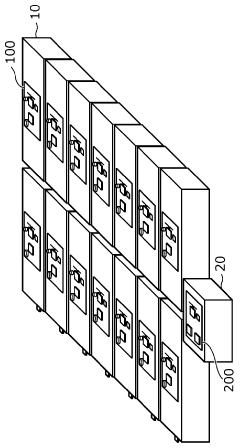

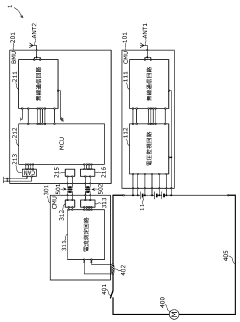

Battery management system, method of battery management and wireless communication device for battery management systems

PatentPendingUS20240178463A1

Innovation

- Implementing a dual-aggregator system with a primary and secondary wireless communication device, where the secondary aggregator can seamlessly replace the primary aggregator without shutting down the system, ensuring continuous data communication and management of battery modules based on measurement data from either aggregator.

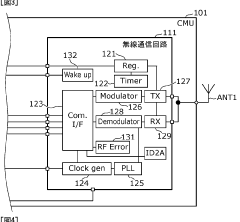

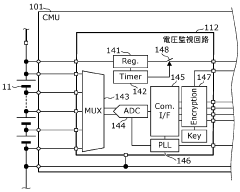

Battery management system

PatentWO2023210655A1

Innovation

- The battery management system incorporates a management circuit and monitoring circuits with a wireless communication circuit and timer circuit, allowing the system to intermittently transition between power-on and power-off states, reducing power consumption by only supplying power when necessary, and utilizing external power sources for communication functions.

BMS Safety Standards

Battery Management Systems (BMS) for consumer electronics must adhere to stringent safety standards to ensure the protection of users and devices. These standards are established by various international organizations and regulatory bodies to address potential risks associated with lithium-ion batteries, which are widely used in portable electronic devices.

The International Electrotechnical Commission (IEC) has developed several standards specifically for BMS safety. IEC 62133 is a key standard that outlines safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard covers aspects such as electrical, mechanical, and environmental safety tests for lithium-ion batteries used in consumer electronics.

Another crucial standard is UL 1642, which focuses on lithium batteries used in consumer products. This standard specifies requirements for construction, performance, and safety of lithium batteries to mitigate risks of fire, explosion, or leakage. BMS designers must ensure compliance with these standards to prevent thermal runaway and other safety hazards.

The IEEE 1625 standard provides a framework for rechargeable batteries in mobile computing devices. It addresses safety considerations for the entire battery system, including the BMS, and emphasizes the importance of proper charging and discharging protocols to maintain battery health and safety.

In addition to these standards, regional regulations such as the European Union's Battery Directive (2006/66/EC) and China's GB/T 18287-2013 standard for mobile phone batteries impose additional safety requirements on BMS designs. These regulations often focus on environmental protection and recycling aspects alongside safety considerations.

BMS safety standards also extend to the software and firmware components. The IEC 61508 standard, which deals with functional safety of electrical/electronic/programmable electronic safety-related systems, is often applied to BMS software to ensure reliable operation and fail-safe mechanisms.

Compliance with these safety standards requires BMS designers to implement various protective features. These include overcharge protection, over-discharge protection, short-circuit protection, and temperature monitoring. Advanced BMS designs may also incorporate cell balancing techniques to prevent individual cells from operating outside their safe voltage range.

As consumer electronics continue to evolve, with trends towards higher energy densities and faster charging capabilities, BMS safety standards are regularly updated to address new challenges. For instance, the emergence of gallium nitride (GaN) chargers has prompted the development of new safety protocols to manage the increased power delivery in compact form factors.

The International Electrotechnical Commission (IEC) has developed several standards specifically for BMS safety. IEC 62133 is a key standard that outlines safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard covers aspects such as electrical, mechanical, and environmental safety tests for lithium-ion batteries used in consumer electronics.

Another crucial standard is UL 1642, which focuses on lithium batteries used in consumer products. This standard specifies requirements for construction, performance, and safety of lithium batteries to mitigate risks of fire, explosion, or leakage. BMS designers must ensure compliance with these standards to prevent thermal runaway and other safety hazards.

The IEEE 1625 standard provides a framework for rechargeable batteries in mobile computing devices. It addresses safety considerations for the entire battery system, including the BMS, and emphasizes the importance of proper charging and discharging protocols to maintain battery health and safety.

In addition to these standards, regional regulations such as the European Union's Battery Directive (2006/66/EC) and China's GB/T 18287-2013 standard for mobile phone batteries impose additional safety requirements on BMS designs. These regulations often focus on environmental protection and recycling aspects alongside safety considerations.

BMS safety standards also extend to the software and firmware components. The IEC 61508 standard, which deals with functional safety of electrical/electronic/programmable electronic safety-related systems, is often applied to BMS software to ensure reliable operation and fail-safe mechanisms.

Compliance with these safety standards requires BMS designers to implement various protective features. These include overcharge protection, over-discharge protection, short-circuit protection, and temperature monitoring. Advanced BMS designs may also incorporate cell balancing techniques to prevent individual cells from operating outside their safe voltage range.

As consumer electronics continue to evolve, with trends towards higher energy densities and faster charging capabilities, BMS safety standards are regularly updated to address new challenges. For instance, the emergence of gallium nitride (GaN) chargers has prompted the development of new safety protocols to manage the increased power delivery in compact form factors.

BMS Environmental Impact

The environmental impact of Battery Management Systems (BMS) in consumer electronics is a critical consideration in the broader context of sustainability and responsible technology development. As consumer electronics continue to proliferate, the cumulative effect of BMS on the environment becomes increasingly significant.

BMS play a crucial role in optimizing battery performance and longevity, which indirectly contributes to reducing electronic waste. By effectively managing charge and discharge cycles, BMS help extend the overall lifespan of batteries, thereby decreasing the frequency of battery replacements and the associated environmental burden of disposal.

However, the production of BMS components itself has environmental implications. The manufacturing process involves the use of various materials, including precious metals and rare earth elements, which require energy-intensive extraction and processing. This contributes to carbon emissions and potential environmental degradation in mining regions.

The energy efficiency of BMS during operation is another important factor. While BMS aim to optimize battery performance, they also consume power themselves. Advanced BMS designs focus on minimizing this power consumption, striking a balance between functionality and energy efficiency to reduce the overall environmental footprint of the device.

End-of-life considerations for BMS are particularly relevant from an environmental perspective. The complex nature of BMS, often involving integrated circuits and specialized components, can make recycling challenging. Proper disposal and recycling protocols are essential to prevent harmful substances from entering the environment and to recover valuable materials.

The trend towards more sophisticated BMS in consumer electronics presents both challenges and opportunities for environmental sustainability. On one hand, more complex systems may require more resources to produce and may be more difficult to recycle. On the other hand, advanced BMS can significantly improve battery efficiency and lifespan, potentially offsetting their production impact through extended device use.

Innovations in BMS design are increasingly focusing on environmental considerations. This includes the development of more easily recyclable components, the use of bio-based or recycled materials in manufacturing, and the implementation of energy-harvesting technologies to reduce the power draw of the BMS itself.

As regulations around electronic waste and product lifecycle management become more stringent, BMS designers and manufacturers are under pressure to consider the entire lifecycle environmental impact of their products. This holistic approach encompasses everything from material sourcing to end-of-life management, driving the industry towards more sustainable practices.

BMS play a crucial role in optimizing battery performance and longevity, which indirectly contributes to reducing electronic waste. By effectively managing charge and discharge cycles, BMS help extend the overall lifespan of batteries, thereby decreasing the frequency of battery replacements and the associated environmental burden of disposal.

However, the production of BMS components itself has environmental implications. The manufacturing process involves the use of various materials, including precious metals and rare earth elements, which require energy-intensive extraction and processing. This contributes to carbon emissions and potential environmental degradation in mining regions.

The energy efficiency of BMS during operation is another important factor. While BMS aim to optimize battery performance, they also consume power themselves. Advanced BMS designs focus on minimizing this power consumption, striking a balance between functionality and energy efficiency to reduce the overall environmental footprint of the device.

End-of-life considerations for BMS are particularly relevant from an environmental perspective. The complex nature of BMS, often involving integrated circuits and specialized components, can make recycling challenging. Proper disposal and recycling protocols are essential to prevent harmful substances from entering the environment and to recover valuable materials.

The trend towards more sophisticated BMS in consumer electronics presents both challenges and opportunities for environmental sustainability. On one hand, more complex systems may require more resources to produce and may be more difficult to recycle. On the other hand, advanced BMS can significantly improve battery efficiency and lifespan, potentially offsetting their production impact through extended device use.

Innovations in BMS design are increasingly focusing on environmental considerations. This includes the development of more easily recyclable components, the use of bio-based or recycled materials in manufacturing, and the implementation of energy-harvesting technologies to reduce the power draw of the BMS itself.

As regulations around electronic waste and product lifecycle management become more stringent, BMS designers and manufacturers are under pressure to consider the entire lifecycle environmental impact of their products. This holistic approach encompasses everything from material sourcing to end-of-life management, driving the industry towards more sustainable practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!