Importance of Battery Management System Calibration in Ultracapacitor Applications

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Calibration Background

Battery Management System (BMS) calibration plays a crucial role in optimizing the performance and longevity of ultracapacitor applications. The background of BMS calibration in this context stems from the unique characteristics of ultracapacitors and the need for precise management of their charge and discharge cycles.

Ultracapacitors, also known as supercapacitors, are energy storage devices that offer high power density, rapid charge and discharge capabilities, and long cycle life compared to traditional batteries. However, they also present unique challenges in terms of voltage management and state of charge estimation, which necessitates specialized calibration techniques for their BMS.

The development of BMS calibration for ultracapacitors has evolved alongside the advancement of ultracapacitor technology itself. Initially, simple voltage-based methods were used to estimate the state of charge and manage the ultracapacitor's operation. However, as applications became more demanding and the need for higher efficiency and reliability grew, more sophisticated calibration techniques were developed.

One of the key drivers for BMS calibration in ultracapacitor applications has been the increasing use of these devices in high-performance and safety-critical systems, such as automotive regenerative braking, renewable energy storage, and industrial power backup. In these applications, accurate state of charge estimation and precise voltage control are essential for maximizing energy efficiency and preventing overcharging or over-discharging, which can lead to reduced performance or even system failure.

The calibration process for ultracapacitor BMS typically involves characterizing the device's behavior under various operating conditions, including different temperatures, charge/discharge rates, and aging states. This characterization data is then used to develop and fine-tune algorithms that can accurately predict the ultracapacitor's state of charge, available power, and remaining useful life.

As ultracapacitor technology has matured, so too has the sophistication of BMS calibration techniques. Modern approaches often incorporate machine learning algorithms and real-time adaptive models to continuously refine the calibration parameters based on the device's actual performance and environmental conditions. This dynamic calibration approach allows for more accurate and reliable management of ultracapacitor systems throughout their operational lifetime.

The importance of BMS calibration in ultracapacitor applications has also been driven by the need for standardization and interoperability. As ultracapacitors find their way into more diverse applications, there is a growing demand for standardized calibration procedures and performance metrics that can ensure consistent and reliable operation across different systems and manufacturers.

Ultracapacitors, also known as supercapacitors, are energy storage devices that offer high power density, rapid charge and discharge capabilities, and long cycle life compared to traditional batteries. However, they also present unique challenges in terms of voltage management and state of charge estimation, which necessitates specialized calibration techniques for their BMS.

The development of BMS calibration for ultracapacitors has evolved alongside the advancement of ultracapacitor technology itself. Initially, simple voltage-based methods were used to estimate the state of charge and manage the ultracapacitor's operation. However, as applications became more demanding and the need for higher efficiency and reliability grew, more sophisticated calibration techniques were developed.

One of the key drivers for BMS calibration in ultracapacitor applications has been the increasing use of these devices in high-performance and safety-critical systems, such as automotive regenerative braking, renewable energy storage, and industrial power backup. In these applications, accurate state of charge estimation and precise voltage control are essential for maximizing energy efficiency and preventing overcharging or over-discharging, which can lead to reduced performance or even system failure.

The calibration process for ultracapacitor BMS typically involves characterizing the device's behavior under various operating conditions, including different temperatures, charge/discharge rates, and aging states. This characterization data is then used to develop and fine-tune algorithms that can accurately predict the ultracapacitor's state of charge, available power, and remaining useful life.

As ultracapacitor technology has matured, so too has the sophistication of BMS calibration techniques. Modern approaches often incorporate machine learning algorithms and real-time adaptive models to continuously refine the calibration parameters based on the device's actual performance and environmental conditions. This dynamic calibration approach allows for more accurate and reliable management of ultracapacitor systems throughout their operational lifetime.

The importance of BMS calibration in ultracapacitor applications has also been driven by the need for standardization and interoperability. As ultracapacitors find their way into more diverse applications, there is a growing demand for standardized calibration procedures and performance metrics that can ensure consistent and reliable operation across different systems and manufacturers.

Ultracapacitor Market Analysis

The ultracapacitor market has been experiencing significant growth in recent years, driven by the increasing demand for energy-efficient and high-performance energy storage solutions across various industries. The global ultracapacitor market size was valued at approximately $1.2 billion in 2020 and is projected to reach $3.5 billion by 2027, growing at a CAGR of around 16% during the forecast period.

The automotive sector represents one of the largest application areas for ultracapacitors, accounting for nearly 40% of the market share. The adoption of ultracapacitors in electric and hybrid vehicles for regenerative braking systems, start-stop applications, and power assist functions has been a major driver of market growth. Additionally, the increasing focus on renewable energy integration and smart grid technologies has created new opportunities for ultracapacitors in the energy sector.

In terms of regional distribution, Asia Pacific dominates the ultracapacitor market, with China and Japan leading in both production and consumption. The region is expected to maintain its dominant position due to the presence of major automotive manufacturers and the rapid adoption of electric vehicles. North America and Europe follow closely, with significant investments in research and development of advanced energy storage technologies.

The market is characterized by intense competition among key players such as Maxwell Technologies (now part of Tesla), Skeleton Technologies, Nippon Chemi-Con Corporation, and LS Mtron. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

One of the key trends shaping the ultracapacitor market is the increasing integration of battery management systems (BMS) with ultracapacitors. This integration is crucial for optimizing the performance, efficiency, and lifespan of ultracapacitor-based energy storage systems. The importance of BMS calibration in ultracapacitor applications has become a focal point for manufacturers and end-users alike, as it directly impacts the overall system reliability and performance.

The growing emphasis on sustainability and environmental regulations is also driving the adoption of ultracapacitors as a more eco-friendly alternative to traditional batteries in certain applications. This trend is particularly evident in the transportation and industrial sectors, where ultracapacitors offer advantages such as rapid charging, high power density, and longer cycle life.

The automotive sector represents one of the largest application areas for ultracapacitors, accounting for nearly 40% of the market share. The adoption of ultracapacitors in electric and hybrid vehicles for regenerative braking systems, start-stop applications, and power assist functions has been a major driver of market growth. Additionally, the increasing focus on renewable energy integration and smart grid technologies has created new opportunities for ultracapacitors in the energy sector.

In terms of regional distribution, Asia Pacific dominates the ultracapacitor market, with China and Japan leading in both production and consumption. The region is expected to maintain its dominant position due to the presence of major automotive manufacturers and the rapid adoption of electric vehicles. North America and Europe follow closely, with significant investments in research and development of advanced energy storage technologies.

The market is characterized by intense competition among key players such as Maxwell Technologies (now part of Tesla), Skeleton Technologies, Nippon Chemi-Con Corporation, and LS Mtron. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

One of the key trends shaping the ultracapacitor market is the increasing integration of battery management systems (BMS) with ultracapacitors. This integration is crucial for optimizing the performance, efficiency, and lifespan of ultracapacitor-based energy storage systems. The importance of BMS calibration in ultracapacitor applications has become a focal point for manufacturers and end-users alike, as it directly impacts the overall system reliability and performance.

The growing emphasis on sustainability and environmental regulations is also driving the adoption of ultracapacitors as a more eco-friendly alternative to traditional batteries in certain applications. This trend is particularly evident in the transportation and industrial sectors, where ultracapacitors offer advantages such as rapid charging, high power density, and longer cycle life.

BMS Calibration Challenges

Battery Management System (BMS) calibration in ultracapacitor applications presents several unique challenges that require careful consideration and innovative solutions. One of the primary difficulties lies in the rapid charge and discharge characteristics of ultracapacitors, which can make accurate state-of-charge (SOC) estimation more complex than in traditional battery systems. The high power density and low energy density of ultracapacitors result in voltage changes that occur much faster than in conventional batteries, necessitating more frequent and precise calibration processes.

Another significant challenge is the temperature sensitivity of ultracapacitors. Their performance and characteristics can vary substantially across different temperature ranges, affecting both capacity and internal resistance. This variability demands that BMS calibration algorithms be robust enough to account for these temperature-induced changes, ensuring accurate monitoring and control under diverse operating conditions.

The aging process of ultracapacitors also poses a unique calibration challenge. Unlike batteries, which typically experience a gradual decline in capacity over time, ultracapacitors may maintain their capacitance while experiencing an increase in internal resistance. This phenomenon requires BMS calibration techniques that can effectively track and adjust for these long-term changes in device characteristics, ensuring optimal performance throughout the ultracapacitor's lifecycle.

Balancing within ultracapacitor arrays presents another calibration hurdle. Due to manufacturing variations and uneven aging, individual cells within an array may develop slight differences in capacitance and internal resistance. The BMS must be calibrated to detect these imbalances and implement appropriate cell balancing strategies to prevent overcharging or underutilization of specific cells, which could lead to reduced overall system performance or premature failure.

Furthermore, the integration of ultracapacitors with other energy storage technologies, such as batteries in hybrid systems, introduces additional calibration complexities. The BMS must be capable of managing and optimizing the performance of both ultracapacitors and batteries simultaneously, requiring sophisticated algorithms that can accurately calibrate and control the state of charge, power distribution, and energy flow between these different storage elements.

Lastly, the wide range of applications for ultracapacitors, from automotive to renewable energy systems, necessitates adaptable calibration approaches. Each application may have unique requirements in terms of power profiles, cycle life expectations, and environmental conditions. Developing BMS calibration methods that can be easily customized or self-adjusting to suit various application scenarios remains a significant challenge in the field.

Another significant challenge is the temperature sensitivity of ultracapacitors. Their performance and characteristics can vary substantially across different temperature ranges, affecting both capacity and internal resistance. This variability demands that BMS calibration algorithms be robust enough to account for these temperature-induced changes, ensuring accurate monitoring and control under diverse operating conditions.

The aging process of ultracapacitors also poses a unique calibration challenge. Unlike batteries, which typically experience a gradual decline in capacity over time, ultracapacitors may maintain their capacitance while experiencing an increase in internal resistance. This phenomenon requires BMS calibration techniques that can effectively track and adjust for these long-term changes in device characteristics, ensuring optimal performance throughout the ultracapacitor's lifecycle.

Balancing within ultracapacitor arrays presents another calibration hurdle. Due to manufacturing variations and uneven aging, individual cells within an array may develop slight differences in capacitance and internal resistance. The BMS must be calibrated to detect these imbalances and implement appropriate cell balancing strategies to prevent overcharging or underutilization of specific cells, which could lead to reduced overall system performance or premature failure.

Furthermore, the integration of ultracapacitors with other energy storage technologies, such as batteries in hybrid systems, introduces additional calibration complexities. The BMS must be capable of managing and optimizing the performance of both ultracapacitors and batteries simultaneously, requiring sophisticated algorithms that can accurately calibrate and control the state of charge, power distribution, and energy flow between these different storage elements.

Lastly, the wide range of applications for ultracapacitors, from automotive to renewable energy systems, necessitates adaptable calibration approaches. Each application may have unique requirements in terms of power profiles, cycle life expectations, and environmental conditions. Developing BMS calibration methods that can be easily customized or self-adjusting to suit various application scenarios remains a significant challenge in the field.

Current BMS Calibration Methods

01 State of Charge (SOC) Estimation and Calibration

Battery Management Systems (BMS) use various methods to estimate and calibrate the State of Charge (SOC) of batteries. This involves measuring voltage, current, and temperature, and applying algorithms to accurately determine the remaining charge. Calibration techniques are employed to improve the accuracy of SOC estimation over time and under different operating conditions.- State of Charge (SOC) Estimation and Calibration: Battery Management Systems (BMS) use various methods to estimate and calibrate the State of Charge (SOC) of batteries. This involves measuring voltage, current, and temperature, and applying algorithms to accurately determine the remaining charge. Calibration techniques are employed to improve the accuracy of SOC estimation over time and under different operating conditions.

- Battery Cell Balancing Calibration: Cell balancing is a crucial aspect of BMS calibration. It involves equalizing the charge levels across multiple cells in a battery pack to optimize performance and lifespan. Calibration methods are used to ensure accurate measurement and control of individual cell voltages, enabling effective balancing strategies.

- Temperature Compensation and Calibration: BMS calibration includes temperature compensation to account for the effects of temperature on battery performance. This involves calibrating temperature sensors and adjusting battery parameters based on temperature readings to maintain accurate measurements and optimal battery operation across various environmental conditions.

- Capacity and Aging Calibration: BMS calibration techniques are employed to assess and adjust for battery capacity changes due to aging and usage patterns. This involves periodic recalibration of capacity estimates, often through full charge-discharge cycles, to maintain accurate predictions of battery performance and remaining useful life.

- Current Sensor Calibration: Accurate current measurement is critical for BMS functionality. Calibration of current sensors involves techniques to compensate for offset errors, gain errors, and temperature drift. This ensures precise measurement of charge and discharge currents, which is essential for SOC estimation and overall battery management.

02 Battery Cell Balancing Calibration

BMS calibration includes methods for balancing individual cells within a battery pack. This process ensures that all cells maintain similar voltage levels, preventing overcharging or undercharging of specific cells. Calibration techniques for cell balancing involve measuring cell voltages, adjusting charge distribution, and compensating for cell variations over time.Expand Specific Solutions03 Temperature Compensation and Calibration

Temperature significantly affects battery performance and lifespan. BMS calibration incorporates temperature compensation techniques to adjust battery parameters and performance estimates based on ambient and internal temperature measurements. This includes calibrating temperature sensors and adjusting charging and discharging algorithms accordingly.Expand Specific Solutions04 Capacity and Health Estimation Calibration

BMS calibration involves methods to estimate and recalibrate battery capacity and overall health. This includes techniques for measuring and analyzing charge/discharge cycles, internal resistance changes, and voltage characteristics over time. Calibration algorithms adjust these estimates to provide accurate information on battery degradation and remaining useful life.Expand Specific Solutions05 Adaptive Calibration Techniques

Advanced BMS calibration employs adaptive techniques that continuously refine calibration parameters based on real-time data and historical performance. These methods use machine learning algorithms and data analytics to improve the accuracy of various battery measurements and estimations over time, adapting to changes in battery characteristics and usage patterns.Expand Specific Solutions

Key Ultracapacitor BMS Players

The Battery Management System (BMS) calibration market for ultracapacitor applications is in a growth phase, driven by increasing adoption of ultracapacitors in various industries. The market size is expanding, with a projected CAGR of over 20% in the coming years. Technologically, BMS calibration for ultracapacitors is advancing rapidly, with companies like Samsung SDI, LG Energy Solution, and UCAP Power leading innovation. These firms are developing more sophisticated and efficient calibration techniques, enhancing the performance and lifespan of ultracapacitor systems. The competitive landscape is intensifying as both established players and startups vie for market share, focusing on improving accuracy, reliability, and integration capabilities of BMS calibration solutions.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an innovative Battery Management System (BMS) calibration approach for ultracapacitor applications, leveraging its extensive experience in automotive and industrial electronics. Their system utilizes a multi-layered calibration strategy, combining hardware-level precision with software-driven adaptive algorithms[1]. Bosch's BMS employs high-frequency sampling techniques to capture rapid voltage fluctuations characteristic of ultracapacitors, ensuring accurate state-of-charge estimation[3]. The calibration process incorporates temperature compensation mechanisms, crucial for maintaining performance across diverse operating conditions. Additionally, Bosch's system features advanced diagnostic capabilities, continuously monitoring cell health and predicting potential failures[5]. The BMS also integrates with Bosch's broader ecosystem of energy management solutions, allowing for optimized energy distribution in complex systems combining ultracapacitors with traditional batteries[7].

Strengths: Comprehensive integration capabilities, advanced diagnostic features, and robust temperature compensation. Weaknesses: Potentially higher cost due to premium positioning, and possible over-engineering for simpler ultracapacitor applications.

UCAP Power, Inc.

Technical Solution: UCAP Power specializes in ultracapacitor-based energy storage solutions, focusing on the critical role of Battery Management System (BMS) calibration. Their approach involves advanced algorithms for precise voltage and temperature monitoring, ensuring optimal performance and longevity of ultracapacitor systems. The company's BMS utilizes adaptive calibration techniques that continuously adjust to changing environmental conditions and usage patterns[1]. This dynamic calibration process allows for real-time optimization of charge and discharge cycles, significantly enhancing the efficiency and reliability of ultracapacitor applications[3]. UCAP Power's system also incorporates predictive maintenance features, using machine learning algorithms to anticipate potential issues before they occur, thereby reducing downtime and extending the overall lifespan of the ultracapacitor units[5].

Strengths: Specialized expertise in ultracapacitor technology, advanced adaptive calibration techniques, and predictive maintenance capabilities. Weaknesses: Potentially limited application range compared to broader energy storage solutions, and possible higher initial costs due to specialized technology.

Innovative BMS Calibration Tech

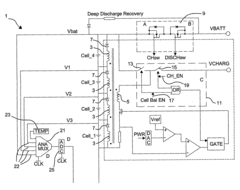

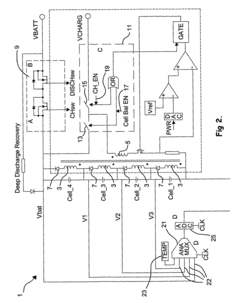

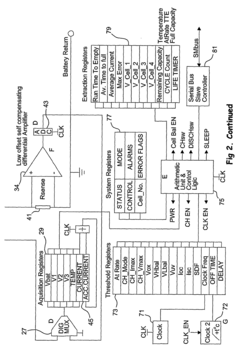

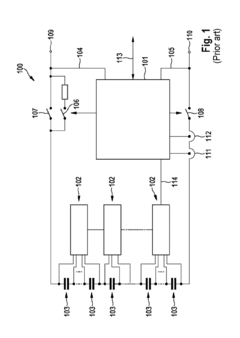

Battery Management System

PatentInactiveUS20080278115A1

Innovation

- A battery management system incorporating programmable logic with digital microprocessors and memory, capable of active cell balancing using a Flyback switched mode converter with synchronous rectifiers, which actively transfers energy between cells, and includes data acquisition devices to monitor and report battery parameters, enabling accurate SoC and SoH determination, and temperature compensation.

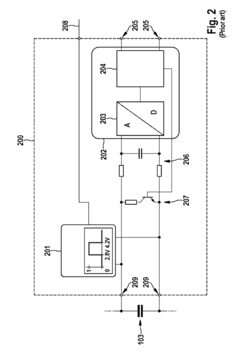

Battery management system having an increased robustness against negative voltages

PatentInactiveUS9793578B2

Innovation

- Incorporating fuses in the supply lines of the cell monitoring units to protect against negative input voltages, with a cost-effective arrangement where only half the number of fuses are used, strategically placed in positive and negative branches to cover most scenarios, and optionally providing fuses in all supply lines for comprehensive protection.

Safety Standards for BMS

Safety standards for Battery Management Systems (BMS) play a crucial role in ensuring the safe and reliable operation of ultracapacitor applications. These standards are designed to address the unique characteristics and potential risks associated with ultracapacitor systems, which differ significantly from traditional battery technologies.

One of the primary safety concerns in ultracapacitor applications is the high power density and rapid charge/discharge capabilities. To mitigate these risks, safety standards for BMS typically include requirements for voltage monitoring and control. These standards often specify the maximum allowable voltage levels and the speed at which the BMS must respond to voltage fluctuations. Additionally, they may mandate the implementation of overvoltage protection mechanisms to prevent damage to the ultracapacitors and surrounding components.

Temperature management is another critical aspect addressed by BMS safety standards. Ultracapacitors can generate significant heat during rapid charge and discharge cycles, potentially leading to thermal runaway or reduced performance. As a result, safety standards often require BMS to incorporate temperature monitoring and control features. These may include specifications for temperature sensor placement, cooling system requirements, and thermal management algorithms.

Current monitoring and control are also essential components of BMS safety standards for ultracapacitor applications. Given the high current capabilities of ultracapacitors, standards typically define maximum current limits and require the BMS to implement overcurrent protection mechanisms. These standards may also specify the response time for current interruption in case of fault conditions.

Safety standards for BMS in ultracapacitor applications often address system-level considerations as well. This includes requirements for isolation and insulation to prevent electrical shorts and ensure the overall safety of the system. Standards may specify minimum isolation resistance levels and define testing procedures to verify compliance.

Furthermore, BMS safety standards typically include provisions for fault detection and reporting. This encompasses requirements for monitoring various system parameters, detecting abnormal conditions, and implementing appropriate safety measures. Standards may define specific fault conditions that the BMS must be capable of identifying and responding to, such as cell imbalance, communication failures, or sensor malfunctions.

Electromagnetic compatibility (EMC) is another important aspect covered by BMS safety standards. Given the high-frequency switching often associated with ultracapacitor systems, standards may specify EMC requirements to ensure that the BMS does not generate excessive electromagnetic interference and remains immune to external electromagnetic disturbances.

In conclusion, safety standards for BMS in ultracapacitor applications are comprehensive and multifaceted, addressing various aspects of system operation and potential risks. These standards are essential for ensuring the safe and reliable performance of ultracapacitor systems across diverse applications and industries.

One of the primary safety concerns in ultracapacitor applications is the high power density and rapid charge/discharge capabilities. To mitigate these risks, safety standards for BMS typically include requirements for voltage monitoring and control. These standards often specify the maximum allowable voltage levels and the speed at which the BMS must respond to voltage fluctuations. Additionally, they may mandate the implementation of overvoltage protection mechanisms to prevent damage to the ultracapacitors and surrounding components.

Temperature management is another critical aspect addressed by BMS safety standards. Ultracapacitors can generate significant heat during rapid charge and discharge cycles, potentially leading to thermal runaway or reduced performance. As a result, safety standards often require BMS to incorporate temperature monitoring and control features. These may include specifications for temperature sensor placement, cooling system requirements, and thermal management algorithms.

Current monitoring and control are also essential components of BMS safety standards for ultracapacitor applications. Given the high current capabilities of ultracapacitors, standards typically define maximum current limits and require the BMS to implement overcurrent protection mechanisms. These standards may also specify the response time for current interruption in case of fault conditions.

Safety standards for BMS in ultracapacitor applications often address system-level considerations as well. This includes requirements for isolation and insulation to prevent electrical shorts and ensure the overall safety of the system. Standards may specify minimum isolation resistance levels and define testing procedures to verify compliance.

Furthermore, BMS safety standards typically include provisions for fault detection and reporting. This encompasses requirements for monitoring various system parameters, detecting abnormal conditions, and implementing appropriate safety measures. Standards may define specific fault conditions that the BMS must be capable of identifying and responding to, such as cell imbalance, communication failures, or sensor malfunctions.

Electromagnetic compatibility (EMC) is another important aspect covered by BMS safety standards. Given the high-frequency switching often associated with ultracapacitor systems, standards may specify EMC requirements to ensure that the BMS does not generate excessive electromagnetic interference and remains immune to external electromagnetic disturbances.

In conclusion, safety standards for BMS in ultracapacitor applications are comprehensive and multifaceted, addressing various aspects of system operation and potential risks. These standards are essential for ensuring the safe and reliable performance of ultracapacitor systems across diverse applications and industries.

Environmental Impact of BMS

The environmental impact of Battery Management Systems (BMS) in ultracapacitor applications is a crucial consideration in the broader context of sustainable energy solutions. As the demand for efficient energy storage systems grows, the role of BMS in minimizing environmental footprint becomes increasingly significant.

BMS calibration plays a vital role in optimizing the performance and longevity of ultracapacitor systems. Proper calibration ensures that the energy storage units operate within their optimal parameters, reducing unnecessary wear and extending their operational lifespan. This directly translates to a reduction in electronic waste, as fewer replacements are required over time.

Furthermore, accurate BMS calibration contributes to improved energy efficiency. By precisely monitoring and controlling the charge and discharge cycles, a well-calibrated BMS minimizes energy losses during operation. This increased efficiency not only enhances the overall performance of the ultracapacitor system but also reduces the energy demand from the grid, potentially lowering the carbon footprint associated with power generation.

The environmental benefits of BMS calibration extend to the realm of raw material conservation. Ultracapacitors often contain rare earth elements and other valuable resources. By ensuring optimal performance and longevity through proper BMS calibration, the demand for these materials is reduced, alleviating pressure on natural resources and minimizing the environmental impact of mining and processing activities.

In the context of electric vehicles and renewable energy systems, where ultracapacitors are increasingly utilized, the environmental impact of BMS calibration becomes even more pronounced. Accurate energy management leads to improved range and performance in electric vehicles, potentially accelerating the transition away from fossil fuel-dependent transportation. In renewable energy applications, optimized ultracapacitor systems can enhance grid stability and energy storage capabilities, facilitating the integration of intermittent renewable sources.

However, it is important to note that the BMS itself has an environmental footprint. The production of electronic components and the energy consumed during the calibration process contribute to the overall environmental impact. Manufacturers and researchers are continuously working on developing more sustainable BMS solutions, incorporating eco-friendly materials and energy-efficient calibration techniques to further reduce the environmental burden.

As the industry moves towards more sustainable practices, the focus on BMS calibration as a means to enhance environmental performance is likely to intensify. Future developments may include the integration of artificial intelligence and machine learning algorithms to optimize BMS calibration processes, further improving energy efficiency and reducing environmental impact across the lifecycle of ultracapacitor applications.

BMS calibration plays a vital role in optimizing the performance and longevity of ultracapacitor systems. Proper calibration ensures that the energy storage units operate within their optimal parameters, reducing unnecessary wear and extending their operational lifespan. This directly translates to a reduction in electronic waste, as fewer replacements are required over time.

Furthermore, accurate BMS calibration contributes to improved energy efficiency. By precisely monitoring and controlling the charge and discharge cycles, a well-calibrated BMS minimizes energy losses during operation. This increased efficiency not only enhances the overall performance of the ultracapacitor system but also reduces the energy demand from the grid, potentially lowering the carbon footprint associated with power generation.

The environmental benefits of BMS calibration extend to the realm of raw material conservation. Ultracapacitors often contain rare earth elements and other valuable resources. By ensuring optimal performance and longevity through proper BMS calibration, the demand for these materials is reduced, alleviating pressure on natural resources and minimizing the environmental impact of mining and processing activities.

In the context of electric vehicles and renewable energy systems, where ultracapacitors are increasingly utilized, the environmental impact of BMS calibration becomes even more pronounced. Accurate energy management leads to improved range and performance in electric vehicles, potentially accelerating the transition away from fossil fuel-dependent transportation. In renewable energy applications, optimized ultracapacitor systems can enhance grid stability and energy storage capabilities, facilitating the integration of intermittent renewable sources.

However, it is important to note that the BMS itself has an environmental footprint. The production of electronic components and the energy consumed during the calibration process contribute to the overall environmental impact. Manufacturers and researchers are continuously working on developing more sustainable BMS solutions, incorporating eco-friendly materials and energy-efficient calibration techniques to further reduce the environmental burden.

As the industry moves towards more sustainable practices, the focus on BMS calibration as a means to enhance environmental performance is likely to intensify. Future developments may include the integration of artificial intelligence and machine learning algorithms to optimize BMS calibration processes, further improving energy efficiency and reducing environmental impact across the lifecycle of ultracapacitor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!