Examination of Feedback Control Mechanisms in Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Feedback Control Background and Objectives

Battery Management Systems (BMS) have become increasingly crucial in the era of electrification, playing a pivotal role in ensuring the safety, efficiency, and longevity of battery systems. The evolution of BMS technology has been driven by the rapid advancement of electric vehicles, renewable energy storage, and portable electronics. Feedback control mechanisms within BMS have emerged as a critical component, enabling real-time monitoring and adjustment of battery parameters to optimize performance and protect against potential hazards.

The primary objective of examining feedback control mechanisms in BMS is to enhance the overall system performance, improve battery life, and ensure safe operation under various conditions. This involves developing sophisticated algorithms that can accurately predict and respond to changes in battery state, temperature, and load demands. By leveraging advanced sensors and data processing techniques, modern BMS aim to provide more precise control over charging and discharging processes, thermal management, and cell balancing.

Historically, BMS feedback control has evolved from simple voltage and current monitoring to complex, multi-variable systems that incorporate machine learning and predictive analytics. Early BMS relied on basic threshold-based controls, which have since given way to more nuanced approaches that consider the dynamic nature of battery behavior. The integration of artificial intelligence and big data analytics has opened new avenues for predictive maintenance and adaptive control strategies, further pushing the boundaries of what is possible in battery management.

One of the key technological trends in BMS feedback control is the move towards distributed architectures. This approach allows for more granular control at the cell level, enabling faster response times and more efficient energy utilization. Additionally, there is a growing focus on developing robust control algorithms that can adapt to battery aging and varying environmental conditions, ensuring consistent performance throughout the battery's lifecycle.

As the demand for high-performance energy storage solutions continues to grow, the importance of advanced feedback control in BMS cannot be overstated. Future developments in this field are expected to focus on improving the accuracy of state estimation techniques, reducing system complexity while enhancing functionality, and integrating BMS more seamlessly with other vehicle or grid systems. The ultimate goal is to create intelligent, self-optimizing battery management systems that can maximize energy efficiency, extend battery life, and provide unparalleled safety assurances.

The primary objective of examining feedback control mechanisms in BMS is to enhance the overall system performance, improve battery life, and ensure safe operation under various conditions. This involves developing sophisticated algorithms that can accurately predict and respond to changes in battery state, temperature, and load demands. By leveraging advanced sensors and data processing techniques, modern BMS aim to provide more precise control over charging and discharging processes, thermal management, and cell balancing.

Historically, BMS feedback control has evolved from simple voltage and current monitoring to complex, multi-variable systems that incorporate machine learning and predictive analytics. Early BMS relied on basic threshold-based controls, which have since given way to more nuanced approaches that consider the dynamic nature of battery behavior. The integration of artificial intelligence and big data analytics has opened new avenues for predictive maintenance and adaptive control strategies, further pushing the boundaries of what is possible in battery management.

One of the key technological trends in BMS feedback control is the move towards distributed architectures. This approach allows for more granular control at the cell level, enabling faster response times and more efficient energy utilization. Additionally, there is a growing focus on developing robust control algorithms that can adapt to battery aging and varying environmental conditions, ensuring consistent performance throughout the battery's lifecycle.

As the demand for high-performance energy storage solutions continues to grow, the importance of advanced feedback control in BMS cannot be overstated. Future developments in this field are expected to focus on improving the accuracy of state estimation techniques, reducing system complexity while enhancing functionality, and integrating BMS more seamlessly with other vehicle or grid systems. The ultimate goal is to create intelligent, self-optimizing battery management systems that can maximize energy efficiency, extend battery life, and provide unparalleled safety assurances.

Market Demand for Advanced BMS Solutions

The demand for advanced Battery Management Systems (BMS) solutions has been steadily increasing, driven by the rapid growth of electric vehicles (EVs) and renewable energy storage systems. As the global push for electrification intensifies, the market for sophisticated BMS technologies is experiencing significant expansion.

In the automotive sector, the rise of EVs has created a substantial need for high-performance BMS solutions. These systems are crucial for optimizing battery life, ensuring safety, and maximizing the range of electric vehicles. Major automakers are investing heavily in BMS technology to gain a competitive edge in the EV market, leading to increased demand for innovative feedback control mechanisms.

The renewable energy sector is another key driver of BMS market growth. As more countries transition to clean energy sources, the need for efficient energy storage systems has surged. Advanced BMS solutions play a vital role in managing large-scale battery installations for grid stabilization and renewable energy integration.

Consumer electronics represent another significant market segment for BMS solutions. With the proliferation of portable devices and the growing demand for longer battery life, manufacturers are seeking more sophisticated BMS technologies to enhance product performance and user satisfaction.

The industrial sector, including manufacturing and telecommunications, is also contributing to the demand for advanced BMS solutions. These industries require reliable power backup systems and efficient energy management, driving the need for robust BMS technologies.

Market analysts project substantial growth in the BMS market over the coming years. The increasing adoption of lithium-ion batteries across various applications is a key factor fueling this growth. As battery technologies continue to evolve, the demand for more advanced and adaptive BMS solutions is expected to rise correspondingly.

The push for sustainability and energy efficiency is further amplifying the market demand. Governments worldwide are implementing stricter regulations on energy consumption and emissions, prompting industries to adopt more efficient battery management technologies.

In response to these market trends, BMS manufacturers are focusing on developing more sophisticated feedback control mechanisms. These include real-time monitoring capabilities, predictive maintenance features, and adaptive control algorithms that can optimize battery performance under various operating conditions.

The market is also seeing a growing demand for BMS solutions that can integrate with broader energy management systems and smart grid technologies. This integration allows for more efficient energy utilization and contributes to the development of smart cities and sustainable infrastructure.

In the automotive sector, the rise of EVs has created a substantial need for high-performance BMS solutions. These systems are crucial for optimizing battery life, ensuring safety, and maximizing the range of electric vehicles. Major automakers are investing heavily in BMS technology to gain a competitive edge in the EV market, leading to increased demand for innovative feedback control mechanisms.

The renewable energy sector is another key driver of BMS market growth. As more countries transition to clean energy sources, the need for efficient energy storage systems has surged. Advanced BMS solutions play a vital role in managing large-scale battery installations for grid stabilization and renewable energy integration.

Consumer electronics represent another significant market segment for BMS solutions. With the proliferation of portable devices and the growing demand for longer battery life, manufacturers are seeking more sophisticated BMS technologies to enhance product performance and user satisfaction.

The industrial sector, including manufacturing and telecommunications, is also contributing to the demand for advanced BMS solutions. These industries require reliable power backup systems and efficient energy management, driving the need for robust BMS technologies.

Market analysts project substantial growth in the BMS market over the coming years. The increasing adoption of lithium-ion batteries across various applications is a key factor fueling this growth. As battery technologies continue to evolve, the demand for more advanced and adaptive BMS solutions is expected to rise correspondingly.

The push for sustainability and energy efficiency is further amplifying the market demand. Governments worldwide are implementing stricter regulations on energy consumption and emissions, prompting industries to adopt more efficient battery management technologies.

In response to these market trends, BMS manufacturers are focusing on developing more sophisticated feedback control mechanisms. These include real-time monitoring capabilities, predictive maintenance features, and adaptive control algorithms that can optimize battery performance under various operating conditions.

The market is also seeing a growing demand for BMS solutions that can integrate with broader energy management systems and smart grid technologies. This integration allows for more efficient energy utilization and contributes to the development of smart cities and sustainable infrastructure.

Current BMS Feedback Control Challenges

Battery Management Systems (BMS) face several critical challenges in implementing effective feedback control mechanisms. One of the primary issues is the complexity of accurately measuring and estimating the state of charge (SOC) and state of health (SOH) of lithium-ion batteries. These parameters are crucial for optimal battery performance and longevity, but they are not directly measurable and must be inferred from other observable variables.

The dynamic nature of battery behavior adds another layer of complexity to feedback control. Batteries exhibit nonlinear characteristics that vary with temperature, charge/discharge rates, and aging. This variability makes it difficult to develop robust control algorithms that can adapt to changing conditions and maintain optimal performance across the battery's lifecycle.

Thermal management presents a significant challenge for BMS feedback control. Batteries generate heat during operation, and temperature variations can significantly impact performance and safety. Developing accurate thermal models and implementing effective cooling strategies while maintaining overall system efficiency is a delicate balancing act.

Cell balancing is another area where current BMS feedback control mechanisms face difficulties. In multi-cell battery packs, individual cells can develop voltage imbalances over time, leading to reduced overall capacity and potential safety risks. Implementing efficient and effective cell balancing algorithms that can operate in real-time without compromising system performance remains a challenge.

The integration of BMS with other vehicle systems, such as power electronics and motor control units, introduces additional complexities in feedback control. Ensuring seamless communication and coordination between these systems while maintaining optimal battery performance and safety is an ongoing challenge.

Data acquisition and processing speed are critical factors in BMS feedback control. The need for real-time monitoring and control of multiple parameters requires high-speed, accurate sensors and powerful processing capabilities. Balancing the need for comprehensive data collection with system cost and complexity is an ongoing challenge for BMS designers.

Lastly, the reliability and robustness of BMS feedback control mechanisms in harsh automotive environments pose significant challenges. BMS must operate consistently under varying temperatures, vibrations, and electromagnetic interference conditions while maintaining accuracy and safety over the vehicle's lifetime.

The dynamic nature of battery behavior adds another layer of complexity to feedback control. Batteries exhibit nonlinear characteristics that vary with temperature, charge/discharge rates, and aging. This variability makes it difficult to develop robust control algorithms that can adapt to changing conditions and maintain optimal performance across the battery's lifecycle.

Thermal management presents a significant challenge for BMS feedback control. Batteries generate heat during operation, and temperature variations can significantly impact performance and safety. Developing accurate thermal models and implementing effective cooling strategies while maintaining overall system efficiency is a delicate balancing act.

Cell balancing is another area where current BMS feedback control mechanisms face difficulties. In multi-cell battery packs, individual cells can develop voltage imbalances over time, leading to reduced overall capacity and potential safety risks. Implementing efficient and effective cell balancing algorithms that can operate in real-time without compromising system performance remains a challenge.

The integration of BMS with other vehicle systems, such as power electronics and motor control units, introduces additional complexities in feedback control. Ensuring seamless communication and coordination between these systems while maintaining optimal battery performance and safety is an ongoing challenge.

Data acquisition and processing speed are critical factors in BMS feedback control. The need for real-time monitoring and control of multiple parameters requires high-speed, accurate sensors and powerful processing capabilities. Balancing the need for comprehensive data collection with system cost and complexity is an ongoing challenge for BMS designers.

Lastly, the reliability and robustness of BMS feedback control mechanisms in harsh automotive environments pose significant challenges. BMS must operate consistently under varying temperatures, vibrations, and electromagnetic interference conditions while maintaining accuracy and safety over the vehicle's lifetime.

Existing BMS Feedback Control Strategies

01 Adaptive control algorithms for battery management

Battery Management Systems (BMS) employ adaptive control algorithms to optimize performance and longevity. These algorithms continuously adjust parameters based on real-time feedback from battery cells, considering factors such as temperature, charge state, and usage patterns. This approach enables dynamic optimization of charging and discharging processes, enhancing overall battery efficiency and lifespan.- Adaptive control algorithms for battery management: Battery management systems employ adaptive control algorithms to optimize performance and efficiency. These algorithms continuously adjust parameters based on real-time feedback from battery sensors, allowing for dynamic responses to changing conditions and improved overall system performance.

- State estimation and prediction in BMS: Advanced state estimation and prediction techniques are implemented in battery management systems to accurately determine battery health, state of charge, and remaining useful life. These methods utilize various sensor inputs and historical data to provide reliable forecasts for optimized battery usage and maintenance.

- Thermal management and control in BMS: Battery management systems incorporate thermal control mechanisms to maintain optimal operating temperatures. Feedback-driven cooling and heating systems are employed to prevent overheating, extend battery life, and ensure safe operation across various environmental conditions.

- Cell balancing and charge distribution: Feedback control mechanisms in battery management systems enable efficient cell balancing and charge distribution. These systems monitor individual cell voltages and adjust charging currents to ensure uniform charge levels across all cells, maximizing overall battery capacity and lifespan.

- Fault detection and mitigation in BMS: Battery management systems utilize feedback control mechanisms for real-time fault detection and mitigation. These systems continuously monitor battery parameters, identify potential issues, and implement corrective actions to prevent failures and ensure safe operation of the battery pack.

02 State estimation and prediction in BMS

Advanced BMS incorporate state estimation and prediction mechanisms to accurately assess battery conditions. These systems use complex models and machine learning techniques to estimate parameters like State of Charge (SoC) and State of Health (SoH). By predicting future battery behavior, the BMS can proactively adjust control strategies, preventing potential issues and optimizing battery performance.Expand Specific Solutions03 Thermal management feedback control

Thermal management is crucial in BMS, and feedback control mechanisms play a vital role. These systems monitor battery temperature in real-time and adjust cooling or heating mechanisms accordingly. By maintaining optimal temperature ranges, the BMS enhances battery efficiency, prevents thermal runaway, and extends battery life.Expand Specific Solutions04 Cell balancing techniques in BMS

BMS employ sophisticated cell balancing techniques to ensure uniform charge distribution across battery cells. Feedback control mechanisms continuously monitor individual cell voltages and adjust charge distribution accordingly. This approach prevents overcharging of individual cells, reduces capacity loss, and extends overall battery pack life.Expand Specific Solutions05 Fault detection and mitigation in BMS

Advanced BMS incorporate feedback control mechanisms for real-time fault detection and mitigation. These systems continuously monitor various parameters to identify potential issues such as short circuits, overcharging, or cell degradation. Upon detecting a fault, the BMS can implement corrective actions, isolate faulty components, or trigger safety protocols to prevent system failure and ensure safe operation.Expand Specific Solutions

Key Players in BMS Technology Industry

The examination of feedback control mechanisms in Battery Management Systems (BMS) is currently in a growth phase, with a rapidly expanding market driven by the increasing adoption of electric vehicles and renewable energy storage solutions. The global BMS market is projected to reach significant value in the coming years, reflecting the technology's critical role in optimizing battery performance and longevity. Major players like LG Energy Solution, Samsung SDI, and Contemporary Amperex Technology Co. are at the forefront of BMS development, with established automotive giants such as GM, Toyota, and Nissan also making substantial investments. The technology's maturity varies, with advanced systems featuring AI and machine learning capabilities emerging from companies like GridBeyond and Renesas Electronics, while continuous improvements in efficiency and safety remain key focus areas across the industry.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented a cutting-edge BMS with advanced feedback control mechanisms. Their system utilizes a multi-modal sensing approach, combining electrical, thermal, and mechanical measurements for comprehensive battery state estimation[10]. The feedback control loop incorporates both model-based and data-driven algorithms to adapt to varying operating conditions and battery aging. LG's BMS employs a unique cell-to-pack architecture, allowing for more granular control and optimization at the cell level while maintaining efficient overall pack management[11]. The system features dynamic power allocation, adjusting energy flow between cells and modules in real-time to maximize performance and extend battery life. Additionally, LG has implemented prognostics and health management (PHM) techniques within their feedback control system, enabling predictive maintenance and adaptive control strategies based on projected battery degradation[12].

Strengths: Multi-modal sensing, cell-to-pack architecture, and integrated prognostics and health management. Weaknesses: Increased system complexity and potential for higher initial costs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced Battery Management System (BMS) with sophisticated feedback control mechanisms. Their system utilizes real-time monitoring and adaptive control algorithms to optimize battery performance and longevity. The BMS employs a multi-layered approach, incorporating cell-level, module-level, and pack-level control strategies[1]. At the cell level, it uses high-precision voltage and temperature sensors to continuously monitor each cell's state. The feedback control loop adjusts charging and discharging rates based on these measurements, preventing overcharging and over-discharging[2]. At the module and pack levels, the system implements load balancing algorithms to ensure uniform energy distribution and thermal management across all cells, significantly extending the battery's overall lifespan[3].

Strengths: Highly accurate cell-level monitoring, advanced load balancing, and thermal management. Weaknesses: Potentially higher cost due to complex sensor network and computational requirements.

Core Innovations in BMS Feedback Mechanisms

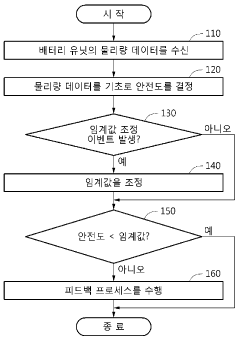

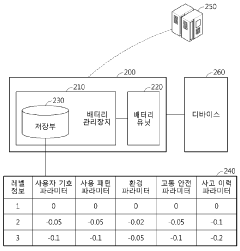

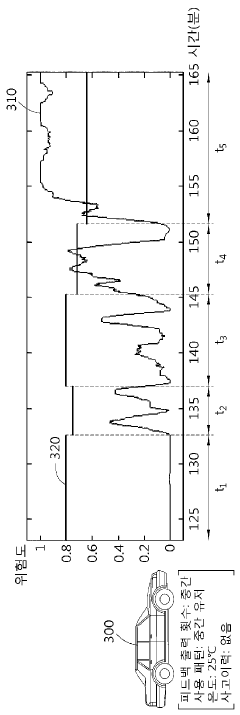

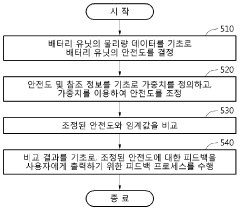

Method and apparatus for managing battery

PatentActiveKR1020180037708A

Innovation

- A battery management method and apparatus that determines safety levels based on physical quantity data, adjusts thresholds using reference information, and provides feedback through visual, auditory, or tactile means when safety levels fall below adjusted thresholds, considering user preferences, usage patterns, environmental conditions, and traffic safety.

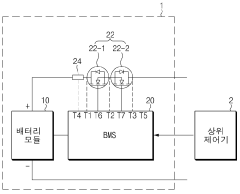

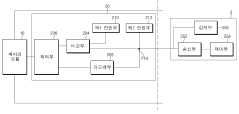

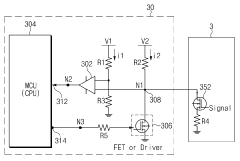

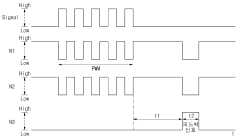

Battery management system and bms control system

PatentActiveKR1020200090530A

Innovation

- A battery management system with a comparator that compares received signals to a preset voltage, a controller that outputs a feedback signal, and a feedback unit that changes the input terminal voltage, allowing the BMS to confirm signal receipt through one-way communication.

Safety Standards for BMS Implementation

Safety standards for Battery Management Systems (BMS) implementation are crucial for ensuring the reliable and secure operation of battery systems across various applications. These standards encompass a wide range of requirements and guidelines that address the design, manufacturing, testing, and operation of BMS components and systems.

One of the primary safety standards for BMS implementation is the ISO 26262 standard, which focuses on functional safety for road vehicles. This standard provides a comprehensive framework for developing safety-critical electrical and electronic systems in automobiles, including BMS. It outlines a systematic approach to identifying and mitigating potential hazards throughout the entire development lifecycle of the BMS.

Another important standard is UL 1642, which specifically addresses the safety of lithium batteries. This standard sets requirements for the construction, testing, and performance of lithium batteries used in various applications, including those managed by BMS. Compliance with UL 1642 ensures that batteries meet stringent safety criteria and can withstand potential abuse conditions.

The IEC 62133 standard is also relevant for BMS implementation, as it covers safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard addresses aspects such as electrical, mechanical, and environmental safety, which are essential considerations for BMS design and operation.

For electric vehicles, the SAE J2464 standard provides guidelines for electric and hybrid vehicle battery systems. This standard outlines test procedures and safety performance criteria for rechargeable energy storage systems, including requirements for BMS functionality and safety features.

In addition to these specific standards, general electrical safety standards such as IEC 61508 and IEC 60730 also play a role in BMS implementation. These standards provide guidance on functional safety for electrical, electronic, and programmable electronic systems, which are applicable to the development of robust and reliable BMS.

Compliance with these safety standards often requires rigorous testing and validation procedures. This includes conducting failure mode and effects analysis (FMEA), fault tree analysis (FTA), and hardware-in-the-loop (HIL) testing to identify potential failure modes and verify the effectiveness of safety mechanisms implemented in the BMS.

Furthermore, safety standards for BMS implementation often emphasize the importance of redundancy and fault tolerance. This may involve implementing multiple layers of protection, such as overcurrent protection, overvoltage protection, and thermal management systems, to ensure the safe operation of the battery system even in the event of component failures.

As the field of battery technology continues to evolve, safety standards for BMS implementation are also subject to regular updates and revisions. Manufacturers and developers must stay informed about the latest standards and requirements to ensure their BMS designs remain compliant and up-to-date with the most current safety practices.

One of the primary safety standards for BMS implementation is the ISO 26262 standard, which focuses on functional safety for road vehicles. This standard provides a comprehensive framework for developing safety-critical electrical and electronic systems in automobiles, including BMS. It outlines a systematic approach to identifying and mitigating potential hazards throughout the entire development lifecycle of the BMS.

Another important standard is UL 1642, which specifically addresses the safety of lithium batteries. This standard sets requirements for the construction, testing, and performance of lithium batteries used in various applications, including those managed by BMS. Compliance with UL 1642 ensures that batteries meet stringent safety criteria and can withstand potential abuse conditions.

The IEC 62133 standard is also relevant for BMS implementation, as it covers safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard addresses aspects such as electrical, mechanical, and environmental safety, which are essential considerations for BMS design and operation.

For electric vehicles, the SAE J2464 standard provides guidelines for electric and hybrid vehicle battery systems. This standard outlines test procedures and safety performance criteria for rechargeable energy storage systems, including requirements for BMS functionality and safety features.

In addition to these specific standards, general electrical safety standards such as IEC 61508 and IEC 60730 also play a role in BMS implementation. These standards provide guidance on functional safety for electrical, electronic, and programmable electronic systems, which are applicable to the development of robust and reliable BMS.

Compliance with these safety standards often requires rigorous testing and validation procedures. This includes conducting failure mode and effects analysis (FMEA), fault tree analysis (FTA), and hardware-in-the-loop (HIL) testing to identify potential failure modes and verify the effectiveness of safety mechanisms implemented in the BMS.

Furthermore, safety standards for BMS implementation often emphasize the importance of redundancy and fault tolerance. This may involve implementing multiple layers of protection, such as overcurrent protection, overvoltage protection, and thermal management systems, to ensure the safe operation of the battery system even in the event of component failures.

As the field of battery technology continues to evolve, safety standards for BMS implementation are also subject to regular updates and revisions. Manufacturers and developers must stay informed about the latest standards and requirements to ensure their BMS designs remain compliant and up-to-date with the most current safety practices.

Environmental Impact of BMS Technologies

The environmental impact of Battery Management System (BMS) technologies is a critical consideration in the development and implementation of feedback control mechanisms for battery systems. As the global demand for energy storage solutions continues to grow, particularly in the electric vehicle and renewable energy sectors, the environmental implications of BMS technologies become increasingly significant.

BMS technologies play a crucial role in optimizing battery performance, extending battery life, and ensuring safe operation. However, their production, use, and disposal can have both positive and negative environmental consequences. On the positive side, effective BMS technologies contribute to the overall efficiency and longevity of battery systems, potentially reducing the need for frequent battery replacements and minimizing electronic waste.

The manufacturing process of BMS components, including sensors, microcontrollers, and power electronics, requires the extraction and processing of raw materials. This can lead to environmental concerns such as resource depletion, energy consumption, and emissions associated with mining and manufacturing activities. Additionally, the production of printed circuit boards and other electronic components often involves the use of hazardous chemicals and materials, which may pose risks to ecosystems if not properly managed.

During the operational phase, BMS technologies can significantly enhance the environmental performance of battery systems. By optimizing charging and discharging cycles, BMS helps to maximize energy efficiency and reduce unnecessary power consumption. This, in turn, can lead to lower greenhouse gas emissions associated with energy production and consumption. Furthermore, advanced BMS algorithms can help prevent overcharging and deep discharging, which can extend battery lifespan and reduce the frequency of battery replacements.

The end-of-life management of BMS components presents another environmental challenge. As electronic waste, these components may contain hazardous materials that require specialized disposal or recycling processes. Proper recycling of BMS components can recover valuable materials and reduce the environmental impact of electronic waste. However, the complexity of these systems and the presence of various materials can make recycling processes more challenging and energy-intensive.

Looking towards the future, the environmental impact of BMS technologies is likely to evolve with advancements in materials science and manufacturing processes. The development of more sustainable and recyclable materials for BMS components could significantly reduce their environmental footprint. Additionally, the integration of artificial intelligence and machine learning algorithms in BMS could further optimize battery performance and energy efficiency, potentially leading to even greater environmental benefits in the long term.

BMS technologies play a crucial role in optimizing battery performance, extending battery life, and ensuring safe operation. However, their production, use, and disposal can have both positive and negative environmental consequences. On the positive side, effective BMS technologies contribute to the overall efficiency and longevity of battery systems, potentially reducing the need for frequent battery replacements and minimizing electronic waste.

The manufacturing process of BMS components, including sensors, microcontrollers, and power electronics, requires the extraction and processing of raw materials. This can lead to environmental concerns such as resource depletion, energy consumption, and emissions associated with mining and manufacturing activities. Additionally, the production of printed circuit boards and other electronic components often involves the use of hazardous chemicals and materials, which may pose risks to ecosystems if not properly managed.

During the operational phase, BMS technologies can significantly enhance the environmental performance of battery systems. By optimizing charging and discharging cycles, BMS helps to maximize energy efficiency and reduce unnecessary power consumption. This, in turn, can lead to lower greenhouse gas emissions associated with energy production and consumption. Furthermore, advanced BMS algorithms can help prevent overcharging and deep discharging, which can extend battery lifespan and reduce the frequency of battery replacements.

The end-of-life management of BMS components presents another environmental challenge. As electronic waste, these components may contain hazardous materials that require specialized disposal or recycling processes. Proper recycling of BMS components can recover valuable materials and reduce the environmental impact of electronic waste. However, the complexity of these systems and the presence of various materials can make recycling processes more challenging and energy-intensive.

Looking towards the future, the environmental impact of BMS technologies is likely to evolve with advancements in materials science and manufacturing processes. The development of more sustainable and recyclable materials for BMS components could significantly reduce their environmental footprint. Additionally, the integration of artificial intelligence and machine learning algorithms in BMS could further optimize battery performance and energy efficiency, potentially leading to even greater environmental benefits in the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!