Thermal Management Strategies in Electric Aviation's Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aviation Battery Thermal Management Evolution

The evolution of thermal management strategies in aviation battery systems has been closely tied to the advancement of electric propulsion technologies in the aerospace industry. Initially, battery thermal management in aviation focused primarily on maintaining safe operating temperatures for lead-acid batteries used in conventional aircraft. As lithium-ion batteries began to replace older technologies due to their higher energy density, the complexity and importance of thermal management increased significantly.

In the early stages of electric aviation development, passive cooling methods were predominantly used. These included natural convection and basic heat sinks, which were sufficient for small-scale applications with limited power requirements. However, as electric aircraft designs grew more ambitious, the limitations of passive cooling became apparent, leading to the exploration of more advanced thermal management techniques.

The next phase saw the introduction of active cooling systems, utilizing forced air convection and liquid cooling loops. These systems provided more precise temperature control and allowed for higher power outputs from battery packs. Liquid cooling, in particular, gained traction due to its superior heat transfer capabilities and ability to maintain more uniform temperatures across battery cells.

As electric aviation projects scaled up, thermal management strategies began to incorporate more sophisticated approaches. Phase change materials (PCMs) were introduced to absorb excess heat during high-load operations and release it during low-load periods, helping to stabilize battery temperatures. Additionally, the integration of thermal management with overall aircraft design became more prevalent, with considerations for aerodynamic cooling and heat dissipation through structural components.

Recent developments have seen a shift towards holistic battery management systems that combine thermal regulation with advanced monitoring and control algorithms. These systems utilize predictive modeling and real-time data analysis to optimize battery performance and longevity. Innovations such as smart thermal runaway prevention and propagation mitigation strategies have become critical components of modern aviation battery thermal management.

The latest frontier in aviation battery thermal management involves the exploration of novel materials and nanotechnology. Research into high thermal conductivity materials, advanced thermal interface materials, and nanostructured heat spreaders promises to enhance heat dissipation efficiency. Furthermore, the development of solid-state batteries with inherently better thermal stability is poised to revolutionize thermal management strategies in future electric aircraft.

In the early stages of electric aviation development, passive cooling methods were predominantly used. These included natural convection and basic heat sinks, which were sufficient for small-scale applications with limited power requirements. However, as electric aircraft designs grew more ambitious, the limitations of passive cooling became apparent, leading to the exploration of more advanced thermal management techniques.

The next phase saw the introduction of active cooling systems, utilizing forced air convection and liquid cooling loops. These systems provided more precise temperature control and allowed for higher power outputs from battery packs. Liquid cooling, in particular, gained traction due to its superior heat transfer capabilities and ability to maintain more uniform temperatures across battery cells.

As electric aviation projects scaled up, thermal management strategies began to incorporate more sophisticated approaches. Phase change materials (PCMs) were introduced to absorb excess heat during high-load operations and release it during low-load periods, helping to stabilize battery temperatures. Additionally, the integration of thermal management with overall aircraft design became more prevalent, with considerations for aerodynamic cooling and heat dissipation through structural components.

Recent developments have seen a shift towards holistic battery management systems that combine thermal regulation with advanced monitoring and control algorithms. These systems utilize predictive modeling and real-time data analysis to optimize battery performance and longevity. Innovations such as smart thermal runaway prevention and propagation mitigation strategies have become critical components of modern aviation battery thermal management.

The latest frontier in aviation battery thermal management involves the exploration of novel materials and nanotechnology. Research into high thermal conductivity materials, advanced thermal interface materials, and nanostructured heat spreaders promises to enhance heat dissipation efficiency. Furthermore, the development of solid-state batteries with inherently better thermal stability is poised to revolutionize thermal management strategies in future electric aircraft.

Electric Aviation Market Demand Analysis

The electric aviation market is experiencing rapid growth, driven by increasing environmental concerns and the push for sustainable transportation solutions. As governments worldwide implement stricter emissions regulations, the demand for electric aircraft is expected to surge in the coming years. The market for electric aviation, particularly in the segment of urban air mobility and short-haul flights, is projected to expand significantly.

Several factors contribute to the rising demand for electric aviation. Firstly, the reduced operating costs associated with electric propulsion systems are attracting both established airlines and new entrants to the market. Electric aircraft offer lower maintenance requirements and fuel costs compared to traditional combustion engine aircraft, making them an economically attractive option for operators.

Additionally, the growing emphasis on reducing carbon emissions in the aviation sector is driving interest in electric aircraft. Many countries have set ambitious targets for carbon neutrality, and electric aviation is seen as a crucial component in achieving these goals. This regulatory push is creating a favorable environment for the adoption of electric aircraft technologies.

The urban air mobility segment, in particular, is showing significant potential. The concept of electric vertical takeoff and landing (eVTOL) aircraft for short-distance travel within and between cities is gaining traction. Several companies are developing eVTOL prototypes, with some expecting to launch commercial services in the next few years. This emerging market is attracting substantial investment from both traditional aerospace companies and new technology firms.

However, the electric aviation market also faces challenges that could impact demand. The limited range of current battery technologies remains a significant hurdle, particularly for longer-haul flights. Advancements in battery technology, specifically in energy density and thermal management, are crucial for expanding the market beyond short-range applications.

Infrastructure development is another critical factor influencing market demand. The widespread adoption of electric aircraft will require substantial investments in charging infrastructure at airports and vertiports. The pace of this infrastructure development will play a key role in determining the growth trajectory of the electric aviation market.

Despite these challenges, the overall outlook for the electric aviation market remains positive. Industry analysts predict strong growth in the coming decades, with the market expected to expand as technology improves and regulatory support increases. The success of early adopters and demonstration projects will be crucial in building confidence and driving wider market acceptance of electric aviation technologies.

Several factors contribute to the rising demand for electric aviation. Firstly, the reduced operating costs associated with electric propulsion systems are attracting both established airlines and new entrants to the market. Electric aircraft offer lower maintenance requirements and fuel costs compared to traditional combustion engine aircraft, making them an economically attractive option for operators.

Additionally, the growing emphasis on reducing carbon emissions in the aviation sector is driving interest in electric aircraft. Many countries have set ambitious targets for carbon neutrality, and electric aviation is seen as a crucial component in achieving these goals. This regulatory push is creating a favorable environment for the adoption of electric aircraft technologies.

The urban air mobility segment, in particular, is showing significant potential. The concept of electric vertical takeoff and landing (eVTOL) aircraft for short-distance travel within and between cities is gaining traction. Several companies are developing eVTOL prototypes, with some expecting to launch commercial services in the next few years. This emerging market is attracting substantial investment from both traditional aerospace companies and new technology firms.

However, the electric aviation market also faces challenges that could impact demand. The limited range of current battery technologies remains a significant hurdle, particularly for longer-haul flights. Advancements in battery technology, specifically in energy density and thermal management, are crucial for expanding the market beyond short-range applications.

Infrastructure development is another critical factor influencing market demand. The widespread adoption of electric aircraft will require substantial investments in charging infrastructure at airports and vertiports. The pace of this infrastructure development will play a key role in determining the growth trajectory of the electric aviation market.

Despite these challenges, the overall outlook for the electric aviation market remains positive. Industry analysts predict strong growth in the coming decades, with the market expected to expand as technology improves and regulatory support increases. The success of early adopters and demonstration projects will be crucial in building confidence and driving wider market acceptance of electric aviation technologies.

Current Challenges in Aviation Battery Cooling

The thermal management of battery systems in electric aviation presents significant challenges due to the unique operating conditions and safety requirements of aircraft. One of the primary issues is the limited space available for cooling systems, which constrains the design and implementation of effective thermal management solutions. Aircraft designers must balance the need for efficient cooling with weight considerations, as every additional kilogram impacts fuel efficiency and overall performance.

Another critical challenge is the high power density required for electric aviation batteries. These batteries generate substantial heat during charging and discharging cycles, particularly during high-power operations such as takeoff and landing. The heat generation can lead to thermal runaway, a potentially catastrophic event where the battery temperature rises uncontrollably, leading to fire or explosion. This risk is exacerbated in aviation applications due to the severe consequences of battery failure during flight.

The varying environmental conditions encountered during flight also pose significant challenges for battery cooling systems. Aircraft operate across a wide range of altitudes and climates, experiencing rapid temperature changes and varying air pressures. Cooling systems must be designed to function effectively across these diverse conditions, maintaining optimal battery temperature regardless of external factors.

Furthermore, the integration of battery cooling systems with other aircraft systems presents complex engineering challenges. The cooling system must not interfere with critical flight systems or compromise the structural integrity of the aircraft. This integration challenge is particularly acute in retrofitting existing aircraft designs for electric propulsion, where space and weight constraints are even more pronounced.

Reliability and redundancy are paramount in aviation, and this extends to battery cooling systems. Designing fail-safe cooling mechanisms that can continue to function effectively even in the event of partial system failure is a significant challenge. This requirement often leads to increased system complexity and weight, further complicating the design process.

Lastly, the regulatory landscape for electric aviation is still evolving, with stringent safety standards being developed. Cooling systems must not only be effective but also meet or exceed these emerging regulatory requirements, which can be a moving target for engineers and designers. This regulatory uncertainty adds another layer of complexity to the development of thermal management strategies for aviation battery systems.

Another critical challenge is the high power density required for electric aviation batteries. These batteries generate substantial heat during charging and discharging cycles, particularly during high-power operations such as takeoff and landing. The heat generation can lead to thermal runaway, a potentially catastrophic event where the battery temperature rises uncontrollably, leading to fire or explosion. This risk is exacerbated in aviation applications due to the severe consequences of battery failure during flight.

The varying environmental conditions encountered during flight also pose significant challenges for battery cooling systems. Aircraft operate across a wide range of altitudes and climates, experiencing rapid temperature changes and varying air pressures. Cooling systems must be designed to function effectively across these diverse conditions, maintaining optimal battery temperature regardless of external factors.

Furthermore, the integration of battery cooling systems with other aircraft systems presents complex engineering challenges. The cooling system must not interfere with critical flight systems or compromise the structural integrity of the aircraft. This integration challenge is particularly acute in retrofitting existing aircraft designs for electric propulsion, where space and weight constraints are even more pronounced.

Reliability and redundancy are paramount in aviation, and this extends to battery cooling systems. Designing fail-safe cooling mechanisms that can continue to function effectively even in the event of partial system failure is a significant challenge. This requirement often leads to increased system complexity and weight, further complicating the design process.

Lastly, the regulatory landscape for electric aviation is still evolving, with stringent safety standards being developed. Cooling systems must not only be effective but also meet or exceed these emerging regulatory requirements, which can be a moving target for engineers and designers. This regulatory uncertainty adds another layer of complexity to the development of thermal management strategies for aviation battery systems.

Existing Thermal Management Solutions

01 Thermal management systems for battery packs

Advanced thermal management systems are designed to regulate the temperature of battery packs in electric vehicles and energy storage systems. These systems utilize various cooling and heating methods to maintain optimal operating temperatures, enhancing battery performance, longevity, and safety. Techniques may include liquid cooling, air cooling, or phase change materials to efficiently dissipate heat and maintain uniform temperature distribution across the battery pack.- Thermal management systems for battery packs: Advanced thermal management systems are designed to regulate the temperature of battery packs in electric vehicles and energy storage systems. These systems utilize various cooling and heating methods to maintain optimal operating temperatures, enhancing battery performance, longevity, and safety. Techniques may include liquid cooling, air cooling, or phase change materials to efficiently dissipate heat or warm the batteries as needed.

- Battery management system with integrated thermal control: Battery management systems (BMS) are being developed with integrated thermal control features. These systems monitor battery temperature, state of charge, and other parameters in real-time, adjusting cooling or heating mechanisms accordingly. The integration of thermal management into the BMS allows for more precise control and coordination of battery operations, leading to improved efficiency and reduced risk of thermal runaway.

- Intelligent cooling strategies for electric vehicle batteries: Innovative cooling strategies are being implemented in electric vehicle battery systems to manage thermal loads during high-power charging and discharging. These may include predictive cooling based on route planning, adaptive cooling systems that respond to driving conditions, and the use of smart algorithms to optimize cooling efficiency. Such strategies aim to extend battery life, improve charging speeds, and enhance overall vehicle performance.

- Thermal management for battery energy storage systems: Large-scale battery energy storage systems require sophisticated thermal management to ensure safe and efficient operation. These systems often employ a combination of active and passive cooling techniques, such as forced air circulation, liquid cooling loops, and thermal insulation. Advanced designs may also incorporate heat recovery systems to improve overall energy efficiency of the storage facility.

- Thermal interface materials for battery pack cooling: Research is focused on developing advanced thermal interface materials to enhance heat transfer between battery cells and cooling systems. These materials aim to reduce thermal resistance, improve heat dissipation, and ensure uniform temperature distribution across battery packs. Innovations in this area include phase change materials, graphene-based composites, and engineered gap fillers that can significantly improve the efficiency of battery thermal management systems.

02 Battery management system with integrated thermal control

Battery management systems (BMS) are being developed with integrated thermal control features. These systems monitor battery temperature in real-time and actively manage thermal conditions to prevent overheating or overcooling. The BMS may adjust charging and discharging rates, activate cooling systems, or initiate protective measures based on temperature data, ensuring optimal battery performance and safety across various operating conditions.Expand Specific Solutions03 Intelligent cooling strategies for electric vehicle batteries

Innovative cooling strategies are being implemented in electric vehicle battery systems to enhance thermal management. These may include smart algorithms that predict heat generation based on driving patterns and environmental conditions, allowing for preemptive cooling. Advanced systems might employ a combination of passive and active cooling methods, such as heat pipes, thermoelectric coolers, or refrigerant-based systems, to efficiently manage battery temperature during high-power demand scenarios.Expand Specific Solutions04 Thermal management in fast-charging applications

Fast-charging technologies for electric vehicle batteries require sophisticated thermal management solutions to handle the increased heat generation. These systems may incorporate rapid heat dissipation techniques, such as advanced liquid cooling circuits or phase change materials. The thermal management system works in conjunction with the charging protocol to optimize charging speed while preventing thermal runaway and maintaining battery health.Expand Specific Solutions05 Battery pack design for improved thermal efficiency

Innovative battery pack designs are being developed to enhance thermal efficiency and management. These designs may include optimized cell arrangement, improved heat spreaders, and integrated cooling channels. Some approaches focus on modular designs that allow for better heat distribution and easier maintenance. Advanced materials with high thermal conductivity are also being incorporated to facilitate more effective heat transfer within the battery pack.Expand Specific Solutions

Key Players in Electric Aviation Industry

The thermal management of battery systems in electric aviation is an emerging field with significant growth potential. The market is in its early stages, characterized by rapid technological advancements and increasing investments. As the demand for electric aircraft rises, the market for thermal management solutions is expected to expand substantially. Companies like Joby Aero, Beta Air, and Lilium eAircraft are at the forefront of developing innovative thermal management strategies for electric aviation batteries. Established players such as Rolls-Royce and Hamilton Sundstrand are also entering this space, leveraging their aerospace expertise. The technology is still evolving, with a focus on improving efficiency, safety, and performance of battery systems in challenging aviation environments.

Joby Aero, Inc.

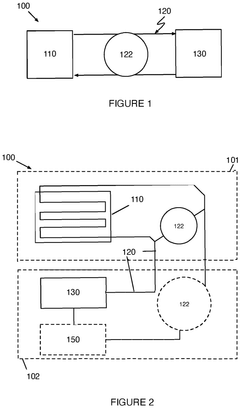

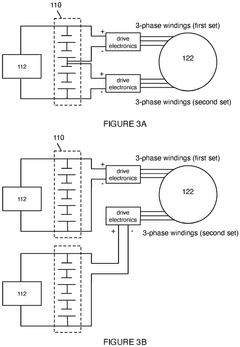

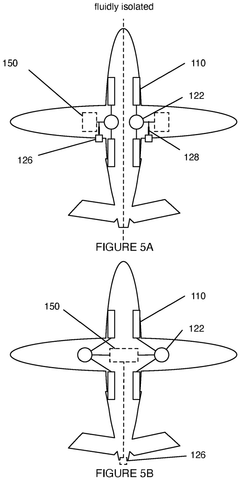

Technical Solution: Joby Aero has developed an advanced thermal management system for their electric aviation batteries, utilizing a combination of active and passive cooling techniques. Their system incorporates a liquid cooling loop that circulates a dielectric coolant through specially designed channels within the battery pack[1]. This coolant absorbs heat generated during battery operation and transfers it to a heat exchanger, where it is dissipated to the surrounding air. Additionally, Joby employs phase change materials (PCMs) strategically placed within the battery pack to absorb excess heat during high-power operations[2]. The company has also implemented a smart thermal management control system that continuously monitors battery temperature and adjusts cooling intensity accordingly, optimizing performance and longevity[3].

Strengths: Efficient heat dissipation, extended battery life, and improved safety. Weaknesses: Increased system complexity and potential weight penalties.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed a comprehensive thermal management strategy for electric aviation batteries, focusing on a holistic approach that integrates cooling systems with overall aircraft design. Their solution incorporates a sophisticated liquid cooling system that utilizes a low-conductivity coolant to minimize electrical risks[1]. The company has also implemented advanced heat sink designs with micro-channel technology, significantly increasing the surface area for heat dissipation[2]. Rolls-Royce's thermal management system is further enhanced by predictive algorithms that anticipate temperature fluctuations based on flight conditions and power demands, allowing for proactive cooling adjustments[3]. Additionally, they have developed a novel battery pack architecture that optimizes airflow and heat distribution, reducing hotspots and improving overall thermal efficiency[4].

Strengths: Integrated design approach, advanced predictive cooling, and improved thermal efficiency. Weaknesses: Potentially higher initial costs and increased system complexity.

Innovative Cooling Techniques for Aviation Batteries

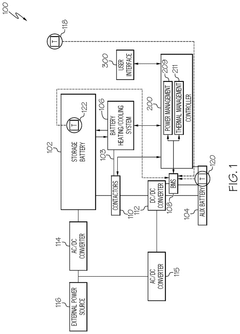

Battery thermal management system and method

PatentPendingEP4538182A2

Innovation

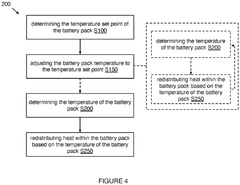

- A battery thermal management system that includes a battery pack, a circulation subsystem with a pump and fluid manifold, and a heat exchange system, which circulates a working fluid to manage temperature distribution within the battery pack and can be distributed between a vehicle and an infrastructure installation to optimize weight and efficiency.

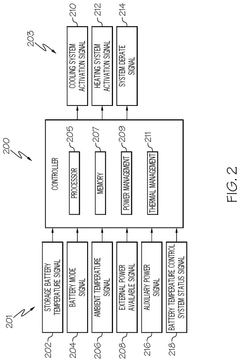

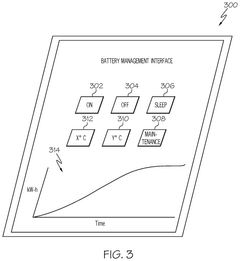

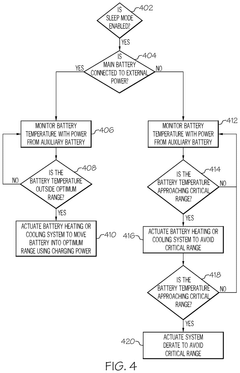

Thermal management of battery systems

PatentPendingUS20240405313A1

Innovation

- A thermal management system that enables a sleep mode to maintain battery temperature control using an auxiliary battery, activating an externally powered mode when connected to external power sources and an internally powered mode when isolated, allowing for heating or cooling of the main storage battery based on temperature readings.

Safety Regulations for Electric Aircraft Batteries

Safety regulations for electric aircraft batteries are a critical aspect of the emerging electric aviation industry. These regulations are designed to ensure the safe operation of electric aircraft and protect passengers, crew, and ground personnel from potential hazards associated with high-capacity lithium-ion batteries.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe are at the forefront of developing and implementing safety standards for electric aircraft batteries. These agencies work closely with industry stakeholders to establish comprehensive guidelines that address the unique challenges posed by electric propulsion systems in aviation.

One of the primary focuses of safety regulations is thermal management. Lithium-ion batteries used in electric aircraft can generate significant heat during operation, charging, and discharging. Overheating can lead to thermal runaway, potentially resulting in fire or explosion. To mitigate this risk, regulations mandate the implementation of robust thermal management systems that can effectively dissipate heat and maintain battery temperatures within safe operating ranges.

Safety regulations also address the structural integrity of battery packs. Electric aircraft batteries must be designed and constructed to withstand the rigors of flight, including vibration, shock, and rapid changes in altitude and temperature. Regulations specify requirements for battery enclosures, mounting systems, and isolation from other aircraft systems to prevent damage and contain potential failures.

Another critical aspect of safety regulations is the requirement for sophisticated battery management systems (BMS). These systems must continuously monitor battery parameters such as voltage, current, and temperature across individual cells and the entire battery pack. The BMS must be capable of detecting and responding to abnormal conditions, including thermal events, cell imbalances, and overcharging.

Regulations also mandate the implementation of redundancy and fail-safe mechanisms in electric aircraft battery systems. This includes requirements for multiple independent power sources, isolation of critical systems, and the ability to safely operate the aircraft in the event of partial battery failure.

Furthermore, safety regulations address the unique challenges of charging and maintaining electric aircraft batteries. Standards are being developed for ground-based charging infrastructure, including protocols for fast charging, safety interlocks, and emergency shutdown procedures. Maintenance regulations specify inspection intervals, testing procedures, and criteria for battery replacement to ensure ongoing safety and performance.

As the electric aviation industry continues to evolve, safety regulations are expected to become increasingly sophisticated. Ongoing research and development in battery technology, thermal management strategies, and safety systems will inform future regulatory updates, ensuring that electric aircraft can operate safely and efficiently in commercial aviation applications.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe are at the forefront of developing and implementing safety standards for electric aircraft batteries. These agencies work closely with industry stakeholders to establish comprehensive guidelines that address the unique challenges posed by electric propulsion systems in aviation.

One of the primary focuses of safety regulations is thermal management. Lithium-ion batteries used in electric aircraft can generate significant heat during operation, charging, and discharging. Overheating can lead to thermal runaway, potentially resulting in fire or explosion. To mitigate this risk, regulations mandate the implementation of robust thermal management systems that can effectively dissipate heat and maintain battery temperatures within safe operating ranges.

Safety regulations also address the structural integrity of battery packs. Electric aircraft batteries must be designed and constructed to withstand the rigors of flight, including vibration, shock, and rapid changes in altitude and temperature. Regulations specify requirements for battery enclosures, mounting systems, and isolation from other aircraft systems to prevent damage and contain potential failures.

Another critical aspect of safety regulations is the requirement for sophisticated battery management systems (BMS). These systems must continuously monitor battery parameters such as voltage, current, and temperature across individual cells and the entire battery pack. The BMS must be capable of detecting and responding to abnormal conditions, including thermal events, cell imbalances, and overcharging.

Regulations also mandate the implementation of redundancy and fail-safe mechanisms in electric aircraft battery systems. This includes requirements for multiple independent power sources, isolation of critical systems, and the ability to safely operate the aircraft in the event of partial battery failure.

Furthermore, safety regulations address the unique challenges of charging and maintaining electric aircraft batteries. Standards are being developed for ground-based charging infrastructure, including protocols for fast charging, safety interlocks, and emergency shutdown procedures. Maintenance regulations specify inspection intervals, testing procedures, and criteria for battery replacement to ensure ongoing safety and performance.

As the electric aviation industry continues to evolve, safety regulations are expected to become increasingly sophisticated. Ongoing research and development in battery technology, thermal management strategies, and safety systems will inform future regulatory updates, ensuring that electric aircraft can operate safely and efficiently in commercial aviation applications.

Environmental Impact of Battery Cooling Systems

The environmental impact of battery cooling systems in electric aviation is a critical consideration as the industry moves towards more sustainable transportation solutions. These systems, while essential for maintaining optimal battery performance and safety, can have significant ecological implications throughout their lifecycle.

The primary environmental concern stems from the energy consumption of cooling systems. Active cooling methods, such as liquid cooling or forced air circulation, require additional power to operate, potentially reducing the overall energy efficiency of electric aircraft. This increased energy demand may partially offset the environmental benefits gained from transitioning to electric propulsion, particularly if the electricity used for cooling is sourced from non-renewable energy sources.

Material selection for cooling systems also plays a crucial role in their environmental footprint. Many cooling fluids and refrigerants used in these systems have high global warming potential (GWP) if released into the atmosphere. The production, transportation, and disposal of these materials contribute to the overall carbon footprint of electric aviation. Additionally, the manufacturing processes for specialized cooling components often involve energy-intensive procedures and the use of rare or environmentally sensitive materials.

End-of-life considerations for battery cooling systems present another environmental challenge. The complexity of these systems, often integrating various materials and components, can make recycling and proper disposal difficult. Improper handling of coolants and other potentially hazardous materials can lead to soil and water contamination, posing risks to ecosystems and human health.

However, advancements in cooling system design are addressing some of these environmental concerns. Passive cooling techniques, such as phase change materials and heat pipes, are being developed to reduce energy consumption. These innovations not only minimize the environmental impact but also contribute to improved aircraft performance by reducing weight and complexity.

The aviation industry is also exploring more environmentally friendly coolants and materials. Natural refrigerants with lower GWP are being investigated as alternatives to traditional synthetic coolants. Furthermore, the integration of recyclable and biodegradable materials in cooling system components is gaining traction, aiming to reduce the environmental impact at the end of the product lifecycle.

As electric aviation continues to evolve, the focus on developing eco-friendly thermal management solutions is intensifying. Research into biomimetic cooling designs, inspired by natural heat dissipation mechanisms, shows promise for creating highly efficient, low-impact cooling systems. Additionally, the potential for integrating cooling systems with other aircraft functions, such as using waste heat for cabin heating or de-icing, could further optimize resource use and reduce overall environmental impact.

The primary environmental concern stems from the energy consumption of cooling systems. Active cooling methods, such as liquid cooling or forced air circulation, require additional power to operate, potentially reducing the overall energy efficiency of electric aircraft. This increased energy demand may partially offset the environmental benefits gained from transitioning to electric propulsion, particularly if the electricity used for cooling is sourced from non-renewable energy sources.

Material selection for cooling systems also plays a crucial role in their environmental footprint. Many cooling fluids and refrigerants used in these systems have high global warming potential (GWP) if released into the atmosphere. The production, transportation, and disposal of these materials contribute to the overall carbon footprint of electric aviation. Additionally, the manufacturing processes for specialized cooling components often involve energy-intensive procedures and the use of rare or environmentally sensitive materials.

End-of-life considerations for battery cooling systems present another environmental challenge. The complexity of these systems, often integrating various materials and components, can make recycling and proper disposal difficult. Improper handling of coolants and other potentially hazardous materials can lead to soil and water contamination, posing risks to ecosystems and human health.

However, advancements in cooling system design are addressing some of these environmental concerns. Passive cooling techniques, such as phase change materials and heat pipes, are being developed to reduce energy consumption. These innovations not only minimize the environmental impact but also contribute to improved aircraft performance by reducing weight and complexity.

The aviation industry is also exploring more environmentally friendly coolants and materials. Natural refrigerants with lower GWP are being investigated as alternatives to traditional synthetic coolants. Furthermore, the integration of recyclable and biodegradable materials in cooling system components is gaining traction, aiming to reduce the environmental impact at the end of the product lifecycle.

As electric aviation continues to evolve, the focus on developing eco-friendly thermal management solutions is intensifying. Research into biomimetic cooling designs, inspired by natural heat dissipation mechanisms, shows promise for creating highly efficient, low-impact cooling systems. Additionally, the potential for integrating cooling systems with other aircraft functions, such as using waste heat for cabin heating or de-icing, could further optimize resource use and reduce overall environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!