How Machine Vision Affects Battery Management Systems in Automated Industries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Machine Vision in BMS: Background and Objectives

Machine vision technology has rapidly evolved over the past decade, revolutionizing various industries, including battery management systems (BMS) in automated manufacturing. This integration marks a significant milestone in the advancement of energy storage solutions and industrial automation. The primary objective of incorporating machine vision into BMS is to enhance the efficiency, reliability, and safety of battery production and management processes.

The evolution of machine vision in BMS can be traced back to the early 2000s when rudimentary image processing techniques were first applied to battery inspection. However, it wasn't until the mid-2010s that significant breakthroughs in deep learning and computer vision algorithms propelled this technology to the forefront of battery manufacturing. These advancements have enabled more sophisticated analysis of battery components, defect detection, and real-time monitoring of battery health.

As the demand for high-performance batteries continues to surge across various sectors, including electric vehicles, renewable energy storage, and consumer electronics, the role of machine vision in BMS has become increasingly critical. The technology aims to address key challenges in battery production, such as ensuring consistent quality, detecting microscopic defects, and optimizing the overall manufacturing process.

One of the primary goals of integrating machine vision into BMS is to achieve 100% inspection of battery cells and packs, a feat that was previously impossible with manual inspection methods. This comprehensive quality control approach significantly reduces the risk of defective batteries entering the market, thereby enhancing product safety and reliability. Additionally, machine vision systems in BMS aim to improve production yields by identifying and rectifying issues in real-time, minimizing waste and optimizing resource utilization.

Another crucial objective is the development of predictive maintenance capabilities. By continuously monitoring battery performance and degradation patterns, machine vision-enabled BMS can forecast potential failures and schedule maintenance activities proactively. This predictive approach not only extends battery life but also ensures optimal performance throughout the battery's lifecycle.

The integration of machine vision in BMS also aligns with the broader trend of Industry 4.0 and the Internet of Things (IoT). The technology serves as a vital data collection point, feeding valuable information into larger industrial automation systems. This data-driven approach enables manufacturers to gain deeper insights into their production processes, facilitate continuous improvement, and drive innovation in battery technology.

As we look towards the future, the objectives for machine vision in BMS are becoming increasingly ambitious. Researchers and industry leaders are working towards developing systems capable of real-time 3D inspection, advanced materials characterization, and even atomic-level defect detection. These advancements promise to push the boundaries of battery performance, longevity, and safety, paving the way for next-generation energy storage solutions.

The evolution of machine vision in BMS can be traced back to the early 2000s when rudimentary image processing techniques were first applied to battery inspection. However, it wasn't until the mid-2010s that significant breakthroughs in deep learning and computer vision algorithms propelled this technology to the forefront of battery manufacturing. These advancements have enabled more sophisticated analysis of battery components, defect detection, and real-time monitoring of battery health.

As the demand for high-performance batteries continues to surge across various sectors, including electric vehicles, renewable energy storage, and consumer electronics, the role of machine vision in BMS has become increasingly critical. The technology aims to address key challenges in battery production, such as ensuring consistent quality, detecting microscopic defects, and optimizing the overall manufacturing process.

One of the primary goals of integrating machine vision into BMS is to achieve 100% inspection of battery cells and packs, a feat that was previously impossible with manual inspection methods. This comprehensive quality control approach significantly reduces the risk of defective batteries entering the market, thereby enhancing product safety and reliability. Additionally, machine vision systems in BMS aim to improve production yields by identifying and rectifying issues in real-time, minimizing waste and optimizing resource utilization.

Another crucial objective is the development of predictive maintenance capabilities. By continuously monitoring battery performance and degradation patterns, machine vision-enabled BMS can forecast potential failures and schedule maintenance activities proactively. This predictive approach not only extends battery life but also ensures optimal performance throughout the battery's lifecycle.

The integration of machine vision in BMS also aligns with the broader trend of Industry 4.0 and the Internet of Things (IoT). The technology serves as a vital data collection point, feeding valuable information into larger industrial automation systems. This data-driven approach enables manufacturers to gain deeper insights into their production processes, facilitate continuous improvement, and drive innovation in battery technology.

As we look towards the future, the objectives for machine vision in BMS are becoming increasingly ambitious. Researchers and industry leaders are working towards developing systems capable of real-time 3D inspection, advanced materials characterization, and even atomic-level defect detection. These advancements promise to push the boundaries of battery performance, longevity, and safety, paving the way for next-generation energy storage solutions.

Market Demand Analysis for Smart BMS

The market demand for smart Battery Management Systems (BMS) in automated industries is experiencing significant growth, driven by the increasing adoption of electric vehicles, renewable energy storage systems, and industrial automation. As machine vision technology continues to advance, its integration with BMS offers new opportunities for enhancing battery performance, safety, and longevity.

The global smart BMS market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2027. This growth is primarily fueled by the automotive sector, where electric vehicles are gaining traction due to environmental concerns and government regulations. The industrial automation sector is also contributing to this demand, as factories and warehouses increasingly rely on automated guided vehicles (AGVs) and robots powered by lithium-ion batteries.

Machine vision's impact on BMS is creating new market segments within the broader smart BMS industry. Companies are developing advanced BMS solutions that incorporate visual inspection and monitoring capabilities, allowing for real-time assessment of battery health and performance. This integration is particularly valuable in automated industries where continuous operation and minimal downtime are critical.

The demand for machine vision-enhanced BMS is driven by several factors. First, there is a growing need for more accurate and reliable battery monitoring in complex industrial environments. Traditional BMS rely on electrical measurements and algorithms, but machine vision can provide additional insights by visually inspecting battery cells for signs of degradation, swelling, or other physical anomalies.

Second, the push for predictive maintenance in automated industries is boosting the demand for smart BMS with advanced diagnostic capabilities. Machine vision-enabled systems can detect early warning signs of battery failure, allowing for proactive maintenance and reducing costly downtime in production lines or logistics operations.

Third, the increasing complexity of battery systems, especially in large-scale applications like grid energy storage, requires more sophisticated management solutions. Machine vision can help in monitoring large battery arrays, identifying potential issues across multiple cells or modules simultaneously.

The market is also seeing a rise in demand for BMS that can integrate with broader Industry 4.0 initiatives. Machine vision-enhanced BMS can provide valuable data for overall equipment effectiveness (OEE) analysis, energy optimization, and predictive analytics platforms.

As the technology matures, we can expect to see increased adoption across various industries, including manufacturing, logistics, aerospace, and renewable energy. The market is likely to witness the emergence of specialized BMS solutions tailored to specific industrial applications, leveraging machine vision to address unique challenges in each sector.

The global smart BMS market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2027. This growth is primarily fueled by the automotive sector, where electric vehicles are gaining traction due to environmental concerns and government regulations. The industrial automation sector is also contributing to this demand, as factories and warehouses increasingly rely on automated guided vehicles (AGVs) and robots powered by lithium-ion batteries.

Machine vision's impact on BMS is creating new market segments within the broader smart BMS industry. Companies are developing advanced BMS solutions that incorporate visual inspection and monitoring capabilities, allowing for real-time assessment of battery health and performance. This integration is particularly valuable in automated industries where continuous operation and minimal downtime are critical.

The demand for machine vision-enhanced BMS is driven by several factors. First, there is a growing need for more accurate and reliable battery monitoring in complex industrial environments. Traditional BMS rely on electrical measurements and algorithms, but machine vision can provide additional insights by visually inspecting battery cells for signs of degradation, swelling, or other physical anomalies.

Second, the push for predictive maintenance in automated industries is boosting the demand for smart BMS with advanced diagnostic capabilities. Machine vision-enabled systems can detect early warning signs of battery failure, allowing for proactive maintenance and reducing costly downtime in production lines or logistics operations.

Third, the increasing complexity of battery systems, especially in large-scale applications like grid energy storage, requires more sophisticated management solutions. Machine vision can help in monitoring large battery arrays, identifying potential issues across multiple cells or modules simultaneously.

The market is also seeing a rise in demand for BMS that can integrate with broader Industry 4.0 initiatives. Machine vision-enhanced BMS can provide valuable data for overall equipment effectiveness (OEE) analysis, energy optimization, and predictive analytics platforms.

As the technology matures, we can expect to see increased adoption across various industries, including manufacturing, logistics, aerospace, and renewable energy. The market is likely to witness the emergence of specialized BMS solutions tailored to specific industrial applications, leveraging machine vision to address unique challenges in each sector.

Current Challenges in BMS with Machine Vision

The integration of machine vision into Battery Management Systems (BMS) in automated industries has introduced new challenges that require innovative solutions. One of the primary obstacles is the complexity of image processing in real-time battery monitoring. As BMS rely on visual data to assess battery health and performance, the sheer volume of information that needs to be processed instantaneously can overwhelm current systems, leading to potential delays in decision-making and response times.

Another significant challenge lies in the accuracy of visual data interpretation. Machine vision systems must be capable of distinguishing between normal wear and tear and critical battery defects. This requires sophisticated algorithms that can adapt to various lighting conditions, battery types, and environmental factors. The risk of false positives or negatives in defect detection can have serious implications for battery safety and operational efficiency.

Data integration poses yet another hurdle. BMS with machine vision generate vast amounts of visual data that need to be seamlessly integrated with other sensor inputs and historical data. Creating a cohesive system that can effectively combine and analyze these diverse data streams in real-time remains a complex task. This integration is crucial for developing a comprehensive understanding of battery health and predicting potential issues before they escalate.

The variability in battery designs and manufacturing processes also presents a challenge for machine vision systems. Each battery type may have unique visual characteristics that require specialized algorithms for accurate assessment. Developing a versatile system that can adapt to this diversity without compromising on accuracy or speed is a significant technical challenge.

Moreover, the harsh environments often found in automated industries can affect the performance of machine vision systems. Dust, vibrations, and extreme temperatures can interfere with camera functionality and image quality, potentially leading to inaccurate readings or system failures. Designing robust hardware and software solutions that can withstand these conditions while maintaining high performance is an ongoing challenge.

Lastly, the cost and complexity of implementing advanced machine vision systems in BMS can be prohibitive for some industries. The initial investment in high-resolution cameras, powerful processors, and sophisticated software can be substantial. Additionally, the need for specialized training for operators and maintenance personnel adds to the overall implementation challenges. Balancing the benefits of machine vision with these cost considerations remains a significant hurdle for widespread adoption in BMS across all sectors of automated industries.

Another significant challenge lies in the accuracy of visual data interpretation. Machine vision systems must be capable of distinguishing between normal wear and tear and critical battery defects. This requires sophisticated algorithms that can adapt to various lighting conditions, battery types, and environmental factors. The risk of false positives or negatives in defect detection can have serious implications for battery safety and operational efficiency.

Data integration poses yet another hurdle. BMS with machine vision generate vast amounts of visual data that need to be seamlessly integrated with other sensor inputs and historical data. Creating a cohesive system that can effectively combine and analyze these diverse data streams in real-time remains a complex task. This integration is crucial for developing a comprehensive understanding of battery health and predicting potential issues before they escalate.

The variability in battery designs and manufacturing processes also presents a challenge for machine vision systems. Each battery type may have unique visual characteristics that require specialized algorithms for accurate assessment. Developing a versatile system that can adapt to this diversity without compromising on accuracy or speed is a significant technical challenge.

Moreover, the harsh environments often found in automated industries can affect the performance of machine vision systems. Dust, vibrations, and extreme temperatures can interfere with camera functionality and image quality, potentially leading to inaccurate readings or system failures. Designing robust hardware and software solutions that can withstand these conditions while maintaining high performance is an ongoing challenge.

Lastly, the cost and complexity of implementing advanced machine vision systems in BMS can be prohibitive for some industries. The initial investment in high-resolution cameras, powerful processors, and sophisticated software can be substantial. Additionally, the need for specialized training for operators and maintenance personnel adds to the overall implementation challenges. Balancing the benefits of machine vision with these cost considerations remains a significant hurdle for widespread adoption in BMS across all sectors of automated industries.

Existing Machine Vision Solutions for BMS

01 Vision-based battery inspection systems

Machine vision systems are used for automated inspection of batteries, detecting defects, and ensuring quality control in battery manufacturing processes. These systems employ cameras and image processing algorithms to identify issues such as physical damage, misalignment, or contamination on battery cells or components.- Vision-based battery inspection systems: Machine vision systems are used for automated inspection of batteries, detecting defects, and ensuring quality control in battery manufacturing processes. These systems employ cameras and image processing algorithms to analyze battery components, surface characteristics, and overall integrity.

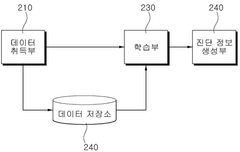

- Battery state estimation using visual data: Advanced algorithms process visual data from cameras to estimate battery state of charge, health, and remaining useful life. This approach combines machine learning techniques with image analysis to provide accurate and real-time information about battery conditions without the need for invasive measurements.

- Thermal imaging for battery management: Thermal cameras are integrated into battery management systems to monitor temperature distribution across battery packs. This allows for early detection of hotspots, potential failures, and optimization of cooling systems, enhancing overall battery performance and safety.

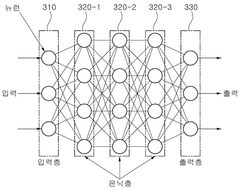

- AI-powered visual analytics for battery systems: Artificial intelligence and deep learning algorithms are applied to visual data from battery systems, enabling predictive maintenance, fault diagnosis, and performance optimization. These systems can identify patterns and anomalies that may not be apparent through traditional monitoring methods.

- Augmented reality interfaces for battery management: Augmented reality (AR) technologies are integrated with machine vision systems to provide intuitive interfaces for battery management. Technicians can use AR displays to visualize real-time battery data, maintenance instructions, and diagnostic information overlaid on physical battery systems.

02 Battery state estimation using visual data

Advanced machine vision techniques are applied to estimate the state of charge, state of health, and other critical parameters of batteries. This involves analyzing visual cues such as electrode color changes, electrolyte levels, or surface characteristics to provide real-time information about battery condition and performance.Expand Specific Solutions03 Thermal imaging for battery management

Thermal cameras are integrated into battery management systems to monitor temperature distribution across battery packs. This helps in early detection of hotspots, thermal runaway conditions, and overall thermal management of the battery system, enhancing safety and performance.Expand Specific Solutions04 AI-powered visual analytics for battery optimization

Artificial intelligence and machine learning algorithms are employed to analyze visual data from batteries, predicting potential failures, optimizing charging strategies, and extending battery life. These systems can learn from historical data to improve accuracy over time.Expand Specific Solutions05 Augmented reality interfaces for battery management

Augmented reality (AR) technologies are integrated with machine vision systems to provide intuitive interfaces for battery management. Technicians can use AR displays to visualize battery health, receive maintenance instructions, and interact with battery data in real-time.Expand Specific Solutions

Key Players in BMS and Machine Vision

The machine vision technology in battery management systems for automated industries is in a growth phase, with increasing market size and technological advancements. The global market for this technology is expanding rapidly, driven by the growing adoption of automation in various industries. Companies like Samsung SDI, LG Energy Solution, and SK On are leading the charge in developing advanced battery management systems integrated with machine vision capabilities. The technology's maturity is progressing, with firms such as Cognex Corp. and OPT Machine Vision Tech Co., Ltd. contributing to innovations in image processing and AI-driven inspection systems. As the technology evolves, it is expected to play a crucial role in enhancing battery performance, safety, and longevity in automated industrial applications.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has implemented an advanced machine vision system in their battery production lines that focuses on enhancing quality control and production efficiency. Their technology utilizes a network of high-resolution cameras and 3D sensors to inspect battery cells and modules at various stages of assembly[13]. Samsung's system employs deep learning algorithms to analyze surface defects, dimensional accuracy, and assembly integrity with micron-level precision[14]. The company has also integrated their machine vision technology with robotic systems for automated handling and sorting of battery components based on visual inspection results[15]. Samsung SDI's approach includes a centralized data management system that allows for real-time monitoring and trend analysis of production quality across multiple facilities.

Strengths: High-precision inspection capabilities, integration with robotic systems, and centralized data management for multi-facility oversight. Weaknesses: Potentially high implementation and maintenance costs, system may be optimized primarily for Samsung's specific battery designs.

Keysight Technologies, Inc.

Technical Solution: Keysight Technologies has developed a suite of machine vision tools specifically for battery management systems in automated industries. Their solution combines high-speed imaging with advanced signal analysis techniques to provide comprehensive quality control throughout the battery production process. Keysight's system can perform real-time electrode coating inspection, detecting defects as small as 10 micrometers[10]. The company's technology also includes spectroscopic analysis capabilities, allowing for non-destructive evaluation of battery cell chemistry and state of charge[11]. Keysight's machine vision platform integrates with their battery test systems, providing a holistic approach to battery quality assurance and performance optimization[12].

Strengths: High-precision defect detection, non-destructive chemical analysis capabilities, and integration with comprehensive battery testing solutions. Weaknesses: May require significant customization for different battery chemistries and form factors.

Core Innovations in BMS Machine Vision

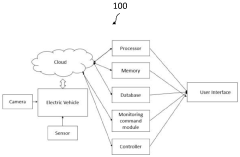

An ai and IoT based electric vehicle monitoring system

PatentPendingIN202241055435A

Innovation

- An AI and IoT-based electric vehicle monitoring system that includes a network communication interface, sensors, processors, memory, a database, a camera, GPS receiver, monitoring command module, and controller, enabling real-time data collection and analysis of battery usage, charging reports, driver behavior, and location-based services to enhance vehicle management and maintenance.

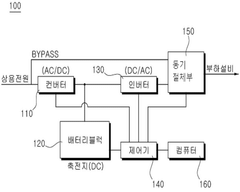

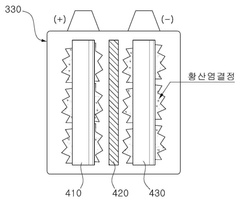

System and Method for monitoring battery based on Artificial Intelligence

PatentActiveKR1020230150026A

Innovation

- An artificial intelligence-based battery monitoring system that identifies defective cells, applies resonant pulses to restore them, and extends battery life by decomposing sulfate crystals using a converter, battery blocks, inverter, synchronous transfer unit, controller, and computer with AI network learning.

Energy Efficiency Impact of Machine Vision on BMS

The integration of machine vision technology into Battery Management Systems (BMS) in automated industries has led to significant improvements in energy efficiency. By leveraging advanced image processing and analysis capabilities, machine vision systems can provide real-time monitoring and optimization of battery performance, resulting in enhanced energy utilization and prolonged battery life.

One of the primary ways machine vision impacts energy efficiency in BMS is through precise state-of-charge (SOC) estimation. Traditional methods often rely on voltage and current measurements, which can be inaccurate due to various factors. Machine vision systems can analyze visual cues such as electrolyte levels, electrode surface conditions, and overall battery appearance to provide more accurate SOC estimates. This improved accuracy allows for better charge and discharge management, reducing energy waste and extending battery lifespan.

Machine vision also enables early detection of battery degradation and potential failures. By continuously monitoring battery cells for signs of wear, corrosion, or physical damage, these systems can identify issues before they escalate into major problems. This proactive approach minimizes energy losses due to faulty cells and prevents catastrophic failures that could lead to system downtime and energy-intensive replacements.

Furthermore, machine vision technology enhances the efficiency of battery pack assembly and maintenance processes. Automated visual inspection systems can quickly identify defects or inconsistencies in battery components during manufacturing, ensuring only high-quality cells are integrated into the final product. This quality control measure contributes to overall energy efficiency by reducing the likelihood of energy losses due to suboptimal battery performance.

In large-scale energy storage applications, machine vision-enabled BMS can optimize the distribution of charge and discharge cycles across multiple battery units. By visually assessing the condition of each battery and correlating it with performance data, the system can make intelligent decisions on which batteries to prioritize for charging or discharging. This load balancing approach maximizes the overall energy efficiency of the storage system and extends the operational life of the entire battery array.

The implementation of machine vision in BMS also facilitates more efficient thermal management. Infrared cameras can detect hotspots or uneven temperature distribution within battery packs, allowing for targeted cooling or heating interventions. This precise thermal control minimizes energy waste from excessive cooling and prevents energy-draining performance degradation caused by suboptimal operating temperatures.

One of the primary ways machine vision impacts energy efficiency in BMS is through precise state-of-charge (SOC) estimation. Traditional methods often rely on voltage and current measurements, which can be inaccurate due to various factors. Machine vision systems can analyze visual cues such as electrolyte levels, electrode surface conditions, and overall battery appearance to provide more accurate SOC estimates. This improved accuracy allows for better charge and discharge management, reducing energy waste and extending battery lifespan.

Machine vision also enables early detection of battery degradation and potential failures. By continuously monitoring battery cells for signs of wear, corrosion, or physical damage, these systems can identify issues before they escalate into major problems. This proactive approach minimizes energy losses due to faulty cells and prevents catastrophic failures that could lead to system downtime and energy-intensive replacements.

Furthermore, machine vision technology enhances the efficiency of battery pack assembly and maintenance processes. Automated visual inspection systems can quickly identify defects or inconsistencies in battery components during manufacturing, ensuring only high-quality cells are integrated into the final product. This quality control measure contributes to overall energy efficiency by reducing the likelihood of energy losses due to suboptimal battery performance.

In large-scale energy storage applications, machine vision-enabled BMS can optimize the distribution of charge and discharge cycles across multiple battery units. By visually assessing the condition of each battery and correlating it with performance data, the system can make intelligent decisions on which batteries to prioritize for charging or discharging. This load balancing approach maximizes the overall energy efficiency of the storage system and extends the operational life of the entire battery array.

The implementation of machine vision in BMS also facilitates more efficient thermal management. Infrared cameras can detect hotspots or uneven temperature distribution within battery packs, allowing for targeted cooling or heating interventions. This precise thermal control minimizes energy waste from excessive cooling and prevents energy-draining performance degradation caused by suboptimal operating temperatures.

Cybersecurity Considerations for Smart BMS

As the integration of smart technologies in Battery Management Systems (BMS) continues to advance, cybersecurity considerations have become paramount. The interconnected nature of smart BMS exposes them to potential cyber threats, necessitating robust security measures to protect critical infrastructure and sensitive data.

One primary concern is the vulnerability of communication channels between BMS components and external systems. These channels, often utilizing wireless protocols, can be susceptible to interception and manipulation. Implementing end-to-end encryption for all data transmissions is crucial to prevent unauthorized access and ensure data integrity. Additionally, secure authentication mechanisms must be employed to verify the identity of devices and users interacting with the BMS.

Another critical aspect is the protection of firmware and software within smart BMS. Regular security updates and patches are essential to address newly discovered vulnerabilities. Implementing secure boot processes and code signing can prevent the execution of unauthorized or tampered code, safeguarding the system's integrity.

Data privacy is also a significant concern, as BMS collect and process vast amounts of sensitive information. Strict access controls and data anonymization techniques should be implemented to protect user privacy and comply with data protection regulations. Furthermore, secure data storage practices, including encryption at rest, must be adopted to prevent data breaches.

The potential for remote attacks on smart BMS necessitates the implementation of robust network security measures. This includes firewalls, intrusion detection systems, and network segmentation to isolate critical BMS components from less secure parts of the network. Regular security audits and penetration testing should be conducted to identify and address potential vulnerabilities.

As smart BMS often integrate with other industrial systems, the concept of "defense in depth" becomes crucial. This multi-layered security approach ensures that if one security measure fails, others are in place to protect the system. This strategy should encompass physical security measures, such as restricted access to BMS hardware, alongside digital security protocols.

Lastly, the human factor in cybersecurity cannot be overlooked. Comprehensive training programs for personnel involved in BMS operation and maintenance are essential. These programs should cover best practices in cybersecurity, including password management, phishing awareness, and incident response procedures. Establishing clear security policies and procedures, and regularly updating them to address emerging threats, is vital for maintaining a strong security posture in smart BMS deployments.

One primary concern is the vulnerability of communication channels between BMS components and external systems. These channels, often utilizing wireless protocols, can be susceptible to interception and manipulation. Implementing end-to-end encryption for all data transmissions is crucial to prevent unauthorized access and ensure data integrity. Additionally, secure authentication mechanisms must be employed to verify the identity of devices and users interacting with the BMS.

Another critical aspect is the protection of firmware and software within smart BMS. Regular security updates and patches are essential to address newly discovered vulnerabilities. Implementing secure boot processes and code signing can prevent the execution of unauthorized or tampered code, safeguarding the system's integrity.

Data privacy is also a significant concern, as BMS collect and process vast amounts of sensitive information. Strict access controls and data anonymization techniques should be implemented to protect user privacy and comply with data protection regulations. Furthermore, secure data storage practices, including encryption at rest, must be adopted to prevent data breaches.

The potential for remote attacks on smart BMS necessitates the implementation of robust network security measures. This includes firewalls, intrusion detection systems, and network segmentation to isolate critical BMS components from less secure parts of the network. Regular security audits and penetration testing should be conducted to identify and address potential vulnerabilities.

As smart BMS often integrate with other industrial systems, the concept of "defense in depth" becomes crucial. This multi-layered security approach ensures that if one security measure fails, others are in place to protect the system. This strategy should encompass physical security measures, such as restricted access to BMS hardware, alongside digital security protocols.

Lastly, the human factor in cybersecurity cannot be overlooked. Comprehensive training programs for personnel involved in BMS operation and maintenance are essential. These programs should cover best practices in cybersecurity, including password management, phishing awareness, and incident response procedures. Establishing clear security policies and procedures, and regularly updating them to address emerging threats, is vital for maintaining a strong security posture in smart BMS deployments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!