Electromagnetic Interference Effects on Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI and BMS Background

Electromagnetic Interference (EMI) and Battery Management Systems (BMS) have become increasingly intertwined in modern technological landscapes. EMI, a disturbance that affects electrical circuits due to electromagnetic radiation or conduction, has been a persistent challenge in electronic systems since the advent of radio communication. As electronic devices have proliferated and become more complex, the potential for EMI has grown exponentially, necessitating robust mitigation strategies.

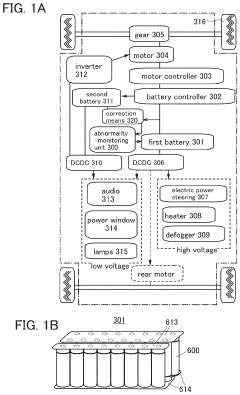

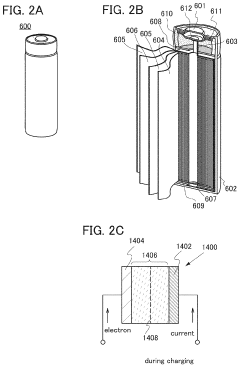

Battery Management Systems, on the other hand, have emerged as critical components in the rapidly expanding field of energy storage and electric vehicles. BMS are responsible for monitoring and controlling the charging and discharging processes of battery packs, ensuring optimal performance, safety, and longevity. The rise of electric vehicles and renewable energy systems has catapulted BMS to the forefront of technological innovation, making their reliability paramount.

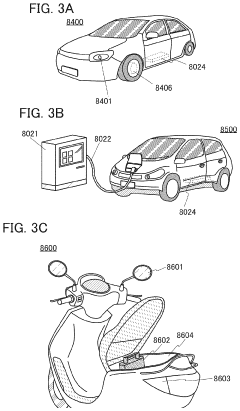

The intersection of EMI and BMS presents a unique set of challenges and opportunities. As BMS become more sophisticated, incorporating advanced sensors and communication modules, they also become more susceptible to electromagnetic interference. This vulnerability is particularly concerning in automotive applications, where BMS operate in close proximity to high-power electrical systems and are exposed to a wide range of external EMI sources.

The potential impacts of EMI on BMS are multifaceted. Interference can lead to inaccurate voltage and temperature readings, compromising the system's ability to maintain optimal battery performance and safety. In severe cases, EMI-induced errors could result in premature battery degradation, system failures, or even safety hazards. These risks are amplified in electric vehicles, where BMS play a crucial role in managing large, high-voltage battery packs.

Historically, EMI mitigation in electronic systems has relied on shielding, filtering, and proper grounding techniques. However, the unique requirements of BMS, including high accuracy, real-time performance, and operation in harsh electromagnetic environments, necessitate more advanced and tailored solutions. This has spurred research into innovative EMI suppression techniques specifically designed for BMS applications.

The evolving regulatory landscape further underscores the importance of addressing EMI in BMS. Standards such as ISO 7637 and CISPR 25 set stringent requirements for electromagnetic compatibility in automotive electronics, including BMS. Compliance with these standards is not just a legal requirement but also a key factor in ensuring product reliability and market acceptance.

As the adoption of electric vehicles and large-scale energy storage systems accelerates, the need for EMI-resistant BMS becomes increasingly critical. This convergence of EMI challenges and BMS advancements presents a fertile ground for technological innovation, driving research into novel materials, circuit designs, and system architectures that can ensure the robust performance of BMS in electromagnetically noisy environments.

Battery Management Systems, on the other hand, have emerged as critical components in the rapidly expanding field of energy storage and electric vehicles. BMS are responsible for monitoring and controlling the charging and discharging processes of battery packs, ensuring optimal performance, safety, and longevity. The rise of electric vehicles and renewable energy systems has catapulted BMS to the forefront of technological innovation, making their reliability paramount.

The intersection of EMI and BMS presents a unique set of challenges and opportunities. As BMS become more sophisticated, incorporating advanced sensors and communication modules, they also become more susceptible to electromagnetic interference. This vulnerability is particularly concerning in automotive applications, where BMS operate in close proximity to high-power electrical systems and are exposed to a wide range of external EMI sources.

The potential impacts of EMI on BMS are multifaceted. Interference can lead to inaccurate voltage and temperature readings, compromising the system's ability to maintain optimal battery performance and safety. In severe cases, EMI-induced errors could result in premature battery degradation, system failures, or even safety hazards. These risks are amplified in electric vehicles, where BMS play a crucial role in managing large, high-voltage battery packs.

Historically, EMI mitigation in electronic systems has relied on shielding, filtering, and proper grounding techniques. However, the unique requirements of BMS, including high accuracy, real-time performance, and operation in harsh electromagnetic environments, necessitate more advanced and tailored solutions. This has spurred research into innovative EMI suppression techniques specifically designed for BMS applications.

The evolving regulatory landscape further underscores the importance of addressing EMI in BMS. Standards such as ISO 7637 and CISPR 25 set stringent requirements for electromagnetic compatibility in automotive electronics, including BMS. Compliance with these standards is not just a legal requirement but also a key factor in ensuring product reliability and market acceptance.

As the adoption of electric vehicles and large-scale energy storage systems accelerates, the need for EMI-resistant BMS becomes increasingly critical. This convergence of EMI challenges and BMS advancements presents a fertile ground for technological innovation, driving research into novel materials, circuit designs, and system architectures that can ensure the robust performance of BMS in electromagnetically noisy environments.

Market Demand Analysis

The market demand for research on electromagnetic interference (EMI) effects on Battery Management Systems (BMS) has been steadily increasing due to the rapid growth of electric vehicles (EVs) and renewable energy storage systems. As these technologies become more prevalent, the need for robust and reliable BMS that can withstand electromagnetic disturbances has become crucial.

The automotive industry, in particular, has been a significant driver of this demand. With the global EV market projected to reach 26.8 million units by 2030, manufacturers are increasingly focused on ensuring the safety and reliability of their vehicles' battery systems. EMI can potentially disrupt the normal functioning of BMS, leading to inaccurate readings, reduced efficiency, or even system failures. This has created a strong market pull for advanced EMI mitigation solutions in BMS design.

The renewable energy sector is another key market for EMI-resistant BMS. As large-scale energy storage systems become more common in grid applications, the need for reliable BMS that can operate in electromagnetically noisy environments has grown. This demand is further amplified by the increasing integration of smart grid technologies, which introduce additional sources of electromagnetic interference.

In the consumer electronics market, the proliferation of portable devices with high-capacity batteries has also contributed to the demand for EMI-resistant BMS. Manufacturers are seeking ways to improve the performance and longevity of their products in various electromagnetic environments, driving research in this area.

The industrial sector, including manufacturing and process industries, represents another significant market for EMI-resistant BMS. As industrial automation and Industry 4.0 initiatives progress, the need for reliable battery systems in electromagnetically challenging environments has increased. This has led to a growing demand for research on EMI effects and mitigation strategies in industrial BMS applications.

The telecommunications industry, with its ongoing expansion of 5G networks and increased reliance on backup power systems, has also emerged as a key market driver for EMI-resistant BMS research. The proximity of high-power transmission equipment to battery systems in telecom installations necessitates robust EMI protection measures.

Overall, the market demand for research on EMI effects on BMS is characterized by a cross-industry need for improved reliability, safety, and performance of battery systems in diverse electromagnetic environments. This demand is expected to continue growing as battery-powered technologies become more pervasive across various sectors, driving innovation in EMI mitigation techniques and BMS design.

The automotive industry, in particular, has been a significant driver of this demand. With the global EV market projected to reach 26.8 million units by 2030, manufacturers are increasingly focused on ensuring the safety and reliability of their vehicles' battery systems. EMI can potentially disrupt the normal functioning of BMS, leading to inaccurate readings, reduced efficiency, or even system failures. This has created a strong market pull for advanced EMI mitigation solutions in BMS design.

The renewable energy sector is another key market for EMI-resistant BMS. As large-scale energy storage systems become more common in grid applications, the need for reliable BMS that can operate in electromagnetically noisy environments has grown. This demand is further amplified by the increasing integration of smart grid technologies, which introduce additional sources of electromagnetic interference.

In the consumer electronics market, the proliferation of portable devices with high-capacity batteries has also contributed to the demand for EMI-resistant BMS. Manufacturers are seeking ways to improve the performance and longevity of their products in various electromagnetic environments, driving research in this area.

The industrial sector, including manufacturing and process industries, represents another significant market for EMI-resistant BMS. As industrial automation and Industry 4.0 initiatives progress, the need for reliable battery systems in electromagnetically challenging environments has increased. This has led to a growing demand for research on EMI effects and mitigation strategies in industrial BMS applications.

The telecommunications industry, with its ongoing expansion of 5G networks and increased reliance on backup power systems, has also emerged as a key market driver for EMI-resistant BMS research. The proximity of high-power transmission equipment to battery systems in telecom installations necessitates robust EMI protection measures.

Overall, the market demand for research on EMI effects on BMS is characterized by a cross-industry need for improved reliability, safety, and performance of battery systems in diverse electromagnetic environments. This demand is expected to continue growing as battery-powered technologies become more pervasive across various sectors, driving innovation in EMI mitigation techniques and BMS design.

EMI Challenges in BMS

Electromagnetic Interference (EMI) poses significant challenges to Battery Management Systems (BMS) in modern electric vehicles and energy storage systems. As the complexity and power density of these systems increase, so does their susceptibility to electromagnetic disturbances. BMS, being the critical component responsible for monitoring and controlling battery performance, safety, and longevity, is particularly vulnerable to EMI effects.

One of the primary challenges is the interference with sensor readings and communication signals within the BMS. Accurate voltage, current, and temperature measurements are crucial for effective battery management, but EMI can introduce noise and errors into these measurements. This can lead to incorrect state-of-charge estimations, imbalanced cell management, and potentially unsafe operating conditions.

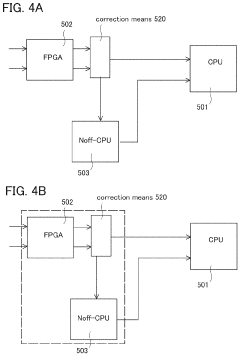

Another significant challenge is the impact of EMI on the BMS's control algorithms and decision-making processes. High-frequency electromagnetic noise can cause microcontrollers and other digital components to malfunction, resulting in erroneous commands being sent to battery pack components. This can lead to suboptimal performance, reduced efficiency, and in extreme cases, system failures or safety hazards.

The increasing use of high-power switching devices in electric powertrains and charging systems further exacerbates the EMI challenges. These devices generate substantial electromagnetic emissions that can couple into BMS circuits, causing disruptions in normal operation. The compact design of modern electric vehicles, where high-power components are in close proximity to sensitive electronics, amplifies this issue.

EMI shielding and filtering techniques traditionally used in electronics design may not always be sufficient for the harsh automotive environment. The need for lightweight, cost-effective solutions that can withstand vibration, temperature extremes, and long-term reliability requirements presents a unique set of challenges for BMS designers.

Furthermore, the regulatory landscape surrounding EMI in automotive applications is becoming increasingly stringent. Compliance with standards such as CISPR 25 and ISO 11452 requires extensive testing and validation, adding complexity and cost to the development process of BMS.

As wireless communication technologies like Bluetooth and Wi-Fi are integrated into modern BMS for remote monitoring and diagnostics, they introduce additional EMI vulnerabilities. These wireless interfaces must be protected against both external interference and the potential for malicious attacks exploiting EMI-induced vulnerabilities.

Addressing these challenges requires a multidisciplinary approach, combining expertise in power electronics, signal processing, electromagnetic compatibility, and system-level design. Innovative solutions such as adaptive filtering, advanced shielding materials, and intelligent EMI mitigation algorithms are areas of active research and development in the field of BMS design.

One of the primary challenges is the interference with sensor readings and communication signals within the BMS. Accurate voltage, current, and temperature measurements are crucial for effective battery management, but EMI can introduce noise and errors into these measurements. This can lead to incorrect state-of-charge estimations, imbalanced cell management, and potentially unsafe operating conditions.

Another significant challenge is the impact of EMI on the BMS's control algorithms and decision-making processes. High-frequency electromagnetic noise can cause microcontrollers and other digital components to malfunction, resulting in erroneous commands being sent to battery pack components. This can lead to suboptimal performance, reduced efficiency, and in extreme cases, system failures or safety hazards.

The increasing use of high-power switching devices in electric powertrains and charging systems further exacerbates the EMI challenges. These devices generate substantial electromagnetic emissions that can couple into BMS circuits, causing disruptions in normal operation. The compact design of modern electric vehicles, where high-power components are in close proximity to sensitive electronics, amplifies this issue.

EMI shielding and filtering techniques traditionally used in electronics design may not always be sufficient for the harsh automotive environment. The need for lightweight, cost-effective solutions that can withstand vibration, temperature extremes, and long-term reliability requirements presents a unique set of challenges for BMS designers.

Furthermore, the regulatory landscape surrounding EMI in automotive applications is becoming increasingly stringent. Compliance with standards such as CISPR 25 and ISO 11452 requires extensive testing and validation, adding complexity and cost to the development process of BMS.

As wireless communication technologies like Bluetooth and Wi-Fi are integrated into modern BMS for remote monitoring and diagnostics, they introduce additional EMI vulnerabilities. These wireless interfaces must be protected against both external interference and the potential for malicious attacks exploiting EMI-induced vulnerabilities.

Addressing these challenges requires a multidisciplinary approach, combining expertise in power electronics, signal processing, electromagnetic compatibility, and system-level design. Innovative solutions such as adaptive filtering, advanced shielding materials, and intelligent EMI mitigation algorithms are areas of active research and development in the field of BMS design.

Current EMI Solutions for BMS

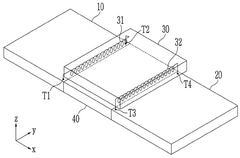

01 EMI shielding techniques for battery management systems

Various shielding techniques are employed to reduce electromagnetic interference in battery management systems. These include the use of conductive enclosures, specialized coatings, and strategic placement of components to minimize EMI emission and susceptibility. Such methods help maintain the integrity of battery system operations in electromagnetic environments.- EMI shielding techniques for battery management systems: Various shielding techniques are employed to reduce electromagnetic interference in battery management systems. These include the use of conductive enclosures, specialized coatings, and strategic placement of components to minimize EMI emission and susceptibility. Such methods help maintain the integrity of battery system operations in electromagnetic environments.

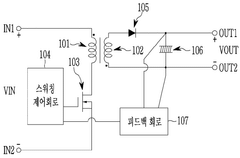

- EMI filtering and suppression in BMS circuits: Battery management systems incorporate EMI filtering and suppression techniques within their circuitry. This involves the use of capacitors, inductors, and ferrite components to attenuate high-frequency noise and prevent electromagnetic interference from affecting sensitive measurement and control functions of the BMS.

- Electromagnetic compatibility design for BMS: Electromagnetic compatibility is a crucial aspect of BMS design, ensuring that the system can function reliably in the presence of electromagnetic disturbances. This involves careful PCB layout, grounding schemes, and component selection to minimize both conducted and radiated emissions while maintaining system immunity to external EMI sources.

- Wireless communication EMI considerations in BMS: As battery management systems increasingly incorporate wireless communication features, special attention is given to mitigating EMI issues related to these wireless interfaces. This includes the selection of appropriate frequency bands, power levels, and antenna designs to ensure reliable communication without compromising the electromagnetic environment of the battery system.

- EMI testing and compliance for battery management systems: Rigorous EMI testing and compliance procedures are implemented for battery management systems to ensure they meet regulatory standards and perform reliably in various electromagnetic environments. This involves conducted and radiated emissions testing, immunity testing, and the development of test methodologies specific to BMS applications.

02 EMI filtering and suppression in BMS circuits

Battery management systems incorporate EMI filtering and suppression techniques within their circuitry. This includes the use of common-mode chokes, ferrite beads, and capacitor networks to attenuate high-frequency noise. These components are strategically placed to reduce both conducted and radiated electromagnetic interference, ensuring reliable BMS operation.Expand Specific Solutions03 Electromagnetic compatibility testing for BMS

Rigorous electromagnetic compatibility testing is conducted on battery management systems to ensure they meet regulatory standards and perform reliably in various electromagnetic environments. This involves subjecting the BMS to controlled EMI sources and measuring its susceptibility and emissions across a range of frequencies and operating conditions.Expand Specific Solutions04 Integration of EMI mitigation in BMS design

EMI mitigation strategies are integrated into the early stages of BMS design. This includes careful PCB layout, component selection, and system architecture to minimize electromagnetic coupling and interference pathways. Designers employ simulation tools and best practices to optimize the electromagnetic performance of the entire battery management system.Expand Specific Solutions05 Adaptive EMI management in smart BMS

Advanced battery management systems incorporate adaptive EMI management techniques. These systems can dynamically adjust their operating parameters based on the detected electromagnetic environment, ensuring optimal performance and protection against varying EMI conditions. This may include adaptive filtering, frequency hopping, or power management strategies to maintain system integrity.Expand Specific Solutions

Key BMS Industry Players

The research on electromagnetic interference effects on battery management systems is in a developing stage, with increasing market size due to the growing electric vehicle industry. The technology's maturity varies among key players. Companies like Samsung SDI, Robert Bosch, and Contemporary Amperex Technology are at the forefront, leveraging their expertise in battery and automotive technologies. Emerging players such as BYD and Beijing Electric Vehicle are also making significant strides. The competitive landscape is diverse, with traditional automotive companies, electronics giants, and specialized battery manufacturers all vying for market share in this critical area of EV technology.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced shielding techniques for their Battery Management Systems (BMS) to mitigate electromagnetic interference (EMI) effects. Their approach includes multi-layer PCB designs with dedicated ground planes and strategic component placement to minimize EMI susceptibility[1]. They have also implemented advanced filtering techniques, such as common-mode chokes and ferrite beads, to suppress high-frequency noise[2]. Samsung's BMS incorporates spread spectrum clock generation to reduce EMI emissions, and utilizes differential signaling for critical communication lines to enhance noise immunity[3]. Additionally, they have developed proprietary EMI-resistant sensors and measurement circuits to ensure accurate battery monitoring even in high-EMI environments[4].

Strengths: Comprehensive EMI mitigation strategy, advanced PCB design techniques, and proprietary EMI-resistant components. Weaknesses: Potential increased production costs due to specialized components and complex designs.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a holistic approach to EMI mitigation in their Battery Management Systems. Their solution integrates hardware and software strategies to create a robust EMI-resistant BMS. On the hardware side, Bosch employs advanced shielding techniques, including metallic enclosures with specialized coatings to attenuate electromagnetic radiation[5]. They have also developed custom-designed EMI filters and transient voltage suppressors to protect sensitive circuits[6]. Bosch's BMS software incorporates adaptive filtering algorithms that can dynamically adjust to changing EMI environments, ensuring consistent performance across various operating conditions[7]. Furthermore, they have implemented redundant communication protocols with error-checking mechanisms to maintain data integrity in high-EMI scenarios[8].

Strengths: Integrated hardware-software approach, adaptive EMI mitigation techniques, and robust communication protocols. Weaknesses: Potentially higher system complexity and increased computational requirements for adaptive algorithms.

Core EMI Shielding Innovations

Device estimating charge state of secondary battery, device detecting abnormality of secondary battery, abnormality detection method of secondary battery, and management system of secondary battery

PatentInactiveUS20210055352A1

Innovation

- A system that includes a charge state estimation device using a Kalman filter-based regression model to measure voltage and current, generate a signal with an opposite phase to cancel electromagnetic noise, and perform machine learning to link noise patterns with driving patterns, enabling accurate abnormality detection and charge rate calculation.

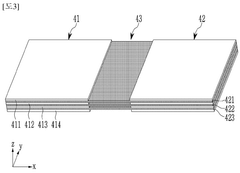

Power supply device, method for forming filter device, and battery system including power supply device

PatentWO2025058491A1

Innovation

- A battery system incorporating a power supply with a filter device that includes a plurality of metal plates and insulating layers between the primary and secondary PCBs, forming a capacitance to reduce EMC noise while maintaining insulation between voltage regions.

EMC Standards for BMS

Electromagnetic Compatibility (EMC) standards for Battery Management Systems (BMS) play a crucial role in ensuring the reliable and safe operation of electric vehicles and energy storage systems. These standards are designed to address the potential electromagnetic interference (EMI) issues that can affect the performance and safety of BMS components.

The International Electrotechnical Commission (IEC) has developed several standards specifically for BMS EMC. IEC 61851-21-2 focuses on EMC requirements for off-board electric vehicle charging systems, while IEC 61000-4 series provides testing and measurement techniques for various electromagnetic phenomena. These standards outline the necessary immunity and emission levels for BMS components.

Automotive-specific EMC standards, such as ISO 11452 and CISPR 25, are also applicable to BMS in electric vehicles. ISO 11452 covers immunity tests for electrical and electronic components in road vehicles, while CISPR 25 addresses radio disturbance characteristics for vehicle protection.

The Society of Automotive Engineers (SAE) has developed J1113 standards, which provide test procedures for determining the electromagnetic compatibility of vehicle components. These standards are widely adopted in the automotive industry and are relevant for BMS applications in electric vehicles.

For industrial and residential applications, IEC 61000-6 series provides generic EMC standards that can be applied to BMS in stationary energy storage systems. These standards define emission and immunity requirements for equipment in various electromagnetic environments.

Compliance with these EMC standards typically involves testing BMS components for both conducted and radiated emissions, as well as their susceptibility to electromagnetic disturbances. Common tests include radiated immunity, conducted immunity, electrostatic discharge (ESD) immunity, and fast transient burst immunity.

As the technology evolves, EMC standards for BMS are continuously updated to address new challenges. For instance, the increasing power levels and switching frequencies in modern BMS designs require more stringent EMC requirements. Additionally, the integration of wireless communication technologies in BMS necessitates consideration of potential interference with other vehicle systems and external devices.

Manufacturers and developers of BMS must stay informed about the latest EMC standards and ensure their products meet or exceed these requirements. This not only ensures regulatory compliance but also contributes to the overall reliability and safety of electric vehicles and energy storage systems.

The International Electrotechnical Commission (IEC) has developed several standards specifically for BMS EMC. IEC 61851-21-2 focuses on EMC requirements for off-board electric vehicle charging systems, while IEC 61000-4 series provides testing and measurement techniques for various electromagnetic phenomena. These standards outline the necessary immunity and emission levels for BMS components.

Automotive-specific EMC standards, such as ISO 11452 and CISPR 25, are also applicable to BMS in electric vehicles. ISO 11452 covers immunity tests for electrical and electronic components in road vehicles, while CISPR 25 addresses radio disturbance characteristics for vehicle protection.

The Society of Automotive Engineers (SAE) has developed J1113 standards, which provide test procedures for determining the electromagnetic compatibility of vehicle components. These standards are widely adopted in the automotive industry and are relevant for BMS applications in electric vehicles.

For industrial and residential applications, IEC 61000-6 series provides generic EMC standards that can be applied to BMS in stationary energy storage systems. These standards define emission and immunity requirements for equipment in various electromagnetic environments.

Compliance with these EMC standards typically involves testing BMS components for both conducted and radiated emissions, as well as their susceptibility to electromagnetic disturbances. Common tests include radiated immunity, conducted immunity, electrostatic discharge (ESD) immunity, and fast transient burst immunity.

As the technology evolves, EMC standards for BMS are continuously updated to address new challenges. For instance, the increasing power levels and switching frequencies in modern BMS designs require more stringent EMC requirements. Additionally, the integration of wireless communication technologies in BMS necessitates consideration of potential interference with other vehicle systems and external devices.

Manufacturers and developers of BMS must stay informed about the latest EMC standards and ensure their products meet or exceed these requirements. This not only ensures regulatory compliance but also contributes to the overall reliability and safety of electric vehicles and energy storage systems.

BMS EMI Testing Methods

Electromagnetic Interference (EMI) testing methods for Battery Management Systems (BMS) are crucial for ensuring the reliability and safety of electric vehicles and energy storage systems. These methods aim to evaluate the susceptibility of BMS to electromagnetic disturbances and their ability to maintain proper functionality in the presence of such interference.

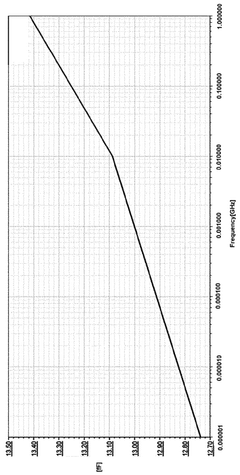

One common testing method is the Bulk Current Injection (BCI) test, which involves injecting a current directly into the wiring harness of the BMS. This method simulates the effects of electromagnetic fields coupling into the system's cables and wires. The BCI test is typically performed over a wide frequency range, usually from 100 kHz to 400 MHz, to assess the BMS's performance under various interference conditions.

Another important testing approach is the Radiated Immunity test, which exposes the entire BMS to electromagnetic fields of varying strengths and frequencies. This test is usually conducted in an anechoic chamber or a shielded room to eliminate external interference. The BMS is subjected to electric fields ranging from 30 V/m to 200 V/m, depending on the specific industry standards and requirements.

The Conducted Immunity test is also essential for BMS EMI testing. This method involves injecting RF signals directly into the power and signal lines of the BMS. The test evaluates the system's ability to maintain proper operation when exposed to conducted disturbances, typically in the frequency range of 150 kHz to 80 MHz.

Electrostatic Discharge (ESD) testing is another critical aspect of BMS EMI evaluation. This test simulates the effects of static electricity discharges that may occur during normal operation or maintenance. ESD tests typically involve applying discharges of up to 15 kV to various points on the BMS enclosure and accessible conductive parts.

To comprehensively assess BMS EMI performance, a combination of these testing methods is often employed. The specific test procedures and limits are typically defined by international standards such as ISO 11452, CISPR 25, and IEC 61000. These standards provide guidelines for test setups, measurement techniques, and acceptance criteria.

It is important to note that BMS EMI testing should be performed not only on individual components but also on the integrated system level. This approach ensures that the BMS can maintain proper functionality and communication with other vehicle systems in the presence of electromagnetic disturbances.

Advanced EMI testing methods for BMS may also include Hardware-in-the-Loop (HIL) simulations, which allow for real-time testing of the BMS under various electromagnetic interference scenarios. This approach enables more comprehensive and dynamic testing, simulating a wide range of operating conditions and potential EMI sources.

One common testing method is the Bulk Current Injection (BCI) test, which involves injecting a current directly into the wiring harness of the BMS. This method simulates the effects of electromagnetic fields coupling into the system's cables and wires. The BCI test is typically performed over a wide frequency range, usually from 100 kHz to 400 MHz, to assess the BMS's performance under various interference conditions.

Another important testing approach is the Radiated Immunity test, which exposes the entire BMS to electromagnetic fields of varying strengths and frequencies. This test is usually conducted in an anechoic chamber or a shielded room to eliminate external interference. The BMS is subjected to electric fields ranging from 30 V/m to 200 V/m, depending on the specific industry standards and requirements.

The Conducted Immunity test is also essential for BMS EMI testing. This method involves injecting RF signals directly into the power and signal lines of the BMS. The test evaluates the system's ability to maintain proper operation when exposed to conducted disturbances, typically in the frequency range of 150 kHz to 80 MHz.

Electrostatic Discharge (ESD) testing is another critical aspect of BMS EMI evaluation. This test simulates the effects of static electricity discharges that may occur during normal operation or maintenance. ESD tests typically involve applying discharges of up to 15 kV to various points on the BMS enclosure and accessible conductive parts.

To comprehensively assess BMS EMI performance, a combination of these testing methods is often employed. The specific test procedures and limits are typically defined by international standards such as ISO 11452, CISPR 25, and IEC 61000. These standards provide guidelines for test setups, measurement techniques, and acceptance criteria.

It is important to note that BMS EMI testing should be performed not only on individual components but also on the integrated system level. This approach ensures that the BMS can maintain proper functionality and communication with other vehicle systems in the presence of electromagnetic disturbances.

Advanced EMI testing methods for BMS may also include Hardware-in-the-Loop (HIL) simulations, which allow for real-time testing of the BMS under various electromagnetic interference scenarios. This approach enables more comprehensive and dynamic testing, simulating a wide range of operating conditions and potential EMI sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!