Investigation of Lightweight Materials in Battery Management Systems

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Lightweight Materials: Background and Objectives

The evolution of Battery Management Systems (BMS) has been closely tied to the rapid development of electric vehicles and renewable energy storage solutions. As these industries have grown, so too has the demand for more efficient, lightweight, and cost-effective BMS components. The integration of lightweight materials in BMS design represents a significant technological advancement, aimed at enhancing overall system performance while reducing weight and improving energy efficiency.

Historically, BMS components were primarily constructed using traditional materials such as steel and heavy-duty plastics. However, the push for improved energy density in battery systems has necessitated a shift towards lighter alternatives. This transition began in the early 2000s and has accelerated significantly over the past decade, driven by advancements in material science and manufacturing processes.

The primary objective of incorporating lightweight materials in BMS is to reduce the overall weight of the battery system without compromising its structural integrity or functionality. This weight reduction directly contributes to increased energy efficiency in electric vehicles, extended range, and improved performance in stationary energy storage systems. Additionally, lightweight materials often offer enhanced thermal management properties, which is crucial for maintaining optimal battery performance and longevity.

Key lightweight materials being explored for BMS applications include advanced polymers, carbon fiber composites, and aluminum alloys. These materials offer significant weight savings compared to traditional options, while also providing excellent mechanical properties and, in some cases, improved thermal conductivity. The integration of these materials requires careful consideration of their electrical properties, as BMS components must maintain high levels of electromagnetic shielding and insulation.

The technological trend in this field is moving towards multi-functional lightweight materials that can serve multiple purposes within the BMS. For instance, researchers are developing conductive polymers that can act as both structural components and contribute to the electrical functionality of the system. This approach not only reduces weight but also simplifies manufacturing processes and potentially lowers production costs.

As the industry progresses, the goals for lightweight material integration in BMS extend beyond mere weight reduction. Future objectives include developing materials with self-healing properties to enhance durability, incorporating smart materials that can adapt to changing environmental conditions, and exploring biodegradable options to improve the environmental sustainability of battery systems at the end of their lifecycle.

In conclusion, the investigation of lightweight materials in Battery Management Systems represents a critical area of research and development in the energy storage sector. The ongoing efforts in this field aim to address the growing demands for more efficient, durable, and environmentally friendly energy storage solutions, paving the way for the next generation of electric vehicles and renewable energy systems.

Historically, BMS components were primarily constructed using traditional materials such as steel and heavy-duty plastics. However, the push for improved energy density in battery systems has necessitated a shift towards lighter alternatives. This transition began in the early 2000s and has accelerated significantly over the past decade, driven by advancements in material science and manufacturing processes.

The primary objective of incorporating lightweight materials in BMS is to reduce the overall weight of the battery system without compromising its structural integrity or functionality. This weight reduction directly contributes to increased energy efficiency in electric vehicles, extended range, and improved performance in stationary energy storage systems. Additionally, lightweight materials often offer enhanced thermal management properties, which is crucial for maintaining optimal battery performance and longevity.

Key lightweight materials being explored for BMS applications include advanced polymers, carbon fiber composites, and aluminum alloys. These materials offer significant weight savings compared to traditional options, while also providing excellent mechanical properties and, in some cases, improved thermal conductivity. The integration of these materials requires careful consideration of their electrical properties, as BMS components must maintain high levels of electromagnetic shielding and insulation.

The technological trend in this field is moving towards multi-functional lightweight materials that can serve multiple purposes within the BMS. For instance, researchers are developing conductive polymers that can act as both structural components and contribute to the electrical functionality of the system. This approach not only reduces weight but also simplifies manufacturing processes and potentially lowers production costs.

As the industry progresses, the goals for lightweight material integration in BMS extend beyond mere weight reduction. Future objectives include developing materials with self-healing properties to enhance durability, incorporating smart materials that can adapt to changing environmental conditions, and exploring biodegradable options to improve the environmental sustainability of battery systems at the end of their lifecycle.

In conclusion, the investigation of lightweight materials in Battery Management Systems represents a critical area of research and development in the energy storage sector. The ongoing efforts in this field aim to address the growing demands for more efficient, durable, and environmentally friendly energy storage solutions, paving the way for the next generation of electric vehicles and renewable energy systems.

Market Analysis for Lightweight BMS Solutions

The market for lightweight Battery Management Systems (BMS) solutions is experiencing significant growth, driven by the increasing demand for electric vehicles (EVs) and the push for more efficient energy storage systems. As automotive manufacturers and energy companies strive to improve the performance and range of their products, the need for lightweight BMS solutions has become paramount.

The global BMS market is projected to expand rapidly in the coming years, with a particular focus on lightweight materials. This growth is primarily attributed to the automotive sector, where weight reduction is crucial for improving EV range and overall efficiency. The aerospace and consumer electronics industries are also contributing to this market expansion, as they seek to reduce the weight of their battery-powered products.

Lightweight BMS solutions offer several advantages over traditional systems. They contribute to overall weight reduction in EVs, which directly translates to improved range and performance. Additionally, these systems often provide better thermal management and more efficient power distribution, further enhancing battery life and vehicle performance.

The market is seeing a shift towards advanced materials such as carbon fiber composites, high-strength aluminum alloys, and engineered plastics. These materials offer significant weight savings while maintaining or even improving the structural integrity and functionality of BMS components. The integration of these materials is enabling manufacturers to create more compact and efficient BMS designs.

Key players in the automotive industry are investing heavily in research and development of lightweight BMS solutions. Major EV manufacturers are partnering with materials science companies and BMS specialists to develop proprietary lightweight systems that give them a competitive edge in the market. This collaboration is driving innovation and accelerating the adoption of new materials and designs.

The market for lightweight BMS solutions is not without challenges. The higher cost of advanced materials and the complexity of integrating them into existing manufacturing processes can be barriers to widespread adoption. However, as production scales up and technologies mature, these costs are expected to decrease, making lightweight BMS solutions more accessible to a broader range of manufacturers.

Geographically, Asia-Pacific is emerging as a key market for lightweight BMS solutions, driven by the rapid growth of EV production in countries like China and South Korea. North America and Europe are also significant markets, with established automotive industries investing heavily in EV technology and lightweight materials.

As the market for lightweight BMS solutions continues to evolve, we can expect to see further innovations in materials science and manufacturing processes. The integration of smart materials, such as those with self-healing properties or enhanced conductivity, could revolutionize BMS design and functionality in the coming years.

The global BMS market is projected to expand rapidly in the coming years, with a particular focus on lightweight materials. This growth is primarily attributed to the automotive sector, where weight reduction is crucial for improving EV range and overall efficiency. The aerospace and consumer electronics industries are also contributing to this market expansion, as they seek to reduce the weight of their battery-powered products.

Lightweight BMS solutions offer several advantages over traditional systems. They contribute to overall weight reduction in EVs, which directly translates to improved range and performance. Additionally, these systems often provide better thermal management and more efficient power distribution, further enhancing battery life and vehicle performance.

The market is seeing a shift towards advanced materials such as carbon fiber composites, high-strength aluminum alloys, and engineered plastics. These materials offer significant weight savings while maintaining or even improving the structural integrity and functionality of BMS components. The integration of these materials is enabling manufacturers to create more compact and efficient BMS designs.

Key players in the automotive industry are investing heavily in research and development of lightweight BMS solutions. Major EV manufacturers are partnering with materials science companies and BMS specialists to develop proprietary lightweight systems that give them a competitive edge in the market. This collaboration is driving innovation and accelerating the adoption of new materials and designs.

The market for lightweight BMS solutions is not without challenges. The higher cost of advanced materials and the complexity of integrating them into existing manufacturing processes can be barriers to widespread adoption. However, as production scales up and technologies mature, these costs are expected to decrease, making lightweight BMS solutions more accessible to a broader range of manufacturers.

Geographically, Asia-Pacific is emerging as a key market for lightweight BMS solutions, driven by the rapid growth of EV production in countries like China and South Korea. North America and Europe are also significant markets, with established automotive industries investing heavily in EV technology and lightweight materials.

As the market for lightweight BMS solutions continues to evolve, we can expect to see further innovations in materials science and manufacturing processes. The integration of smart materials, such as those with self-healing properties or enhanced conductivity, could revolutionize BMS design and functionality in the coming years.

Current Challenges in BMS Weight Reduction

Battery Management Systems (BMS) play a crucial role in ensuring the safety, efficiency, and longevity of battery packs in electric vehicles and other applications. However, as the automotive industry strives for increased range and performance, the weight of BMS components has become a significant concern. The current challenges in BMS weight reduction are multifaceted and require innovative solutions to overcome.

One of the primary challenges is the trade-off between functionality and weight. BMS units need to incorporate numerous sensors, control circuits, and communication interfaces to monitor and manage battery cells effectively. These components contribute significantly to the overall weight of the system. Reducing the number of components without compromising functionality is a complex task that requires advanced integration techniques and novel circuit designs.

Material selection presents another significant challenge. Traditional BMS enclosures and circuit boards often use materials that prioritize durability and heat dissipation over weight reduction. Finding lightweight alternatives that can withstand the harsh automotive environment, including extreme temperatures and vibrations, while maintaining structural integrity and electromagnetic shielding properties, is a major hurdle for engineers.

The miniaturization of BMS components is an ongoing challenge. While advancements in semiconductor technology have led to smaller integrated circuits, the need for robust connections, thermal management, and isolation between high-voltage and low-voltage circuits limits the extent of miniaturization. Balancing size reduction with reliability and safety requirements remains a complex issue.

Power consumption is another factor contributing to BMS weight. Higher power consumption necessitates larger batteries or more extensive cooling systems, both of which add weight. Developing low-power BMS architectures that can operate efficiently without compromising performance is a significant challenge, especially as battery systems become more complex and data-intensive.

Manufacturing processes also present challenges in weight reduction efforts. Traditional assembly methods may require additional structural components or fasteners that add unnecessary weight. Developing new manufacturing techniques that allow for the integration of components and reduction of assembly parts while maintaining scalability and cost-effectiveness is a key area of focus.

Regulatory compliance and safety standards pose additional constraints on weight reduction initiatives. BMS must meet stringent requirements for electrical safety, electromagnetic compatibility, and crash worthiness. These standards often necessitate the use of specific materials or design features that can add weight to the system.

Lastly, the cost implications of lightweight materials and advanced manufacturing processes present a significant challenge. While weight reduction is desirable, it must be achieved without substantially increasing the overall cost of the BMS, as this would impact the competitiveness of electric vehicles in the market.

One of the primary challenges is the trade-off between functionality and weight. BMS units need to incorporate numerous sensors, control circuits, and communication interfaces to monitor and manage battery cells effectively. These components contribute significantly to the overall weight of the system. Reducing the number of components without compromising functionality is a complex task that requires advanced integration techniques and novel circuit designs.

Material selection presents another significant challenge. Traditional BMS enclosures and circuit boards often use materials that prioritize durability and heat dissipation over weight reduction. Finding lightweight alternatives that can withstand the harsh automotive environment, including extreme temperatures and vibrations, while maintaining structural integrity and electromagnetic shielding properties, is a major hurdle for engineers.

The miniaturization of BMS components is an ongoing challenge. While advancements in semiconductor technology have led to smaller integrated circuits, the need for robust connections, thermal management, and isolation between high-voltage and low-voltage circuits limits the extent of miniaturization. Balancing size reduction with reliability and safety requirements remains a complex issue.

Power consumption is another factor contributing to BMS weight. Higher power consumption necessitates larger batteries or more extensive cooling systems, both of which add weight. Developing low-power BMS architectures that can operate efficiently without compromising performance is a significant challenge, especially as battery systems become more complex and data-intensive.

Manufacturing processes also present challenges in weight reduction efforts. Traditional assembly methods may require additional structural components or fasteners that add unnecessary weight. Developing new manufacturing techniques that allow for the integration of components and reduction of assembly parts while maintaining scalability and cost-effectiveness is a key area of focus.

Regulatory compliance and safety standards pose additional constraints on weight reduction initiatives. BMS must meet stringent requirements for electrical safety, electromagnetic compatibility, and crash worthiness. These standards often necessitate the use of specific materials or design features that can add weight to the system.

Lastly, the cost implications of lightweight materials and advanced manufacturing processes present a significant challenge. While weight reduction is desirable, it must be achieved without substantially increasing the overall cost of the BMS, as this would impact the competitiveness of electric vehicles in the market.

Existing Lightweight Material Solutions for BMS

01 Lightweight composite materials

Composite materials are used to create lightweight structures with high strength-to-weight ratios. These materials often combine different components such as fibers, resins, and core materials to achieve desired properties. They are widely used in aerospace, automotive, and sporting goods industries to reduce weight while maintaining structural integrity.- Lightweight composite materials: Composite materials are used to create lightweight structures with high strength-to-weight ratios. These materials often combine different components such as fibers, resins, and core materials to achieve desired properties. They are widely used in aerospace, automotive, and sporting goods industries to reduce weight while maintaining structural integrity.

- Lightweight metal alloys: Advanced metal alloys, particularly those based on aluminum, magnesium, or titanium, are developed to provide lightweight solutions for various applications. These alloys offer reduced weight compared to traditional metals while maintaining necessary strength and durability. They are commonly used in transportation, construction, and consumer products.

- Foam-based lightweight materials: Foam materials, including polymer foams and metal foams, are utilized to create lightweight structures with excellent insulation properties. These materials feature a cellular structure that provides low density while offering good energy absorption and thermal insulation. They find applications in packaging, construction, and automotive industries.

- Lightweight nanomaterials: Nanomaterials, such as carbon nanotubes and graphene, are incorporated into various matrices to create ultra-lightweight materials with exceptional mechanical properties. These advanced materials offer significant weight reduction potential while enhancing strength, stiffness, and other functional properties. They are being explored for use in aerospace, electronics, and energy storage applications.

- Lightweight textile-based materials: Advanced textiles and fabrics are developed to create lightweight materials for various applications. These include high-performance fibers, 3D woven structures, and textile composites. Such materials offer weight reduction while providing flexibility, strength, and other desired properties. They are used in protective gear, sportswear, and technical textiles.

02 Lightweight metals and alloys

Lightweight metals and alloys, such as aluminum, magnesium, and titanium, are utilized in various applications to reduce overall weight. These materials offer a good balance of strength and low density, making them suitable for use in transportation, construction, and consumer products where weight reduction is crucial.Expand Specific Solutions03 Foam-based lightweight materials

Foam-based materials, including polymer foams and metal foams, are used to create lightweight structures with excellent insulation properties. These materials have a high volume of gas-filled pores, resulting in low density and weight. They are commonly used in packaging, insulation, and cushioning applications.Expand Specific Solutions04 Lightweight concrete and construction materials

Lightweight concrete and other construction materials are developed to reduce the overall weight of buildings and structures. These materials often incorporate lightweight aggregates, air-entraining agents, or other additives to decrease density while maintaining adequate strength and durability for construction purposes.Expand Specific Solutions05 Nanostructured lightweight materials

Nanostructured materials, such as carbon nanotubes and graphene, are utilized to create ultra-lightweight materials with exceptional strength and stiffness. These materials exploit the unique properties of nanoscale structures to achieve high performance-to-weight ratios, making them suitable for advanced applications in aerospace, electronics, and energy storage.Expand Specific Solutions

Key Players in Lightweight BMS Development

The investigation of lightweight materials in Battery Management Systems (BMS) is currently in a growth phase, with increasing market demand driven by the automotive and energy storage sectors. The global BMS market is projected to expand significantly, fueled by the rising adoption of electric vehicles and renewable energy systems. Technologically, the field is advancing rapidly, with companies like LG Energy Solution, Samsung SDI, and Contemporary Amperex Technology leading innovation. These firms are developing advanced lightweight materials and designs to enhance BMS efficiency and performance. While established players dominate, emerging companies like BattGenie are introducing novel software solutions, indicating a dynamic competitive landscape with opportunities for technological breakthroughs and market disruption.

BYD Co., Ltd.

Technical Solution: BYD has developed a lightweight BMS solution focusing on material innovation and system integration. Their approach utilizes a combination of aluminum-lithium alloys and advanced polymers for the BMS housing, achieving a weight reduction of up to 35% compared to traditional designs[1]. BYD has also implemented a highly integrated circuit design, combining multiple functions into single chips to reduce overall system size and weight. The company's lightweight BMS incorporates advanced thermal management techniques, including the use of graphene-enhanced heat spreaders for improved heat dissipation[3]. Additionally, BYD has developed a smart cell balancing algorithm that optimizes battery performance while minimizing the need for additional hardware[5].

Strengths: Significant weight reduction, improved thermal management, and enhanced system integration. Weaknesses: Potential higher costs associated with specialized materials and manufacturing processes.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has focused on developing a lightweight BMS using advanced polymer composites and miniaturized electronics. Their system incorporates a high-strength, low-density polymer matrix reinforced with carbon nanotubes, resulting in a 30% weight reduction compared to conventional BMS designs[2]. Samsung's approach also includes the integration of highly efficient microprocessors and sensors, allowing for a more compact overall design. The company has implemented advanced thermal management techniques, utilizing phase-change materials (PCMs) to regulate battery temperature more effectively[4]. Furthermore, Samsung SDI has developed a wireless BMS technology, eliminating the need for heavy wiring harnesses and further reducing system weight[6].

Strengths: Significant weight reduction, improved thermal management, and wireless connectivity. Weaknesses: Potential concerns about long-term durability of polymer composites and higher initial costs.

Innovative Lightweight Materials for BMS Applications

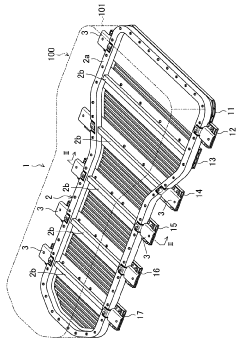

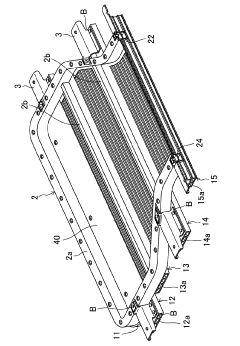

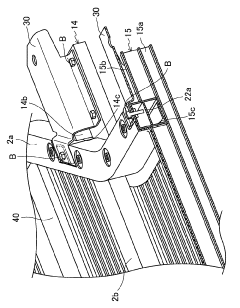

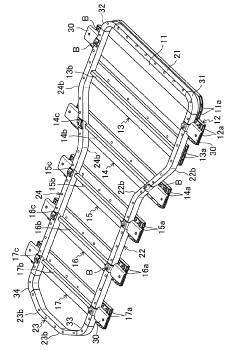

Battery container

PatentInactiveJP2015099703A

Innovation

- The battery container incorporates a resin material with integrated reinforcing members that are insert-molded together, enhancing their reinforcing effect and allowing for a thinner design.

Environmental Impact of Lightweight BMS Materials

The adoption of lightweight materials in Battery Management Systems (BMS) has significant environmental implications throughout the product lifecycle. From production to end-of-life disposal, these materials can contribute to reduced environmental impact compared to traditional BMS components.

During the manufacturing phase, lightweight materials often require less energy-intensive processes, resulting in lower greenhouse gas emissions. For instance, the production of carbon fiber reinforced polymers (CFRP) typically generates fewer emissions compared to traditional metals like steel or aluminum. This reduction in energy consumption during manufacturing contributes to a smaller carbon footprint for the overall BMS production.

In the use phase, lightweight BMS materials play a crucial role in improving the energy efficiency of electric vehicles (EVs). By reducing the overall weight of the vehicle, these materials help extend the driving range and decrease energy consumption. This translates to lower indirect emissions from power generation, particularly in regions where the electricity grid still relies heavily on fossil fuels.

The durability and corrosion resistance of many lightweight materials used in BMS can lead to extended product lifespans. This longevity reduces the need for frequent replacements, thereby minimizing waste generation and the environmental impact associated with manufacturing replacement parts.

At the end of the product lifecycle, the recyclability of lightweight BMS materials becomes a critical factor. Many advanced composites and alloys used in lightweight BMS designs are recyclable, allowing for the recovery and reuse of valuable materials. This circular approach helps conserve natural resources and reduces the environmental burden of waste disposal.

However, it is important to note that some lightweight materials may pose challenges in recycling processes. For example, certain polymer composites may require specialized recycling techniques, which are not yet widely available. This highlights the need for continued research and development in recycling technologies to fully realize the environmental benefits of lightweight BMS materials.

The use of lightweight materials in BMS also contributes to the overall reduction of hazardous substances in automotive components. Many traditional BMS materials contain heavy metals or toxic compounds, which can leach into the environment if not properly managed. Lightweight alternatives often offer safer, more environmentally friendly options that reduce the risk of soil and water contamination.

In conclusion, the environmental impact of lightweight BMS materials is generally positive, offering benefits in terms of reduced emissions, improved energy efficiency, and potential for recycling. However, ongoing efforts are needed to address recycling challenges and further optimize the lifecycle environmental performance of these materials in Battery Management Systems.

During the manufacturing phase, lightweight materials often require less energy-intensive processes, resulting in lower greenhouse gas emissions. For instance, the production of carbon fiber reinforced polymers (CFRP) typically generates fewer emissions compared to traditional metals like steel or aluminum. This reduction in energy consumption during manufacturing contributes to a smaller carbon footprint for the overall BMS production.

In the use phase, lightweight BMS materials play a crucial role in improving the energy efficiency of electric vehicles (EVs). By reducing the overall weight of the vehicle, these materials help extend the driving range and decrease energy consumption. This translates to lower indirect emissions from power generation, particularly in regions where the electricity grid still relies heavily on fossil fuels.

The durability and corrosion resistance of many lightweight materials used in BMS can lead to extended product lifespans. This longevity reduces the need for frequent replacements, thereby minimizing waste generation and the environmental impact associated with manufacturing replacement parts.

At the end of the product lifecycle, the recyclability of lightweight BMS materials becomes a critical factor. Many advanced composites and alloys used in lightweight BMS designs are recyclable, allowing for the recovery and reuse of valuable materials. This circular approach helps conserve natural resources and reduces the environmental burden of waste disposal.

However, it is important to note that some lightweight materials may pose challenges in recycling processes. For example, certain polymer composites may require specialized recycling techniques, which are not yet widely available. This highlights the need for continued research and development in recycling technologies to fully realize the environmental benefits of lightweight BMS materials.

The use of lightweight materials in BMS also contributes to the overall reduction of hazardous substances in automotive components. Many traditional BMS materials contain heavy metals or toxic compounds, which can leach into the environment if not properly managed. Lightweight alternatives often offer safer, more environmentally friendly options that reduce the risk of soil and water contamination.

In conclusion, the environmental impact of lightweight BMS materials is generally positive, offering benefits in terms of reduced emissions, improved energy efficiency, and potential for recycling. However, ongoing efforts are needed to address recycling challenges and further optimize the lifecycle environmental performance of these materials in Battery Management Systems.

Safety Considerations for Lightweight BMS Design

Safety considerations are paramount in the design and implementation of lightweight Battery Management Systems (BMS) for electric vehicles and energy storage applications. As manufacturers strive to reduce the weight of BMS components, it is crucial to maintain or enhance safety standards to ensure the reliability and longevity of battery systems.

One of the primary safety concerns in lightweight BMS design is the potential for thermal runaway. The use of lightweight materials may affect heat dissipation properties, potentially leading to increased risk of overheating. To address this, designers must carefully select materials with optimal thermal conductivity and implement advanced cooling strategies. This may include the integration of phase-change materials or the development of novel heat-spreading techniques to efficiently manage thermal loads.

Electrical safety is another critical aspect that requires careful consideration in lightweight BMS designs. The reduction in material mass could potentially compromise the system's ability to withstand electrical faults or short circuits. To mitigate this risk, engineers must focus on developing robust insulation techniques and incorporating fail-safe mechanisms. This may involve the use of advanced composite materials that offer both lightweight properties and excellent electrical insulation characteristics.

Mechanical integrity is equally important in ensuring the safety of lightweight BMS. The structural stability of the system must be maintained under various operating conditions, including vibration, shock, and extreme temperatures. Designers should employ advanced simulation tools to analyze the mechanical behavior of lightweight materials and optimize the structural design to withstand expected stresses and strains.

Environmental factors also play a significant role in the safety considerations for lightweight BMS. The materials used must be resistant to corrosion, moisture, and other environmental contaminants that could compromise the system's integrity over time. This necessitates the development and testing of protective coatings and encapsulation techniques specifically tailored for lightweight materials.

Electromagnetic compatibility (EMC) is another crucial safety aspect that must be addressed in lightweight BMS design. The reduction in shielding mass could potentially increase the system's susceptibility to electromagnetic interference. Engineers must implement innovative EMC solutions, such as the integration of conductive layers within composite materials or the development of lightweight, high-performance EMI shielding materials.

Lastly, the safety considerations for lightweight BMS extend to the manufacturing and assembly processes. The use of novel materials may require the development of new joining techniques and quality control measures to ensure consistent performance and reliability. This may involve the implementation of advanced non-destructive testing methods and the establishment of rigorous quality assurance protocols specific to lightweight BMS components.

One of the primary safety concerns in lightweight BMS design is the potential for thermal runaway. The use of lightweight materials may affect heat dissipation properties, potentially leading to increased risk of overheating. To address this, designers must carefully select materials with optimal thermal conductivity and implement advanced cooling strategies. This may include the integration of phase-change materials or the development of novel heat-spreading techniques to efficiently manage thermal loads.

Electrical safety is another critical aspect that requires careful consideration in lightweight BMS designs. The reduction in material mass could potentially compromise the system's ability to withstand electrical faults or short circuits. To mitigate this risk, engineers must focus on developing robust insulation techniques and incorporating fail-safe mechanisms. This may involve the use of advanced composite materials that offer both lightweight properties and excellent electrical insulation characteristics.

Mechanical integrity is equally important in ensuring the safety of lightweight BMS. The structural stability of the system must be maintained under various operating conditions, including vibration, shock, and extreme temperatures. Designers should employ advanced simulation tools to analyze the mechanical behavior of lightweight materials and optimize the structural design to withstand expected stresses and strains.

Environmental factors also play a significant role in the safety considerations for lightweight BMS. The materials used must be resistant to corrosion, moisture, and other environmental contaminants that could compromise the system's integrity over time. This necessitates the development and testing of protective coatings and encapsulation techniques specifically tailored for lightweight materials.

Electromagnetic compatibility (EMC) is another crucial safety aspect that must be addressed in lightweight BMS design. The reduction in shielding mass could potentially increase the system's susceptibility to electromagnetic interference. Engineers must implement innovative EMC solutions, such as the integration of conductive layers within composite materials or the development of lightweight, high-performance EMI shielding materials.

Lastly, the safety considerations for lightweight BMS extend to the manufacturing and assembly processes. The use of novel materials may require the development of new joining techniques and quality control measures to ensure consistent performance and reliability. This may involve the implementation of advanced non-destructive testing methods and the establishment of rigorous quality assurance protocols specific to lightweight BMS components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!