Battery Management Systems in Stress Environments

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Stress Environment Background and Objectives

Battery Management Systems (BMS) have become increasingly critical in modern energy storage applications, particularly in environments subject to high stress. The evolution of BMS technology has been driven by the growing demand for efficient, reliable, and safe energy storage solutions across various industries, including automotive, aerospace, and renewable energy sectors.

The primary objective of researching BMS in stress environments is to enhance the performance, safety, and longevity of battery systems under extreme conditions. These conditions may include high temperatures, vibrations, electromagnetic interference, and rapid charge-discharge cycles. As batteries are increasingly deployed in demanding applications, such as electric vehicles operating in harsh climates or energy storage systems in remote locations, the need for robust BMS solutions has become paramount.

Historically, BMS development has focused on basic functionalities like cell balancing and overcharge protection. However, the trend towards more complex and high-performance battery systems has necessitated a shift in focus. Modern BMS research aims to develop intelligent systems capable of real-time monitoring, predictive maintenance, and adaptive control strategies that can respond to changing environmental stresses.

One of the key technological trends in this field is the integration of advanced sensors and data analytics. These innovations allow for more precise monitoring of battery health and performance under stress, enabling proactive measures to prevent failures and optimize battery life. Additionally, there is a growing emphasis on developing BMS architectures that are modular and scalable, capable of adapting to different battery chemistries and configurations.

The global push towards electrification and renewable energy has further accelerated the need for advanced BMS solutions. As countries set ambitious targets for electric vehicle adoption and grid-scale energy storage, the demand for BMS capable of operating reliably in diverse and challenging environments has surged. This has led to increased investment in research and development, with a focus on improving the resilience and efficiency of BMS in stress conditions.

Looking ahead, the objectives of BMS research in stress environments are multifaceted. They include developing more accurate state-of-charge and state-of-health estimation algorithms that remain reliable under extreme conditions, creating thermal management systems that can operate efficiently across a wide temperature range, and designing fault-tolerant architectures that ensure system integrity even in the face of component failures or external disturbances.

The primary objective of researching BMS in stress environments is to enhance the performance, safety, and longevity of battery systems under extreme conditions. These conditions may include high temperatures, vibrations, electromagnetic interference, and rapid charge-discharge cycles. As batteries are increasingly deployed in demanding applications, such as electric vehicles operating in harsh climates or energy storage systems in remote locations, the need for robust BMS solutions has become paramount.

Historically, BMS development has focused on basic functionalities like cell balancing and overcharge protection. However, the trend towards more complex and high-performance battery systems has necessitated a shift in focus. Modern BMS research aims to develop intelligent systems capable of real-time monitoring, predictive maintenance, and adaptive control strategies that can respond to changing environmental stresses.

One of the key technological trends in this field is the integration of advanced sensors and data analytics. These innovations allow for more precise monitoring of battery health and performance under stress, enabling proactive measures to prevent failures and optimize battery life. Additionally, there is a growing emphasis on developing BMS architectures that are modular and scalable, capable of adapting to different battery chemistries and configurations.

The global push towards electrification and renewable energy has further accelerated the need for advanced BMS solutions. As countries set ambitious targets for electric vehicle adoption and grid-scale energy storage, the demand for BMS capable of operating reliably in diverse and challenging environments has surged. This has led to increased investment in research and development, with a focus on improving the resilience and efficiency of BMS in stress conditions.

Looking ahead, the objectives of BMS research in stress environments are multifaceted. They include developing more accurate state-of-charge and state-of-health estimation algorithms that remain reliable under extreme conditions, creating thermal management systems that can operate efficiently across a wide temperature range, and designing fault-tolerant architectures that ensure system integrity even in the face of component failures or external disturbances.

Market Analysis for Robust BMS Solutions

The market for robust Battery Management Systems (BMS) in stress environments is experiencing significant growth, driven by the increasing demand for reliable energy storage solutions in challenging applications. Industries such as aerospace, defense, automotive, and industrial sectors are key drivers of this market expansion, as they require BMS solutions capable of withstanding extreme temperatures, vibrations, and other harsh conditions.

In the aerospace and defense sectors, the need for robust BMS solutions is particularly acute. These industries demand high-performance energy storage systems that can operate reliably in extreme environments, from the frigid temperatures of high-altitude flight to the intense heat and vibration of military applications. The market for BMS in these sectors is expected to grow steadily as more electric and hybrid-electric aircraft enter service and as military vehicles increasingly rely on advanced energy storage systems.

The automotive industry is another major contributor to the robust BMS market. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is a pressing need for BMS solutions that can ensure optimal battery performance and safety under various stress conditions. This includes managing thermal issues in extreme climates, handling high-current charging and discharging cycles, and maintaining battery health during long-term operation.

Industrial applications, including renewable energy storage, grid stabilization, and remote power systems, also drive demand for robust BMS solutions. These applications often involve outdoor installations or harsh industrial environments where batteries are exposed to temperature extremes, dust, humidity, and other challenging factors. The ability of a BMS to maintain battery performance and longevity under these conditions is crucial for the reliability and cost-effectiveness of these systems.

The market analysis reveals a trend towards more integrated and intelligent BMS solutions. Manufacturers are developing systems that not only monitor and protect batteries but also provide advanced features such as predictive maintenance, real-time performance optimization, and seamless integration with other vehicle or system components. This trend is particularly evident in the EV market, where BMS plays a critical role in range prediction, charging optimization, and overall vehicle efficiency.

Geographically, North America and Europe are leading markets for robust BMS solutions, driven by their strong aerospace, defense, and automotive industries. However, the Asia-Pacific region is showing the fastest growth, fueled by the rapid expansion of EV production and increasing investments in renewable energy storage systems.

As the market for robust BMS solutions continues to expand, competition among manufacturers is intensifying. Key players are focusing on developing more resilient, efficient, and cost-effective BMS technologies to gain a competitive edge. This competition is driving innovation in areas such as advanced sensors, thermal management techniques, and AI-powered battery health prediction algorithms.

In the aerospace and defense sectors, the need for robust BMS solutions is particularly acute. These industries demand high-performance energy storage systems that can operate reliably in extreme environments, from the frigid temperatures of high-altitude flight to the intense heat and vibration of military applications. The market for BMS in these sectors is expected to grow steadily as more electric and hybrid-electric aircraft enter service and as military vehicles increasingly rely on advanced energy storage systems.

The automotive industry is another major contributor to the robust BMS market. With the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is a pressing need for BMS solutions that can ensure optimal battery performance and safety under various stress conditions. This includes managing thermal issues in extreme climates, handling high-current charging and discharging cycles, and maintaining battery health during long-term operation.

Industrial applications, including renewable energy storage, grid stabilization, and remote power systems, also drive demand for robust BMS solutions. These applications often involve outdoor installations or harsh industrial environments where batteries are exposed to temperature extremes, dust, humidity, and other challenging factors. The ability of a BMS to maintain battery performance and longevity under these conditions is crucial for the reliability and cost-effectiveness of these systems.

The market analysis reveals a trend towards more integrated and intelligent BMS solutions. Manufacturers are developing systems that not only monitor and protect batteries but also provide advanced features such as predictive maintenance, real-time performance optimization, and seamless integration with other vehicle or system components. This trend is particularly evident in the EV market, where BMS plays a critical role in range prediction, charging optimization, and overall vehicle efficiency.

Geographically, North America and Europe are leading markets for robust BMS solutions, driven by their strong aerospace, defense, and automotive industries. However, the Asia-Pacific region is showing the fastest growth, fueled by the rapid expansion of EV production and increasing investments in renewable energy storage systems.

As the market for robust BMS solutions continues to expand, competition among manufacturers is intensifying. Key players are focusing on developing more resilient, efficient, and cost-effective BMS technologies to gain a competitive edge. This competition is driving innovation in areas such as advanced sensors, thermal management techniques, and AI-powered battery health prediction algorithms.

Current BMS Challenges in Extreme Conditions

Battery Management Systems (BMS) face significant challenges when operating in extreme conditions, particularly in stress environments. These challenges stem from the harsh conditions that can severely impact the performance, safety, and longevity of battery systems. One of the primary issues is temperature management, as extreme heat or cold can dramatically affect battery chemistry and efficiency.

In high-temperature environments, BMS must contend with accelerated chemical reactions within the battery cells, which can lead to thermal runaway, reduced capacity, and shortened lifespan. Conversely, in extremely cold conditions, battery performance can degrade significantly, with reduced power output and difficulty in charging. The BMS must adapt its control strategies to mitigate these temperature-related issues, often requiring sophisticated thermal management systems.

Vibration and shock present another set of challenges for BMS in stress environments. These mechanical stresses can cause physical damage to battery components, potentially leading to internal short circuits or connection failures. The BMS must be robust enough to withstand these forces while maintaining accurate monitoring and control of the battery system.

Humidity and corrosive atmospheres pose additional threats to BMS functionality. Moisture ingress can lead to short circuits and corrosion of electrical components, while corrosive gases can degrade sensors and circuitry. Designing BMS that are adequately sealed and protected against these environmental factors is crucial for maintaining reliability in harsh conditions.

Electromagnetic interference (EMI) is a significant concern in certain stress environments, particularly in industrial or military applications. The BMS must be shielded and designed to operate accurately despite potential EMI, which can otherwise lead to erroneous readings and compromised battery management.

Power management becomes more critical in stress environments, where energy efficiency and reliability are paramount. The BMS must optimize battery performance while preventing over-discharge or overcharging, which can be more challenging when operating conditions are extreme and unpredictable.

Lastly, the integration of BMS with other vehicle or system components becomes more complex in stress environments. The BMS must communicate effectively with other systems, such as power converters or motor controllers, while maintaining its core functions under adverse conditions. This requires robust communication protocols and interfaces that can withstand environmental stresses.

Addressing these challenges requires innovative approaches in BMS design, including advanced materials, sophisticated algorithms, and redundant systems to ensure reliability and safety in the most demanding applications.

In high-temperature environments, BMS must contend with accelerated chemical reactions within the battery cells, which can lead to thermal runaway, reduced capacity, and shortened lifespan. Conversely, in extremely cold conditions, battery performance can degrade significantly, with reduced power output and difficulty in charging. The BMS must adapt its control strategies to mitigate these temperature-related issues, often requiring sophisticated thermal management systems.

Vibration and shock present another set of challenges for BMS in stress environments. These mechanical stresses can cause physical damage to battery components, potentially leading to internal short circuits or connection failures. The BMS must be robust enough to withstand these forces while maintaining accurate monitoring and control of the battery system.

Humidity and corrosive atmospheres pose additional threats to BMS functionality. Moisture ingress can lead to short circuits and corrosion of electrical components, while corrosive gases can degrade sensors and circuitry. Designing BMS that are adequately sealed and protected against these environmental factors is crucial for maintaining reliability in harsh conditions.

Electromagnetic interference (EMI) is a significant concern in certain stress environments, particularly in industrial or military applications. The BMS must be shielded and designed to operate accurately despite potential EMI, which can otherwise lead to erroneous readings and compromised battery management.

Power management becomes more critical in stress environments, where energy efficiency and reliability are paramount. The BMS must optimize battery performance while preventing over-discharge or overcharging, which can be more challenging when operating conditions are extreme and unpredictable.

Lastly, the integration of BMS with other vehicle or system components becomes more complex in stress environments. The BMS must communicate effectively with other systems, such as power converters or motor controllers, while maintaining its core functions under adverse conditions. This requires robust communication protocols and interfaces that can withstand environmental stresses.

Addressing these challenges requires innovative approaches in BMS design, including advanced materials, sophisticated algorithms, and redundant systems to ensure reliability and safety in the most demanding applications.

Existing BMS Solutions for Harsh Environments

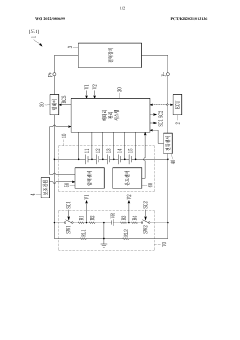

01 Battery monitoring and control systems

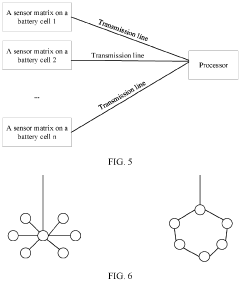

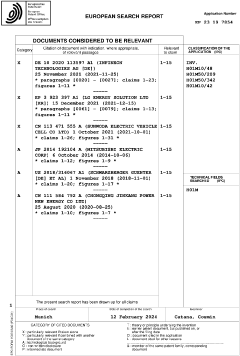

These systems monitor various parameters of batteries, such as voltage, current, and temperature, to optimize performance and ensure safe operation. They can adjust charging and discharging rates, balance cells, and provide real-time data on battery health and status.- Battery monitoring and control systems: These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.

- Thermal management in battery systems: Thermal management is crucial for battery performance and safety. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and maintaining optimal operating conditions. They may include sensors, cooling circuits, and control algorithms to manage heat distribution across battery packs.

- Cell balancing techniques: Cell balancing ensures that all cells in a battery pack maintain similar voltage levels, preventing overcharging or undercharging of individual cells. This can be achieved through passive or active balancing methods, improving overall battery pack performance and longevity.

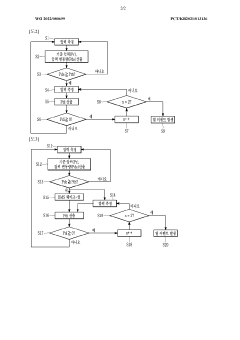

- State of charge and state of health estimation: Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are crucial for optimizing battery usage, predicting remaining range in electric vehicles, and scheduling maintenance or replacement of battery packs.

- Battery management for electric vehicles: Specialized battery management systems for electric vehicles focus on optimizing range, fast charging capabilities, and integrating with vehicle systems. These systems may include features like regenerative braking energy recovery, power distribution management, and integration with vehicle navigation systems for range prediction.

02 Thermal management in battery systems

Thermal management is crucial for maintaining optimal battery performance and longevity. These systems regulate battery temperature through cooling or heating mechanisms, preventing overheating and ensuring efficient operation across various environmental conditions.Expand Specific Solutions03 Battery state estimation techniques

Advanced algorithms and methods are used to estimate important battery states such as state of charge (SOC), state of health (SOH), and remaining useful life. These estimations help in optimizing battery usage, predicting maintenance needs, and improving overall system reliability.Expand Specific Solutions04 Integration with renewable energy systems

Battery management systems are designed to work seamlessly with renewable energy sources like solar and wind. They optimize energy storage and distribution, manage grid interactions, and ensure efficient use of renewable resources in conjunction with battery systems.Expand Specific Solutions05 Safety and fault detection in battery systems

These systems incorporate advanced safety features and fault detection mechanisms. They can identify potential issues such as short circuits, overcharging, or cell degradation, and take preventive actions to protect the battery and connected equipment from damage.Expand Specific Solutions

Key Players in Stress-Resistant BMS Industry

The research on Battery Management Systems in Stress Environments is in a rapidly evolving phase, with the market expected to grow significantly due to increasing demand for electric vehicles and renewable energy storage. The competitive landscape is characterized by a mix of established players and innovative startups. Companies like LG Energy Solution, Samsung SDI, and Bosch are leveraging their extensive experience in battery technology to develop advanced BMS solutions. Emerging players such as BattGenie and GridBeyond are focusing on AI-powered systems to optimize battery performance in challenging conditions. The technology is maturing, with major automotive manufacturers like GM and Stellantis investing heavily in BMS development for their electric vehicle platforms.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced Battery Management Systems (BMS) for stress environments, focusing on thermal management and state estimation. Their system utilizes machine learning algorithms to predict battery behavior under extreme conditions, enhancing safety and performance[1]. The BMS incorporates real-time monitoring of cell voltages, temperatures, and internal resistance, allowing for adaptive control strategies. In high-stress situations, such as rapid temperature changes or mechanical shocks, the system can quickly adjust charging and discharging parameters to protect the battery pack[3]. LG's BMS also features a multi-layer safety protocol, including hardware fuses and software-based cell balancing, to prevent thermal runaway and extend battery life in harsh environments[5].

Strengths: Advanced thermal management, predictive algorithms for stress conditions, and multi-layer safety protocols. Weaknesses: Potential complexity in implementation and higher initial costs compared to simpler BMS solutions.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered a robust Battery Management System tailored for stress environments, emphasizing durability and reliability. Their BMS employs a distributed architecture, with multiple microcontrollers monitoring different battery modules, enhancing fault tolerance in high-stress scenarios[2]. The system features advanced sensor fusion techniques, combining data from voltage, current, and temperature sensors with accelerometers and strain gauges to detect and respond to mechanical stresses[4]. Samsung's BMS utilizes adaptive algorithms that adjust battery parameters based on environmental conditions, such as extreme temperatures or vibrations, to optimize performance and longevity[6]. Additionally, they have implemented a predictive maintenance system that uses historical data and machine learning to anticipate potential failures before they occur, particularly useful in stress-prone applications[8].

Strengths: Distributed architecture for enhanced reliability, comprehensive sensor integration, and predictive maintenance capabilities. Weaknesses: Potentially higher hardware costs due to multiple controllers and sensors.

Core Innovations in Stress-Tolerant BMS Design

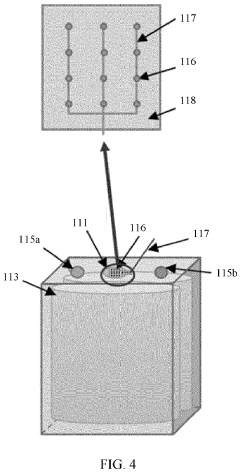

Battery system thermal event detection method and battery system using same

PatentWO2022080699A1

Innovation

- A battery system with a pressure sensor inside the battery pack that measures internal pressure and calculates reference pressures to detect pressure variations, waking up the battery management system if a predetermined threshold is exceeded, allowing for thermal event detection and subsequent measurement of cell voltage, temperature, and insulation resistance to determine battery pack abnormalities.

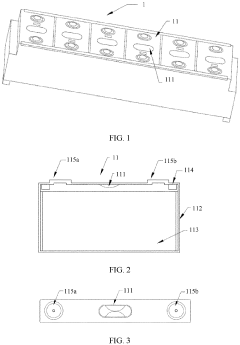

Battery cell, battery module, battery pack, energy storage system, and electric vehicle

PatentPendingEP4345979A1

Innovation

- Incorporating stress sensors on the explosion-proof valve of battery cells, connected to a processor, to detect stress deformation in real-time, allowing for timely monitoring and potential fire extinguishing, without requiring large-scale test equipment.

Environmental Impact of BMS in Extreme Conditions

Battery Management Systems (BMS) operating in stress environments face significant environmental challenges that can impact their performance, reliability, and overall effectiveness. Extreme conditions such as high temperatures, extreme cold, high humidity, and corrosive atmospheres can have profound effects on BMS functionality and the batteries they manage.

In high-temperature environments, BMS components may experience accelerated degradation, leading to reduced lifespan and potential failure. Thermal management becomes crucial, as excessive heat can cause battery cells to expand, potentially leading to internal short circuits or even thermal runaway. BMS must adapt their charging and discharging strategies to mitigate these risks, often resulting in reduced battery capacity and performance.

Conversely, extremely cold environments present their own set of challenges. Battery chemical reactions slow down significantly at low temperatures, reducing power output and capacity. BMS must implement sophisticated heating strategies to maintain optimal battery temperature, which can lead to increased energy consumption and reduced overall system efficiency.

High humidity and corrosive atmospheres can cause accelerated corrosion of BMS components and battery connectors. This can lead to increased electrical resistance, reduced efficiency, and potential system failures. BMS designs for these environments often require enhanced protective coatings and sealed enclosures, which can increase cost and complexity.

The environmental impact of BMS in extreme conditions extends beyond the immediate system. In marine applications, for instance, the potential for battery leakage or failure due to stress conditions could have severe consequences for aquatic ecosystems. Similarly, in aerospace applications, BMS failure could lead to catastrophic events with far-reaching environmental implications.

To address these challenges, BMS designers are increasingly focusing on robust environmental protection measures. These include advanced thermal management systems, corrosion-resistant materials, and adaptive control algorithms that can adjust battery usage patterns based on environmental conditions. However, these solutions often come at the cost of increased energy consumption, which can indirectly contribute to greater environmental impact through increased demand on power generation systems.

The development of more environmentally resilient BMS also drives innovation in battery chemistry and construction. For example, solid-state batteries are being explored for their potential to withstand extreme temperatures and reduce the risk of leakage in harsh environments. These advancements could lead to more environmentally friendly and resilient energy storage solutions for a wide range of applications.

In high-temperature environments, BMS components may experience accelerated degradation, leading to reduced lifespan and potential failure. Thermal management becomes crucial, as excessive heat can cause battery cells to expand, potentially leading to internal short circuits or even thermal runaway. BMS must adapt their charging and discharging strategies to mitigate these risks, often resulting in reduced battery capacity and performance.

Conversely, extremely cold environments present their own set of challenges. Battery chemical reactions slow down significantly at low temperatures, reducing power output and capacity. BMS must implement sophisticated heating strategies to maintain optimal battery temperature, which can lead to increased energy consumption and reduced overall system efficiency.

High humidity and corrosive atmospheres can cause accelerated corrosion of BMS components and battery connectors. This can lead to increased electrical resistance, reduced efficiency, and potential system failures. BMS designs for these environments often require enhanced protective coatings and sealed enclosures, which can increase cost and complexity.

The environmental impact of BMS in extreme conditions extends beyond the immediate system. In marine applications, for instance, the potential for battery leakage or failure due to stress conditions could have severe consequences for aquatic ecosystems. Similarly, in aerospace applications, BMS failure could lead to catastrophic events with far-reaching environmental implications.

To address these challenges, BMS designers are increasingly focusing on robust environmental protection measures. These include advanced thermal management systems, corrosion-resistant materials, and adaptive control algorithms that can adjust battery usage patterns based on environmental conditions. However, these solutions often come at the cost of increased energy consumption, which can indirectly contribute to greater environmental impact through increased demand on power generation systems.

The development of more environmentally resilient BMS also drives innovation in battery chemistry and construction. For example, solid-state batteries are being explored for their potential to withstand extreme temperatures and reduce the risk of leakage in harsh environments. These advancements could lead to more environmentally friendly and resilient energy storage solutions for a wide range of applications.

Safety Standards for Stress-Resistant BMS

Safety standards for stress-resistant Battery Management Systems (BMS) are crucial in ensuring the reliable and secure operation of battery systems in challenging environments. These standards encompass a wide range of requirements and specifications designed to address the unique challenges posed by stress conditions such as extreme temperatures, vibrations, and electromagnetic interference.

One of the primary focuses of safety standards for stress-resistant BMS is thermal management. These standards typically mandate the implementation of robust thermal monitoring and control systems capable of maintaining optimal battery temperatures even in extreme heat or cold. This includes requirements for temperature sensors, cooling systems, and thermal runaway prevention mechanisms.

Mechanical integrity is another key aspect addressed by these safety standards. BMS components must be designed and constructed to withstand significant physical stresses, including vibrations, shocks, and impacts. Standards often specify minimum levels of shock resistance and vibration tolerance, as well as requirements for secure mounting and protection against environmental factors like dust and moisture.

Electromagnetic compatibility (EMC) is a critical consideration in stress-resistant BMS safety standards. These systems must be able to function reliably in environments with high levels of electromagnetic interference, such as industrial settings or near high-voltage power lines. Standards typically include specifications for EMC shielding, grounding, and protection against voltage spikes and surges.

Safety standards also address the critical issue of fault detection and management in stress environments. This includes requirements for robust diagnostic systems capable of identifying and responding to a wide range of potential faults, from cell imbalances to short circuits. Standards often specify minimum response times for fault detection and mitigation, as well as requirements for fail-safe modes and emergency shutdown procedures.

Data integrity and communication reliability are essential components of stress-resistant BMS safety standards. These systems must maintain accurate data collection and transmission even under challenging conditions. Standards typically include specifications for data encryption, error checking, and redundancy in communication systems to ensure reliable operation in high-stress environments.

Lastly, safety standards for stress-resistant BMS often include specific requirements for testing and certification. These may involve subjecting BMS components to rigorous stress tests, including thermal cycling, vibration testing, and EMC testing. Certification processes ensure that BMS systems meet or exceed the required safety and performance standards before deployment in stress environments.

One of the primary focuses of safety standards for stress-resistant BMS is thermal management. These standards typically mandate the implementation of robust thermal monitoring and control systems capable of maintaining optimal battery temperatures even in extreme heat or cold. This includes requirements for temperature sensors, cooling systems, and thermal runaway prevention mechanisms.

Mechanical integrity is another key aspect addressed by these safety standards. BMS components must be designed and constructed to withstand significant physical stresses, including vibrations, shocks, and impacts. Standards often specify minimum levels of shock resistance and vibration tolerance, as well as requirements for secure mounting and protection against environmental factors like dust and moisture.

Electromagnetic compatibility (EMC) is a critical consideration in stress-resistant BMS safety standards. These systems must be able to function reliably in environments with high levels of electromagnetic interference, such as industrial settings or near high-voltage power lines. Standards typically include specifications for EMC shielding, grounding, and protection against voltage spikes and surges.

Safety standards also address the critical issue of fault detection and management in stress environments. This includes requirements for robust diagnostic systems capable of identifying and responding to a wide range of potential faults, from cell imbalances to short circuits. Standards often specify minimum response times for fault detection and mitigation, as well as requirements for fail-safe modes and emergency shutdown procedures.

Data integrity and communication reliability are essential components of stress-resistant BMS safety standards. These systems must maintain accurate data collection and transmission even under challenging conditions. Standards typically include specifications for data encryption, error checking, and redundancy in communication systems to ensure reliable operation in high-stress environments.

Lastly, safety standards for stress-resistant BMS often include specific requirements for testing and certification. These may involve subjecting BMS components to rigorous stress tests, including thermal cycling, vibration testing, and EMC testing. Certification processes ensure that BMS systems meet or exceed the required safety and performance standards before deployment in stress environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!