Assessing the Environmental Impact of Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Environmental Context and Objectives

Battery Management Systems (BMS) have become increasingly crucial in the context of global efforts to transition towards sustainable energy solutions. As the world grapples with climate change and environmental degradation, the role of BMS in optimizing battery performance and longevity has gained significant attention. This technology is not only essential for the efficient operation of electric vehicles and renewable energy storage systems but also plays a vital role in minimizing the environmental impact of battery production and disposal.

The primary objective of assessing the environmental impact of BMS is to understand and quantify the ecological footprint of these systems throughout their lifecycle. This assessment aims to identify areas where BMS can contribute to reducing the overall environmental impact of battery-powered technologies. By optimizing battery performance, BMS can extend battery life, reduce waste, and improve energy efficiency, all of which have direct positive effects on the environment.

The evolution of BMS technology has been closely tied to advancements in battery chemistry and energy storage applications. From simple voltage monitoring systems to sophisticated predictive algorithms, BMS has undergone significant transformations. These developments have been driven by the need for more efficient and environmentally friendly energy storage solutions, particularly in the automotive and renewable energy sectors.

Current trends in BMS development focus on improving accuracy in state-of-charge and state-of-health estimations, enhancing thermal management capabilities, and implementing advanced predictive maintenance features. These innovations aim to maximize battery lifespan and performance while minimizing resource consumption and environmental impact. Additionally, there is a growing emphasis on developing BMS that can support the integration of second-life batteries into the energy grid, further extending the useful life of battery systems and reducing waste.

The environmental context of BMS extends beyond its immediate application in battery systems. It encompasses the entire lifecycle of batteries, from raw material extraction to manufacturing, use, and end-of-life management. BMS plays a critical role in each of these stages by optimizing battery performance, reducing the frequency of battery replacements, and facilitating more efficient recycling processes.

As we look towards the future, the objectives for BMS in an environmental context are multifaceted. These include further reducing the carbon footprint of battery-powered systems, enhancing the circular economy of batteries through improved lifecycle management, and supporting the broader transition to renewable energy sources. Achieving these objectives will require continued innovation in BMS technology, as well as closer collaboration between technology developers, policymakers, and environmental scientists.

The primary objective of assessing the environmental impact of BMS is to understand and quantify the ecological footprint of these systems throughout their lifecycle. This assessment aims to identify areas where BMS can contribute to reducing the overall environmental impact of battery-powered technologies. By optimizing battery performance, BMS can extend battery life, reduce waste, and improve energy efficiency, all of which have direct positive effects on the environment.

The evolution of BMS technology has been closely tied to advancements in battery chemistry and energy storage applications. From simple voltage monitoring systems to sophisticated predictive algorithms, BMS has undergone significant transformations. These developments have been driven by the need for more efficient and environmentally friendly energy storage solutions, particularly in the automotive and renewable energy sectors.

Current trends in BMS development focus on improving accuracy in state-of-charge and state-of-health estimations, enhancing thermal management capabilities, and implementing advanced predictive maintenance features. These innovations aim to maximize battery lifespan and performance while minimizing resource consumption and environmental impact. Additionally, there is a growing emphasis on developing BMS that can support the integration of second-life batteries into the energy grid, further extending the useful life of battery systems and reducing waste.

The environmental context of BMS extends beyond its immediate application in battery systems. It encompasses the entire lifecycle of batteries, from raw material extraction to manufacturing, use, and end-of-life management. BMS plays a critical role in each of these stages by optimizing battery performance, reducing the frequency of battery replacements, and facilitating more efficient recycling processes.

As we look towards the future, the objectives for BMS in an environmental context are multifaceted. These include further reducing the carbon footprint of battery-powered systems, enhancing the circular economy of batteries through improved lifecycle management, and supporting the broader transition to renewable energy sources. Achieving these objectives will require continued innovation in BMS technology, as well as closer collaboration between technology developers, policymakers, and environmental scientists.

Market Demand for Eco-Friendly BMS

The market demand for eco-friendly Battery Management Systems (BMS) has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations aimed at reducing carbon emissions. This trend is particularly evident in the automotive sector, where the shift towards electric vehicles (EVs) has accelerated the need for more sustainable battery technologies.

Consumer awareness of environmental issues has played a significant role in shaping market demand. As end-users become more conscious of their carbon footprint, they are increasingly seeking products with lower environmental impact. This has led to a surge in demand for EVs and, consequently, for advanced BMS that can optimize battery performance while minimizing ecological harm.

The industrial sector has also shown a growing interest in eco-friendly BMS solutions. Companies are recognizing the long-term benefits of implementing sustainable technologies, both in terms of cost savings and corporate social responsibility. This has resulted in increased adoption of green BMS in various applications, from renewable energy storage to industrial equipment.

Government policies and regulations have been instrumental in driving market demand for environmentally friendly BMS. Many countries have implemented strict emissions standards and are offering incentives for the adoption of clean technologies. These measures have created a favorable market environment for eco-friendly BMS, encouraging both manufacturers and consumers to invest in greener alternatives.

The energy storage sector represents another significant market for eco-friendly BMS. As renewable energy sources become more prevalent, the need for efficient and sustainable energy storage solutions has grown. This has led to increased demand for advanced BMS that can maximize the lifespan and performance of battery systems while minimizing environmental impact.

Market research indicates that the global eco-friendly BMS market is expected to experience substantial growth in the coming years. Factors such as technological advancements, decreasing costs of battery technologies, and increasing awareness of environmental issues are likely to fuel this growth.

However, challenges remain in meeting the market demand for eco-friendly BMS. These include the need for further improvements in battery technology, the development of more efficient recycling processes, and the establishment of comprehensive lifecycle assessment methodologies. Addressing these challenges will be crucial in fully realizing the potential of the eco-friendly BMS market.

In conclusion, the market demand for eco-friendly BMS is robust and growing, driven by a combination of environmental concerns, regulatory pressures, and technological advancements. As the world continues to prioritize sustainability, this demand is expected to further intensify, creating significant opportunities for innovation and growth in the BMS industry.

Consumer awareness of environmental issues has played a significant role in shaping market demand. As end-users become more conscious of their carbon footprint, they are increasingly seeking products with lower environmental impact. This has led to a surge in demand for EVs and, consequently, for advanced BMS that can optimize battery performance while minimizing ecological harm.

The industrial sector has also shown a growing interest in eco-friendly BMS solutions. Companies are recognizing the long-term benefits of implementing sustainable technologies, both in terms of cost savings and corporate social responsibility. This has resulted in increased adoption of green BMS in various applications, from renewable energy storage to industrial equipment.

Government policies and regulations have been instrumental in driving market demand for environmentally friendly BMS. Many countries have implemented strict emissions standards and are offering incentives for the adoption of clean technologies. These measures have created a favorable market environment for eco-friendly BMS, encouraging both manufacturers and consumers to invest in greener alternatives.

The energy storage sector represents another significant market for eco-friendly BMS. As renewable energy sources become more prevalent, the need for efficient and sustainable energy storage solutions has grown. This has led to increased demand for advanced BMS that can maximize the lifespan and performance of battery systems while minimizing environmental impact.

Market research indicates that the global eco-friendly BMS market is expected to experience substantial growth in the coming years. Factors such as technological advancements, decreasing costs of battery technologies, and increasing awareness of environmental issues are likely to fuel this growth.

However, challenges remain in meeting the market demand for eco-friendly BMS. These include the need for further improvements in battery technology, the development of more efficient recycling processes, and the establishment of comprehensive lifecycle assessment methodologies. Addressing these challenges will be crucial in fully realizing the potential of the eco-friendly BMS market.

In conclusion, the market demand for eco-friendly BMS is robust and growing, driven by a combination of environmental concerns, regulatory pressures, and technological advancements. As the world continues to prioritize sustainability, this demand is expected to further intensify, creating significant opportunities for innovation and growth in the BMS industry.

BMS Environmental Challenges

Battery Management Systems (BMS) play a crucial role in optimizing the performance and longevity of battery systems. However, their implementation and operation also present several environmental challenges that need to be addressed. One of the primary concerns is the energy consumption of BMS itself. While these systems are designed to improve overall battery efficiency, they require power to operate, which can contribute to increased energy usage and associated carbon emissions.

The manufacturing process of BMS components also raises environmental issues. The production of electronic components, sensors, and control units involves the use of rare earth elements and precious metals, which often have significant environmental impacts during extraction and processing. Additionally, the complex nature of BMS hardware often makes recycling and proper disposal challenging, potentially leading to electronic waste accumulation.

Another environmental challenge associated with BMS is the potential for chemical leakage or contamination. In the event of system malfunction or physical damage, there is a risk of hazardous materials from batteries or BMS components being released into the environment. This can lead to soil and water pollution, posing threats to ecosystems and human health.

The lifecycle impact of BMS is also a concern. As battery technology evolves rapidly, older BMS may become obsolete, necessitating frequent upgrades or replacements. This turnover can result in increased electronic waste and resource consumption, contradicting sustainability goals.

Furthermore, the software algorithms used in BMS for performance optimization may inadvertently lead to suboptimal charging or discharging patterns from an environmental perspective. For instance, prioritizing battery longevity over energy efficiency could result in higher overall energy consumption and emissions over the battery's lifetime.

The scalability of BMS environmental impacts is another challenge, particularly as battery systems are increasingly adopted in various applications, from electric vehicles to grid-scale energy storage. The cumulative effect of BMS-related environmental issues could become significant as deployment scales up.

Lastly, the lack of standardization in BMS design and implementation across different manufacturers and applications complicates efforts to assess and mitigate environmental impacts uniformly. This diversity makes it challenging to develop comprehensive recycling programs or implement industry-wide environmental best practices for BMS.

Addressing these environmental challenges requires a holistic approach, considering the entire lifecycle of BMS from production to disposal. Innovations in eco-friendly materials, energy-efficient designs, and improved recycling techniques are crucial for minimizing the environmental footprint of Battery Management Systems.

The manufacturing process of BMS components also raises environmental issues. The production of electronic components, sensors, and control units involves the use of rare earth elements and precious metals, which often have significant environmental impacts during extraction and processing. Additionally, the complex nature of BMS hardware often makes recycling and proper disposal challenging, potentially leading to electronic waste accumulation.

Another environmental challenge associated with BMS is the potential for chemical leakage or contamination. In the event of system malfunction or physical damage, there is a risk of hazardous materials from batteries or BMS components being released into the environment. This can lead to soil and water pollution, posing threats to ecosystems and human health.

The lifecycle impact of BMS is also a concern. As battery technology evolves rapidly, older BMS may become obsolete, necessitating frequent upgrades or replacements. This turnover can result in increased electronic waste and resource consumption, contradicting sustainability goals.

Furthermore, the software algorithms used in BMS for performance optimization may inadvertently lead to suboptimal charging or discharging patterns from an environmental perspective. For instance, prioritizing battery longevity over energy efficiency could result in higher overall energy consumption and emissions over the battery's lifetime.

The scalability of BMS environmental impacts is another challenge, particularly as battery systems are increasingly adopted in various applications, from electric vehicles to grid-scale energy storage. The cumulative effect of BMS-related environmental issues could become significant as deployment scales up.

Lastly, the lack of standardization in BMS design and implementation across different manufacturers and applications complicates efforts to assess and mitigate environmental impacts uniformly. This diversity makes it challenging to develop comprehensive recycling programs or implement industry-wide environmental best practices for BMS.

Addressing these environmental challenges requires a holistic approach, considering the entire lifecycle of BMS from production to disposal. Innovations in eco-friendly materials, energy-efficient designs, and improved recycling techniques are crucial for minimizing the environmental footprint of Battery Management Systems.

Current Eco-BMS Solutions

01 Energy efficiency optimization

Battery Management Systems (BMS) can be designed to optimize energy efficiency, reducing overall power consumption and minimizing environmental impact. This includes implementing advanced algorithms for charge/discharge control, thermal management, and power distribution to extend battery life and reduce waste.- Efficient energy management and resource optimization: Battery Management Systems (BMS) can significantly reduce environmental impact by optimizing energy usage, extending battery life, and improving overall system efficiency. This includes intelligent charging and discharging strategies, power distribution management, and adaptive control algorithms that minimize energy waste and maximize resource utilization.

- Recycling and end-of-life management: BMS can play a crucial role in facilitating the recycling and proper disposal of batteries at the end of their lifecycle. By monitoring battery health and performance, these systems can help identify when batteries are ready for recycling, ensuring timely and environmentally responsible disposal. This approach reduces waste and promotes the circular economy in battery production and use.

- Thermal management and safety enhancements: Advanced BMS incorporate thermal management features that not only improve battery performance but also enhance safety and reduce the risk of environmental hazards. By preventing overheating and managing temperature distribution, these systems minimize the potential for thermal runaway and associated environmental risks, such as fires or chemical leaks.

- Integration with renewable energy systems: BMS can be designed to integrate seamlessly with renewable energy sources, such as solar and wind power. This integration allows for more efficient storage and utilization of clean energy, reducing reliance on fossil fuels and decreasing overall carbon emissions. The systems can optimize charging cycles based on the availability of renewable energy, further enhancing environmental benefits.

- Smart grid and load balancing capabilities: BMS with smart grid integration capabilities can contribute to more efficient energy distribution and consumption at a larger scale. These systems enable load balancing, demand response, and grid stabilization, which can lead to reduced energy waste, improved grid reliability, and lower overall environmental impact of energy systems.

02 Recycling and end-of-life management

BMS can incorporate features to facilitate easier recycling and proper disposal of batteries at the end of their lifecycle. This may include monitoring battery health, predicting end-of-life, and providing data to support efficient recycling processes, thus reducing environmental pollution and resource depletion.Expand Specific Solutions03 Smart grid integration

BMS can be designed to integrate with smart grids, enabling better load balancing, demand response, and renewable energy integration. This can lead to more efficient use of energy resources and reduced reliance on fossil fuels, thereby decreasing the overall carbon footprint of the power system.Expand Specific Solutions04 Sustainable materials and manufacturing

The environmental impact of BMS can be reduced by using sustainable materials in their construction and implementing eco-friendly manufacturing processes. This includes the use of recyclable components, reduction of hazardous materials, and optimization of production methods to minimize energy consumption and waste.Expand Specific Solutions05 Life cycle assessment and carbon footprint reduction

BMS can incorporate features for continuous monitoring and assessment of the battery's environmental impact throughout its lifecycle. This includes tracking carbon emissions, energy consumption, and resource utilization, enabling users and manufacturers to make informed decisions to reduce the overall environmental footprint of battery systems.Expand Specific Solutions

Key BMS Industry Players

The environmental impact assessment of Battery Management Systems (BMS) is at a critical juncture, with the industry experiencing rapid growth due to increasing adoption of electric vehicles and renewable energy storage solutions. The market is expanding significantly, driven by major players like LG Energy Solution, Samsung SDI, and BYD. These companies are investing heavily in research and development to improve BMS efficiency and sustainability. The technology is maturing quickly, with advancements in areas such as thermal management, state-of-charge estimation, and cell balancing. However, challenges remain in optimizing battery life cycles and reducing the environmental footprint of production processes. As the industry evolves, collaboration between automotive manufacturers like Toyota and Honda and specialized BMS providers is becoming increasingly important to address these environmental concerns.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced Battery Management System (BMS) that incorporates AI-driven predictive analytics to optimize battery performance and longevity. Their system continuously monitors cell voltages, temperatures, and current flow, using machine learning algorithms to predict potential issues before they occur[1]. This proactive approach allows for real-time adjustments to charging and discharging patterns, significantly reducing battery degradation and extending overall lifespan. The company has also implemented a closed-loop recycling system for their batteries, where end-of-life batteries are collected and processed to recover valuable materials, reducing the environmental impact of battery production[3]. Additionally, LG Energy Solution has introduced a cloud-based BMS that enables remote monitoring and over-the-air updates, further enhancing the system's efficiency and adaptability to changing environmental conditions[5].

Strengths: Advanced AI integration for predictive maintenance, closed-loop recycling system, and remote monitoring capabilities. Weaknesses: Potential data privacy concerns with cloud-based systems and reliance on complex algorithms that may require frequent updates.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an eco-friendly Battery Management System that focuses on minimizing the carbon footprint throughout the battery lifecycle. Their BMS utilizes advanced thermal management techniques, including phase-change materials and intelligent cooling systems, to maintain optimal battery temperature without excessive energy consumption[2]. The company has also implemented a "green cell" technology that reduces the use of harmful materials in battery production, such as replacing conventional organic electrolytes with more environmentally friendly alternatives[4]. Samsung SDI's BMS incorporates a sophisticated State of Health (SOH) estimation algorithm that accurately predicts battery life, enabling more efficient use and timely recycling. Furthermore, the company has invested in developing solid-state battery technology, which promises higher energy density and reduced environmental impact compared to traditional lithium-ion batteries[6].

Strengths: Advanced thermal management, reduced use of harmful materials, and investment in next-generation battery technologies. Weaknesses: Higher initial costs associated with advanced materials and potential challenges in scaling up new technologies.

Green BMS Technologies

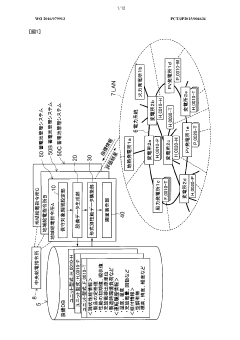

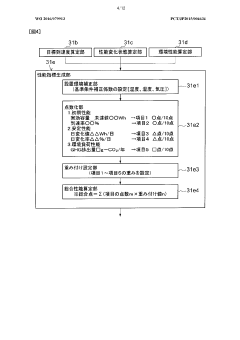

Storage cell management system and storage cell management method

PatentWO2016079913A1

Innovation

- A storage battery management system comprising an information acquisition unit, performance evaluation unit, and evaluation result output unit that acquires and evaluates performance data, including environmental factors, to provide maintenance insights and optimize battery operation.

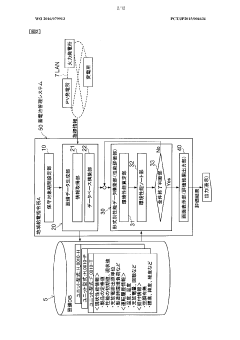

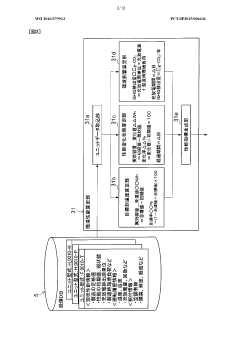

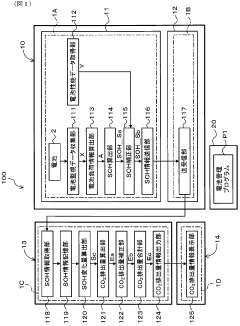

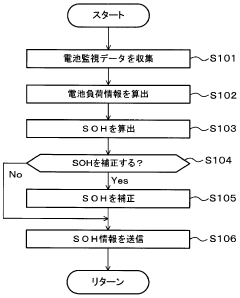

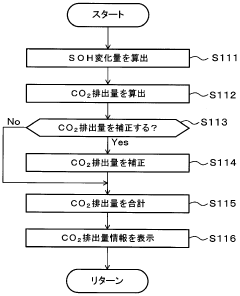

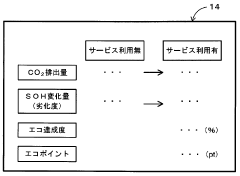

Battery management program and battery management system

PatentWO2024142521A1

Innovation

- A battery management system that acquires State of Health (SOH) information from battery monitoring data and calculates emissions based on this data, using a combination of sensors and processors to provide accurate environmental load factor emissions information.

BMS Lifecycle Assessment

Battery Management Systems (BMS) play a crucial role in the performance and safety of battery-powered devices and electric vehicles. However, their environmental impact throughout their lifecycle is often overlooked. A comprehensive lifecycle assessment of BMS is essential to understand and mitigate their environmental footprint.

The BMS lifecycle begins with raw material extraction and processing. Key components such as integrated circuits, sensors, and printed circuit boards require various metals and minerals, including copper, gold, and rare earth elements. The mining and refining of these materials can lead to significant environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions.

Manufacturing processes for BMS components involve energy-intensive operations, such as semiconductor fabrication and circuit board assembly. These processes often require cleanroom environments and specialized equipment, contributing to high energy consumption and potential chemical waste generation. The use of solvents, acids, and other chemicals in manufacturing can also pose environmental risks if not properly managed.

During the use phase, BMS contribute to the overall energy efficiency of battery systems by optimizing charging and discharging processes. This can indirectly reduce the environmental impact by extending battery life and improving overall system efficiency. However, the continuous operation of BMS also consumes energy, which should be factored into the lifecycle assessment.

End-of-life considerations for BMS are particularly important. As electronic components, they contain valuable materials that can be recycled, but also potentially hazardous substances that require proper disposal. The complexity of BMS circuits can make disassembly and material recovery challenging, highlighting the need for design-for-recycling approaches.

Transportation and distribution of BMS throughout their lifecycle also contribute to their environmental impact. This includes the movement of raw materials, components, and finished products, often across global supply chains. The associated fuel consumption and emissions must be considered in a comprehensive assessment.

To accurately assess the environmental impact of BMS, various methodologies can be employed. Life Cycle Assessment (LCA) is a standardized approach that quantifies environmental impacts across all stages of a product's life. This can be complemented by other tools such as carbon footprinting and water footprint analysis to provide a more detailed picture of specific environmental aspects.

Improving the environmental performance of BMS requires a holistic approach. This may include designing for longevity and recyclability, optimizing manufacturing processes, sourcing materials responsibly, and improving energy efficiency during operation. Additionally, developing effective recycling and disposal strategies for end-of-life BMS is crucial to closing the loop and minimizing overall environmental impact.

The BMS lifecycle begins with raw material extraction and processing. Key components such as integrated circuits, sensors, and printed circuit boards require various metals and minerals, including copper, gold, and rare earth elements. The mining and refining of these materials can lead to significant environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions.

Manufacturing processes for BMS components involve energy-intensive operations, such as semiconductor fabrication and circuit board assembly. These processes often require cleanroom environments and specialized equipment, contributing to high energy consumption and potential chemical waste generation. The use of solvents, acids, and other chemicals in manufacturing can also pose environmental risks if not properly managed.

During the use phase, BMS contribute to the overall energy efficiency of battery systems by optimizing charging and discharging processes. This can indirectly reduce the environmental impact by extending battery life and improving overall system efficiency. However, the continuous operation of BMS also consumes energy, which should be factored into the lifecycle assessment.

End-of-life considerations for BMS are particularly important. As electronic components, they contain valuable materials that can be recycled, but also potentially hazardous substances that require proper disposal. The complexity of BMS circuits can make disassembly and material recovery challenging, highlighting the need for design-for-recycling approaches.

Transportation and distribution of BMS throughout their lifecycle also contribute to their environmental impact. This includes the movement of raw materials, components, and finished products, often across global supply chains. The associated fuel consumption and emissions must be considered in a comprehensive assessment.

To accurately assess the environmental impact of BMS, various methodologies can be employed. Life Cycle Assessment (LCA) is a standardized approach that quantifies environmental impacts across all stages of a product's life. This can be complemented by other tools such as carbon footprinting and water footprint analysis to provide a more detailed picture of specific environmental aspects.

Improving the environmental performance of BMS requires a holistic approach. This may include designing for longevity and recyclability, optimizing manufacturing processes, sourcing materials responsibly, and improving energy efficiency during operation. Additionally, developing effective recycling and disposal strategies for end-of-life BMS is crucial to closing the loop and minimizing overall environmental impact.

BMS Environmental Regulations

Battery Management Systems (BMS) are increasingly subject to environmental regulations as the global focus on sustainability intensifies. These regulations aim to minimize the ecological impact of BMS throughout their lifecycle, from production to disposal. The European Union's Restriction of Hazardous Substances (RoHS) Directive is a cornerstone of BMS environmental regulations, limiting the use of certain hazardous materials in electrical and electronic equipment, including lead, mercury, and cadmium.

The End-of-Life Vehicles (ELV) Directive further regulates the automotive sector, mandating the recycling and recovery of materials from vehicles, including their battery systems. This directive has significant implications for BMS design and end-of-life management in electric and hybrid vehicles.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Resource Conservation and Recovery Act (RCRA), which governs the disposal of hazardous waste, including certain components of BMS. The EPA also oversees the implementation of the Mercury-Containing and Rechargeable Battery Management Act, which promotes the collection and recycling of batteries.

China's Ministry of Industry and Information Technology (MIIT) has implemented regulations on the recycling of new energy vehicle batteries, including requirements for BMS to facilitate easier disassembly and recycling. These regulations are part of China's broader push towards a circular economy in the electric vehicle sector.

The International Electrotechnical Commission (IEC) has developed standards such as IEC 62133 for safety requirements for portable batteries and IEC 62619 for safety requirements for large format lithium-ion cells and batteries. These standards, while not regulations per se, often inform regulatory frameworks and industry best practices for BMS environmental considerations.

Emerging regulations are focusing on the carbon footprint of BMS production and operation. The EU's proposed Battery Regulation aims to establish sustainability requirements for batteries, including carbon footprint declarations, minimum recycled content, and due diligence obligations for raw material sourcing.

As environmental concerns grow, regulations are likely to become more stringent, potentially requiring BMS manufacturers to implement design for environment (DfE) principles, improve energy efficiency, and enhance the recyclability of their systems. This regulatory landscape is driving innovation in BMS technology, pushing for more sustainable materials and processes in their production and operation.

The End-of-Life Vehicles (ELV) Directive further regulates the automotive sector, mandating the recycling and recovery of materials from vehicles, including their battery systems. This directive has significant implications for BMS design and end-of-life management in electric and hybrid vehicles.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Resource Conservation and Recovery Act (RCRA), which governs the disposal of hazardous waste, including certain components of BMS. The EPA also oversees the implementation of the Mercury-Containing and Rechargeable Battery Management Act, which promotes the collection and recycling of batteries.

China's Ministry of Industry and Information Technology (MIIT) has implemented regulations on the recycling of new energy vehicle batteries, including requirements for BMS to facilitate easier disassembly and recycling. These regulations are part of China's broader push towards a circular economy in the electric vehicle sector.

The International Electrotechnical Commission (IEC) has developed standards such as IEC 62133 for safety requirements for portable batteries and IEC 62619 for safety requirements for large format lithium-ion cells and batteries. These standards, while not regulations per se, often inform regulatory frameworks and industry best practices for BMS environmental considerations.

Emerging regulations are focusing on the carbon footprint of BMS production and operation. The EU's proposed Battery Regulation aims to establish sustainability requirements for batteries, including carbon footprint declarations, minimum recycled content, and due diligence obligations for raw material sourcing.

As environmental concerns grow, regulations are likely to become more stringent, potentially requiring BMS manufacturers to implement design for environment (DfE) principles, improve energy efficiency, and enhance the recyclability of their systems. This regulatory landscape is driving innovation in BMS technology, pushing for more sustainable materials and processes in their production and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!