How Digital Twins Enhance Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin BMS Evolution

The evolution of Digital Twin technology in Battery Management Systems (BMS) represents a significant advancement in the field of energy storage and management. This progression can be traced through several key stages, each marked by technological breakthroughs and increased integration of digital and physical systems.

In the early stages, BMS primarily focused on basic monitoring and control functions. These systems were designed to measure voltage, current, and temperature, providing rudimentary protection against overcharging and over-discharging. The data collected was limited and often analyzed retrospectively, offering little real-time insight into battery performance.

As computing power and sensor technology advanced, BMS began to incorporate more sophisticated algorithms for state estimation. This phase saw the introduction of more accurate methods for determining the State of Charge (SoC) and State of Health (SoH) of batteries. These improvements allowed for better optimization of battery usage and more precise predictions of battery life.

The next significant leap came with the integration of machine learning and artificial intelligence into BMS. This development enabled more complex analysis of battery behavior, including the ability to predict potential failures and optimize charging strategies based on historical data and usage patterns. However, these systems were still largely reactive, responding to changes in battery conditions rather than proactively managing them.

The concept of Digital Twins in BMS emerged as a natural progression from these earlier advancements. Digital Twins create a virtual replica of the physical battery system, allowing for real-time simulation and analysis. This technology enables predictive maintenance, performance optimization, and enhanced decision-making capabilities.

In recent years, the evolution of Digital Twin BMS has been characterized by increased connectivity and data integration. Modern systems can now incorporate data from various sources, including environmental conditions, grid status, and even user behavior patterns. This holistic approach allows for more comprehensive battery management strategies that consider a wide range of factors affecting battery performance and longevity.

The latest developments in Digital Twin BMS focus on creating more accurate and dynamic models. These advanced systems can adapt in real-time to changing conditions, providing unprecedented levels of precision in battery management. They also offer the potential for virtual testing of new battery designs and management strategies, significantly reducing development time and costs.

Looking forward, the evolution of Digital Twin BMS is likely to continue towards even greater integration with other smart systems, such as smart grids and Internet of Things (IoT) devices. This integration will enable more efficient energy management on a larger scale, potentially revolutionizing how we approach energy storage and distribution in various applications, from electric vehicles to renewable energy systems.

In the early stages, BMS primarily focused on basic monitoring and control functions. These systems were designed to measure voltage, current, and temperature, providing rudimentary protection against overcharging and over-discharging. The data collected was limited and often analyzed retrospectively, offering little real-time insight into battery performance.

As computing power and sensor technology advanced, BMS began to incorporate more sophisticated algorithms for state estimation. This phase saw the introduction of more accurate methods for determining the State of Charge (SoC) and State of Health (SoH) of batteries. These improvements allowed for better optimization of battery usage and more precise predictions of battery life.

The next significant leap came with the integration of machine learning and artificial intelligence into BMS. This development enabled more complex analysis of battery behavior, including the ability to predict potential failures and optimize charging strategies based on historical data and usage patterns. However, these systems were still largely reactive, responding to changes in battery conditions rather than proactively managing them.

The concept of Digital Twins in BMS emerged as a natural progression from these earlier advancements. Digital Twins create a virtual replica of the physical battery system, allowing for real-time simulation and analysis. This technology enables predictive maintenance, performance optimization, and enhanced decision-making capabilities.

In recent years, the evolution of Digital Twin BMS has been characterized by increased connectivity and data integration. Modern systems can now incorporate data from various sources, including environmental conditions, grid status, and even user behavior patterns. This holistic approach allows for more comprehensive battery management strategies that consider a wide range of factors affecting battery performance and longevity.

The latest developments in Digital Twin BMS focus on creating more accurate and dynamic models. These advanced systems can adapt in real-time to changing conditions, providing unprecedented levels of precision in battery management. They also offer the potential for virtual testing of new battery designs and management strategies, significantly reducing development time and costs.

Looking forward, the evolution of Digital Twin BMS is likely to continue towards even greater integration with other smart systems, such as smart grids and Internet of Things (IoT) devices. This integration will enable more efficient energy management on a larger scale, potentially revolutionizing how we approach energy storage and distribution in various applications, from electric vehicles to renewable energy systems.

Market Demand Analysis

The market demand for digital twin technology in battery management systems (BMS) has been experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage solutions. As the global push for electrification and sustainable energy intensifies, the need for more efficient, reliable, and cost-effective battery systems has become paramount.

In the automotive sector, the rapid expansion of the EV market has created a substantial demand for advanced BMS solutions. Digital twins offer a powerful tool for optimizing battery performance, extending lifespan, and enhancing safety. Major automakers and EV manufacturers are increasingly integrating digital twin technology into their BMS to gain competitive advantages and meet stringent regulatory requirements.

The renewable energy sector is another key driver of market demand for digital twin-enhanced BMS. As grid-scale energy storage systems become more prevalent, the need for sophisticated battery management solutions has grown exponentially. Digital twins enable more accurate predictions of battery degradation, optimize charging and discharging cycles, and improve overall system efficiency.

Consumer electronics manufacturers are also recognizing the value of digital twins in BMS. With the growing demand for longer-lasting and faster-charging devices, digital twin technology offers a means to optimize battery performance and lifespan in smartphones, laptops, and other portable devices.

The industrial sector presents another significant market opportunity for digital twin-enhanced BMS. As factories and manufacturing facilities increasingly adopt automation and electrification, the demand for reliable and efficient energy storage solutions has surged. Digital twins can help optimize the performance of industrial battery systems, reduce downtime, and improve overall operational efficiency.

Market analysts project substantial growth in the digital twin BMS market over the coming years. The technology's ability to reduce battery-related risks, improve performance, and extend battery life aligns well with the broader trends in electrification and sustainability. Additionally, the increasing focus on predictive maintenance and real-time monitoring across various industries further fuels the demand for digital twin solutions in BMS.

However, challenges such as high initial implementation costs and the need for specialized expertise may temporarily hinder market growth. Despite these obstacles, the long-term benefits of digital twin technology in BMS, including reduced operational costs and improved battery performance, are expected to drive continued market expansion across multiple sectors.

In the automotive sector, the rapid expansion of the EV market has created a substantial demand for advanced BMS solutions. Digital twins offer a powerful tool for optimizing battery performance, extending lifespan, and enhancing safety. Major automakers and EV manufacturers are increasingly integrating digital twin technology into their BMS to gain competitive advantages and meet stringent regulatory requirements.

The renewable energy sector is another key driver of market demand for digital twin-enhanced BMS. As grid-scale energy storage systems become more prevalent, the need for sophisticated battery management solutions has grown exponentially. Digital twins enable more accurate predictions of battery degradation, optimize charging and discharging cycles, and improve overall system efficiency.

Consumer electronics manufacturers are also recognizing the value of digital twins in BMS. With the growing demand for longer-lasting and faster-charging devices, digital twin technology offers a means to optimize battery performance and lifespan in smartphones, laptops, and other portable devices.

The industrial sector presents another significant market opportunity for digital twin-enhanced BMS. As factories and manufacturing facilities increasingly adopt automation and electrification, the demand for reliable and efficient energy storage solutions has surged. Digital twins can help optimize the performance of industrial battery systems, reduce downtime, and improve overall operational efficiency.

Market analysts project substantial growth in the digital twin BMS market over the coming years. The technology's ability to reduce battery-related risks, improve performance, and extend battery life aligns well with the broader trends in electrification and sustainability. Additionally, the increasing focus on predictive maintenance and real-time monitoring across various industries further fuels the demand for digital twin solutions in BMS.

However, challenges such as high initial implementation costs and the need for specialized expertise may temporarily hinder market growth. Despite these obstacles, the long-term benefits of digital twin technology in BMS, including reduced operational costs and improved battery performance, are expected to drive continued market expansion across multiple sectors.

Technical Challenges

The implementation of digital twins in Battery Management Systems (BMS) faces several technical challenges that need to be addressed for successful integration and optimal performance. One of the primary obstacles is the complexity of accurately modeling battery behavior. Batteries are dynamic systems influenced by numerous factors, including temperature, state of charge, and usage patterns. Creating a digital twin that can precisely replicate these intricate interactions requires sophisticated algorithms and extensive data processing capabilities.

Data acquisition and management present another significant challenge. To create an effective digital twin, a vast amount of real-time data must be collected from various sensors embedded in the battery system. This data needs to be transmitted, stored, and processed efficiently, which demands robust communication infrastructure and high-performance computing systems. Ensuring data integrity and security throughout this process is crucial, particularly in applications where battery performance is critical for safety and reliability.

The integration of digital twins with existing BMS architectures poses technical difficulties. Many current BMS designs may not be equipped to handle the additional computational requirements and data flow associated with digital twin implementation. Upgrading or redesigning these systems to accommodate digital twin functionality while maintaining compatibility with existing hardware and software components can be a complex and resource-intensive task.

Scalability is another challenge that needs to be addressed. As the number of batteries in a system increases, the computational demands of managing multiple digital twins grow exponentially. Developing efficient algorithms and distributed computing solutions that can handle large-scale battery systems without compromising real-time performance is a significant technical hurdle.

The accuracy of predictive models used in digital twins is critical for effective battery management. However, developing models that can accurately forecast battery degradation, remaining useful life, and performance under various operating conditions is a complex task. These models must account for a wide range of variables and be continuously refined based on real-world data, which requires sophisticated machine learning techniques and ongoing model validation processes.

Lastly, the challenge of real-time synchronization between the physical battery and its digital counterpart cannot be overlooked. Maintaining an up-to-date digital representation that reflects the current state of the battery with minimal latency is crucial for timely decision-making and control actions. This requires high-speed data processing and efficient algorithms that can quickly update the digital twin based on incoming sensor data while accounting for potential communication delays or data inconsistencies.

Data acquisition and management present another significant challenge. To create an effective digital twin, a vast amount of real-time data must be collected from various sensors embedded in the battery system. This data needs to be transmitted, stored, and processed efficiently, which demands robust communication infrastructure and high-performance computing systems. Ensuring data integrity and security throughout this process is crucial, particularly in applications where battery performance is critical for safety and reliability.

The integration of digital twins with existing BMS architectures poses technical difficulties. Many current BMS designs may not be equipped to handle the additional computational requirements and data flow associated with digital twin implementation. Upgrading or redesigning these systems to accommodate digital twin functionality while maintaining compatibility with existing hardware and software components can be a complex and resource-intensive task.

Scalability is another challenge that needs to be addressed. As the number of batteries in a system increases, the computational demands of managing multiple digital twins grow exponentially. Developing efficient algorithms and distributed computing solutions that can handle large-scale battery systems without compromising real-time performance is a significant technical hurdle.

The accuracy of predictive models used in digital twins is critical for effective battery management. However, developing models that can accurately forecast battery degradation, remaining useful life, and performance under various operating conditions is a complex task. These models must account for a wide range of variables and be continuously refined based on real-world data, which requires sophisticated machine learning techniques and ongoing model validation processes.

Lastly, the challenge of real-time synchronization between the physical battery and its digital counterpart cannot be overlooked. Maintaining an up-to-date digital representation that reflects the current state of the battery with minimal latency is crucial for timely decision-making and control actions. This requires high-speed data processing and efficient algorithms that can quickly update the digital twin based on incoming sensor data while accounting for potential communication delays or data inconsistencies.

Current DT-BMS Solutions

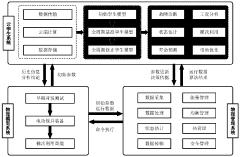

01 Digital twin modeling for battery management systems

Digital twin technology is applied to battery management systems to create virtual representations of physical batteries. These models simulate battery behavior, performance, and degradation in real-time, enabling predictive maintenance and optimization of battery life and efficiency.- Digital twin modeling for battery management systems: Digital twin technology is applied to battery management systems to create virtual representations of physical batteries. This allows for real-time monitoring, predictive maintenance, and optimization of battery performance. The digital twin model simulates various battery parameters and conditions, enabling better decision-making and improved battery life management.

- Machine learning integration in battery digital twins: Machine learning algorithms are incorporated into digital twin models for battery management systems. These algorithms analyze historical and real-time data to predict battery behavior, detect anomalies, and optimize charging strategies. The integration of machine learning enhances the accuracy of battery state estimation and improves overall system efficiency.

- Cloud-based battery management using digital twins: Cloud computing platforms are utilized to host and process digital twin models for battery management systems. This approach enables scalable data storage, advanced analytics, and remote monitoring of multiple battery systems. Cloud-based digital twins facilitate collaborative decision-making and provide insights across entire fleets of batteries.

- Real-time battery health monitoring and diagnostics: Digital twin technology enables real-time monitoring of battery health and performance. The system continuously analyzes battery parameters such as voltage, current, and temperature to assess the state of health, detect potential issues, and provide early warnings. This proactive approach helps prevent failures and extends battery lifespan.

- Optimization of battery charging and discharging strategies: Digital twin models are used to optimize battery charging and discharging strategies. By simulating various scenarios and analyzing historical data, the system determines the most efficient charging profiles and usage patterns. This optimization leads to improved battery performance, longer cycle life, and reduced energy consumption.

02 Real-time monitoring and data analysis in battery management

Advanced sensors and data analytics are integrated into battery management systems to collect and analyze real-time data on battery performance, health, and operating conditions. This enables more accurate state estimation and predictive capabilities for battery systems.Expand Specific Solutions03 AI and machine learning integration in battery digital twins

Artificial intelligence and machine learning algorithms are incorporated into digital twin battery management systems to improve prediction accuracy, optimize charging strategies, and enhance overall system performance. These technologies enable adaptive learning and continuous improvement of battery models.Expand Specific Solutions04 Cloud-based battery management and digital twin platforms

Cloud computing platforms are utilized to host digital twin models of battery systems, enabling scalable and distributed management of large-scale battery installations. These platforms facilitate remote monitoring, data storage, and advanced analytics for improved battery management across multiple locations.Expand Specific Solutions05 Integration of digital twins with energy management systems

Digital twin battery management systems are integrated with broader energy management systems to optimize overall energy utilization and grid interaction. This integration enables better coordination of battery storage with renewable energy sources and grid demands, improving energy efficiency and reliability.Expand Specific Solutions

Key Industry Players

The digital twin technology for enhancing Battery Management Systems (BMS) is in a growth phase, with increasing market adoption across various industries. The global digital twin market size is projected to reach $48.2 billion by 2026, with a CAGR of 58%. In terms of technological maturity, companies like LG Electronics, SK Innovation, and Siemens AG are leading the way with advanced implementations. Academic institutions such as Beihang University and Wuhan University of Technology are contributing to research and development. While the technology is evolving rapidly, it is not yet fully mature, with ongoing advancements in real-time data integration, predictive analytics, and AI-driven optimization for BMS applications.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has implemented a comprehensive Digital Twin solution for Battery Management Systems in large-scale energy storage applications. Their approach integrates real-time grid data with advanced battery models to create a virtual representation of entire energy storage systems. The digital twin technology enables State Grid to optimize battery dispatch, predict grid stability issues, and manage the integration of renewable energy sources more effectively[9]. The system incorporates AI-driven predictive maintenance algorithms to minimize downtime and extend the lifespan of battery assets. State Grid has successfully deployed this technology in several smart grid projects across China, demonstrating its effectiveness in managing complex, large-scale energy storage systems[10].

Strengths: Large-scale implementation in grid-level applications, integration with renewable energy systems, and proven effectiveness in complex energy storage management. Weaknesses: May be less applicable to smaller-scale or consumer-level battery systems, potentially requires significant infrastructure investment.

SK Innovation Co., Ltd.

Technical Solution: SK Innovation has developed an advanced Digital Twin system for their Battery Management Systems, focusing on electric vehicle applications. Their approach combines real-time battery data with sophisticated electrochemical models to create a highly accurate virtual representation of battery behavior. The system utilizes AI algorithms to predict battery degradation, optimize charging cycles, and extend overall battery life[3]. SK Innovation's digital twin technology also incorporates thermal management simulations, allowing for precise control of battery temperature during various operating conditions. The company has reported significant improvements in battery performance and longevity through the implementation of this technology in their latest EV battery designs[4].

Strengths: Highly accurate electrochemical modeling, focus on EV applications, and proven improvements in battery performance. Weaknesses: Potentially limited to EV-specific applications, may require extensive data collection for optimal performance.

Core DT-BMS Technologies

Full-cycle power battery management system applying digital twinning technology

PatentActiveCN111581850A

Innovation

- A full-cycle power battery management system composed of a physical model system, a physical management system and a cloud twin system is used to build a battery twin model through data collection, processing and uploading to the cloud to achieve data closed loop and data sharing, combining short time scale and long time Scale algorithm, optimize information transmission and computing platform utilization, and conduct refined energy management.

Self-adapting digital twins

PatentWO2020231428A1

Innovation

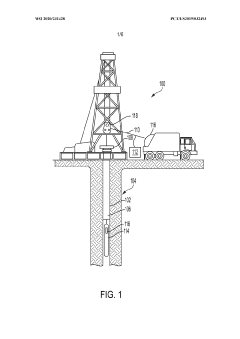

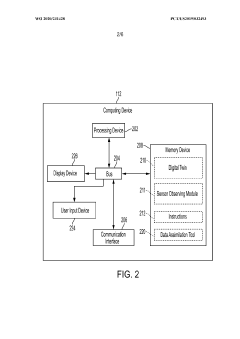

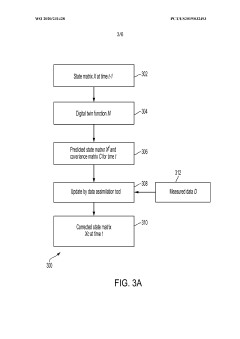

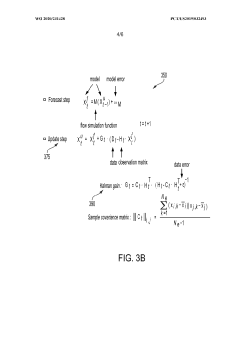

- A self-adapting digital twin system that uses sensor data and numerical regression techniques to iteratively update model parameters, employing an Ensemble Kalman Filter for data assimilation, allowing for real-time optimization and prediction of hydrocarbon recovery processes, including detection of impending failures.

Cybersecurity Aspects

The integration of digital twins in Battery Management Systems (BMS) introduces new cybersecurity challenges that must be addressed to ensure the integrity and reliability of these systems. As digital twins create virtual representations of physical battery systems, they become potential targets for cyber attacks, which could compromise the safety and performance of electric vehicles and energy storage systems.

One of the primary cybersecurity concerns is the protection of data transmission between the physical battery system and its digital twin. This communication channel must be secured to prevent unauthorized access, data manipulation, or interception. Encryption protocols and secure communication channels are essential to safeguard the sensitive information exchanged between the physical and virtual environments.

Another critical aspect is the protection of the digital twin itself from cyber threats. As the digital twin contains valuable data and models representing the battery system, it becomes an attractive target for malicious actors. Robust access controls, authentication mechanisms, and regular security audits are necessary to prevent unauthorized access to the digital twin and its associated data.

The interconnected nature of digital twins also raises concerns about potential vulnerabilities in the broader ecosystem. As these systems often integrate with other IoT devices and cloud platforms, any weakness in the connected infrastructure could potentially be exploited to gain access to the digital twin or the physical battery system. Implementing a comprehensive security strategy that encompasses the entire ecosystem is crucial to mitigate these risks.

Furthermore, the use of artificial intelligence and machine learning algorithms in digital twins for predictive maintenance and optimization introduces additional security considerations. These algorithms must be protected against adversarial attacks that could manipulate their outputs, leading to incorrect decisions or compromised battery performance.

Ensuring the integrity of data used to create and update digital twins is another critical cybersecurity aspect. Tampered or falsified data could lead to inaccurate representations of the physical battery system, potentially resulting in incorrect decisions or actions. Implementing data validation mechanisms and maintaining a secure chain of custody for all data inputs is essential to maintain the reliability of the digital twin.

As digital twins become more prevalent in Battery Management Systems, cybersecurity measures must evolve to address emerging threats. This includes developing industry standards and best practices specifically tailored to the unique challenges posed by digital twins in the context of battery systems. Regular security assessments, penetration testing, and continuous monitoring are necessary to identify and mitigate potential vulnerabilities proactively.

One of the primary cybersecurity concerns is the protection of data transmission between the physical battery system and its digital twin. This communication channel must be secured to prevent unauthorized access, data manipulation, or interception. Encryption protocols and secure communication channels are essential to safeguard the sensitive information exchanged between the physical and virtual environments.

Another critical aspect is the protection of the digital twin itself from cyber threats. As the digital twin contains valuable data and models representing the battery system, it becomes an attractive target for malicious actors. Robust access controls, authentication mechanisms, and regular security audits are necessary to prevent unauthorized access to the digital twin and its associated data.

The interconnected nature of digital twins also raises concerns about potential vulnerabilities in the broader ecosystem. As these systems often integrate with other IoT devices and cloud platforms, any weakness in the connected infrastructure could potentially be exploited to gain access to the digital twin or the physical battery system. Implementing a comprehensive security strategy that encompasses the entire ecosystem is crucial to mitigate these risks.

Furthermore, the use of artificial intelligence and machine learning algorithms in digital twins for predictive maintenance and optimization introduces additional security considerations. These algorithms must be protected against adversarial attacks that could manipulate their outputs, leading to incorrect decisions or compromised battery performance.

Ensuring the integrity of data used to create and update digital twins is another critical cybersecurity aspect. Tampered or falsified data could lead to inaccurate representations of the physical battery system, potentially resulting in incorrect decisions or actions. Implementing data validation mechanisms and maintaining a secure chain of custody for all data inputs is essential to maintain the reliability of the digital twin.

As digital twins become more prevalent in Battery Management Systems, cybersecurity measures must evolve to address emerging threats. This includes developing industry standards and best practices specifically tailored to the unique challenges posed by digital twins in the context of battery systems. Regular security assessments, penetration testing, and continuous monitoring are necessary to identify and mitigate potential vulnerabilities proactively.

Standardization Efforts

Standardization efforts in the field of digital twins for battery management systems (BMS) are crucial for ensuring interoperability, reliability, and widespread adoption of this technology. Several organizations and industry consortia are working towards developing common standards and protocols to facilitate the integration of digital twins in BMS applications.

The International Electrotechnical Commission (IEC) has been at the forefront of standardization efforts, developing guidelines for the implementation of digital twins in various industries, including energy storage systems. The IEC Technical Committee 57 (TC 57) is specifically focused on power systems management and associated information exchange, which encompasses digital twin applications for BMS.

In parallel, the Institute of Electrical and Electronics Engineers (IEEE) has established working groups dedicated to standardizing digital twin technologies. The IEEE P2888 series of standards aims to provide a framework for digital twin applications across different domains, including energy storage systems and battery management.

The Industrial Internet Consortium (IIC) has also contributed to the standardization landscape by developing reference architectures and frameworks for digital twins. Their efforts include guidelines for implementing digital twins in industrial settings, which can be adapted for BMS applications.

Collaboration between industry leaders and research institutions has led to the development of open-source platforms and protocols for digital twin implementation. These initiatives aim to create a common language and architecture for digital twins, facilitating easier integration and data exchange between different BMS components and systems.

Standardization efforts also focus on data models and communication protocols specific to battery systems. The development of standardized data formats and APIs for battery-related information enables seamless integration of digital twins with existing BMS infrastructure and other energy management systems.

Cybersecurity considerations are a critical aspect of standardization efforts. Organizations such as the National Institute of Standards and Technology (NIST) are working on guidelines for securing digital twin implementations, ensuring that sensitive battery data and control systems are protected from potential cyber threats.

As the adoption of digital twins in BMS continues to grow, ongoing standardization efforts will play a crucial role in shaping the future of this technology. These initiatives will help overcome integration challenges, reduce implementation costs, and accelerate the widespread adoption of digital twins in battery management applications across various industries.

The International Electrotechnical Commission (IEC) has been at the forefront of standardization efforts, developing guidelines for the implementation of digital twins in various industries, including energy storage systems. The IEC Technical Committee 57 (TC 57) is specifically focused on power systems management and associated information exchange, which encompasses digital twin applications for BMS.

In parallel, the Institute of Electrical and Electronics Engineers (IEEE) has established working groups dedicated to standardizing digital twin technologies. The IEEE P2888 series of standards aims to provide a framework for digital twin applications across different domains, including energy storage systems and battery management.

The Industrial Internet Consortium (IIC) has also contributed to the standardization landscape by developing reference architectures and frameworks for digital twins. Their efforts include guidelines for implementing digital twins in industrial settings, which can be adapted for BMS applications.

Collaboration between industry leaders and research institutions has led to the development of open-source platforms and protocols for digital twin implementation. These initiatives aim to create a common language and architecture for digital twins, facilitating easier integration and data exchange between different BMS components and systems.

Standardization efforts also focus on data models and communication protocols specific to battery systems. The development of standardized data formats and APIs for battery-related information enables seamless integration of digital twins with existing BMS infrastructure and other energy management systems.

Cybersecurity considerations are a critical aspect of standardization efforts. Organizations such as the National Institute of Standards and Technology (NIST) are working on guidelines for securing digital twin implementations, ensuring that sensitive battery data and control systems are protected from potential cyber threats.

As the adoption of digital twins in BMS continues to grow, ongoing standardization efforts will play a crucial role in shaping the future of this technology. These initiatives will help overcome integration challenges, reduce implementation costs, and accelerate the widespread adoption of digital twins in battery management applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!