Optimizing Data Acquisition in Battery Management Systems

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Data Acquisition Background and Objectives

Battery Management Systems (BMS) have become an integral part of modern energy storage solutions, playing a crucial role in ensuring the safety, efficiency, and longevity of battery systems. The optimization of data acquisition in BMS represents a critical area of technological advancement, with far-reaching implications for various industries, including automotive, renewable energy, and consumer electronics.

The evolution of BMS technology can be traced back to the early 1990s when the first rudimentary systems were introduced to monitor and protect rechargeable batteries. As battery technologies advanced, particularly with the widespread adoption of lithium-ion batteries, the complexity and importance of BMS grew exponentially. The primary objective of data acquisition in BMS has consistently been to gather accurate, real-time information about battery parameters such as voltage, current, temperature, and state of charge.

Over the past decade, the focus has shifted towards more sophisticated data acquisition techniques, driven by the need for higher precision, faster response times, and the ability to manage increasingly complex battery configurations. This shift has been necessitated by the growing demands of electric vehicles, grid-scale energy storage systems, and portable electronic devices, all of which require more advanced battery management capabilities.

The current technological landscape presents both opportunities and challenges for BMS data acquisition. On one hand, advancements in sensor technologies, microprocessors, and communication protocols have enabled more comprehensive and accurate data collection. On the other hand, the increasing complexity of battery systems, coupled with the demand for real-time analytics and predictive capabilities, has raised the bar for data acquisition performance.

Looking ahead, the trajectory of BMS data acquisition is poised to intersect with emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies promise to revolutionize how battery data is collected, processed, and utilized, potentially leading to significant improvements in battery performance, lifespan, and safety.

The optimization of data acquisition in BMS aims to address several key objectives. Firstly, it seeks to enhance the accuracy and reliability of battery state estimation, which is crucial for optimal battery utilization and longevity. Secondly, it aims to improve the speed and efficiency of data collection and processing, enabling faster response times to critical events such as thermal runaway or cell imbalance. Thirdly, it strives to reduce the overall cost and complexity of BMS hardware and software, making advanced battery management more accessible across various applications.

As we delve deeper into the technological aspects of optimizing data acquisition in BMS, it becomes clear that this field sits at the intersection of multiple disciplines, including electrical engineering, computer science, and materials science. The ongoing research and development in this area not only promise to enhance the performance and reliability of existing battery systems but also pave the way for next-generation energy storage solutions that could revolutionize how we generate, store, and utilize electrical energy.

The evolution of BMS technology can be traced back to the early 1990s when the first rudimentary systems were introduced to monitor and protect rechargeable batteries. As battery technologies advanced, particularly with the widespread adoption of lithium-ion batteries, the complexity and importance of BMS grew exponentially. The primary objective of data acquisition in BMS has consistently been to gather accurate, real-time information about battery parameters such as voltage, current, temperature, and state of charge.

Over the past decade, the focus has shifted towards more sophisticated data acquisition techniques, driven by the need for higher precision, faster response times, and the ability to manage increasingly complex battery configurations. This shift has been necessitated by the growing demands of electric vehicles, grid-scale energy storage systems, and portable electronic devices, all of which require more advanced battery management capabilities.

The current technological landscape presents both opportunities and challenges for BMS data acquisition. On one hand, advancements in sensor technologies, microprocessors, and communication protocols have enabled more comprehensive and accurate data collection. On the other hand, the increasing complexity of battery systems, coupled with the demand for real-time analytics and predictive capabilities, has raised the bar for data acquisition performance.

Looking ahead, the trajectory of BMS data acquisition is poised to intersect with emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies promise to revolutionize how battery data is collected, processed, and utilized, potentially leading to significant improvements in battery performance, lifespan, and safety.

The optimization of data acquisition in BMS aims to address several key objectives. Firstly, it seeks to enhance the accuracy and reliability of battery state estimation, which is crucial for optimal battery utilization and longevity. Secondly, it aims to improve the speed and efficiency of data collection and processing, enabling faster response times to critical events such as thermal runaway or cell imbalance. Thirdly, it strives to reduce the overall cost and complexity of BMS hardware and software, making advanced battery management more accessible across various applications.

As we delve deeper into the technological aspects of optimizing data acquisition in BMS, it becomes clear that this field sits at the intersection of multiple disciplines, including electrical engineering, computer science, and materials science. The ongoing research and development in this area not only promise to enhance the performance and reliability of existing battery systems but also pave the way for next-generation energy storage solutions that could revolutionize how we generate, store, and utilize electrical energy.

Market Demand for Advanced BMS Solutions

The demand for advanced Battery Management Systems (BMS) solutions has been steadily increasing in recent years, driven by the rapid growth of electric vehicles (EVs) and renewable energy storage systems. As the global push for electrification and sustainable energy solutions intensifies, the market for sophisticated BMS technologies is experiencing significant expansion.

In the automotive sector, the rise of EVs has created a substantial need for more efficient and reliable BMS solutions. Major automakers are investing heavily in electric vehicle technology, with many committing to fully electric lineups in the coming decades. This shift has led to a surge in demand for BMS that can optimize battery performance, extend range, and ensure safety.

The renewable energy sector is another key driver of BMS market growth. As more countries and businesses adopt solar and wind power, the need for advanced energy storage systems has increased. These systems require sophisticated BMS to manage large-scale battery installations, optimize charging and discharging cycles, and maximize the lifespan of battery assets.

Consumer electronics represent another significant market for advanced BMS solutions. With the proliferation of smartphones, laptops, and other portable devices, there is a growing demand for BMS that can enhance battery life, improve charging speeds, and ensure device safety.

Industrial applications, including robotics and automation systems, are also contributing to the expanding BMS market. These sectors require robust and reliable power management solutions to maintain operational efficiency and minimize downtime.

The market demand for advanced BMS solutions is further fueled by the increasing focus on sustainability and energy efficiency. Governments worldwide are implementing stricter regulations on emissions and energy consumption, driving industries to adopt more sophisticated battery management technologies.

As the complexity of battery systems increases, there is a growing need for BMS that can handle higher voltages, manage larger battery packs, and provide more accurate state-of-charge and state-of-health estimations. This has led to a demand for BMS with advanced features such as predictive maintenance capabilities, real-time monitoring, and integration with artificial intelligence and machine learning algorithms.

The global BMS market is expected to continue its upward trajectory, with particularly strong growth in regions such as Asia-Pacific, North America, and Europe. These regions are at the forefront of EV adoption and renewable energy integration, driving the need for cutting-edge BMS technologies.

In the automotive sector, the rise of EVs has created a substantial need for more efficient and reliable BMS solutions. Major automakers are investing heavily in electric vehicle technology, with many committing to fully electric lineups in the coming decades. This shift has led to a surge in demand for BMS that can optimize battery performance, extend range, and ensure safety.

The renewable energy sector is another key driver of BMS market growth. As more countries and businesses adopt solar and wind power, the need for advanced energy storage systems has increased. These systems require sophisticated BMS to manage large-scale battery installations, optimize charging and discharging cycles, and maximize the lifespan of battery assets.

Consumer electronics represent another significant market for advanced BMS solutions. With the proliferation of smartphones, laptops, and other portable devices, there is a growing demand for BMS that can enhance battery life, improve charging speeds, and ensure device safety.

Industrial applications, including robotics and automation systems, are also contributing to the expanding BMS market. These sectors require robust and reliable power management solutions to maintain operational efficiency and minimize downtime.

The market demand for advanced BMS solutions is further fueled by the increasing focus on sustainability and energy efficiency. Governments worldwide are implementing stricter regulations on emissions and energy consumption, driving industries to adopt more sophisticated battery management technologies.

As the complexity of battery systems increases, there is a growing need for BMS that can handle higher voltages, manage larger battery packs, and provide more accurate state-of-charge and state-of-health estimations. This has led to a demand for BMS with advanced features such as predictive maintenance capabilities, real-time monitoring, and integration with artificial intelligence and machine learning algorithms.

The global BMS market is expected to continue its upward trajectory, with particularly strong growth in regions such as Asia-Pacific, North America, and Europe. These regions are at the forefront of EV adoption and renewable energy integration, driving the need for cutting-edge BMS technologies.

Current Challenges in BMS Data Acquisition

Battery Management Systems (BMS) play a crucial role in ensuring the safety, efficiency, and longevity of battery packs. However, the current landscape of BMS data acquisition faces several significant challenges that hinder optimal performance and reliability.

One of the primary challenges is the increasing complexity of battery systems. As battery packs grow larger and more sophisticated, the volume and variety of data that needs to be collected and processed have expanded exponentially. This surge in data points puts immense pressure on BMS hardware and software, often leading to bottlenecks in data processing and increased latency in decision-making.

The accuracy and reliability of sensor measurements present another major hurdle. BMS rely heavily on various sensors to monitor critical parameters such as voltage, current, temperature, and state of charge. However, sensor drift, calibration errors, and environmental factors can introduce inaccuracies in the collected data. These discrepancies can lead to suboptimal battery management decisions, potentially compromising safety and performance.

Data synchronization across multiple cells and modules within a battery pack poses a significant challenge. Ensuring that all measurements are taken simultaneously and accurately time-stamped is crucial for precise state estimation and balancing. However, achieving this level of synchronization becomes increasingly difficult as the number of cells and modules in a battery pack grows.

The trade-off between sampling frequency and power consumption presents another dilemma. Higher sampling rates provide more detailed and up-to-date information about the battery's state but come at the cost of increased power consumption. This is particularly problematic in applications where energy efficiency is paramount, such as in electric vehicles or portable devices.

Electromagnetic interference (EMI) and noise in the harsh environments where batteries often operate can significantly impact data acquisition quality. Shielding and filtering techniques must be employed to mitigate these effects, but they add complexity and cost to the BMS design.

The integration of advanced algorithms for state estimation and predictive analytics into BMS data acquisition systems presents both opportunities and challenges. While these algorithms can greatly enhance battery management capabilities, they often require more computational power and more sophisticated data acquisition strategies.

Lastly, the lack of standardization in BMS data acquisition protocols and interfaces across different manufacturers and applications creates interoperability issues. This fragmentation makes it difficult to develop universal solutions and hinders the adoption of best practices across the industry.

Addressing these challenges requires a multifaceted approach, combining advancements in sensor technology, data processing algorithms, system architecture, and standardization efforts. As the demand for more efficient and reliable energy storage solutions continues to grow, overcoming these obstacles in BMS data acquisition will be crucial for the next generation of battery systems.

One of the primary challenges is the increasing complexity of battery systems. As battery packs grow larger and more sophisticated, the volume and variety of data that needs to be collected and processed have expanded exponentially. This surge in data points puts immense pressure on BMS hardware and software, often leading to bottlenecks in data processing and increased latency in decision-making.

The accuracy and reliability of sensor measurements present another major hurdle. BMS rely heavily on various sensors to monitor critical parameters such as voltage, current, temperature, and state of charge. However, sensor drift, calibration errors, and environmental factors can introduce inaccuracies in the collected data. These discrepancies can lead to suboptimal battery management decisions, potentially compromising safety and performance.

Data synchronization across multiple cells and modules within a battery pack poses a significant challenge. Ensuring that all measurements are taken simultaneously and accurately time-stamped is crucial for precise state estimation and balancing. However, achieving this level of synchronization becomes increasingly difficult as the number of cells and modules in a battery pack grows.

The trade-off between sampling frequency and power consumption presents another dilemma. Higher sampling rates provide more detailed and up-to-date information about the battery's state but come at the cost of increased power consumption. This is particularly problematic in applications where energy efficiency is paramount, such as in electric vehicles or portable devices.

Electromagnetic interference (EMI) and noise in the harsh environments where batteries often operate can significantly impact data acquisition quality. Shielding and filtering techniques must be employed to mitigate these effects, but they add complexity and cost to the BMS design.

The integration of advanced algorithms for state estimation and predictive analytics into BMS data acquisition systems presents both opportunities and challenges. While these algorithms can greatly enhance battery management capabilities, they often require more computational power and more sophisticated data acquisition strategies.

Lastly, the lack of standardization in BMS data acquisition protocols and interfaces across different manufacturers and applications creates interoperability issues. This fragmentation makes it difficult to develop universal solutions and hinders the adoption of best practices across the industry.

Addressing these challenges requires a multifaceted approach, combining advancements in sensor technology, data processing algorithms, system architecture, and standardization efforts. As the demand for more efficient and reliable energy storage solutions continues to grow, overcoming these obstacles in BMS data acquisition will be crucial for the next generation of battery systems.

Existing Data Acquisition Optimization Methods

01 Data acquisition systems for battery management

Battery management systems utilize specialized data acquisition systems to collect and process information from batteries. These systems monitor various parameters such as voltage, current, temperature, and state of charge to ensure optimal battery performance and longevity. The acquired data is used for real-time analysis, predictive maintenance, and overall battery health assessment.- Data acquisition and monitoring systems for battery management: Battery Management Systems (BMS) utilize advanced data acquisition techniques to monitor various parameters of batteries in real-time. These systems collect and analyze data on voltage, current, temperature, and state of charge to optimize battery performance, ensure safety, and extend battery life. The acquired data is used for predictive maintenance, fault detection, and overall system efficiency improvement.

- Wireless communication and data transmission in BMS: Modern Battery Management Systems incorporate wireless communication technologies for efficient data transmission. This allows for remote monitoring, control, and diagnostics of battery systems. Wireless protocols enable real-time data sharing between battery modules, central management units, and user interfaces, facilitating seamless integration with other systems and enhancing overall operational flexibility.

- Machine learning and AI integration in BMS data analysis: Advanced Battery Management Systems leverage machine learning and artificial intelligence algorithms to analyze the acquired data. These technologies enable predictive analytics, pattern recognition, and adaptive control strategies. By processing large volumes of historical and real-time data, AI-powered BMS can optimize charging cycles, predict battery degradation, and enhance overall system performance.

- Sensor technologies for accurate battery data acquisition: Battery Management Systems employ a variety of sensor technologies to accurately acquire data from battery cells and modules. These sensors measure parameters such as voltage, current, temperature, and internal resistance with high precision. Advanced sensing techniques, including electrochemical impedance spectroscopy and optical fiber sensors, provide detailed insights into battery health and performance, enabling more effective management strategies.

- Data storage and management in BMS: Efficient data storage and management are crucial components of Battery Management Systems. These systems incorporate robust database structures and data handling algorithms to store, process, and retrieve large volumes of battery-related information. Advanced data compression techniques and cloud integration enable long-term data retention for historical analysis and system optimization, while ensuring data security and accessibility.

02 Integration of battery management with IoT and cloud technologies

Modern battery management systems leverage Internet of Things (IoT) and cloud technologies for enhanced data acquisition and analysis. This integration allows for remote monitoring, real-time data transmission, and centralized storage of battery information. Cloud-based platforms enable advanced analytics, machine learning algorithms, and predictive modeling to optimize battery performance and lifespan.Expand Specific Solutions03 Sensor networks for comprehensive battery monitoring

Advanced sensor networks are employed in battery management systems to gather comprehensive data on battery conditions. These networks include various types of sensors such as voltage sensors, current sensors, temperature sensors, and pressure sensors. The distributed sensor network enables high-resolution data acquisition, allowing for detailed analysis of individual cells and overall battery pack performance.Expand Specific Solutions04 Machine learning and AI in battery data analysis

Battery management systems increasingly incorporate machine learning and artificial intelligence techniques for data analysis. These advanced algorithms process large volumes of battery data to identify patterns, predict potential issues, and optimize charging and discharging cycles. AI-driven systems can adapt to changing battery conditions and user behavior, enhancing overall system efficiency and battery lifespan.Expand Specific Solutions05 Energy management and load balancing in battery systems

Data acquisition in battery management systems plays a crucial role in energy management and load balancing. By continuously monitoring battery parameters and energy consumption patterns, these systems can optimize power distribution, manage peak loads, and implement intelligent charging strategies. This approach ensures efficient energy utilization and extends the operational life of battery systems in various applications.Expand Specific Solutions

Key Players in BMS Technology Industry

The optimization of data acquisition in Battery Management Systems (BMS) is currently in a growth phase, with the market expanding rapidly due to increasing demand for electric vehicles and energy storage solutions. The global BMS market size is projected to reach significant figures in the coming years, driven by advancements in battery technology and the push for more efficient energy management. Technologically, the field is evolving quickly, with companies like Panasonic, LG Energy Solution, and Robert Bosch leading the way in innovation. These industry giants, along with emerging players such as BYD and Zitara Technologies, are investing heavily in research and development to improve data acquisition techniques, enhance battery performance, and extend lifespan. The competition is fierce, with automotive manufacturers like Honda and Volkswagen also entering the fray, indicating the technology's growing maturity and cross-industry relevance.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed an advanced Battery Management System (BMS) that optimizes data acquisition through a multi-layered approach. Their system employs high-precision voltage and current sensors with adaptive sampling rates, allowing for real-time monitoring of battery cells[1]. The BMS utilizes machine learning algorithms to predict battery behavior and adjust data collection frequency accordingly, reducing unnecessary data overhead[3]. Panasonic's solution also incorporates a distributed architecture, where local processing units handle immediate data analysis, transmitting only relevant information to the central BMS, thus optimizing network bandwidth and response times[5].

Strengths: High precision monitoring, adaptive data collection, and efficient distributed processing. Weaknesses: Potentially higher initial implementation cost and complexity in system integration.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has innovated in BMS data acquisition by implementing a smart sensor network with integrated edge computing capabilities. Their system uses advanced algorithms to filter and compress data at the source, significantly reducing the volume of raw data transmitted[2]. The BMS employs a dynamic prioritization scheme, allocating higher bandwidth to critical parameters during high-stress conditions such as rapid charging or extreme temperatures[4]. LG's solution also features a cloud-connected platform that enables over-the-air updates to optimize data acquisition strategies based on aggregated fleet data and evolving battery chemistries[6].

Strengths: Efficient data compression, adaptive prioritization, and cloud-enabled optimization. Weaknesses: Reliance on cloud connectivity may pose challenges in areas with poor network coverage.

Innovative Approaches in BMS Data Collection

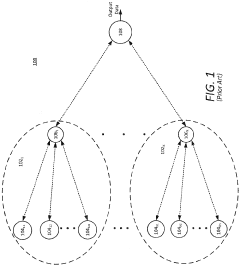

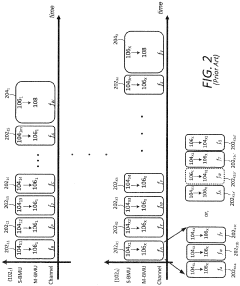

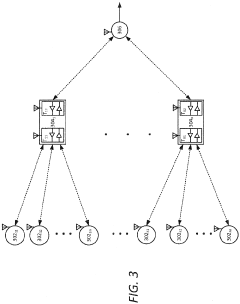

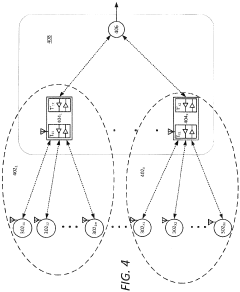

Hybrid three-tier battery management system for fast data acquisition time

PatentInactiveEP3731535A1

Innovation

- A three-tier hierarchical network structure with dual data transceivers in master nodes allows for concurrent communication with sensor and top-level nodes, using wireless and wired transceivers to facilitate faster data acquisition and reduce data acquisition time by distributing communication loads effectively.

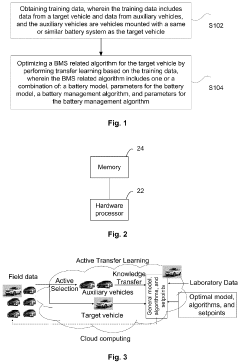

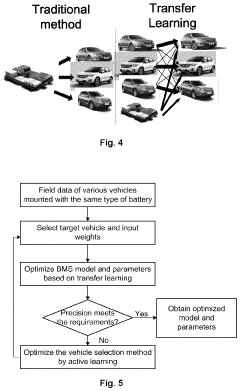

Method and apparatus for optimizing battery management system

PatentActiveUS12012014B2

Innovation

- The method employs transfer learning using training data from target and auxiliary vehicles with similar battery systems, optimizing algorithms through cloud computing and connected vehicle technology to adapt to individual driving and charging patterns, enabling the battery management system to learn from past usage and adapt to novel situations.

Regulatory Framework for BMS Technologies

The regulatory framework for Battery Management System (BMS) technologies plays a crucial role in ensuring the safety, reliability, and performance of battery systems across various industries. As the adoption of electric vehicles and energy storage systems continues to grow, governments and regulatory bodies worldwide have been developing and refining standards and guidelines to address the unique challenges posed by BMS technologies.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that include requirements for electric vehicle battery systems. These standards focus on crash safety, thermal management, and electrical isolation. The Society of Automotive Engineers (SAE) has also developed several standards, such as J2464 and J2929, which provide guidelines for electric and hybrid vehicle battery systems, including BMS requirements.

The European Union has implemented the UN/ECE Regulation No. 100, which outlines safety requirements for electric power train vehicles. This regulation includes specific provisions for battery management systems, addressing issues such as overcharge protection, thermal management, and state-of-charge monitoring. Additionally, the EU Battery Directive (2006/66/EC) sets requirements for battery recycling and disposal, which indirectly impacts BMS design and implementation.

In China, the GB/T 31467 standard series provides comprehensive guidelines for lithium-ion traction battery packs and systems used in electric vehicles. These standards cover various aspects of BMS technologies, including safety requirements, test methods, and performance criteria. The Chinese government has also introduced subsidy programs that incentivize the development and adoption of advanced BMS technologies in electric vehicles.

International standards organizations, such as the International Electrotechnical Commission (IEC), have developed standards like IEC 62619 and IEC 62660, which address safety requirements for lithium-ion batteries in industrial applications and electric road vehicles, respectively. These standards provide a framework for BMS design and implementation across different applications and regions.

As the technology evolves, regulatory frameworks are continuously updated to address emerging challenges and opportunities in BMS technologies. For instance, there is a growing focus on cybersecurity in BMS, with organizations like the United Nations Economic Commission for Europe (UNECE) developing regulations to address potential vulnerabilities in connected vehicle systems, including battery management.

The regulatory landscape for BMS technologies also extends to data privacy and management, particularly as advanced BMS systems collect and process large amounts of data for optimization and predictive maintenance. Regulations such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the United States have implications for how BMS data is collected, stored, and utilized.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that include requirements for electric vehicle battery systems. These standards focus on crash safety, thermal management, and electrical isolation. The Society of Automotive Engineers (SAE) has also developed several standards, such as J2464 and J2929, which provide guidelines for electric and hybrid vehicle battery systems, including BMS requirements.

The European Union has implemented the UN/ECE Regulation No. 100, which outlines safety requirements for electric power train vehicles. This regulation includes specific provisions for battery management systems, addressing issues such as overcharge protection, thermal management, and state-of-charge monitoring. Additionally, the EU Battery Directive (2006/66/EC) sets requirements for battery recycling and disposal, which indirectly impacts BMS design and implementation.

In China, the GB/T 31467 standard series provides comprehensive guidelines for lithium-ion traction battery packs and systems used in electric vehicles. These standards cover various aspects of BMS technologies, including safety requirements, test methods, and performance criteria. The Chinese government has also introduced subsidy programs that incentivize the development and adoption of advanced BMS technologies in electric vehicles.

International standards organizations, such as the International Electrotechnical Commission (IEC), have developed standards like IEC 62619 and IEC 62660, which address safety requirements for lithium-ion batteries in industrial applications and electric road vehicles, respectively. These standards provide a framework for BMS design and implementation across different applications and regions.

As the technology evolves, regulatory frameworks are continuously updated to address emerging challenges and opportunities in BMS technologies. For instance, there is a growing focus on cybersecurity in BMS, with organizations like the United Nations Economic Commission for Europe (UNECE) developing regulations to address potential vulnerabilities in connected vehicle systems, including battery management.

The regulatory landscape for BMS technologies also extends to data privacy and management, particularly as advanced BMS systems collect and process large amounts of data for optimization and predictive maintenance. Regulations such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the United States have implications for how BMS data is collected, stored, and utilized.

Environmental Impact of Optimized BMS Data Acquisition

Optimizing data acquisition in Battery Management Systems (BMS) can have significant environmental implications, both positive and negative. The primary environmental benefit stems from improved battery efficiency and longevity, which directly reduces the need for battery replacements and the associated environmental costs of production and disposal. By accurately monitoring and managing battery parameters, optimized BMS data acquisition enables more precise control over charging and discharging cycles, minimizing unnecessary wear and extending battery life.

This optimization also contributes to reduced energy waste during charging processes. More efficient charging leads to lower overall energy consumption, which, in turn, decreases the carbon footprint associated with battery-powered devices and electric vehicles. In the context of renewable energy systems, such as solar or wind power installations, optimized BMS data acquisition enhances the integration of energy storage solutions, facilitating a more stable and efficient use of intermittent renewable sources.

However, the environmental impact is not solely positive. The implementation of advanced data acquisition systems in BMS may require additional hardware components, potentially increasing the overall electronic waste generated when these systems reach end-of-life. The production of more sophisticated sensors and processing units for data acquisition could also lead to increased resource consumption and manufacturing-related emissions.

Furthermore, the increased data processing and transmission associated with optimized BMS data acquisition systems may result in higher energy consumption for data centers and communication networks. This indirect environmental cost should be considered when evaluating the overall environmental impact of these systems.

In the broader context of the circular economy, optimized BMS data acquisition can play a crucial role in battery second-life applications. By providing more accurate and detailed information about battery health and performance throughout its lifecycle, these systems enable better decision-making regarding when and how to repurpose batteries for less demanding applications, thereby extending their useful life and reducing waste.

The environmental impact also extends to the transportation sector, particularly in electric vehicles. Optimized BMS data acquisition contributes to more accurate range predictions and efficient energy management, potentially reducing range anxiety and promoting wider adoption of electric vehicles. This shift towards electrification, supported by advanced BMS technologies, can significantly reduce greenhouse gas emissions from the transportation sector.

In conclusion, while the environmental benefits of optimized BMS data acquisition are substantial, particularly in terms of battery efficiency and longevity, it is essential to consider the full lifecycle impact of these systems. Balancing the positive effects of improved energy management against the potential increase in electronic waste and energy consumption for data processing will be crucial in maximizing the net environmental benefit of these technological advancements.

This optimization also contributes to reduced energy waste during charging processes. More efficient charging leads to lower overall energy consumption, which, in turn, decreases the carbon footprint associated with battery-powered devices and electric vehicles. In the context of renewable energy systems, such as solar or wind power installations, optimized BMS data acquisition enhances the integration of energy storage solutions, facilitating a more stable and efficient use of intermittent renewable sources.

However, the environmental impact is not solely positive. The implementation of advanced data acquisition systems in BMS may require additional hardware components, potentially increasing the overall electronic waste generated when these systems reach end-of-life. The production of more sophisticated sensors and processing units for data acquisition could also lead to increased resource consumption and manufacturing-related emissions.

Furthermore, the increased data processing and transmission associated with optimized BMS data acquisition systems may result in higher energy consumption for data centers and communication networks. This indirect environmental cost should be considered when evaluating the overall environmental impact of these systems.

In the broader context of the circular economy, optimized BMS data acquisition can play a crucial role in battery second-life applications. By providing more accurate and detailed information about battery health and performance throughout its lifecycle, these systems enable better decision-making regarding when and how to repurpose batteries for less demanding applications, thereby extending their useful life and reducing waste.

The environmental impact also extends to the transportation sector, particularly in electric vehicles. Optimized BMS data acquisition contributes to more accurate range predictions and efficient energy management, potentially reducing range anxiety and promoting wider adoption of electric vehicles. This shift towards electrification, supported by advanced BMS technologies, can significantly reduce greenhouse gas emissions from the transportation sector.

In conclusion, while the environmental benefits of optimized BMS data acquisition are substantial, particularly in terms of battery efficiency and longevity, it is essential to consider the full lifecycle impact of these systems. Balancing the positive effects of improved energy management against the potential increase in electronic waste and energy consumption for data processing will be crucial in maximizing the net environmental benefit of these technological advancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!