Safety-Critical Applications of Battery Management Systems in Industry

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Safety Evolution

The evolution of Battery Management System (BMS) safety in industry has been marked by significant advancements and a growing emphasis on reliability and risk mitigation. Initially, BMS designs focused primarily on basic monitoring and protection functions, with limited integration of safety features. As the adoption of battery-powered systems increased across various industrial sectors, the need for more sophisticated safety mechanisms became apparent.

In the early stages, BMS safety features were largely reactive, designed to respond to immediate threats such as overcharging, over-discharging, and short circuits. These systems relied heavily on hardware-based protection circuits and simple firmware algorithms. However, as the complexity and scale of battery applications grew, particularly in safety-critical industries like automotive and aerospace, the limitations of these basic systems became evident.

The next phase of BMS safety evolution saw the introduction of more proactive and predictive safety measures. Advanced algorithms were developed to anticipate potential failure modes based on historical data and real-time monitoring. This shift towards predictive maintenance and fault detection significantly enhanced the overall safety profile of battery systems in industrial applications.

Concurrently, the integration of BMS with other vehicle or industrial control systems became a key focus. This system-level approach to safety allowed for more comprehensive risk management, considering not just the battery pack in isolation but its interactions with other critical components. The development of standardized communication protocols facilitated this integration, enabling seamless data exchange and coordinated safety responses across multiple subsystems.

Recent years have witnessed a surge in the application of artificial intelligence and machine learning techniques in BMS safety. These technologies have enabled more nuanced and adaptive safety strategies, capable of learning from operational data and adjusting parameters in real-time to optimize both performance and safety. This has been particularly crucial in addressing the challenges posed by new battery chemistries and increasingly demanding operational environments.

The regulatory landscape has also played a significant role in shaping BMS safety evolution. Stringent safety standards and certification requirements have driven continuous improvements in BMS design and testing methodologies. This has led to the development of more robust validation processes, including extensive simulation and accelerated life testing, to ensure BMS reliability under a wide range of conditions.

Looking ahead, the trajectory of BMS safety evolution points towards even greater integration of advanced technologies. The emergence of solid-state batteries and other next-generation energy storage solutions will likely necessitate further innovations in BMS safety strategies. Additionally, the growing importance of cybersecurity in industrial systems is expected to drive new developments in BMS security features, protecting against potential cyber threats that could compromise safety.

In the early stages, BMS safety features were largely reactive, designed to respond to immediate threats such as overcharging, over-discharging, and short circuits. These systems relied heavily on hardware-based protection circuits and simple firmware algorithms. However, as the complexity and scale of battery applications grew, particularly in safety-critical industries like automotive and aerospace, the limitations of these basic systems became evident.

The next phase of BMS safety evolution saw the introduction of more proactive and predictive safety measures. Advanced algorithms were developed to anticipate potential failure modes based on historical data and real-time monitoring. This shift towards predictive maintenance and fault detection significantly enhanced the overall safety profile of battery systems in industrial applications.

Concurrently, the integration of BMS with other vehicle or industrial control systems became a key focus. This system-level approach to safety allowed for more comprehensive risk management, considering not just the battery pack in isolation but its interactions with other critical components. The development of standardized communication protocols facilitated this integration, enabling seamless data exchange and coordinated safety responses across multiple subsystems.

Recent years have witnessed a surge in the application of artificial intelligence and machine learning techniques in BMS safety. These technologies have enabled more nuanced and adaptive safety strategies, capable of learning from operational data and adjusting parameters in real-time to optimize both performance and safety. This has been particularly crucial in addressing the challenges posed by new battery chemistries and increasingly demanding operational environments.

The regulatory landscape has also played a significant role in shaping BMS safety evolution. Stringent safety standards and certification requirements have driven continuous improvements in BMS design and testing methodologies. This has led to the development of more robust validation processes, including extensive simulation and accelerated life testing, to ensure BMS reliability under a wide range of conditions.

Looking ahead, the trajectory of BMS safety evolution points towards even greater integration of advanced technologies. The emergence of solid-state batteries and other next-generation energy storage solutions will likely necessitate further innovations in BMS safety strategies. Additionally, the growing importance of cybersecurity in industrial systems is expected to drive new developments in BMS security features, protecting against potential cyber threats that could compromise safety.

Industrial BMS Demand

The demand for Battery Management Systems (BMS) in industrial applications has been steadily increasing, driven by the growing adoption of electric and hybrid vehicles, renewable energy storage systems, and the overall electrification trend across various industries. Safety-critical applications of BMS are particularly crucial in sectors where battery failure could lead to catastrophic consequences, such as in aerospace, automotive, and large-scale energy storage systems.

In the automotive industry, the shift towards electric vehicles has created a significant market for advanced BMS solutions. As electric vehicles become more prevalent, the need for reliable and safe battery management becomes paramount. The global electric vehicle market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly impacting the demand for industrial BMS.

The renewable energy sector is another major driver for industrial BMS demand. As countries worldwide push for cleaner energy sources, the installation of large-scale battery storage systems for grid stabilization and energy management is on the rise. These systems require sophisticated BMS to ensure optimal performance, longevity, and safety of the battery arrays.

In the aerospace industry, the development of electric and hybrid aircraft has created a new frontier for BMS applications. The stringent safety requirements in aviation necessitate highly advanced and reliable BMS solutions to monitor and manage onboard battery systems.

The industrial automation sector is also contributing to the increased demand for BMS. As factories and manufacturing plants incorporate more electric-powered equipment and autonomous systems, the need for efficient and safe battery management grows. This is particularly evident in applications such as automated guided vehicles (AGVs) and robotic systems used in warehouses and production lines.

The marine industry is another emerging market for industrial BMS. With the push for cleaner propulsion systems in ships and boats, battery-powered and hybrid vessels are becoming more common. These applications require robust BMS to ensure safe operation in harsh marine environments.

Furthermore, the telecommunications industry's expansion of 5G networks has led to an increased demand for backup power systems, which in turn drives the need for reliable BMS solutions to manage these critical power sources.

As industries continue to prioritize safety and efficiency, the demand for BMS in safety-critical applications is expected to grow further. This trend is reinforced by stringent regulations and standards governing battery safety across various sectors, compelling manufacturers to invest in advanced BMS technologies.

In the automotive industry, the shift towards electric vehicles has created a significant market for advanced BMS solutions. As electric vehicles become more prevalent, the need for reliable and safe battery management becomes paramount. The global electric vehicle market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly impacting the demand for industrial BMS.

The renewable energy sector is another major driver for industrial BMS demand. As countries worldwide push for cleaner energy sources, the installation of large-scale battery storage systems for grid stabilization and energy management is on the rise. These systems require sophisticated BMS to ensure optimal performance, longevity, and safety of the battery arrays.

In the aerospace industry, the development of electric and hybrid aircraft has created a new frontier for BMS applications. The stringent safety requirements in aviation necessitate highly advanced and reliable BMS solutions to monitor and manage onboard battery systems.

The industrial automation sector is also contributing to the increased demand for BMS. As factories and manufacturing plants incorporate more electric-powered equipment and autonomous systems, the need for efficient and safe battery management grows. This is particularly evident in applications such as automated guided vehicles (AGVs) and robotic systems used in warehouses and production lines.

The marine industry is another emerging market for industrial BMS. With the push for cleaner propulsion systems in ships and boats, battery-powered and hybrid vessels are becoming more common. These applications require robust BMS to ensure safe operation in harsh marine environments.

Furthermore, the telecommunications industry's expansion of 5G networks has led to an increased demand for backup power systems, which in turn drives the need for reliable BMS solutions to manage these critical power sources.

As industries continue to prioritize safety and efficiency, the demand for BMS in safety-critical applications is expected to grow further. This trend is reinforced by stringent regulations and standards governing battery safety across various sectors, compelling manufacturers to invest in advanced BMS technologies.

BMS Safety Challenges

Battery Management Systems (BMS) play a crucial role in ensuring the safe operation of batteries in various industrial applications. However, as the demand for high-performance energy storage solutions grows, so do the safety challenges associated with BMS implementation. One of the primary concerns is thermal runaway, a potentially catastrophic event where battery cells overheat and cause a chain reaction of rapid temperature increase. BMS must be designed to detect and prevent such occurrences through accurate temperature monitoring and control mechanisms.

Another significant challenge is the accurate estimation of State of Charge (SoC) and State of Health (SoH) in safety-critical applications. Precise measurements of these parameters are essential for preventing overcharging, over-discharging, and ensuring the overall longevity of the battery system. Inaccurate estimations can lead to unexpected system failures or reduced performance, which can be particularly dangerous in applications such as electric vehicles or medical devices.

Cybersecurity has emerged as a growing concern in BMS safety. As industrial systems become increasingly connected, the risk of malicious attacks on BMS increases. Unauthorized access to BMS could potentially lead to system manipulation, data theft, or even deliberate sabotage of battery operations. Implementing robust security measures, including encryption, authentication protocols, and regular software updates, is crucial to mitigate these risks.

The complexity of modern battery systems also presents challenges in fault detection and diagnosis. BMS must be capable of identifying and isolating faults at the cell, module, and pack levels to prevent cascading failures. This requires sophisticated algorithms and sensor networks that can quickly process large amounts of data and make real-time decisions to maintain system integrity.

Environmental factors pose additional safety challenges for BMS in industrial settings. Extreme temperatures, humidity, vibration, and electromagnetic interference can all affect BMS performance and reliability. Designing systems that can withstand these harsh conditions while maintaining accurate monitoring and control functions is essential for ensuring safety in diverse industrial applications.

Regulatory compliance adds another layer of complexity to BMS safety challenges. As safety standards evolve, BMS designs must adapt to meet new requirements, which may involve significant redesigns or upgrades to existing systems. Staying ahead of regulatory changes and ensuring compliance across different regions and industries is a continuous challenge for BMS developers and manufacturers.

Lastly, the integration of BMS with other industrial systems and processes presents interoperability challenges. Ensuring seamless communication and coordination between BMS and other critical systems, such as power management units or industrial control systems, is vital for maintaining overall system safety and efficiency. Addressing these multifaceted safety challenges requires a comprehensive approach that combines advanced technology, rigorous testing, and continuous innovation in BMS design and implementation.

Another significant challenge is the accurate estimation of State of Charge (SoC) and State of Health (SoH) in safety-critical applications. Precise measurements of these parameters are essential for preventing overcharging, over-discharging, and ensuring the overall longevity of the battery system. Inaccurate estimations can lead to unexpected system failures or reduced performance, which can be particularly dangerous in applications such as electric vehicles or medical devices.

Cybersecurity has emerged as a growing concern in BMS safety. As industrial systems become increasingly connected, the risk of malicious attacks on BMS increases. Unauthorized access to BMS could potentially lead to system manipulation, data theft, or even deliberate sabotage of battery operations. Implementing robust security measures, including encryption, authentication protocols, and regular software updates, is crucial to mitigate these risks.

The complexity of modern battery systems also presents challenges in fault detection and diagnosis. BMS must be capable of identifying and isolating faults at the cell, module, and pack levels to prevent cascading failures. This requires sophisticated algorithms and sensor networks that can quickly process large amounts of data and make real-time decisions to maintain system integrity.

Environmental factors pose additional safety challenges for BMS in industrial settings. Extreme temperatures, humidity, vibration, and electromagnetic interference can all affect BMS performance and reliability. Designing systems that can withstand these harsh conditions while maintaining accurate monitoring and control functions is essential for ensuring safety in diverse industrial applications.

Regulatory compliance adds another layer of complexity to BMS safety challenges. As safety standards evolve, BMS designs must adapt to meet new requirements, which may involve significant redesigns or upgrades to existing systems. Staying ahead of regulatory changes and ensuring compliance across different regions and industries is a continuous challenge for BMS developers and manufacturers.

Lastly, the integration of BMS with other industrial systems and processes presents interoperability challenges. Ensuring seamless communication and coordination between BMS and other critical systems, such as power management units or industrial control systems, is vital for maintaining overall system safety and efficiency. Addressing these multifaceted safety challenges requires a comprehensive approach that combines advanced technology, rigorous testing, and continuous innovation in BMS design and implementation.

Current BMS Solutions

01 Battery monitoring and control systems

These systems monitor various parameters of batteries, such as voltage, current, and temperature, to optimize performance and ensure safe operation. They often include features for balancing cell voltages, managing charging and discharging cycles, and providing diagnostic information.- Battery monitoring and control systems: These systems monitor battery parameters such as voltage, current, and temperature to optimize performance and ensure safe operation. They often include features for balancing cell voltages, managing charging and discharging cycles, and providing diagnostic information.

- Thermal management in battery systems: Thermal management solutions are crucial for maintaining optimal battery temperature, which affects performance, lifespan, and safety. These systems may include cooling mechanisms, heat dissipation techniques, and temperature monitoring to prevent overheating and ensure efficient operation.

- State of charge and state of health estimation: Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are critical for predicting remaining battery life, optimizing charging strategies, and scheduling maintenance.

- Battery management for electric vehicles: Specialized battery management systems for electric vehicles focus on optimizing range, fast charging capabilities, and integrating with vehicle systems. These systems often include features for regenerative braking, power distribution, and adapting to various driving conditions.

- Smart grid integration and energy storage management: Battery management systems designed for grid-scale energy storage and smart grid applications. These systems focus on load balancing, peak shaving, and integrating renewable energy sources. They often include advanced communication protocols for grid interaction and energy management strategies.

02 Thermal management in battery systems

Thermal management is crucial for maintaining optimal battery performance and longevity. This includes cooling systems, heat dissipation methods, and temperature regulation strategies to prevent overheating and ensure efficient operation across various environmental conditions.Expand Specific Solutions03 State of charge and state of health estimation

Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. These estimations are critical for predicting remaining battery life, optimizing charging strategies, and scheduling maintenance.Expand Specific Solutions04 Battery pack design and cell balancing

This involves the arrangement and interconnection of individual cells to form battery packs, as well as implementing cell balancing techniques. Proper design and balancing ensure uniform performance across all cells, extending overall battery life and improving system reliability.Expand Specific Solutions05 Integration with energy management systems

Battery management systems are increasingly integrated with broader energy management systems, particularly in applications like electric vehicles and renewable energy storage. This integration allows for optimized energy distribution, improved grid interaction, and enhanced overall system efficiency.Expand Specific Solutions

Key BMS Manufacturers

The safety-critical applications of Battery Management Systems (BMS) in industry are at a crucial stage of development, with the market experiencing rapid growth and technological advancements. The industry is transitioning from early adoption to mainstream implementation, driven by increasing demand for electric vehicles and renewable energy storage solutions. The global BMS market size is projected to expand significantly, fueled by stringent safety regulations and the need for efficient energy management. Technologically, companies like Contemporary Amperex Technology, Robert Bosch GmbH, and A123 Systems are leading the way with innovative BMS solutions, focusing on improving safety, performance, and longevity of battery systems. The competitive landscape is diverse, with established automotive giants, specialized battery manufacturers, and emerging tech startups all vying for market share in this rapidly evolving sector.

Contemporary Amperex Technology Co., Ltd.

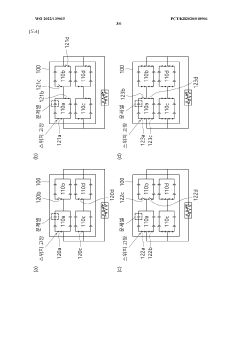

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed a state-of-the-art Battery Management System for safety-critical industrial applications. Their BMS utilizes artificial intelligence and big data analytics to enhance battery performance and safety. The system employs machine learning algorithms to continuously improve SOC and SOH estimations, achieving accuracy rates of up to 95%[6]. CATL's BMS features a cloud-connected architecture, allowing for remote monitoring and over-the-air updates to optimize battery performance and safety protocols. The system incorporates advanced cell balancing techniques, including active balancing, which can significantly extend battery life and improve overall system efficiency[7]. CATL's BMS also includes a comprehensive safety management system with multi-level protection mechanisms, including cell-level fusing and intelligent current interruption devices.

Strengths: AI-driven performance optimization, cloud connectivity for remote management, and advanced cell balancing. Weaknesses: Potential data security concerns due to cloud connectivity and may require significant computational resources.

Robert Bosch GmbH

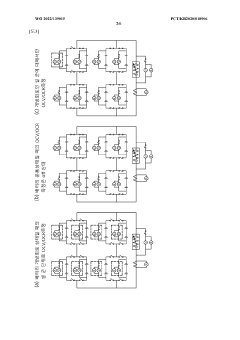

Technical Solution: Robert Bosch GmbH has developed an advanced Battery Management System (BMS) for safety-critical applications in industry. Their system utilizes a distributed architecture with intelligent cell monitoring units (CMUs) connected to a central control unit. This approach allows for real-time monitoring of individual cell voltages, temperatures, and internal resistance[1]. The BMS employs sophisticated algorithms for state estimation, including state of charge (SOC) and state of health (SOH) calculations, which are crucial for predicting battery performance and preventing safety incidents[2]. Bosch's system also incorporates predictive diagnostics and prognostics capabilities, enabling early detection of potential failures and optimizing maintenance schedules[3]. Additionally, their BMS features redundant communication protocols and fail-safe mechanisms to ensure continuous operation in critical scenarios.

Strengths: Highly accurate cell monitoring, advanced state estimation algorithms, and predictive maintenance capabilities. Weaknesses: Potentially higher cost due to distributed architecture and may require more complex integration in existing systems.

BMS Safety Innovations

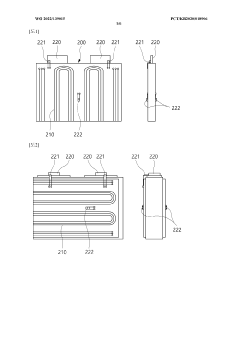

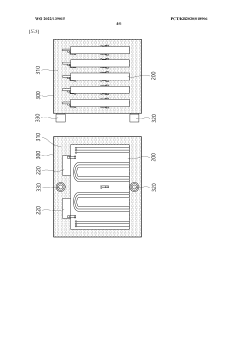

Battery safety system comprising battery cooling apparatus

PatentWO2022139015A1

Innovation

- A battery safety system that includes a measuring unit for individual cell-level monitoring of voltage, current, resistance, temperature, and volume changes, along with a control unit to block external power to problematic cells and a cooling unit for enhanced cooling efficiency through direct contact with a cooling solution, allowing for precise identification and mitigation of safety issues.

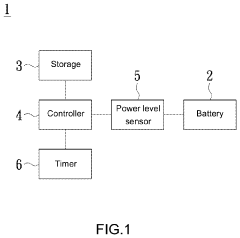

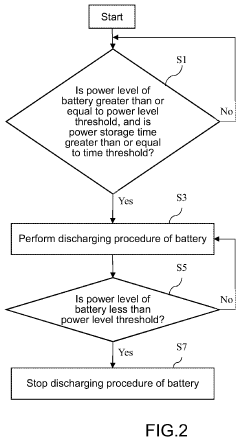

Battery safety management system and procedure thereof

PatentActiveUS20230246468A1

Innovation

- A battery safety management system that includes a controller, storage, and power level sensor, which executes a procedure to determine if the battery power level and storage time exceed thresholds, initiating a discharging process to prevent prolonged high power states and subsequently reducing the risk of swelling and damage.

BMS Standards & Regs

Battery Management Systems (BMS) in safety-critical industrial applications are subject to stringent standards and regulations to ensure reliability, performance, and safety. These standards are developed by various international organizations and regulatory bodies to address the unique challenges posed by battery systems in industrial environments.

The International Electrotechnical Commission (IEC) has established several standards relevant to BMS in safety-critical applications. IEC 62619 focuses on safety requirements for lithium-ion batteries in industrial applications, while IEC 61508 provides guidelines for functional safety of electrical/electronic/programmable electronic safety-related systems. These standards outline requirements for system design, risk assessment, and safety integrity levels.

In the automotive sector, ISO 26262 is a crucial standard for functional safety of electrical and electronic systems in road vehicles. This standard has been adapted for industrial applications, providing a framework for developing safety-critical BMS in various industrial settings. It emphasizes a systematic approach to hazard analysis and risk assessment throughout the product development lifecycle.

The Underwriters Laboratories (UL) has developed UL 1973, which addresses safety requirements for stationary energy storage systems and equipment. This standard is particularly relevant for large-scale industrial battery installations and covers aspects such as thermal management, electrical safety, and fire protection.

In the United States, the National Fire Protection Association (NFPA) has established NFPA 855, which provides installation requirements for stationary energy storage systems. This standard addresses fire safety concerns associated with large-scale battery installations in industrial settings.

The European Union's ATEX Directive (2014/34/EU) is crucial for BMS applications in potentially explosive atmospheres. It sets requirements for equipment and protective systems intended for use in these environments, ensuring that battery systems do not become ignition sources.

Compliance with these standards and regulations often requires extensive testing and certification processes. Third-party certification bodies, such as TÜV and DNV GL, play a significant role in verifying compliance and issuing certifications for BMS in safety-critical industrial applications.

As the technology evolves, standards and regulations continue to adapt. Emerging areas of focus include cybersecurity requirements for BMS, as outlined in IEC 62443, and environmental considerations addressed by regulations such as the EU's Restriction of Hazardous Substances (RoHS) Directive.

The International Electrotechnical Commission (IEC) has established several standards relevant to BMS in safety-critical applications. IEC 62619 focuses on safety requirements for lithium-ion batteries in industrial applications, while IEC 61508 provides guidelines for functional safety of electrical/electronic/programmable electronic safety-related systems. These standards outline requirements for system design, risk assessment, and safety integrity levels.

In the automotive sector, ISO 26262 is a crucial standard for functional safety of electrical and electronic systems in road vehicles. This standard has been adapted for industrial applications, providing a framework for developing safety-critical BMS in various industrial settings. It emphasizes a systematic approach to hazard analysis and risk assessment throughout the product development lifecycle.

The Underwriters Laboratories (UL) has developed UL 1973, which addresses safety requirements for stationary energy storage systems and equipment. This standard is particularly relevant for large-scale industrial battery installations and covers aspects such as thermal management, electrical safety, and fire protection.

In the United States, the National Fire Protection Association (NFPA) has established NFPA 855, which provides installation requirements for stationary energy storage systems. This standard addresses fire safety concerns associated with large-scale battery installations in industrial settings.

The European Union's ATEX Directive (2014/34/EU) is crucial for BMS applications in potentially explosive atmospheres. It sets requirements for equipment and protective systems intended for use in these environments, ensuring that battery systems do not become ignition sources.

Compliance with these standards and regulations often requires extensive testing and certification processes. Third-party certification bodies, such as TÜV and DNV GL, play a significant role in verifying compliance and issuing certifications for BMS in safety-critical industrial applications.

As the technology evolves, standards and regulations continue to adapt. Emerging areas of focus include cybersecurity requirements for BMS, as outlined in IEC 62443, and environmental considerations addressed by regulations such as the EU's Restriction of Hazardous Substances (RoHS) Directive.

BMS Failure Analysis

Battery Management System (BMS) failures in safety-critical industrial applications can have severe consequences, ranging from operational disruptions to catastrophic accidents. Understanding the root causes and mechanisms of BMS failures is crucial for developing robust safety measures and improving system reliability.

BMS failures can be broadly categorized into hardware and software failures. Hardware failures often stem from component degradation, manufacturing defects, or environmental stressors. Common hardware failure modes include sensor malfunctions, connection issues, and power supply failures. These can lead to inaccurate measurements, communication breakdowns, or complete system shutdowns.

Software failures, on the other hand, typically result from programming errors, algorithm limitations, or inadequate fault handling. These may manifest as incorrect state-of-charge estimations, improper thermal management, or failure to detect and mitigate potential hazards. Software failures can be particularly insidious, as they may not be immediately apparent and can propagate through the system undetected.

Environmental factors play a significant role in BMS failures. Extreme temperatures, humidity, vibration, and electromagnetic interference can all contribute to system degradation and malfunction. In industrial settings, these environmental stressors are often more severe and variable, necessitating robust design and thorough testing protocols.

Failure modes can also be classified based on their impact on system functionality. Critical failures result in immediate and complete loss of BMS functionality, potentially leading to dangerous situations such as thermal runaway or overcharging. Degraded performance failures, while less severe, can still compromise safety and efficiency over time.

Analysis of BMS failures often reveals complex interactions between multiple factors. For instance, a minor software glitch combined with a degraded sensor may lead to a cascading failure that compromises the entire system. This underscores the importance of comprehensive failure mode and effects analysis (FMEA) in BMS design and implementation.

Predictive maintenance strategies, leveraging advanced data analytics and machine learning algorithms, are increasingly being employed to detect early signs of BMS failure. These approaches analyze patterns in sensor data, system performance metrics, and environmental conditions to identify potential issues before they escalate into critical failures.

To mitigate the risk of BMS failures, redundancy and fault-tolerant design principles are crucial. This may involve implementing multiple independent measurement channels, employing diverse sensor technologies, and incorporating fail-safe mechanisms that ensure safe system operation even in the event of partial failures.

BMS failures can be broadly categorized into hardware and software failures. Hardware failures often stem from component degradation, manufacturing defects, or environmental stressors. Common hardware failure modes include sensor malfunctions, connection issues, and power supply failures. These can lead to inaccurate measurements, communication breakdowns, or complete system shutdowns.

Software failures, on the other hand, typically result from programming errors, algorithm limitations, or inadequate fault handling. These may manifest as incorrect state-of-charge estimations, improper thermal management, or failure to detect and mitigate potential hazards. Software failures can be particularly insidious, as they may not be immediately apparent and can propagate through the system undetected.

Environmental factors play a significant role in BMS failures. Extreme temperatures, humidity, vibration, and electromagnetic interference can all contribute to system degradation and malfunction. In industrial settings, these environmental stressors are often more severe and variable, necessitating robust design and thorough testing protocols.

Failure modes can also be classified based on their impact on system functionality. Critical failures result in immediate and complete loss of BMS functionality, potentially leading to dangerous situations such as thermal runaway or overcharging. Degraded performance failures, while less severe, can still compromise safety and efficiency over time.

Analysis of BMS failures often reveals complex interactions between multiple factors. For instance, a minor software glitch combined with a degraded sensor may lead to a cascading failure that compromises the entire system. This underscores the importance of comprehensive failure mode and effects analysis (FMEA) in BMS design and implementation.

Predictive maintenance strategies, leveraging advanced data analytics and machine learning algorithms, are increasingly being employed to detect early signs of BMS failure. These approaches analyze patterns in sensor data, system performance metrics, and environmental conditions to identify potential issues before they escalate into critical failures.

To mitigate the risk of BMS failures, redundancy and fault-tolerant design principles are crucial. This may involve implementing multiple independent measurement channels, employing diverse sensor technologies, and incorporating fail-safe mechanisms that ensure safe system operation even in the event of partial failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!