Enhancing User Interfaces through Piezoelectric Touch Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Touch Sensor Evolution and Objectives

Piezoelectric touch sensors have emerged as a transformative technology in the realm of user interfaces, revolutionizing the way we interact with electronic devices. The evolution of these sensors can be traced back to the discovery of the piezoelectric effect in the late 19th century. This phenomenon, where certain materials generate an electric charge in response to mechanical stress, laid the foundation for the development of piezoelectric touch sensors.

In the early stages, piezoelectric materials were primarily used in industrial applications and scientific instruments. However, as technology advanced, researchers began to explore their potential in human-machine interfaces. The miniaturization of electronic components and the increasing demand for more intuitive and responsive user interfaces drove the development of piezoelectric touch sensors for consumer electronics.

The first significant breakthrough came in the late 1990s when piezoelectric touch sensors were integrated into mobile devices. These early implementations provided basic touch functionality, allowing users to interact with screens using styluses or fingers. As the technology matured, multi-touch capabilities were introduced, enabling more complex gestures and interactions.

The objectives of enhancing user interfaces through piezoelectric touch sensors have evolved significantly over time. Initially, the focus was on improving the accuracy and responsiveness of touch inputs. This led to the development of more sensitive piezoelectric materials and advanced signal processing techniques to reduce latency and increase precision.

As the technology progressed, the objectives expanded to include haptic feedback integration. Piezoelectric actuators were incorporated into touch sensors to provide tactile sensations, simulating the feel of physical buttons or textures on a flat surface. This advancement aimed to enhance the user experience by providing a more natural and intuitive interaction with digital interfaces.

Another key objective in the evolution of piezoelectric touch sensors has been the development of flexible and conformable sensors. This goal aligns with the trend towards curved and foldable displays, enabling touch functionality on non-flat surfaces and opening up new possibilities for device form factors.

Energy efficiency has also become a critical objective in recent years. Researchers and engineers have been working on optimizing the power consumption of piezoelectric touch sensors, making them more suitable for battery-powered devices and contributing to overall device longevity.

Looking ahead, the objectives for piezoelectric touch sensors in user interfaces continue to expand. Current research focuses on increasing sensitivity to detect varying levels of pressure, enabling new interaction paradigms. There is also a push towards integrating additional sensing capabilities, such as temperature and humidity detection, to create more context-aware interfaces.

In the early stages, piezoelectric materials were primarily used in industrial applications and scientific instruments. However, as technology advanced, researchers began to explore their potential in human-machine interfaces. The miniaturization of electronic components and the increasing demand for more intuitive and responsive user interfaces drove the development of piezoelectric touch sensors for consumer electronics.

The first significant breakthrough came in the late 1990s when piezoelectric touch sensors were integrated into mobile devices. These early implementations provided basic touch functionality, allowing users to interact with screens using styluses or fingers. As the technology matured, multi-touch capabilities were introduced, enabling more complex gestures and interactions.

The objectives of enhancing user interfaces through piezoelectric touch sensors have evolved significantly over time. Initially, the focus was on improving the accuracy and responsiveness of touch inputs. This led to the development of more sensitive piezoelectric materials and advanced signal processing techniques to reduce latency and increase precision.

As the technology progressed, the objectives expanded to include haptic feedback integration. Piezoelectric actuators were incorporated into touch sensors to provide tactile sensations, simulating the feel of physical buttons or textures on a flat surface. This advancement aimed to enhance the user experience by providing a more natural and intuitive interaction with digital interfaces.

Another key objective in the evolution of piezoelectric touch sensors has been the development of flexible and conformable sensors. This goal aligns with the trend towards curved and foldable displays, enabling touch functionality on non-flat surfaces and opening up new possibilities for device form factors.

Energy efficiency has also become a critical objective in recent years. Researchers and engineers have been working on optimizing the power consumption of piezoelectric touch sensors, making them more suitable for battery-powered devices and contributing to overall device longevity.

Looking ahead, the objectives for piezoelectric touch sensors in user interfaces continue to expand. Current research focuses on increasing sensitivity to detect varying levels of pressure, enabling new interaction paradigms. There is also a push towards integrating additional sensing capabilities, such as temperature and humidity detection, to create more context-aware interfaces.

Market Demand for Advanced User Interfaces

The market demand for advanced user interfaces has been steadily growing, driven by the increasing sophistication of consumer electronics and the need for more intuitive and responsive human-machine interactions. Piezoelectric touch sensors represent a significant advancement in this field, offering enhanced sensitivity, durability, and versatility compared to traditional touch technologies.

In recent years, the global touch sensor market has experienced substantial growth, with projections indicating continued expansion. This growth is primarily fueled by the widespread adoption of smartphones, tablets, and other touch-enabled devices across various industries. The automotive sector, in particular, has shown a strong interest in advanced touch interfaces for in-vehicle infotainment systems and control panels, creating new opportunities for piezoelectric sensor technology.

Consumer expectations for seamless and natural interactions with devices have risen dramatically. Users now demand interfaces that are not only responsive but also capable of detecting varying levels of pressure and providing haptic feedback. Piezoelectric touch sensors excel in meeting these requirements, offering precise force measurement capabilities and the potential for localized haptic feedback without the need for additional actuators.

The healthcare industry has also emerged as a significant market for advanced user interfaces. Medical devices and equipment increasingly incorporate touch-based controls, requiring highly reliable and easily sanitizable interfaces. Piezoelectric sensors, with their solid-state nature and resistance to contaminants, are well-positioned to address these specific needs.

Another driving factor for the adoption of piezoelectric touch sensors is the trend towards bezel-less and flexible displays in consumer electronics. These design trends require touch sensing solutions that can be integrated seamlessly into curved or irregular surfaces, a capability at which piezoelectric sensors excel.

The industrial and manufacturing sectors are showing increased interest in robust touch interfaces for harsh environments. Piezoelectric sensors' durability and ability to function under extreme conditions make them attractive for use in industrial control panels, outdoor kiosks, and rugged mobile devices.

As the Internet of Things (IoT) continues to expand, the demand for innovative user interfaces extends to smart home devices, wearables, and other connected products. Piezoelectric touch sensors offer the potential for creating more intuitive and interactive experiences in these emerging product categories, further driving market growth.

In recent years, the global touch sensor market has experienced substantial growth, with projections indicating continued expansion. This growth is primarily fueled by the widespread adoption of smartphones, tablets, and other touch-enabled devices across various industries. The automotive sector, in particular, has shown a strong interest in advanced touch interfaces for in-vehicle infotainment systems and control panels, creating new opportunities for piezoelectric sensor technology.

Consumer expectations for seamless and natural interactions with devices have risen dramatically. Users now demand interfaces that are not only responsive but also capable of detecting varying levels of pressure and providing haptic feedback. Piezoelectric touch sensors excel in meeting these requirements, offering precise force measurement capabilities and the potential for localized haptic feedback without the need for additional actuators.

The healthcare industry has also emerged as a significant market for advanced user interfaces. Medical devices and equipment increasingly incorporate touch-based controls, requiring highly reliable and easily sanitizable interfaces. Piezoelectric sensors, with their solid-state nature and resistance to contaminants, are well-positioned to address these specific needs.

Another driving factor for the adoption of piezoelectric touch sensors is the trend towards bezel-less and flexible displays in consumer electronics. These design trends require touch sensing solutions that can be integrated seamlessly into curved or irregular surfaces, a capability at which piezoelectric sensors excel.

The industrial and manufacturing sectors are showing increased interest in robust touch interfaces for harsh environments. Piezoelectric sensors' durability and ability to function under extreme conditions make them attractive for use in industrial control panels, outdoor kiosks, and rugged mobile devices.

As the Internet of Things (IoT) continues to expand, the demand for innovative user interfaces extends to smart home devices, wearables, and other connected products. Piezoelectric touch sensors offer the potential for creating more intuitive and interactive experiences in these emerging product categories, further driving market growth.

Current Challenges in Piezoelectric Touch Technology

Piezoelectric touch technology, while promising, faces several significant challenges that hinder its widespread adoption and optimal performance in user interfaces. One of the primary obstacles is the sensitivity and accuracy of touch detection. Piezoelectric sensors often struggle to differentiate between intentional touches and accidental contacts or environmental vibrations, leading to false inputs and reduced user experience.

Another major challenge lies in the integration of piezoelectric sensors into existing device architectures. The need for specialized materials and manufacturing processes can increase production costs and complexity, making it difficult for manufacturers to incorporate this technology into their products at scale. Additionally, the durability and longevity of piezoelectric sensors in high-use environments remain concerns, as repeated stress and environmental factors can degrade their performance over time.

Power consumption presents another hurdle for piezoelectric touch technology. While generally energy-efficient, these sensors still require careful power management, especially in battery-operated devices where every milliwatt counts. Balancing sensitivity with power efficiency is a delicate task that engineers continue to grapple with.

The limited range of detectable forces is also a significant challenge. Current piezoelectric sensors often struggle to accurately measure a wide spectrum of touch pressures, from light taps to firm presses. This limitation restricts the potential for more nuanced and diverse user interactions that could otherwise enhance the user interface experience.

Interference from electromagnetic fields and temperature fluctuations poses yet another challenge. Piezoelectric materials can be sensitive to these external factors, potentially leading to inaccurate readings or inconsistent performance across different environments. Developing robust shielding and compensation mechanisms is crucial for ensuring reliable operation in various real-world scenarios.

Lastly, the challenge of standardization and compatibility looms large. As piezoelectric touch technology evolves, the lack of industry-wide standards for implementation and interfacing with other systems can impede its adoption and interoperability. This fragmentation in the market can lead to confusion among developers and end-users, slowing down the technology's integration into mainstream devices.

Addressing these challenges requires concerted efforts in materials science, signal processing, manufacturing techniques, and software development. As researchers and engineers work to overcome these hurdles, the potential for piezoelectric touch technology to revolutionize user interfaces remains significant, promising more intuitive, responsive, and versatile interaction paradigms in the future.

Another major challenge lies in the integration of piezoelectric sensors into existing device architectures. The need for specialized materials and manufacturing processes can increase production costs and complexity, making it difficult for manufacturers to incorporate this technology into their products at scale. Additionally, the durability and longevity of piezoelectric sensors in high-use environments remain concerns, as repeated stress and environmental factors can degrade their performance over time.

Power consumption presents another hurdle for piezoelectric touch technology. While generally energy-efficient, these sensors still require careful power management, especially in battery-operated devices where every milliwatt counts. Balancing sensitivity with power efficiency is a delicate task that engineers continue to grapple with.

The limited range of detectable forces is also a significant challenge. Current piezoelectric sensors often struggle to accurately measure a wide spectrum of touch pressures, from light taps to firm presses. This limitation restricts the potential for more nuanced and diverse user interactions that could otherwise enhance the user interface experience.

Interference from electromagnetic fields and temperature fluctuations poses yet another challenge. Piezoelectric materials can be sensitive to these external factors, potentially leading to inaccurate readings or inconsistent performance across different environments. Developing robust shielding and compensation mechanisms is crucial for ensuring reliable operation in various real-world scenarios.

Lastly, the challenge of standardization and compatibility looms large. As piezoelectric touch technology evolves, the lack of industry-wide standards for implementation and interfacing with other systems can impede its adoption and interoperability. This fragmentation in the market can lead to confusion among developers and end-users, slowing down the technology's integration into mainstream devices.

Addressing these challenges requires concerted efforts in materials science, signal processing, manufacturing techniques, and software development. As researchers and engineers work to overcome these hurdles, the potential for piezoelectric touch technology to revolutionize user interfaces remains significant, promising more intuitive, responsive, and versatile interaction paradigms in the future.

Existing Piezoelectric Touch Solutions

01 Piezoelectric touch sensor design for user interfaces

Piezoelectric materials are used to create touch-sensitive interfaces that can detect pressure and force. These sensors can be integrated into various devices to provide tactile feedback and improve user interaction. The design often involves layering piezoelectric elements with electrodes to create a responsive touch surface.- Piezoelectric touch sensor design for user interfaces: Piezoelectric materials are used to create touch-sensitive interfaces that can detect pressure and force. These sensors can be integrated into various devices to provide tactile feedback and improve user interaction. The design often involves layering piezoelectric elements with electrodes to create a responsive touch surface.

- Haptic feedback in piezoelectric touch interfaces: Piezoelectric touch sensors can be designed to provide haptic feedback to users, enhancing the tactile experience of interacting with digital interfaces. This feedback can simulate the feeling of pressing physical buttons or provide other tactile cues, improving user engagement and interface usability.

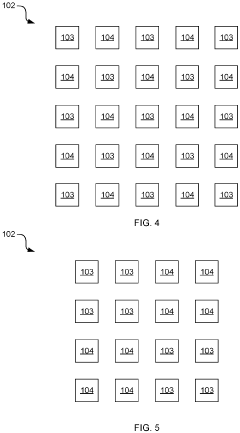

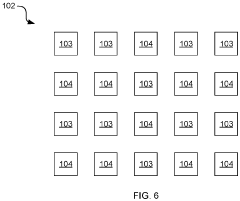

- Multi-touch and gesture recognition using piezoelectric sensors: Advanced piezoelectric touch interfaces can support multi-touch interactions and complex gesture recognition. These systems use arrays of sensors to detect multiple points of contact simultaneously, enabling intuitive gestures like pinch-to-zoom or multi-finger swipes for navigation and control.

- Integration of piezoelectric touch sensors in flexible displays: Piezoelectric touch sensors can be incorporated into flexible or curved display technologies, allowing for touch-sensitive interfaces on non-flat surfaces. This integration enables the creation of innovative form factors for devices and new interaction paradigms for users.

- Signal processing and noise reduction for piezoelectric touch interfaces: Effective signal processing techniques are crucial for improving the accuracy and responsiveness of piezoelectric touch sensors. These methods involve filtering out environmental noise, calibrating sensor sensitivity, and interpreting complex touch patterns to ensure reliable user input detection and interface performance.

02 Haptic feedback in piezoelectric touch interfaces

Piezoelectric touch sensors can be designed to provide haptic feedback to users, enhancing the tactile experience. This feedback can simulate button presses or texture sensations, improving user engagement and interface usability. The technology allows for customizable vibration patterns and intensities.Expand Specific Solutions03 Multi-touch and gesture recognition using piezoelectric sensors

Advanced piezoelectric touch interfaces can support multi-touch interactions and complex gesture recognition. These systems use arrays of sensors to detect multiple points of contact simultaneously, enabling intuitive gestures like pinch-to-zoom or multi-finger swipes for navigation and control.Expand Specific Solutions04 Integration of piezoelectric touch sensors in flexible displays

Piezoelectric touch sensors can be incorporated into flexible or curved display technologies. This integration allows for the creation of bendable or foldable devices with touch-sensitive surfaces, expanding the possibilities for innovative product designs and user interface concepts.Expand Specific Solutions05 Signal processing and noise reduction in piezoelectric touch interfaces

Effective signal processing techniques are crucial for improving the accuracy and responsiveness of piezoelectric touch sensors. This includes methods for noise reduction, calibration, and interpreting complex touch patterns. Advanced algorithms can help distinguish between intentional touches and environmental factors, enhancing overall system reliability.Expand Specific Solutions

Key Players in Touch Interface Industry

The market for piezoelectric touch sensor technology is in a growth phase, with increasing adoption across consumer electronics, automotive, and industrial applications. The global market size is projected to expand significantly in the coming years, driven by demand for more intuitive and responsive user interfaces. While the core technology is relatively mature, ongoing innovation focuses on improving sensitivity, durability, and integration capabilities. Key players like Apple, Sony, and Qualcomm are investing heavily in R&D to enhance their offerings, while specialized firms such as Aito BV and Cambridge Touch Technologies are pushing the boundaries of piezoelectric sensing. The competitive landscape is diverse, with both established electronics giants and innovative startups vying for market share in this rapidly evolving field.

Apple, Inc.

Technical Solution: Apple has developed advanced piezoelectric touch sensors for enhancing user interfaces across its product line. Their technology utilizes an array of piezoelectric elements integrated into device screens and surfaces. These sensors can detect minute pressure variations, enabling precise force-sensitive input[1]. Apple's implementation allows for 3D Touch and Haptic Touch features, providing users with additional input options based on the pressure applied[2]. The system can distinguish between light taps and firm presses, opening up new interaction paradigms. Apple has also integrated this technology with their Taptic Engine, creating localized haptic feedback that corresponds to on-screen actions[3], further enhancing the user experience.

Strengths: Highly precise force detection, seamless integration with existing devices, enhanced user interaction options. Weaknesses: Potentially higher production costs, increased complexity in software development to fully utilize the technology.

Immersion Corp.

Technical Solution: Immersion Corporation specializes in haptic feedback technologies, including those utilizing piezoelectric touch sensors. Their approach focuses on creating realistic tactile sensations in response to user interactions. Immersion's technology employs an array of piezoelectric actuators that can be precisely controlled to generate a wide range of haptic effects[4]. These actuators are capable of producing both subtle vibrations and more pronounced tactile feedback. The company's solutions are designed to be integrated into various devices, from smartphones to automotive interfaces, enhancing user engagement and providing non-visual cues[5]. Immersion's technology also includes advanced algorithms that synchronize haptic feedback with visual and audio cues, creating a more immersive multi-sensory experience.

Strengths: Extensive experience in haptic technologies, wide range of applications across industries. Weaknesses: Reliance on partnerships for implementation, potential patent conflicts with other major players.

Innovative Piezoelectric Sensing Techniques

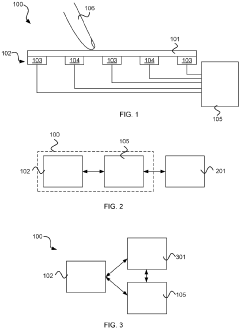

A piezoelectric sensing device

PatentPendingEP4040265A1

Innovation

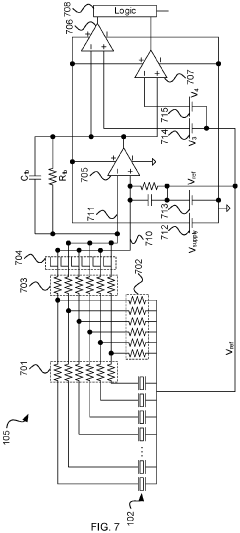

- A device comprising a touch surface with a plurality of piezoelectric sensors, where a subset of sensors is assigned positive and another subset negative signs, and a wakeup circuitry that produces a sum signal by combining these signals, allowing for differentiation between localized pressure and common-mode signals, and providing a wakeup signal only when specific threshold conditions are met.

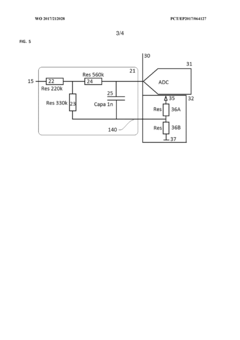

Detection of piezoelectric sensor elements

PatentWO2017212028A1

Innovation

- A matrix of piezoelectric sensor elements with measuring circuits configured for rows and columns, along with a wake-up trigger that activates the system only when a touch is detected, reducing energy consumption and complexity by maintaining a low-power mode until triggered, and utilizing a single activity detecting and touch recognition circuit.

Materials Science Advancements for Piezoelectric Sensors

The field of piezoelectric touch sensors has witnessed significant advancements in materials science, driving improvements in user interface technologies. Recent developments in piezoelectric materials have focused on enhancing sensitivity, durability, and flexibility to meet the demands of modern touch-based devices.

One of the key areas of progress has been in the development of lead-free piezoelectric materials. Traditionally, lead zirconate titanate (PZT) has been widely used due to its excellent piezoelectric properties. However, environmental concerns have led researchers to explore alternative compositions. Potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) based materials have emerged as promising candidates, offering comparable performance to PZT while being environmentally friendly.

Nanostructured piezoelectric materials have also gained attention for their enhanced properties. By manipulating the material structure at the nanoscale, researchers have achieved improved sensitivity and responsiveness. Zinc oxide (ZnO) nanowires and barium titanate (BaTiO3) nanoparticles have shown particular promise in this regard, enabling the creation of highly sensitive touch sensors with fast response times.

Flexible piezoelectric materials represent another significant advancement. Polymer-based piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers, have been developed to create bendable and stretchable touch sensors. These materials can be integrated into curved surfaces and wearable devices, expanding the potential applications of piezoelectric touch sensors.

Composite materials combining piezoelectric ceramics with polymers have also been explored to balance the high piezoelectric coefficients of ceramics with the flexibility of polymers. These composites offer a compromise between performance and mechanical properties, making them suitable for a wide range of touch-sensitive applications.

Advancements in thin-film deposition techniques have enabled the fabrication of ultra-thin piezoelectric layers. Techniques such as pulsed laser deposition and chemical vapor deposition have been refined to produce high-quality piezoelectric films with thicknesses in the nanometer range. These thin films can be integrated into microelectromechanical systems (MEMS) and other miniaturized devices, opening up new possibilities for compact and efficient touch sensors.

The development of self-powered piezoelectric sensors has also been a focus of materials science research. By optimizing the energy harvesting capabilities of piezoelectric materials, researchers have created touch sensors that can generate their own power from mechanical inputs, reducing or eliminating the need for external power sources.

One of the key areas of progress has been in the development of lead-free piezoelectric materials. Traditionally, lead zirconate titanate (PZT) has been widely used due to its excellent piezoelectric properties. However, environmental concerns have led researchers to explore alternative compositions. Potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) based materials have emerged as promising candidates, offering comparable performance to PZT while being environmentally friendly.

Nanostructured piezoelectric materials have also gained attention for their enhanced properties. By manipulating the material structure at the nanoscale, researchers have achieved improved sensitivity and responsiveness. Zinc oxide (ZnO) nanowires and barium titanate (BaTiO3) nanoparticles have shown particular promise in this regard, enabling the creation of highly sensitive touch sensors with fast response times.

Flexible piezoelectric materials represent another significant advancement. Polymer-based piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers, have been developed to create bendable and stretchable touch sensors. These materials can be integrated into curved surfaces and wearable devices, expanding the potential applications of piezoelectric touch sensors.

Composite materials combining piezoelectric ceramics with polymers have also been explored to balance the high piezoelectric coefficients of ceramics with the flexibility of polymers. These composites offer a compromise between performance and mechanical properties, making them suitable for a wide range of touch-sensitive applications.

Advancements in thin-film deposition techniques have enabled the fabrication of ultra-thin piezoelectric layers. Techniques such as pulsed laser deposition and chemical vapor deposition have been refined to produce high-quality piezoelectric films with thicknesses in the nanometer range. These thin films can be integrated into microelectromechanical systems (MEMS) and other miniaturized devices, opening up new possibilities for compact and efficient touch sensors.

The development of self-powered piezoelectric sensors has also been a focus of materials science research. By optimizing the energy harvesting capabilities of piezoelectric materials, researchers have created touch sensors that can generate their own power from mechanical inputs, reducing or eliminating the need for external power sources.

Energy Harvesting Potential in Touch Interfaces

The integration of energy harvesting capabilities into touch interfaces represents a significant advancement in sustainable user interface design. Piezoelectric touch sensors, already known for their ability to enhance user interactions, offer a unique opportunity to capture and utilize the mechanical energy generated through touch interactions. This energy harvesting potential could revolutionize the power management of mobile and wearable devices, potentially extending battery life or even enabling self-powered operation in certain applications.

The principle behind energy harvesting in touch interfaces relies on the piezoelectric effect, where certain materials generate an electric charge in response to applied mechanical stress. In the context of touch interfaces, each tap, swipe, or press on the screen could be converted into electrical energy. While the amount of energy harvested from individual interactions may be small, the cumulative effect over numerous interactions throughout a day could be substantial.

Current research in this area focuses on optimizing the energy conversion efficiency of piezoelectric materials used in touch sensors. Advanced materials such as lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) are being explored for their superior piezoelectric properties. Additionally, novel nanostructured materials and composites are being developed to enhance the energy harvesting capabilities while maintaining the sensitivity and responsiveness required for touch interfaces.

The potential applications of energy harvesting touch interfaces are diverse. In smartphones and tablets, harvested energy could be used to supplement battery power, potentially extending device usage time between charges. For wearable devices like smartwatches, where battery size is a significant constraint, energy harvesting could play a crucial role in extending functionality and reducing the need for frequent charging. In IoT devices and environmental sensors, this technology could enable self-powered operation, eliminating the need for battery replacement or external power sources in certain scenarios.

However, challenges remain in implementing this technology effectively. The primary hurdle is balancing the energy harvesting capability with the need for a responsive and accurate touch interface. Engineers must ensure that the energy harvesting mechanism does not interfere with the primary function of the touch sensor. Additionally, the development of efficient energy storage and management systems is crucial to effectively utilize the harvested energy.

As research progresses, we can anticipate the emergence of more sophisticated energy harvesting touch interfaces. Future developments may include adaptive systems that optimize energy harvesting based on user interaction patterns, or integration with other energy harvesting technologies like solar cells or thermal generators. The convergence of these technologies could lead to truly self-sustaining electronic devices, marking a significant step towards more sustainable and energy-efficient consumer electronics.

The principle behind energy harvesting in touch interfaces relies on the piezoelectric effect, where certain materials generate an electric charge in response to applied mechanical stress. In the context of touch interfaces, each tap, swipe, or press on the screen could be converted into electrical energy. While the amount of energy harvested from individual interactions may be small, the cumulative effect over numerous interactions throughout a day could be substantial.

Current research in this area focuses on optimizing the energy conversion efficiency of piezoelectric materials used in touch sensors. Advanced materials such as lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) are being explored for their superior piezoelectric properties. Additionally, novel nanostructured materials and composites are being developed to enhance the energy harvesting capabilities while maintaining the sensitivity and responsiveness required for touch interfaces.

The potential applications of energy harvesting touch interfaces are diverse. In smartphones and tablets, harvested energy could be used to supplement battery power, potentially extending device usage time between charges. For wearable devices like smartwatches, where battery size is a significant constraint, energy harvesting could play a crucial role in extending functionality and reducing the need for frequent charging. In IoT devices and environmental sensors, this technology could enable self-powered operation, eliminating the need for battery replacement or external power sources in certain scenarios.

However, challenges remain in implementing this technology effectively. The primary hurdle is balancing the energy harvesting capability with the need for a responsive and accurate touch interface. Engineers must ensure that the energy harvesting mechanism does not interfere with the primary function of the touch sensor. Additionally, the development of efficient energy storage and management systems is crucial to effectively utilize the harvested energy.

As research progresses, we can anticipate the emergence of more sophisticated energy harvesting touch interfaces. Future developments may include adaptive systems that optimize energy harvesting based on user interaction patterns, or integration with other energy harvesting technologies like solar cells or thermal generators. The convergence of these technologies could lead to truly self-sustaining electronic devices, marking a significant step towards more sustainable and energy-efficient consumer electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!